Method for preparing graphene film

A technology of graphene film and graphene dispersion, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as research on the surface characteristics of graphene, achieve large-scale production, and the method is simple and easy , good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the first step, take 200ml of 2mg / ml graphene oxide ethanol dispersion and pour it into the spray gun.

[0025] In the second step, the glass substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 30 minutes, and then dried and placed on a heating platform with the temperature set at 25°C.

[0026] In the third step, the dispersion liquid is sprayed onto the substrate with a spray gun to obtain a graphene oxide film.

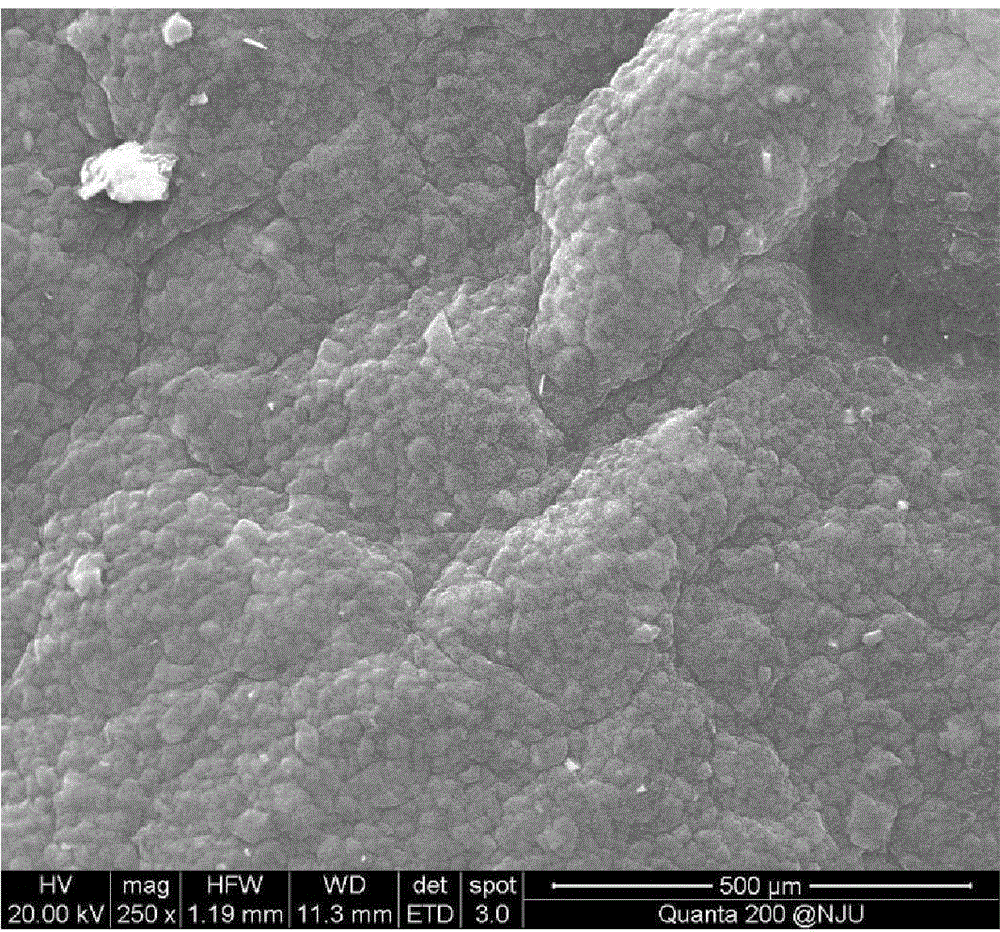

[0027] The fourth step is to put the obtained graphene oxide film into a container containing hydrazine hydrate, seal it well, heat it to 95° C. and maintain it for 24 hours, and reduce it with hydrazine vapor to finally obtain a graphene film. figure 1 A picture of the surface morphology of the film.

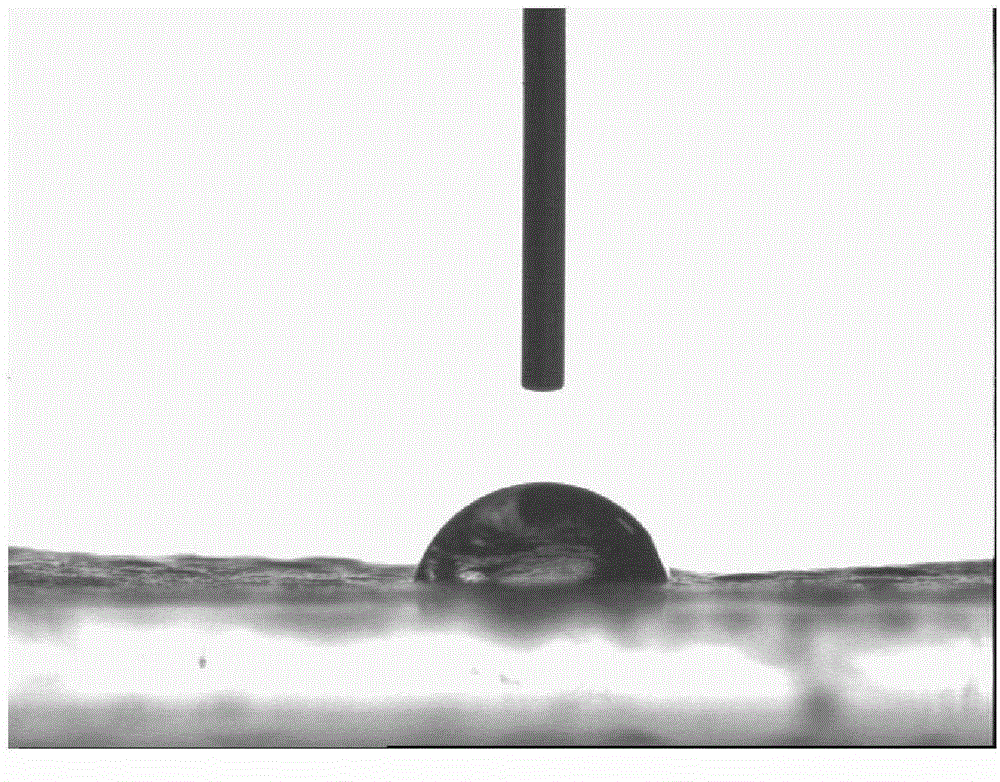

[0028] In the fifth step, the wetting angle test was carried out to the prepared graphene film, such as figure 2 As shown, it can be seen that the wetting angle is about 82°, which indicates that the film is hydrophilic (...

Embodiment 2

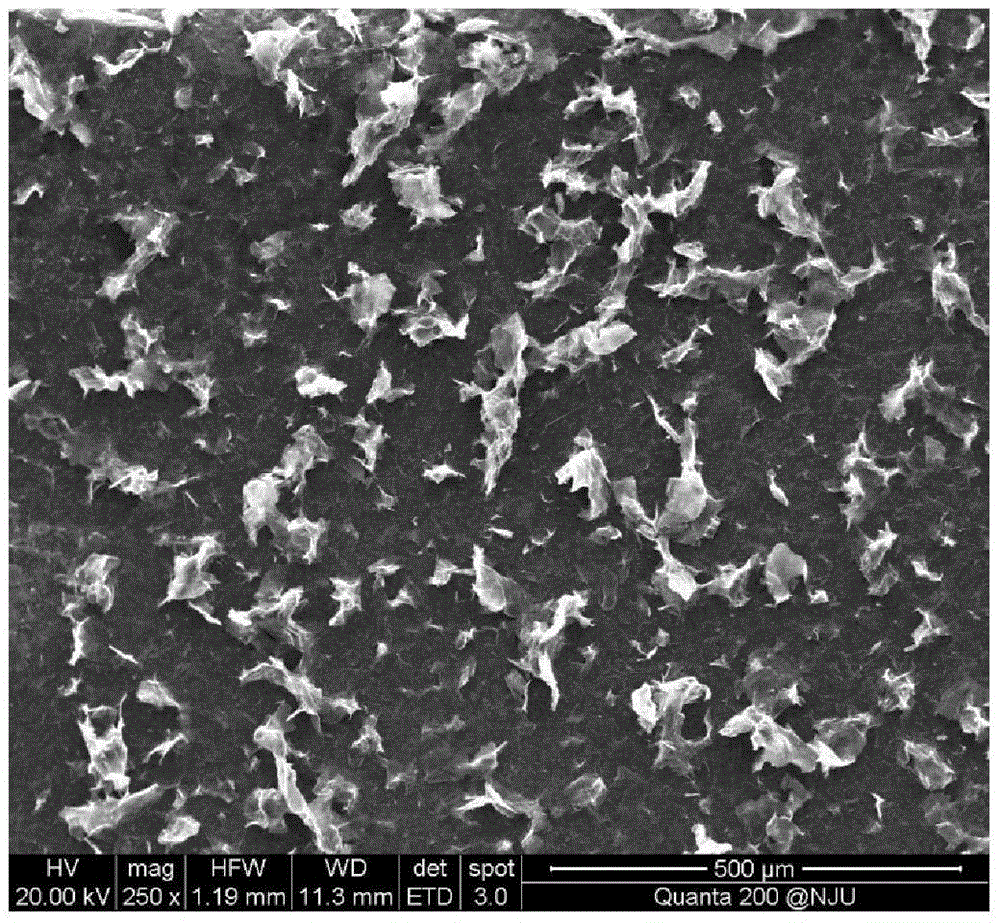

[0030] The control method is basically the same as in Example 1, except that the substrate temperature is 50°C, and the surface picture of the obtained sample is image 3 shown, compared to figure 1 , appearing rougher; Figure 4 Its wetting angle test chart shows that the wetting angle is 105°, showing hydrophobic properties.

Embodiment 3

[0032] The control method is basically the same as in Example 1, except that the substrate temperature is 70°C, and the scanning electron microscope of the obtained sample is as follows: Figure 5 As shown, the surface becomes rougher compared to figure 1 , image 3 ; Image 6 It is its wetting angle test chart, the wetting angle is about 137°, showing strong hydrophobic characteristics. Then, the obtained strongly hydrophobic sample is modified with carbon particles, that is, the sample is burned in a candle flame, Figure 7 It is the scanning electron microscope picture, it is obvious that carbon particles are attached to the graphene sheet; Figure 8 It is its wetting angle test, the wetting angle is 155°, showing super-hydrophobic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com