Coil coating having special anode oxidation effect and special for aluminum plate coiled material and preparation method of coil coating

A technology of anodizing and special effects, which is applied in the direction of polyester coatings, coatings, metal-free paints, etc., can solve the problems that aluminum powder paints are difficult to paint and produce anodized surface effects, so as to reduce production costs, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

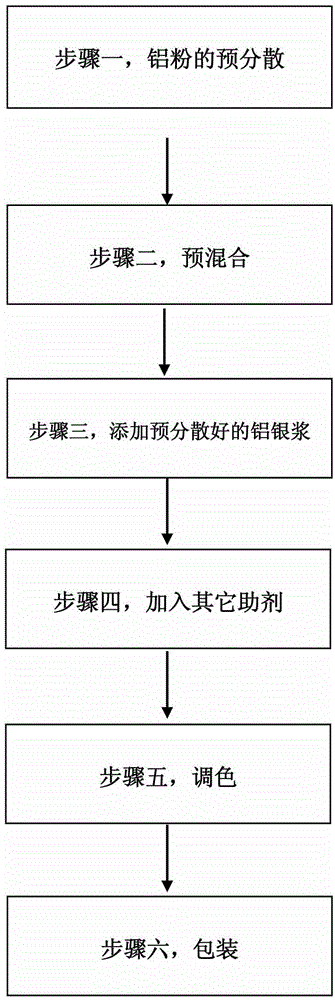

Method used

Image

Examples

Embodiment Construction

[0049] specific implementation plan

[0050] The present invention will be further described below in conjunction with specific embodiments.

[0051] An anodized special-effect coil coating for aluminum coils, characterized in that it includes the following components and their weight percentages:

[0052] Solvent: 2-10%

[0053] Dispersant: 0.5-1%

[0054] Catalyst: 0.5-1%

[0055]Amino 5-10%

[0056] Defoamer: 0.3-0.5%

[0057] Adhesive: 0.3%-0.5%

[0058] Leveling agent 0.3-0.6%

[0059] Alignment aids: 1-2%

[0060] Antistatic additives: 0.5-1%

[0061] Nanoscale treatment of aluminum powder: 15-25%

[0062] Polyester resin 40-50%

[0063] Fluorine modified polyester resin 10-20%

[0064] Nanoscale toner: 0.1-1%.

[0065] As a more specific embodiment: the above-mentioned solvent contains the following four components: 10% xylene, 10% n-butanol, 70% butyl ester, 10% ethylene glycol monobutyl ether; and the catalyst contains the following One or two component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com