Integrated device for removing carbon dioxide gas in gas

A gas and body technology, which is applied in the field of integrated devices for removing carbon dioxide gas in gas, can solve the problems of large floor space, large investment, complicated operation, etc., and achieves space saving, good toughness and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

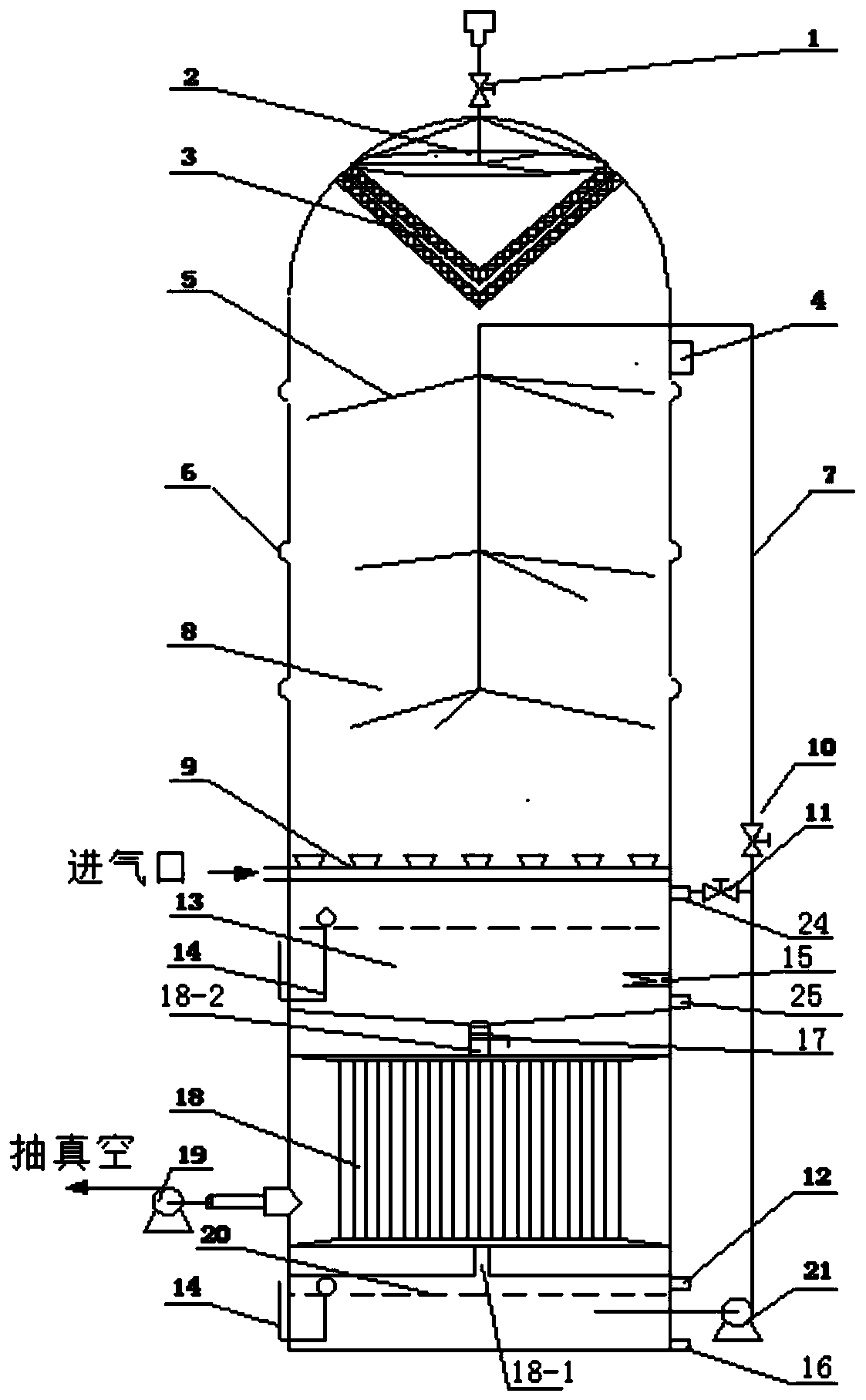

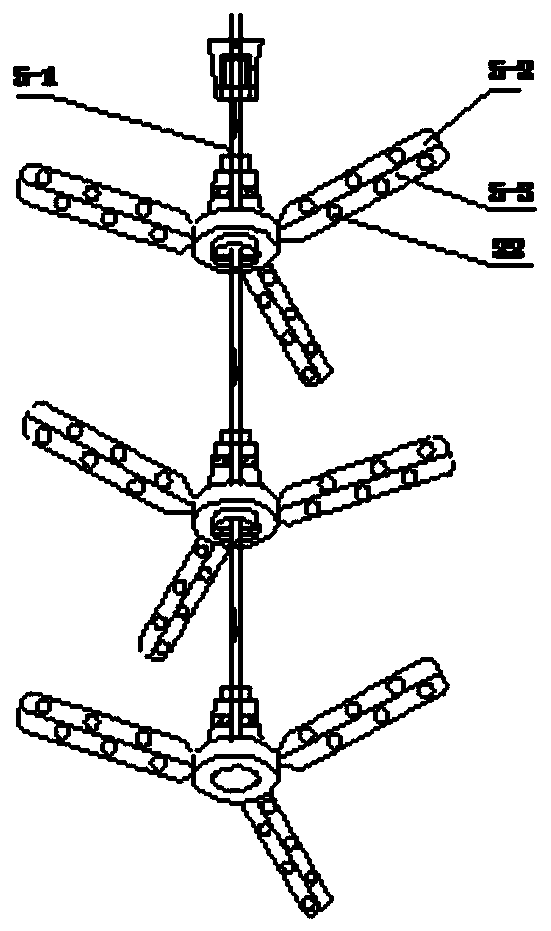

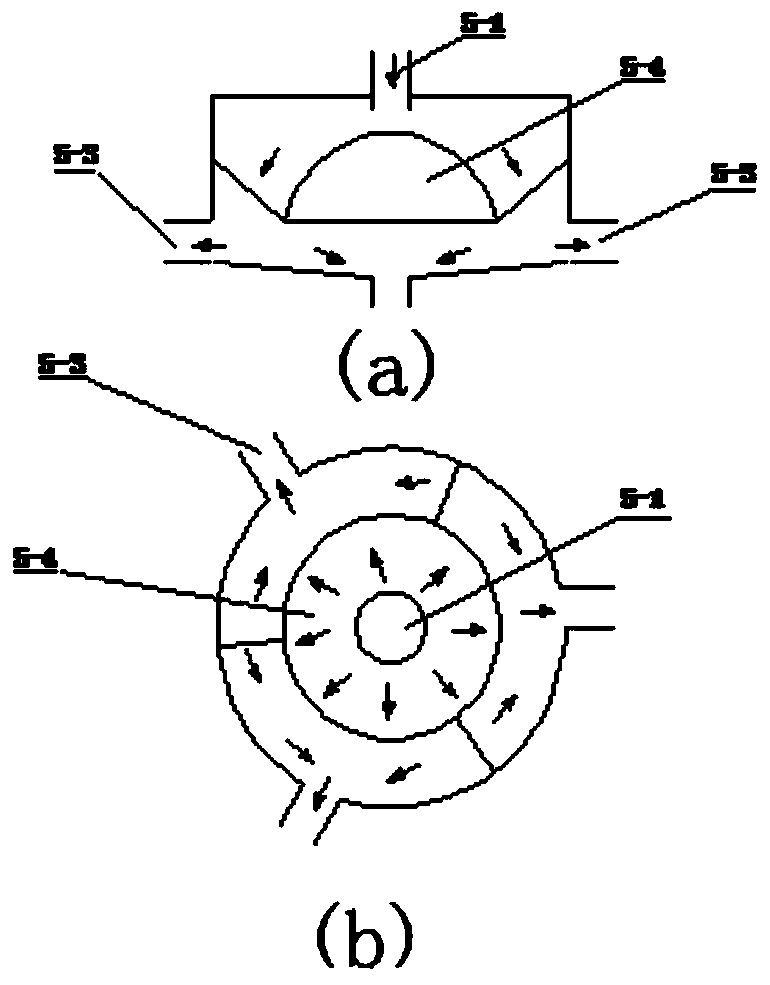

[0053] Use the above-mentioned method for removing CO from the gas 2 Gas integrated device for CO in biogas 2 When the gas is processed, first inject the alcohol amine poor liquid effusion chamber 20 into the alcohol amine solution, which can be determined by observing the liquid level gauge 14. When the set threshold is reached, the circulation pump 21 is turned on, the control valve 11 is closed, and the control valve 10 is opened. The alcohol amine solution is made to flow into the shower 5, and the control flow rate is 100 L / h. After starting the motor 4 and driving the sprayer 5 to rotate and spray out the alcohol amine solution, the intake pipe 9 is fed into the biogas, and at this time, the CO in the biogas 2 Absorbed by alcohol amine solution, which carries CO 2Falling into the alkanolamine-rich liquid effusion chamber 13, the purified biogas continues to rise, and the purified biogas passes through the secondary mist eliminator 3 to remove the moisture carried in th...

Embodiment 2

[0055] Use the above for CO removal from gases 2 Gas integrated device for CO in biogas 2 When the gas is processed, first inject the alcohol amine poor liquid effusion chamber 20 into the alcohol amine solution, which can be determined by observing the liquid level gauge 14. When the set threshold is reached, the circulation pump 21 is turned on, the control valve 11 is closed, and the control valve 10 is opened. The alcohol amine solution is made to flow into the sprayer 5, and the control flow rate is 120 L / h at this moment. Start the motor 4, and drive the sprayer 5 to rotate and spray out the alcohol amine solution, and the intake pipe 9 is fed into the biogas. At this time, the CO in the biogas 2 Absorbed by alcohol amine solution, which carries CO 2 Falling into the alcohol amine-rich liquid effusion chamber 13, the purified biogas continues to rise, and the purified biogas passes through the secondary demister 3 to remove the moisture carried in the biogas, except th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com