Low-temperature curing primer-topcoat coil coating back paint and preparation method thereof

A technology of coil coating and back coating, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor corrosion resistance, low curing temperature and high temperature, achieve low curing temperature and reduce energy consumption , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

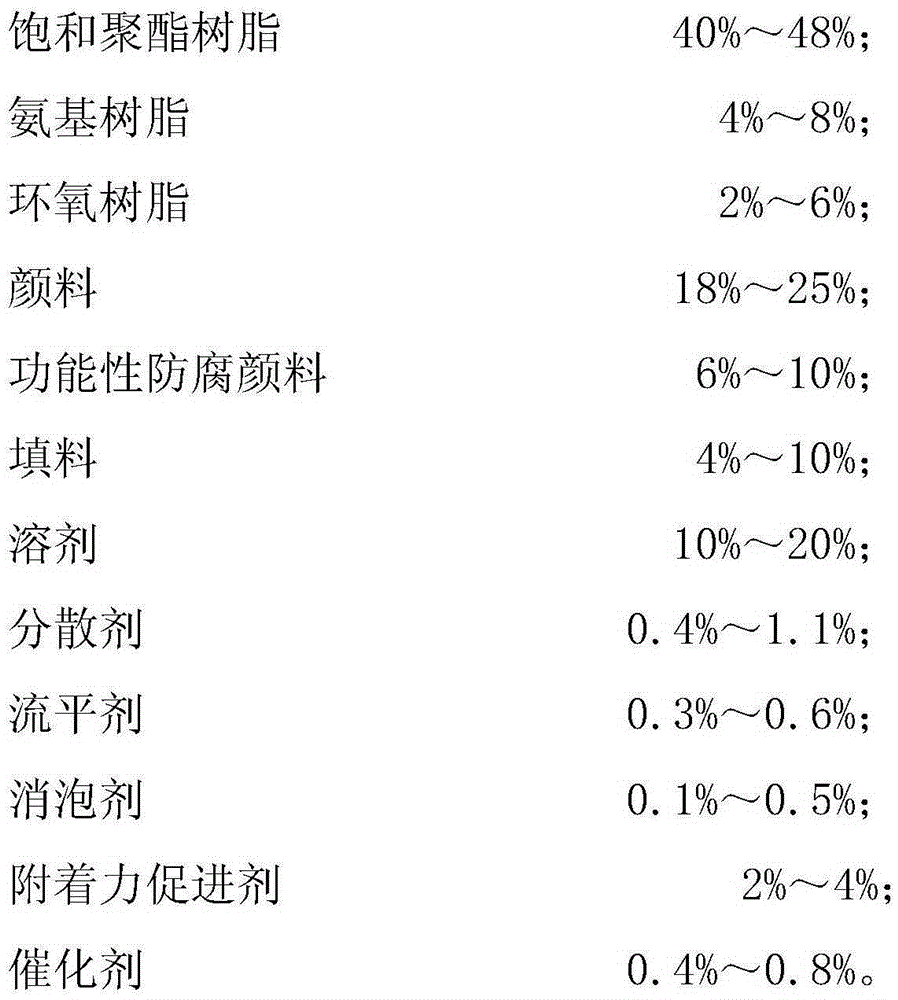

Method used

Image

Examples

Embodiment 1

[0023] A kind of coil coating back paint that the low-temperature curing bottom surface of present embodiment describes, it is made of containing 44 parts by weight B301 high reactivity long-chain type low-hydroxyl polyester resin, 11.2 parts of mixed solvent (being S-150 aromatic hydrocarbon Solvent: mixed dibasic ester DBE=6:4 mixture), 0.8 parts of dispersant BYK104, 0.4 parts of leveling agent polyether modified polyacrylate, 20 parts of rutile titanium dioxide, 0.1 parts of carbon black, 6 parts of functional Anti-corrosion pigment aluminum tripolyphosphate, 5 parts of precipitated barium sulfate, 3 parts of 609 epoxy resin, 6 parts of CYMEL303 amino resin, 3 parts of adhesion promoter Hemings Deqian's PLH, 0.1 part of defoamer BYK1790 and 0.4 Parts of closed dinonyl naphthalene disulfonic acid catalyst.

[0024] The preparation method of a low-temperature curing bottom-surface-integrated coil coating back paint is as follows: 44 parts of B301 high-reactivity long-chain l...

Embodiment 2

[0029] A kind of coil coating back paint that the low-temperature curing bottom surface of present embodiment describes, it is made of containing 45 parts by weight B301 high reactivity long-chain type low-hydroxyl polyester resin, 10 parts of solvent (being S-150 aromatic hydrocarbon solvent : Ethylene glycol butyl ether = 5:5 mixture), 0.4 parts of dispersant BYK110, 0.6 parts of leveling agent fluorine-modified polyacrylate, 18 parts of rutile titanium dioxide, 0.3 parts of carbon black, 8 parts of functional anti-corrosion pigment phosphoric acid Zinc, 7 parts of precipitated barium sulfate, 2 parts of 609 epoxy resin, 6 parts of CYMEL303 amino resin, 2.2 parts of adhesion promoter Hemings Deqian's PLH, 0.1 part of defoamer BYK1790 and 0.4 parts of closed type II Nonyl naphthalene disulfonic acid catalyst composition.

[0030] Add 45 parts of B301 high-reactivity long-chain low-hydroxyl polyester resin, 7 parts of solvent, 0.4 parts of dispersant, and 0.8 parts of leveling...

Embodiment 3

[0034]A kind of coil coating back paint that the low-temperature curing bottom surface of present embodiment describes, it is made of containing 48 parts by weight B301 high reactivity long-chain type low-hydroxyl polyester resin, 10 parts of solvent (being ethylene glycol butyl ether: DBE: S-150 aromatic hydrocarbon solvent: butanol = 4:3:2:1 mixture), 1.1 parts of dispersant BYK104, 0.3 parts of leveling agent polyether modified polyacrylate, 16 parts of rutile titanium dioxide, 0.3 parts Organic lemon yellow, 6 parts of functional anti-corrosion pigment aluminum tripolyphosphate, 4.2 parts of precipitated barium sulfate, 3 parts of 609 epoxy resin, 8 parts of CYMEL303 amino resin, 2 parts of adhesion promoter Hemings Deqian's PLH, It consists of 0.5 parts of defoamer BYK1790 and 0.6 parts of blocked dinonyl naphthalene disulfonic acid catalyst.

[0035] Add 48 parts of B301 high-reactivity long-chain low-hydroxyl polyester resin, 7 parts of solvent, 1.1 parts of dispersant,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com