Energy-saving flue gas pollutant treatment system using waste heat of thermal power plant

A technology for pollutant treatment and thermal power plants, which is applied in heat pumps, climate sustainability, and reduction of greenhouse gases. It can solve the problems of high energy consumption of the flue gas ultra-low emission treatment system, and the heat cannot meet the flue gas reheater. Achieve the effects of reducing losses, reducing energy consumption and operating costs, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

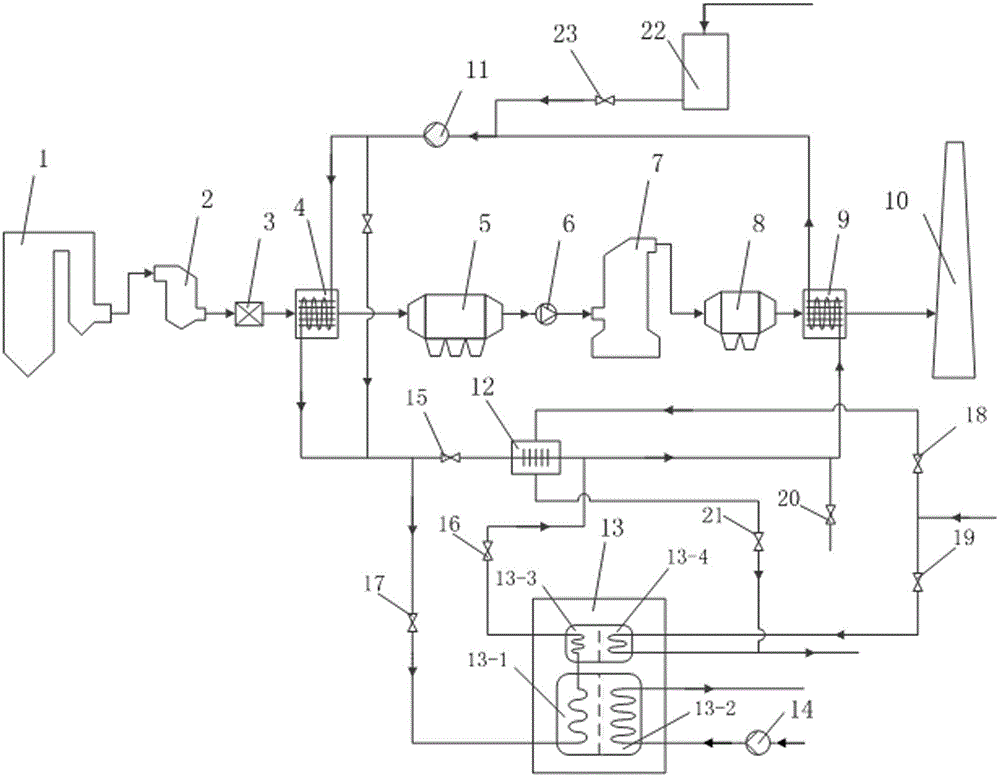

[0022] In this embodiment, the structure of the present invention is described in detail with reference to the drawings.

[0023] Referring to the accompanying drawings, the present invention provides an energy-saving flue gas pollutant treatment system utilizing waste heat from a thermal power plant, the system includes a flue gas cooler 4 and a flue gas reheater 9, and the flue gas cooler 4 and A steam auxiliary heater 12 is installed on the pipeline of the medium water circulation system between the flue gas reheaters 9. The function of the steam auxiliary heater 12 is to mix the supplementary steam with the medium water and send it to the flue gas when the boiler is running at low load. A reheater 9, an energy-saving branch circuit utilizing waste heat from a thermal power plant is also provided between the flue gas cooler 4 and the flue gas reheater 9 .

[0024] The energy-saving branch is provided with a first-type absorption heat pump 13, and the first-type absorption h...

Embodiment 2

[0037] heat balance mode of operation, such as figure 1 As shown, after the flue gas is discharged from the boiler 1, it passes through the SCR denitrification reactor 2, the air preheater 3, the flue gas cooler 4, the electrostatic precipitator 5, the induced draft fan 6, the FGD desulfurization tower 7, and the wet electrostatic precipitator 8 (may or may not be provided), flue gas reheater 9, and finally discharge through chimney 10. When the boiler is running at full load, the heat released by the flue gas cooler 4 meets the heat required by the flue gas reheater 9, the first type of absorption heat pump 13 stops, the valve 15 is opened, and the valves 17, 16, 18 and 19 are closed , the booster pump 11 is running, and the flue gas pollutant treatment system provided by the present invention is running in a heat self-balance state.

Embodiment 3

[0039] In the working mode of the energy-saving branch, the flow of flue gas pollutants is consistent with that in Embodiment 2, and Embodiment 1 and Embodiment 2 are combined.

[0040] When the heat released by the flue gas cooler cannot meet the heat required by the flue gas reheater when the boiler is not operating at full load, the controller of the first type of absorption heat pump 13 receives the signal from the control system of the flue gas co-processing system Start, valves 15 and 18 are closed, valves 17, 16 and 19 are opened, water diversion pump 14 is opened, and booster pump 11 runs. According to the flue gas inlet and outlet flow, temperature and medium water inlet and outlet flow, temperature, steam parameters of the flue gas cooler and flue gas reheater, the temperature of the open cycle cooling water or closed cooling water is automatically adjusted to enter the generator 13- 4 steam flow rate and the open-type circulating cooling water or closed-type cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com