Aerogel material as well as preparation method and application thereof

An aerogel and gel technology, applied in the field of aerogel, can solve the problems of slow development and preparation of aerogel, and achieve the effects of good molding ability, good adsorption performance, and beneficial to cost control and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

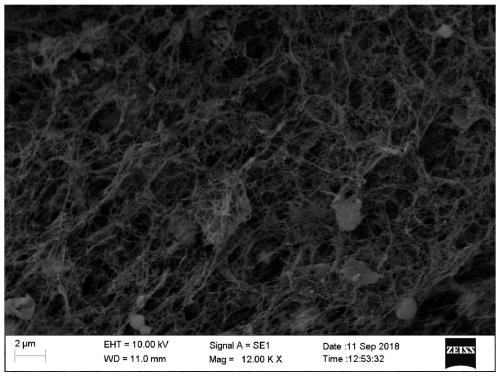

Image

Examples

Embodiment 1

[0053] A preparation method of an airgel material, comprising the steps of:

[0054] 1) Put the waste paper in a lithium bromide solution with a mass percentage of 40%, and stir it in an oil bath at 150°C until it no longer dissolves or gel appears, then pour the mixed solution into a mold, and put it under room temperature Cool to get a gel;

[0055] 2) Soak in deionized water and continuously replace the gel until no precipitation is detected by silver nitrate to obtain a hydrogel;

[0056] 3) At room temperature, place the hydrogel in tert-butanol aqueous solutions with tert-butanol mass percentages of 30%, 60% and 100% in turn, and stand in each concentration of tert-butanol for 24 hours, and replace it every 12 hours A tert-butanol solution of the same mass percentage to obtain an alcohol gel;

[0057] 4) Freeze-drying the alcogel (freeze at -60° C., drying vacuum degree is 1 Pa) to obtain an airgel material.

Embodiment 2

[0059] A preparation method of an airgel material, comprising the steps of:

[0060] 1) Put the waste paper in a lithium bromide solution with a mass percentage of 50%, and stir it in an oil bath at 130°C until it no longer dissolves or gel appears, then pour the mixed solution into a mold, and put it under room temperature Cool to get a gel;

[0061] 2) Soak in deionized water and continuously replace the gel until no precipitation is detected by silver nitrate to obtain a hydrogel;

[0062] 3) At room temperature, place the hydrogel in 30%, 60% and 100% tert-butanol aqueous solutions in sequence, and let stand in each concentration of tert-butanol for 24 hours, and replace the same mass every 12 hours. Percentage of tert-butanol solution to obtain alcohol gel;

[0063] 4) Freeze-drying the alcogel (freeze at -60° C., drying vacuum degree is 1 Pa) to obtain an airgel material.

Embodiment 3

[0065] A preparation method of an airgel material, comprising the steps of:

[0066] 1) Put the waste paper in a lithium bromide solution with a mass percentage of 60%, and stir it in an oil bath at 130°C until it no longer dissolves or gel appears, then pour the mixed solution into a mold, and put it under room temperature Cool to get a gel;

[0067] 2) Soak in deionized water and continuously replace the gel until no precipitation is detected by silver nitrate to obtain a hydrogel;

[0068] 3) At room temperature, place the hydrogel in 30%, 60% and 100% tert-butanol aqueous solutions in sequence, and let stand in each concentration of tert-butanol for 24 hours, and replace the same mass every 12 hours. Percentage of tert-butanol solution to obtain alcohol gel;

[0069] 4) Freeze-drying the alcohol gel (freeze at -60°C, drying vacuum is 1Pa) to obtain an airgel material;

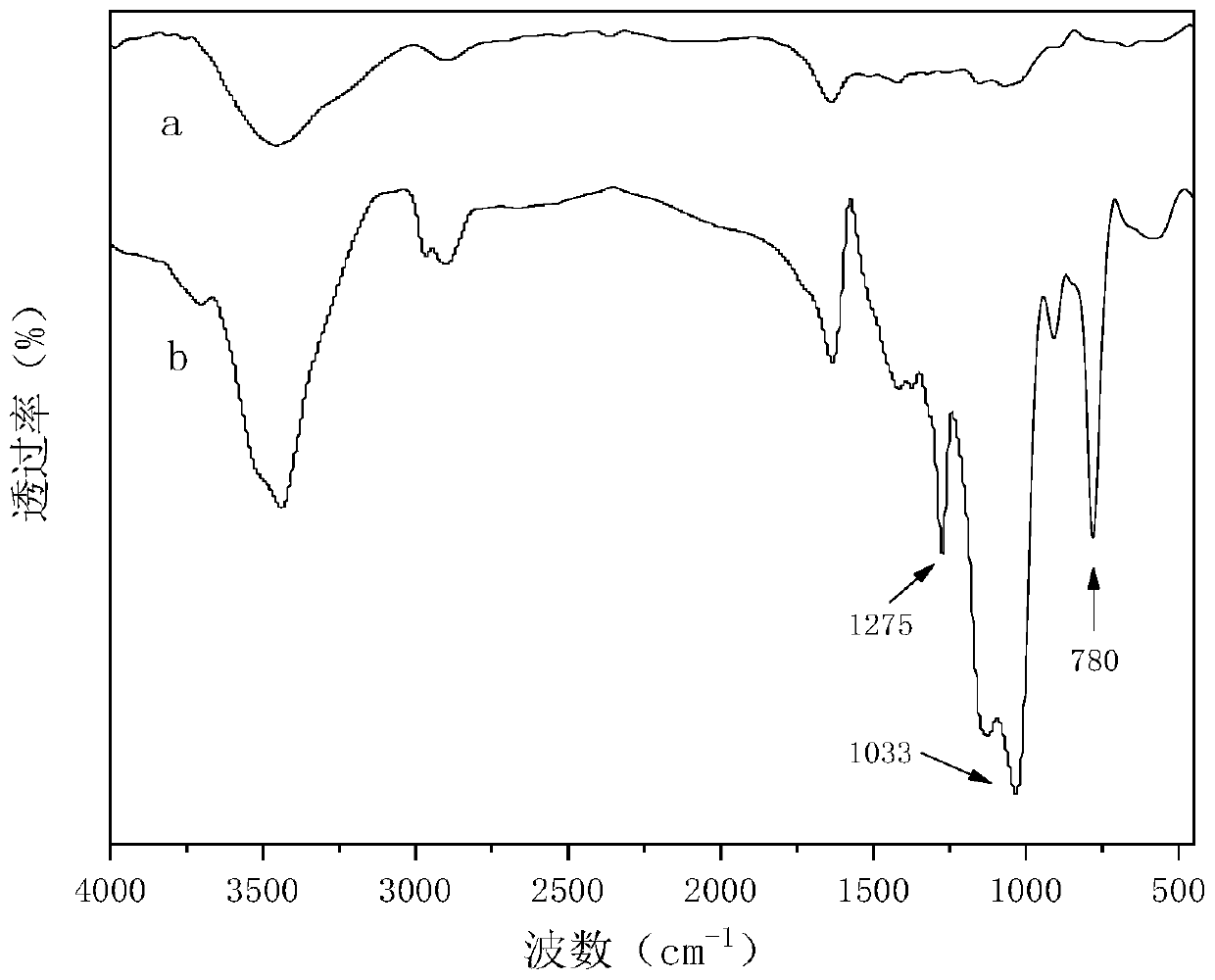

[0070] 5) Put the airgel material in a glass bottle, and place an open beaker containing 600 μL modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com