Patents

Literature

32results about How to "Achieve chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imitation marble brick prepared by construction waste and preparation method thereof

InactiveCN109650792AReduce cement consumptionReduce dosageSolid waste managementCeramic shaping apparatusFlexural strengthSurface layer

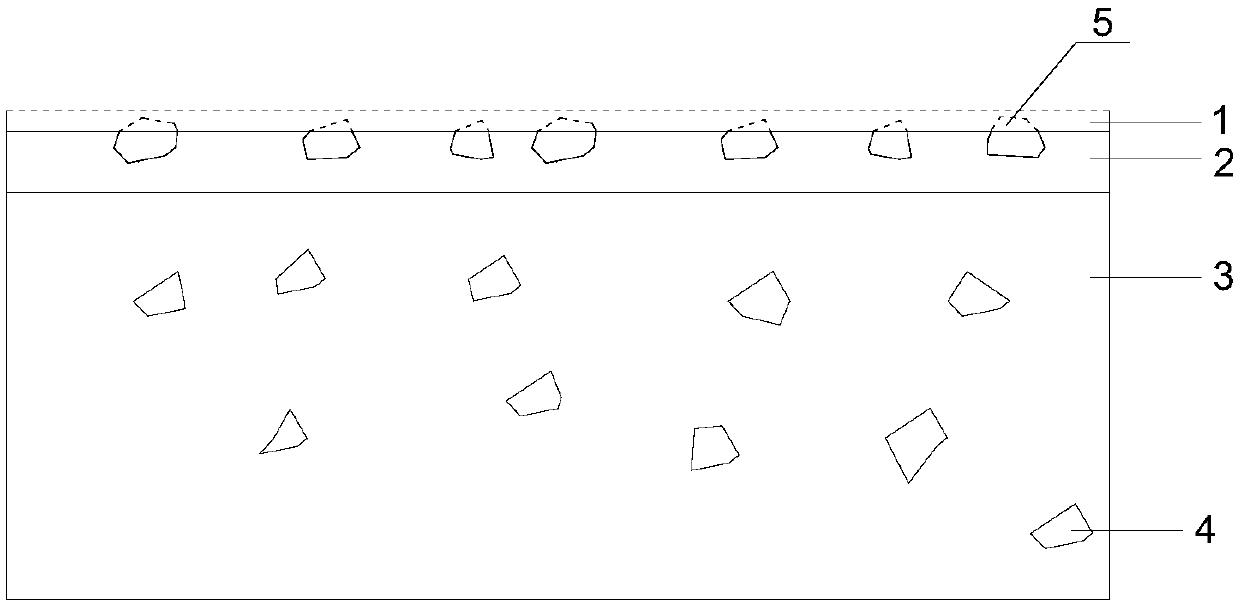

The invention provides an imitation marble brick prepared by the construction waste. The brick comprises a three-layer structure, which is successively a superficial layer, a surface layer material and a bottom layer material. The superficial layer is obtained by polishing after the surface layer material is coated with a curing agent; the surface layer material comprises high-quality recycled coarse aggregate; and the bottom layer material comprises general-quality recycled coarse aggregate and general-quality recycled fine aggregate. Meanwhile, the invention provides a manufacture method ofthe imitation marble brick. The recycled material produced by the construction waste accounts for more than 80% of the total materials. The flexural strength of the prepared imitation marble brick is4-6.5 MPa, and the surface marble pattern is durable in use.

Owner:深圳市绿发鹏程环保科技有限公司

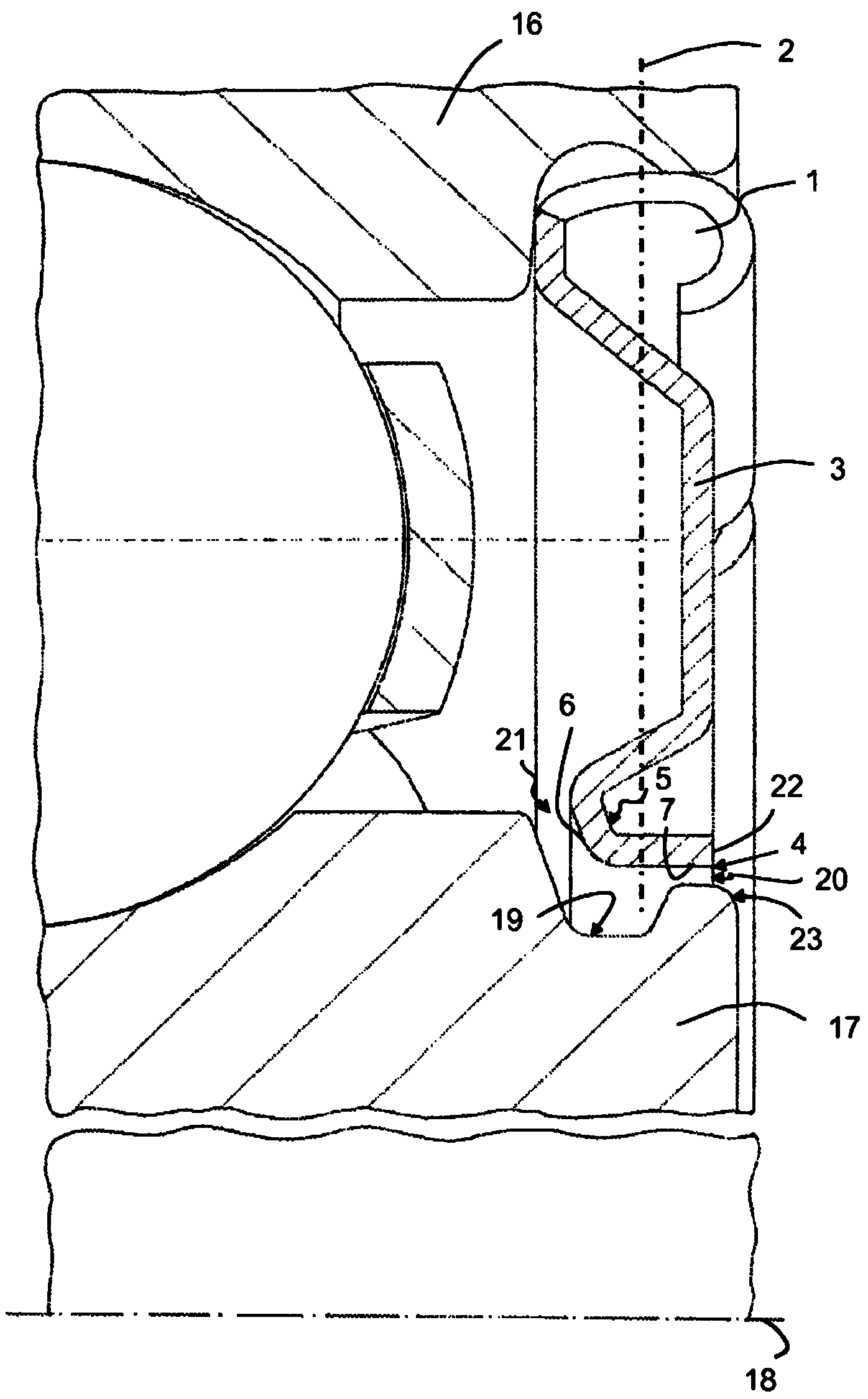

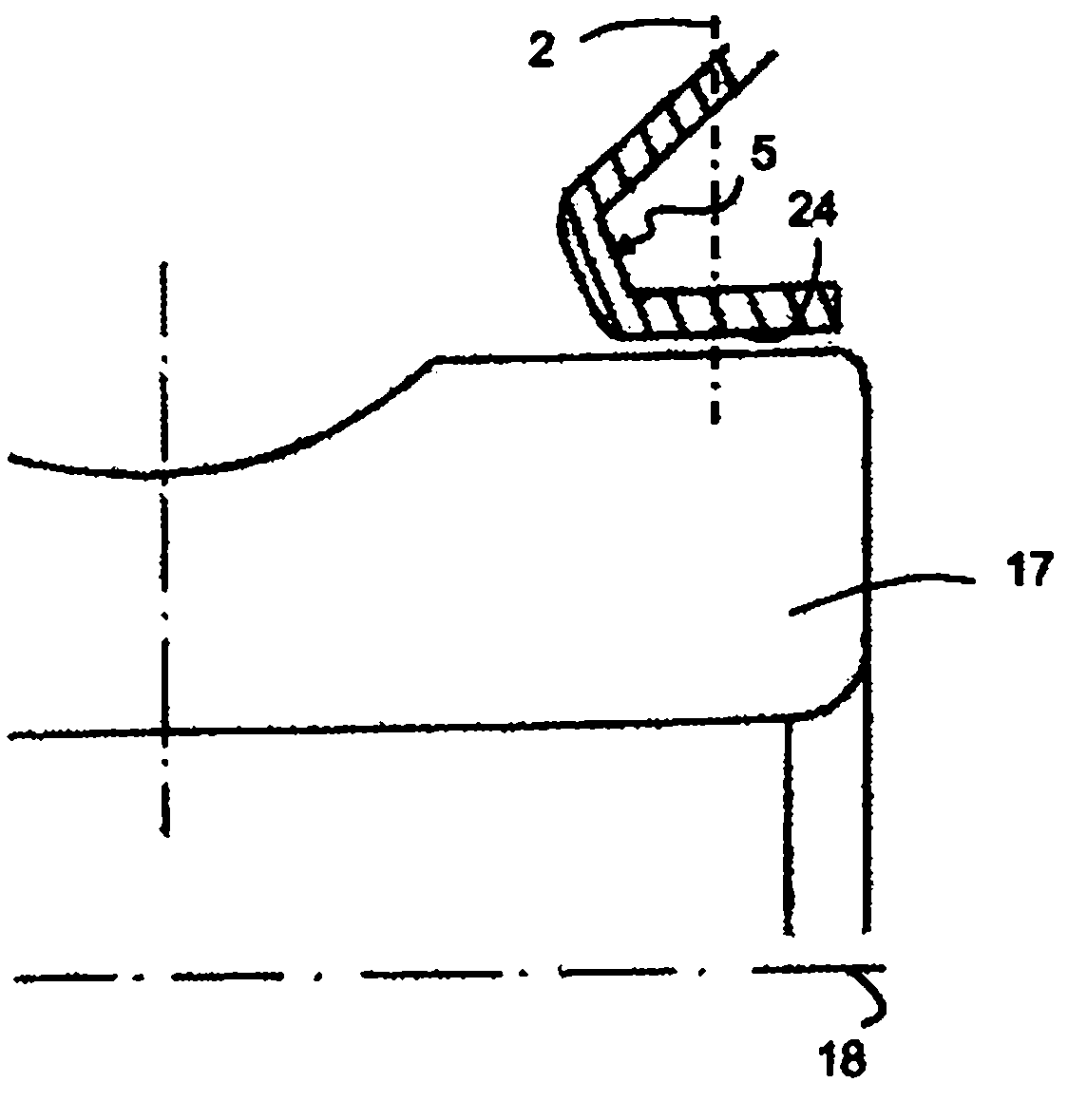

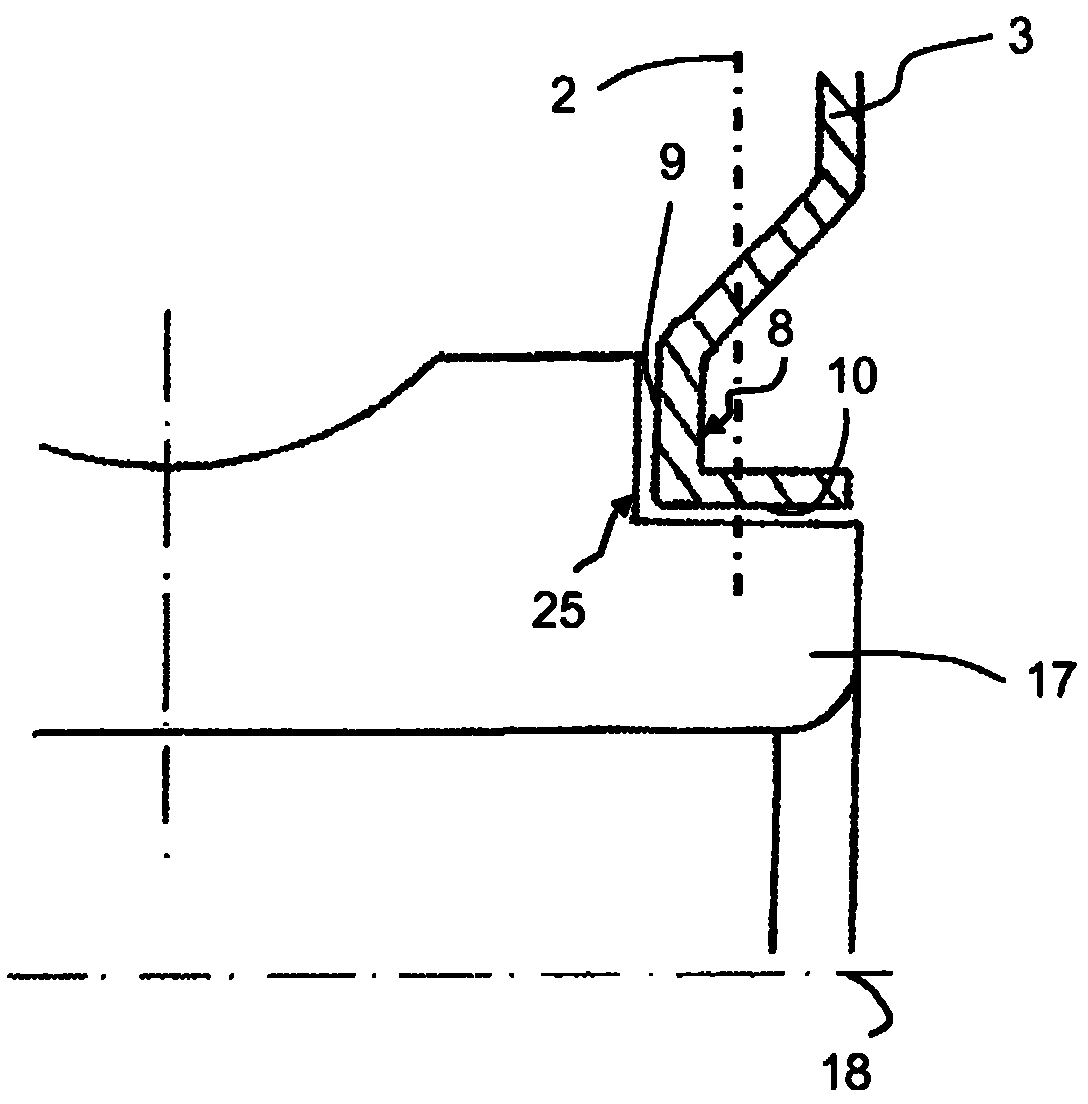

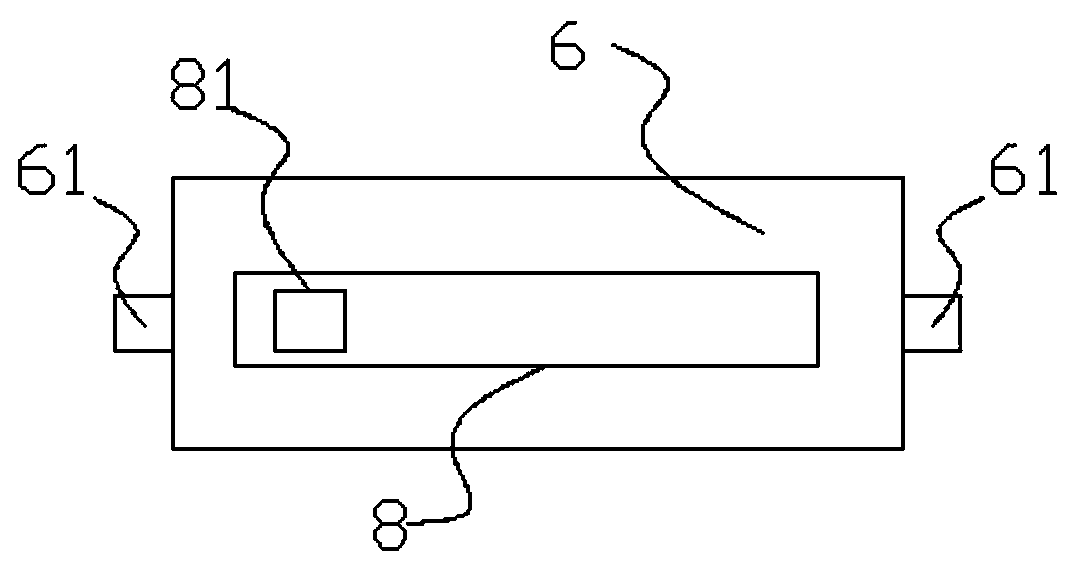

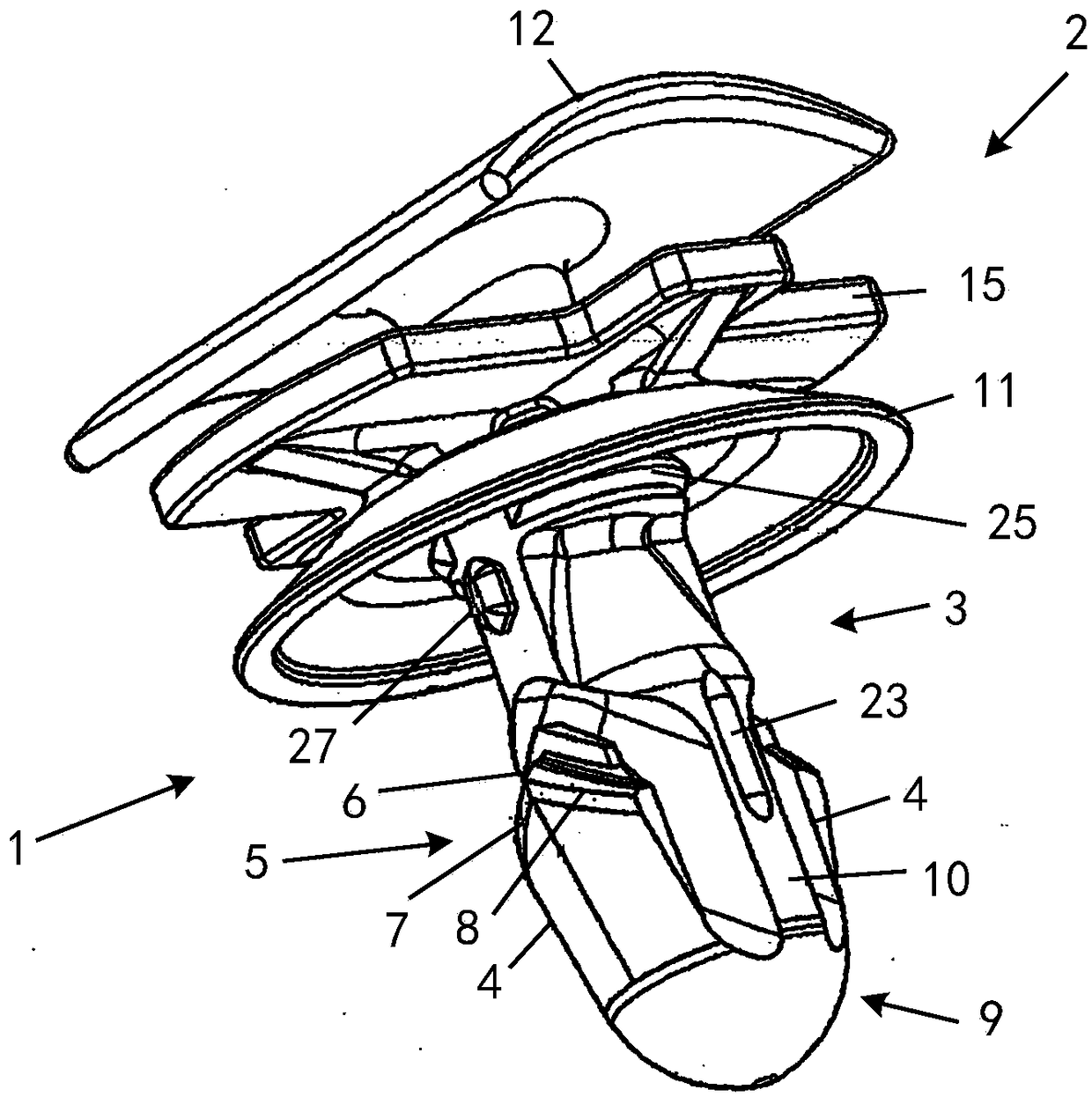

Sealing assembly for a rolling bearing

ActiveCN102428285AAvoid enteringReduce entryBall bearingsBearing componentsRolling-element bearingMechanical engineering

The invention relates to a sealing assembly for a rolling bearing, the sealing assembly having at least one cover element (1) for covering a bearing gap along a cover plane (2), the cover element (1), for securing purposes, having a securing section and a sealing collar as well as a base part (3) connecting the securing section and the sealing collar, and at least one sealing surface (6, 7, 9, 10) being provided on the sealing collar for non-contact sealing. According to the invention, at its starting section, the sealing collar extends from the base part (3) diagonally toward the inner side of the cover element (1) facing the bearing interior and at its end section it extends from the inside toward the outer side of the cover element (1) facing away from the bearing interior. At the same time, the sealing collar forms a sealing surface (7, 10) substantially perpendicular to the cover plane (2) and at the end of the end section at least one edge (4) impeding the inflow of impurities into the bearing interior.

Owner:SCHAEFFLER TECH AG & CO KG

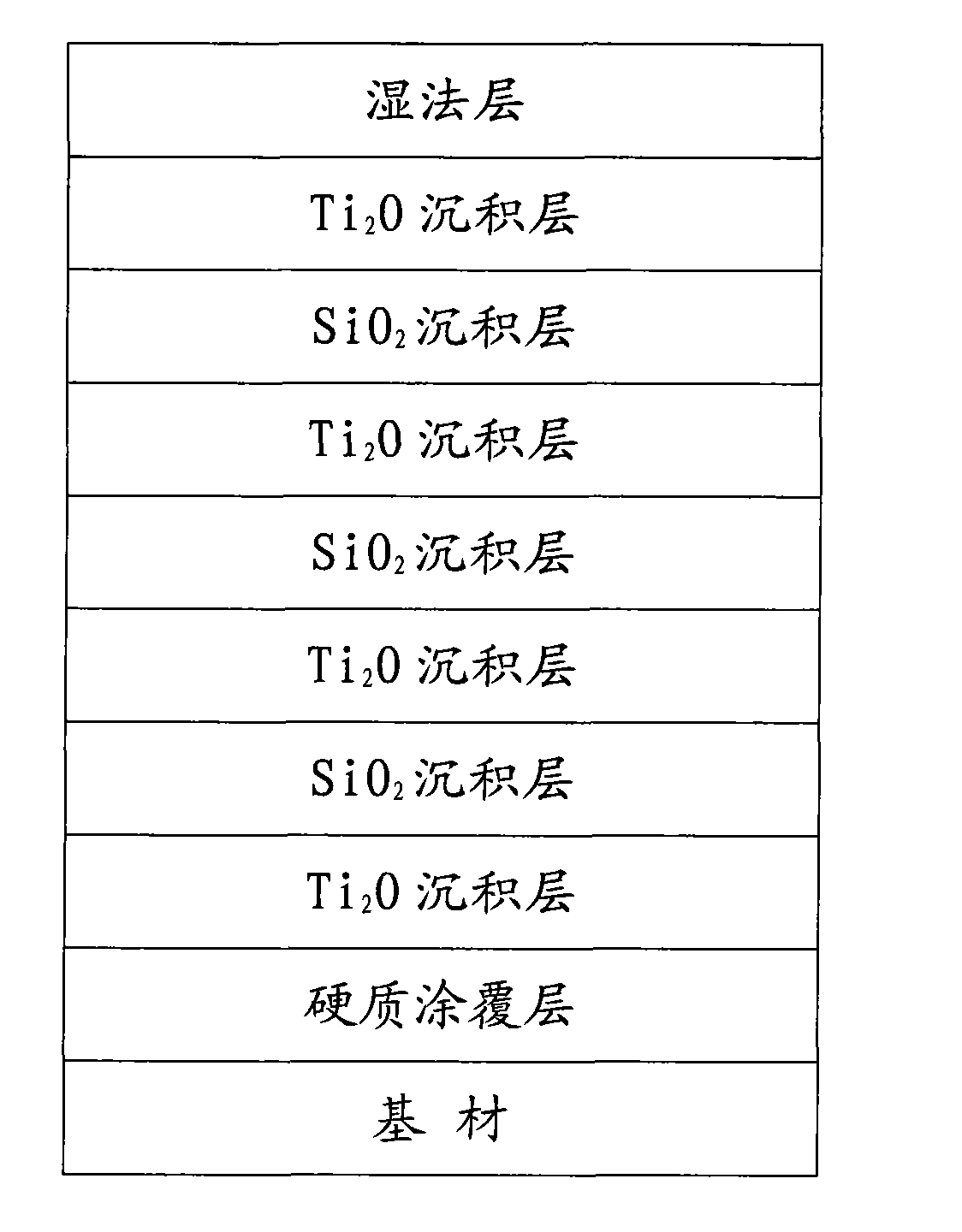

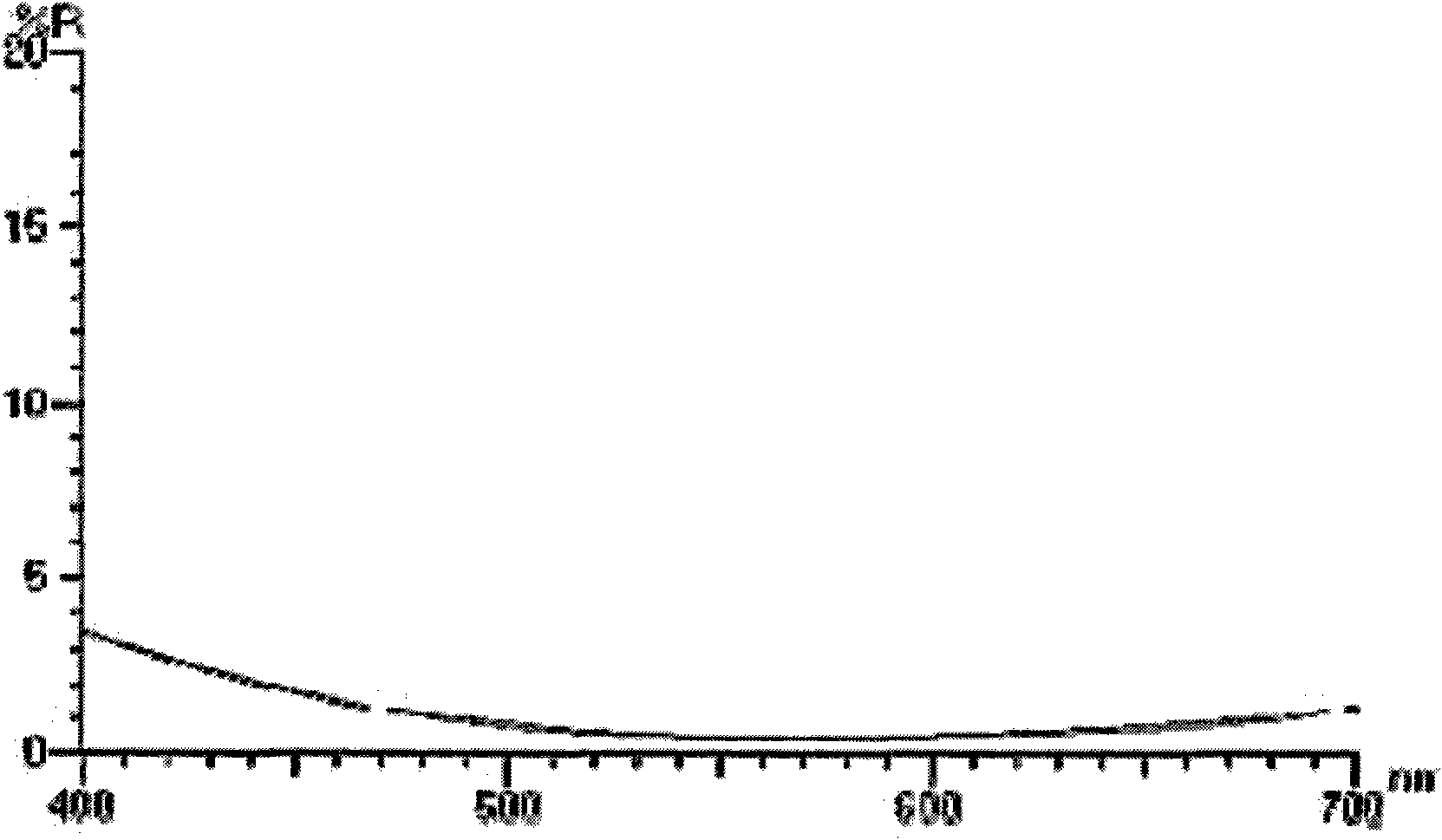

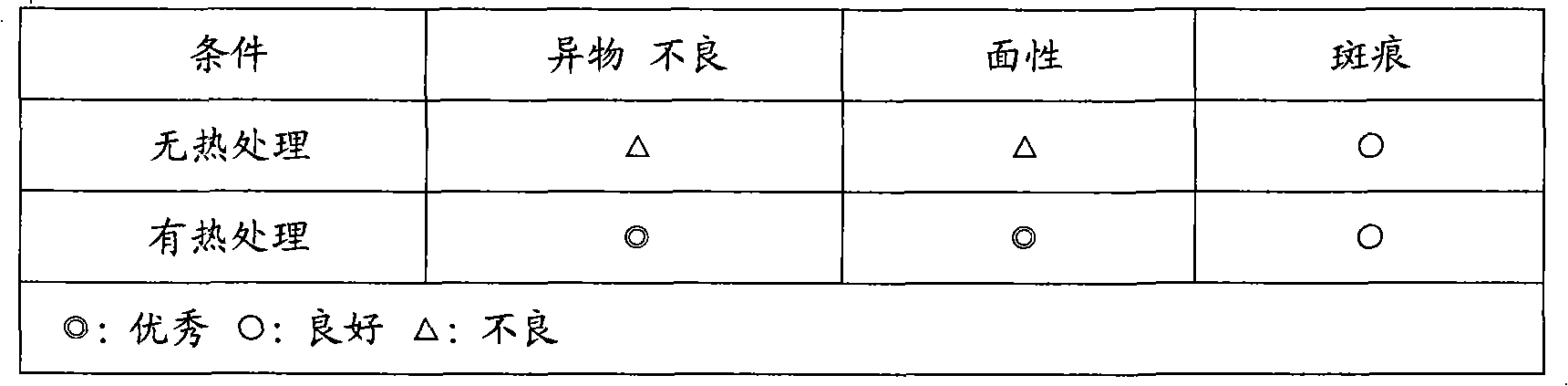

Anti-reflection plastic film and preparation method thereof

InactiveCN102375164AAchieving wear resistanceAchieve water resistanceSynthetic resin layered productsCoatingsOligomerRefractive index

The invention discloses an anti-reflection plastic film. The film is formed by sequentially laminating a base material, a hard coating layer, a deposition layer and a wet method layer, wherein the hard coating layer covers the upper layer, the lower layer or the upper and lower layers of the base material; the deposition layer is formed by repeatedly and alternately depositing a high-refractive index deposition layer and a low-refractive index deposition layer which are sequentially and alternately laminated; and the high-refractive index deposition layer is formed on the upmost layer. A preparation method for the film comprises the following steps of: (a) preparing a hard coating layer composition; (b) coating the hard coating layer composition obtained in the step (a) onto one surface or two surfaces of the base material, and performing photopolymerization to form the hard coating layer; (c) sequentially and alternately coating the high-refractive index deposition layer and the lower-refractive index deposition layer on the hard coating layer by a vacuum deposition method, a sputtering method or an ion gold-plating method; (d) preparing polysiloxane oligomer; and (e) coating the polysiloxane oligomer obtained in the step (d) onto the high-refractive index deposition layer on the upmost layer by a wet deposition method. The film prepared by the technical scheme has high abrasion resistance, water resistance and chemical resistance, a good anti-reflection effect and excellent physical and chemical properties and can be suitable for various optical parts.

Owner:SUTA ELECTRONICS TECH SHANGHAI

Nanometer protective coating special for aluminum non-stick pan, preparing method and coating technology of coating

InactiveCN110066596AImprove appearance qualityAchieve corrosion resistanceFireproof paintsCooking-vessel materialsUV curingAlcohol

The invention discloses a nanometer protective coating special for an aluminum non-stick pan. The nanometer protective coating is prepared from, by weight, 70-80 parts of polyamideimide, 10-20 parts of nanoscale graphene, 15-30 parts of nanometer calcium carbonate, 30-40 parts of isomeric alcohol ethoxylates, 1-5 parts of a dispersing agent and 20-50 parts of a solvent. A special technical formulais adopted, a graphene mother liquor is added, and the good effects of easy cleaning, good thermal performance, and resistance to corrosion, high temperature and chemicals can be achieved; meanwhile,through a unique coating technology, surface treatment is conducted in advance, so that the coating has good adhesive force during spray coating, through the technologies of multiple times of spray coating, drying and UV curing, the requirement for spray-coating attractiveness is met, and the appearance quality of spray-coated colored paint is improved.

Owner:北京百年初心科技有限公司

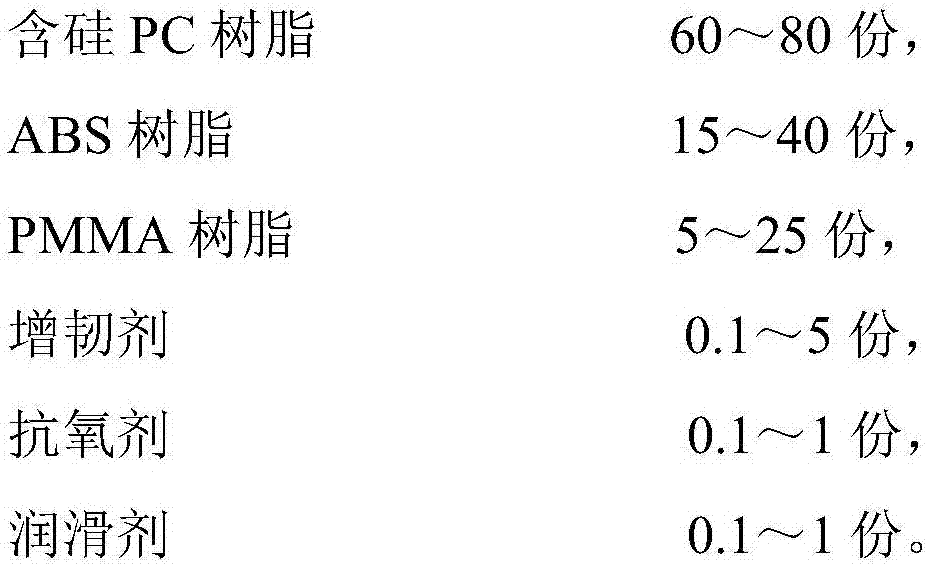

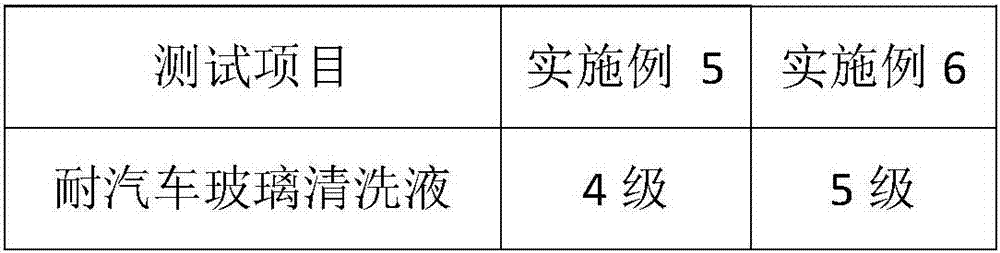

PC/ABS alloy material with excellent chemical substance resistance, and preparation method thereof

The invention relates to a PC / ABS alloy material with excellent chemical substance resistance, and a preparation method thereof. The PC / ABS alloy material comprises, by weight, 60-80 parts of silicon-containing PC resin, 15-40 parts of ABS resin, 5-25 parts of PMMA resin, 0.1-5 parts of a flexibilizer, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method comprises the following steps: 1, adding the silicon-containing PC resin, the ABS resin, the PMMA resin, the flexibilizer, the antioxidant and the lubricant into a mixing stirrer, and mixing all added materials; and 2, feeding a mixture obtained in step 1 to a double screw extruder through a main feeding opening, and carrying out blend granulation to prepare the PC / ABS alloy material with excellent chemical substance resistance. The silicon-containing PC resin with excellent chemical substance resistance is used, the PMMA resin is added, and the PMMA in a molten state has a lower viscosity than the PC and the ABS and can easily aggregate on the surface of a product in the injection molding process to form a protection layer on the surface of the product in order to improve the chemical substance resistance of the PC / ABS resin.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

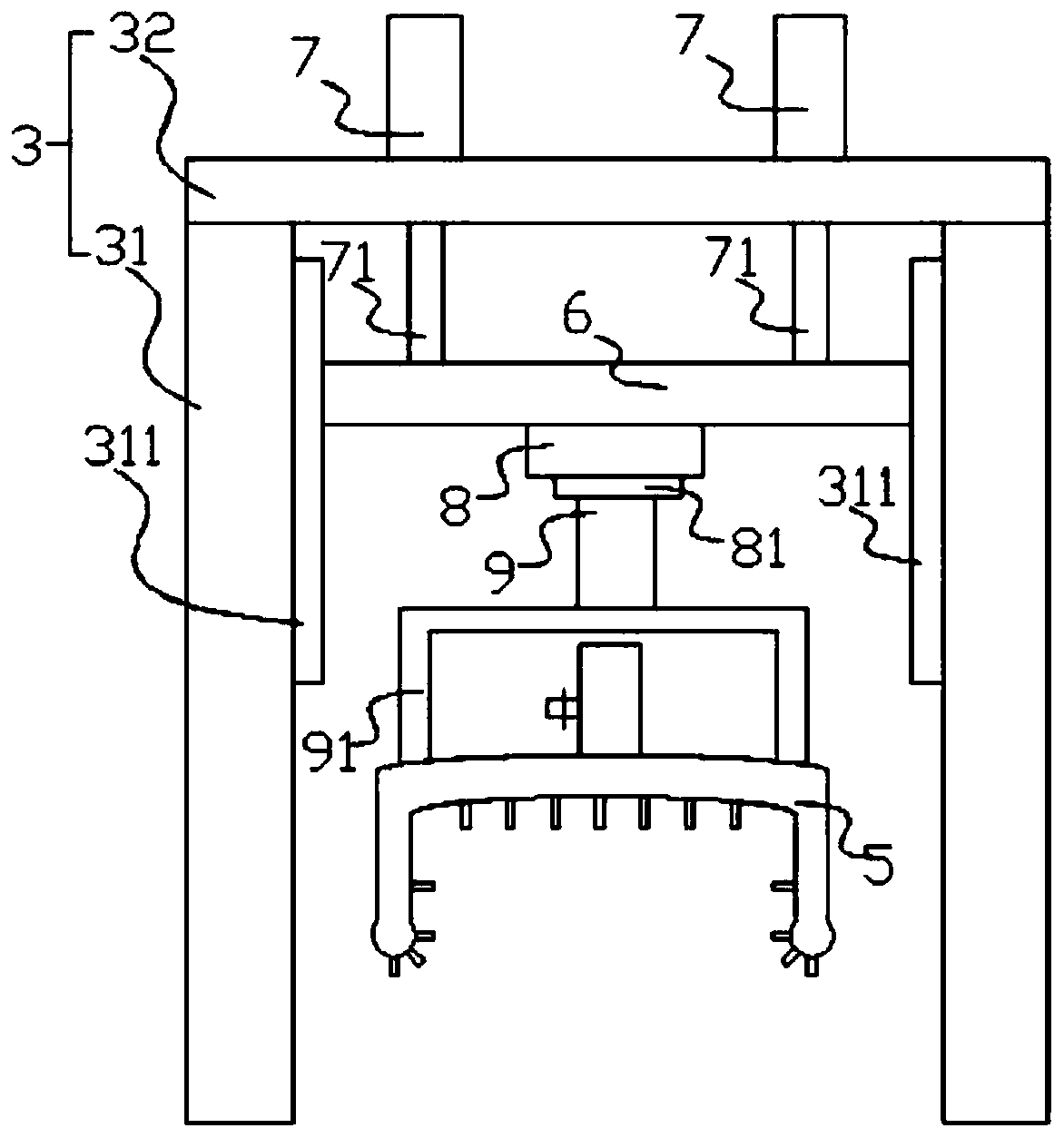

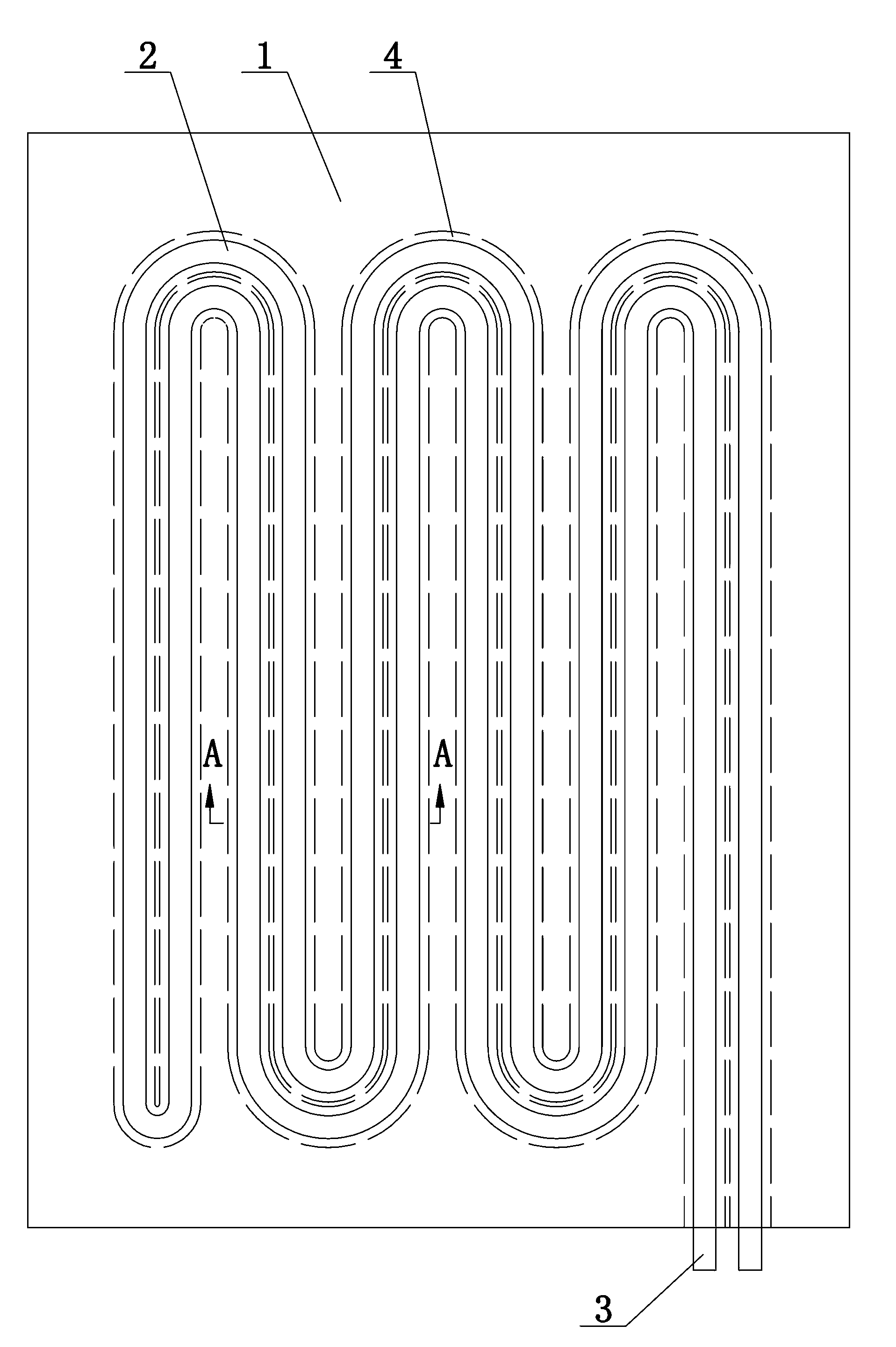

Production process of solar heat collecting plate and heat collecting panel utilized by same

InactiveCN103196247ANot easy to fall offImprove seismic performanceSolar heat devicesSolar thermal energy generationThermodynamicsAdhesive

The invention provides a production process of a solar heat collecting plate and a heat collecting panel utilized by the solar heat collecting plate. The production process comprises the following steps of: impacting a carbon-free steel plate to form the heat collecting panel with a groove; spraying a vitreous inorganic composite material on the light gathering surface of the heat collecting panel; sintering at high temperature; fusing the heat collecting panel with the inorganic composite material to form a novel black composite material; and fixing a heat conducting pipe filled with a superconducting medium on the groove in the back surface of the heat collecting plate by utilizing a high-temperature resistant adhesive, thereby forming the solar heat collecting plate with the enamel superconducting medium. The solar heat collecting plate provided by the invention is difficult in coating shedding, good in anti-vibration property, resistant to high temperature and low temperature, resistant to disaster weather such as hailstone, resistant to impact and difficult to break.

Owner:郸城县英耐姆复合材料有限公司

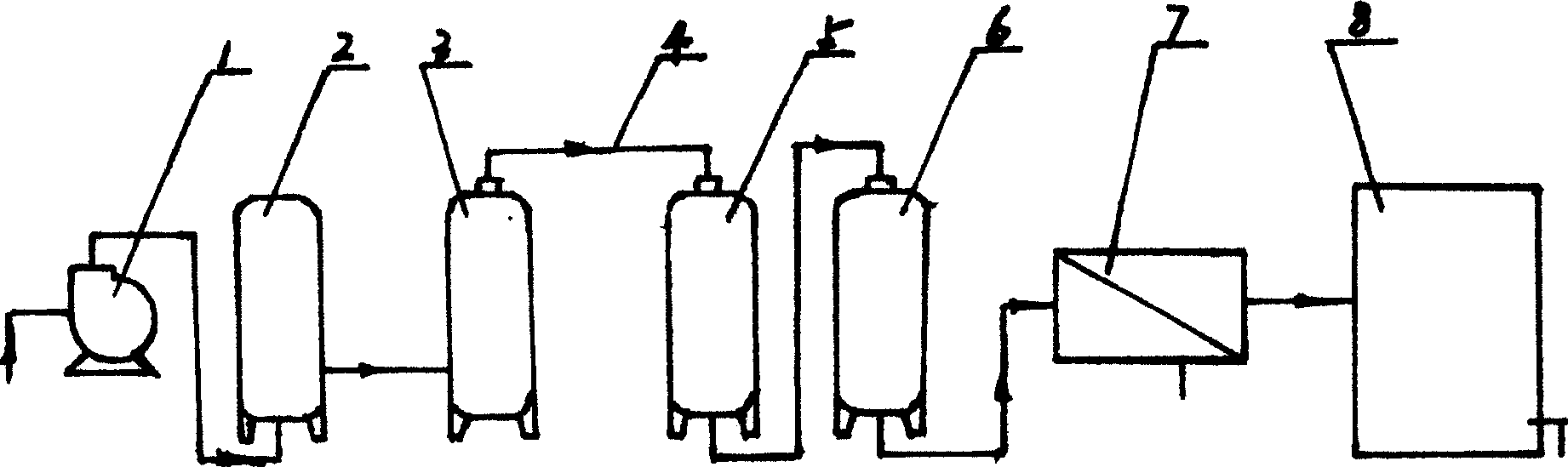

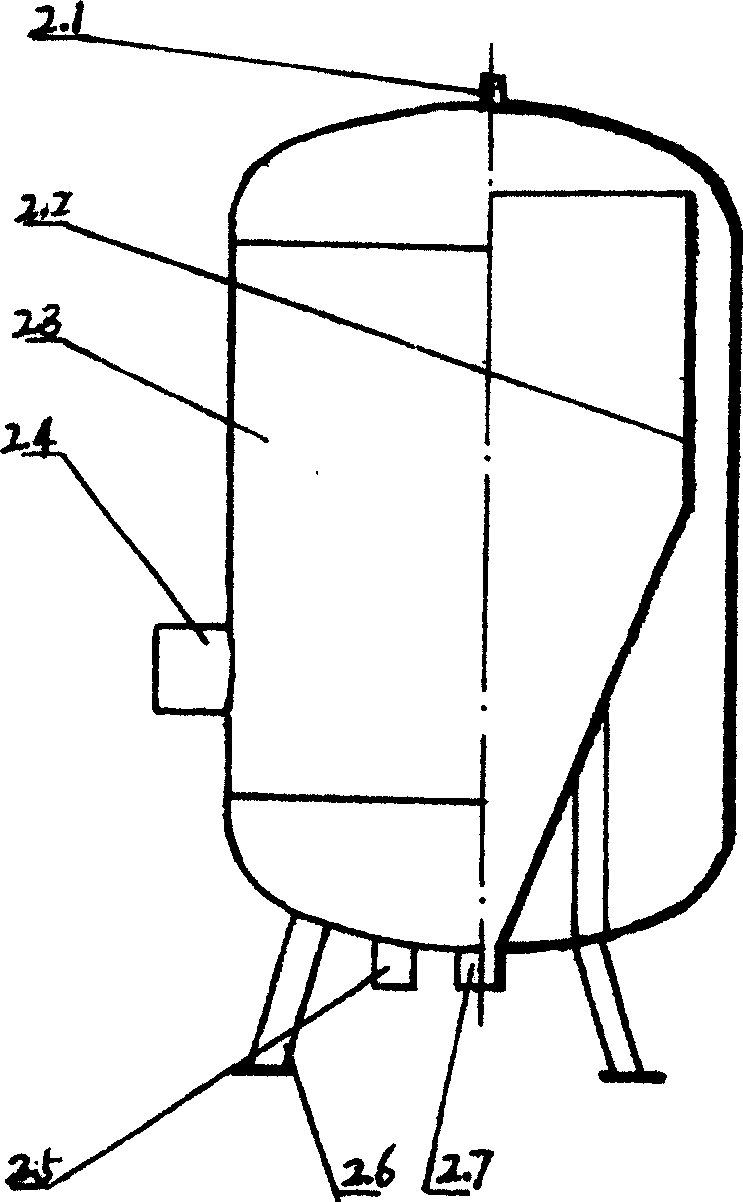

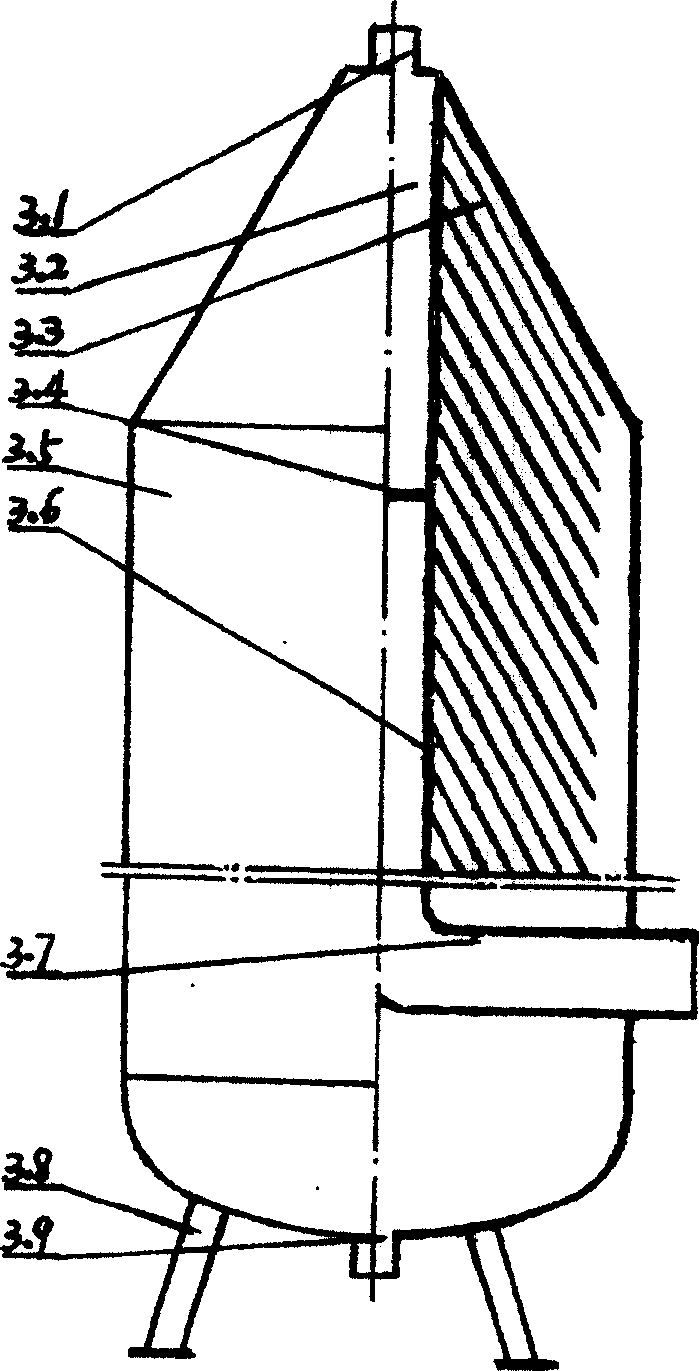

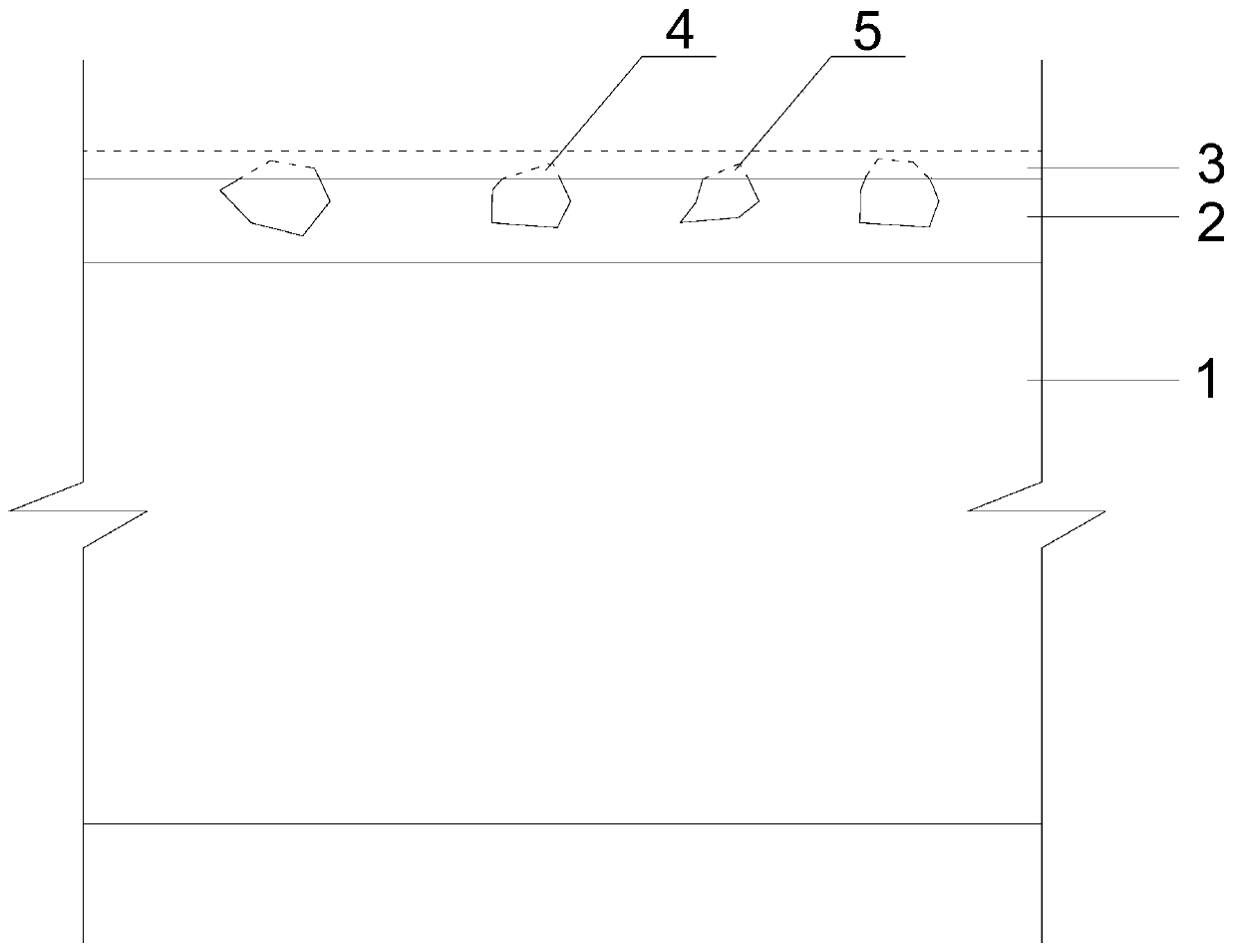

Drinking water emergency purifying process and its apparatus

InactiveCN100463870CEfficient killingImprove cohesionSedimentation separationWater/sewage treatment bu osmosis/dialysisPotable waterFiltration

The invention relates to a drinking water emergency purifying process and device. And the process flow: raw water-->water pump--> hybrid reaction--> precipitation--> filtering--> reverse osmosis purification--> purified water; and the device comprises water pump fixed in a load carrier, flocculator with taper-foot internal tube, precipitator with built-in downward-water injection umbrella flow splitting plate, filter, adsorber, reverse osmosis purifier and water tank, connected together through pipelines, where the polluted raw water is pumped by water pump into the flocculator, precipitator, filter and adsorber for pretreatment, then enters into the reverse osmosis purifier for thorough purification and turns into drinking water. And it can effectively remove suspended matters, organic matters, bacilli, viruses, and other harmful components from the water, and has anti-chemcial, anti-atom and anti-biology effects.

Owner:葫芦岛北方膜技术工业有限公司

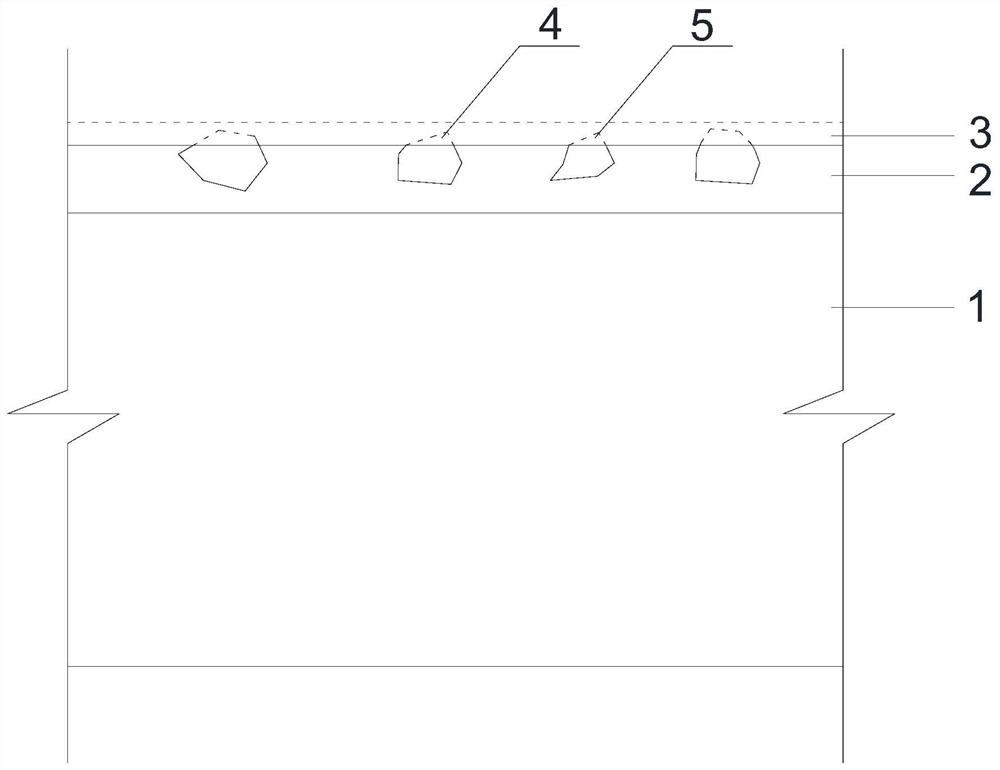

Light emitting road surface and preparation method thereof

ActiveCN110395952ATo achieve the artistic effect of appreciationBeautiful art deco effectSurface layerBrick

A light emitting road surface material comprises a surface layer material and a base layer material from top to bottom in turn, wherein that base layer material comprises the following components in parts by weight: cement 120-240; regenerated micro-powder of construction wastes 10-70; recycled coarse aggregate of construction wastes 500-900; construction waste recycled fine aggregate 200-600; water 60-140; water reducer <=6. The surface layer material comprises the following components in parts by weight: white cement 120-240; colored powder <=80; construction waste recycled fine aggregate 200-600; water 60-140; water reducer <=6. The invention further provides a light emitting road surface. The invention provides a light emitting road surface and a preparation method thereof, wherein thelight emitting art road is made of construction waste, the luminous aggregate and the brick aggregate can be inlaid according to a certain pattern, and the luminous aggregate and the brick aggregatehave an artistic effect after polishing, and the evening appreciation effect is better.

Owner:TONGJI UNIV

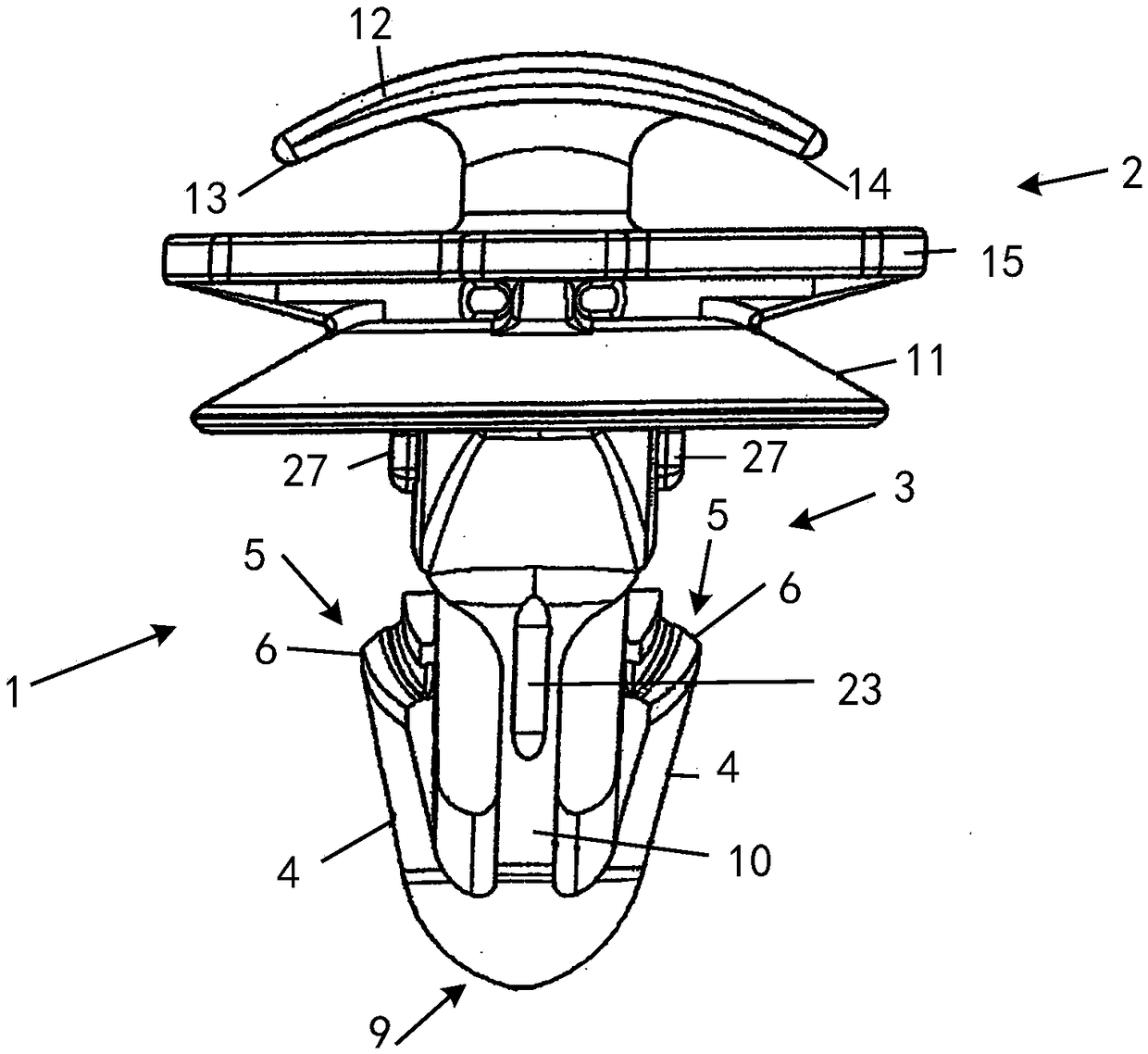

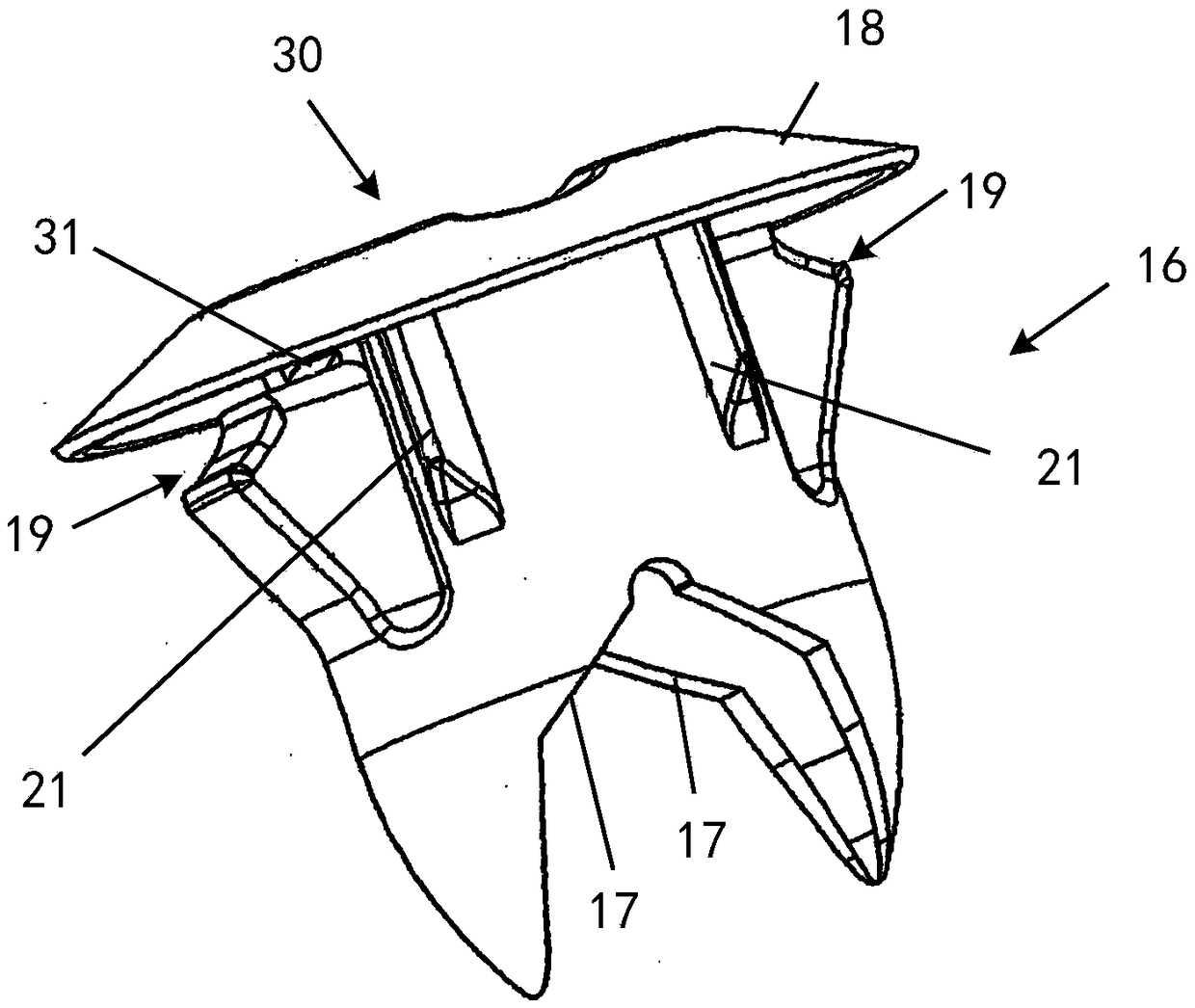

Device for retaining a component to be secured to a support part, system, and use of a device for retaining a component

InactiveCN109311432AImproved snug and reliable holdAchieve chemical resistanceSnap-action fastenersSheet joiningEngineeringMechanical engineering

Owner:A RAYMOND & CO

Anti-acid concrete for manufacturing top pipe

The invention relates to the field of top pipe manufacturing and discloses anti-acid concrete for manufacturing a top pipe. The anti-acid concrete is characterized by being prepared from the following components in parts by weight: 35 to 50 parts of coal gangue, 20 to 30 parts of limestone, 9 to 21 parts of calcium lignosulfonate, 13 to 21 parts of borax, 30 to 45 parts of calcium carbonate, 19 to 32 parts of calcium sulfate, 2 to 6 parts of epoxy resin, 5 to 10 parts of fluorocarbon emulsion, 4 to 8 parts of mesh quartz sand, 0.2 to 0.8 part of hydroxy propyl methyl cellulose, 1 to 5 parts of tributyl phosphate, 1 to 2 parts of polyvinyl alcohol and 2.4 to 3.2 parts of polysilicone. The anti-acid concrete disclosed by the invention achieves the aims of permanent waterproof, moisture-proof and chemical corrosion resisting properties. The problems that the existing top pipe manufactured on the basis of common concrete has cracks and is corroded in acidic soil are solved.

Owner:成都市德容建筑劳务有限公司

Acidic corrosion resistant coating for machining

InactiveCN107903781AWaterproof up toAchieve moisture resistanceAnti-corrosive paintsPolyester coatingsPorosityDiboride

The invention relates to the field of mechanical processing protective coatings, and discloses a mechanical processing anti-acid corrosion coating. Hydrophobic agent, deionized water, acrylonitrile, vanadium diboride, tributyl phosphate, polyvinyl alcohol and polysilicone, by using the inherent chemical properties and porosity of the organic membrane itself, using water as the carrier, with the help of water penetration The effect reacts with the acidic substances outside the organic diaphragm, and acts along or against the direction of water pressure, so as to achieve the purpose of waterproof, moisture-proof, and chemical corrosion resistance, and solve the problem that the existing protective coating is corroded by the acidic environment, which causes mechanical surface damage. Exposure to the external environment reduces its service life.

Owner:成都龙泉马龙机械厂

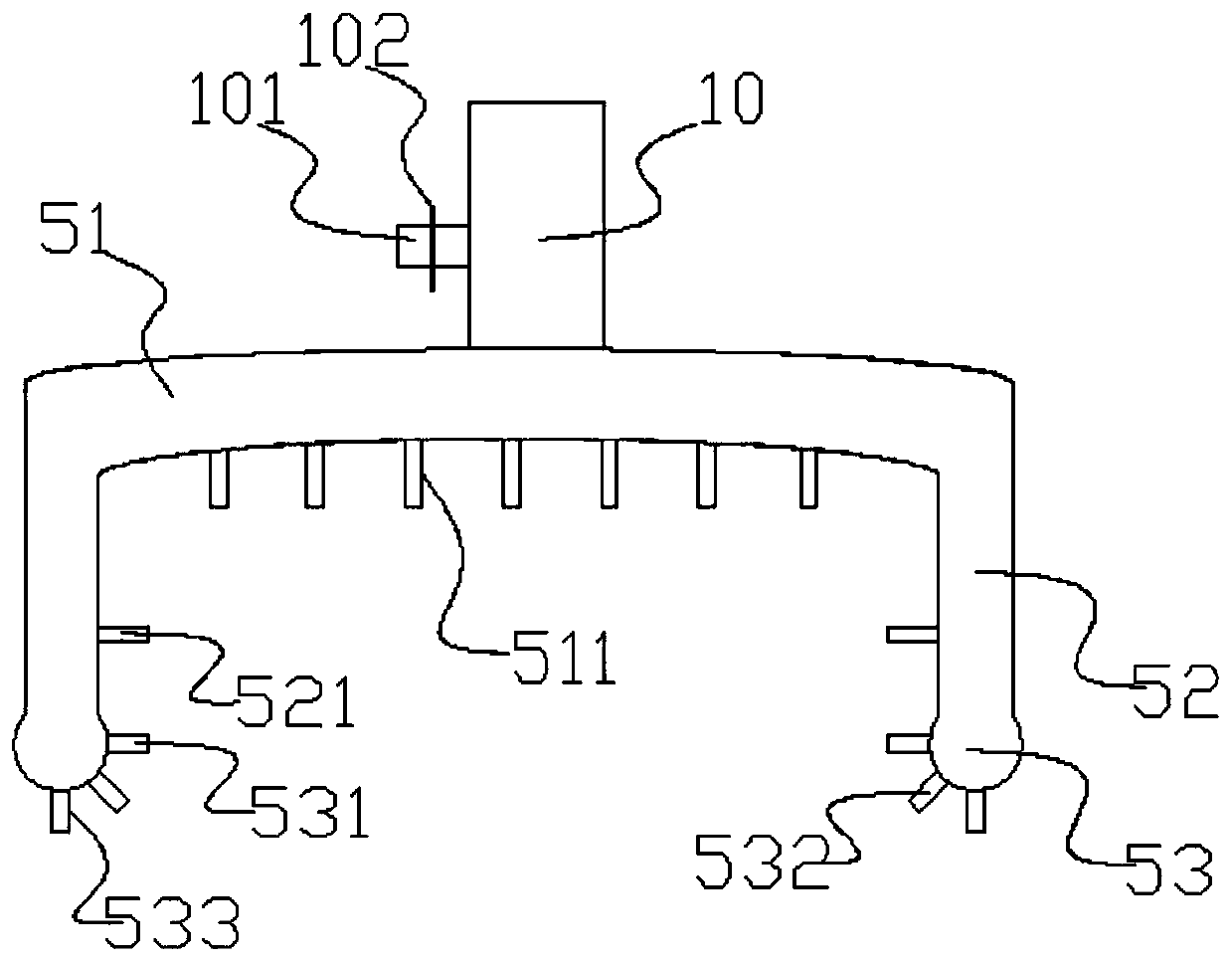

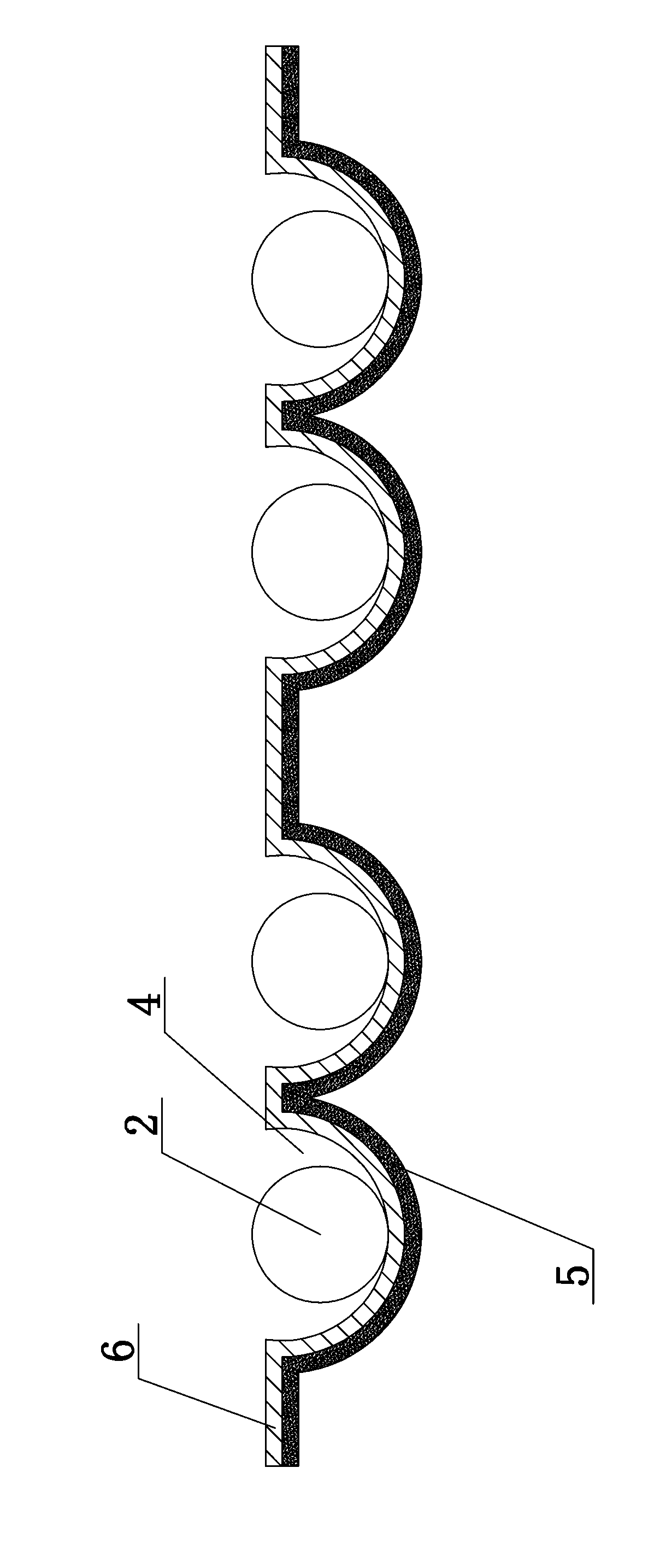

Packing for substrate plating jig and the substrate plating jig using same

InactiveCN106103813AAdjustable lengthReduce manufacturing costContacting devicesSealing devicesEngineeringMechanical engineering

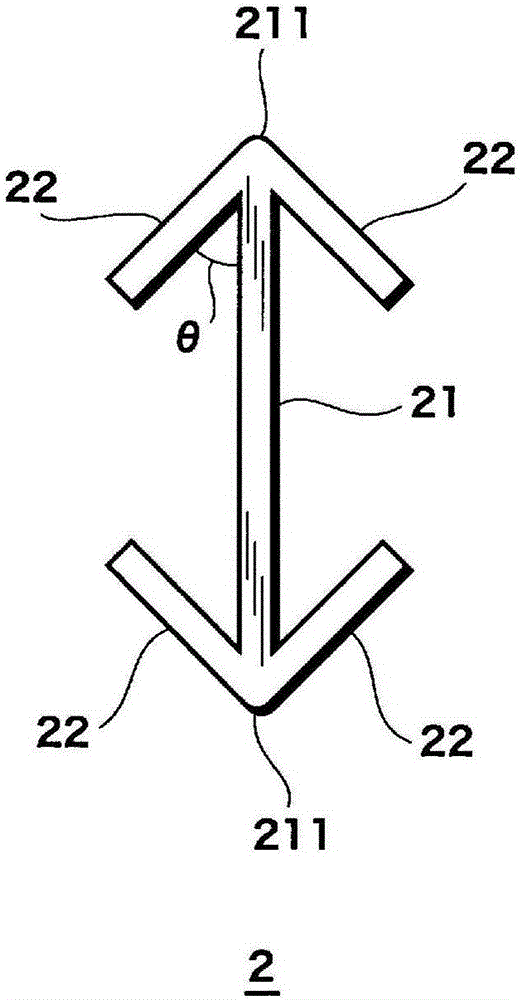

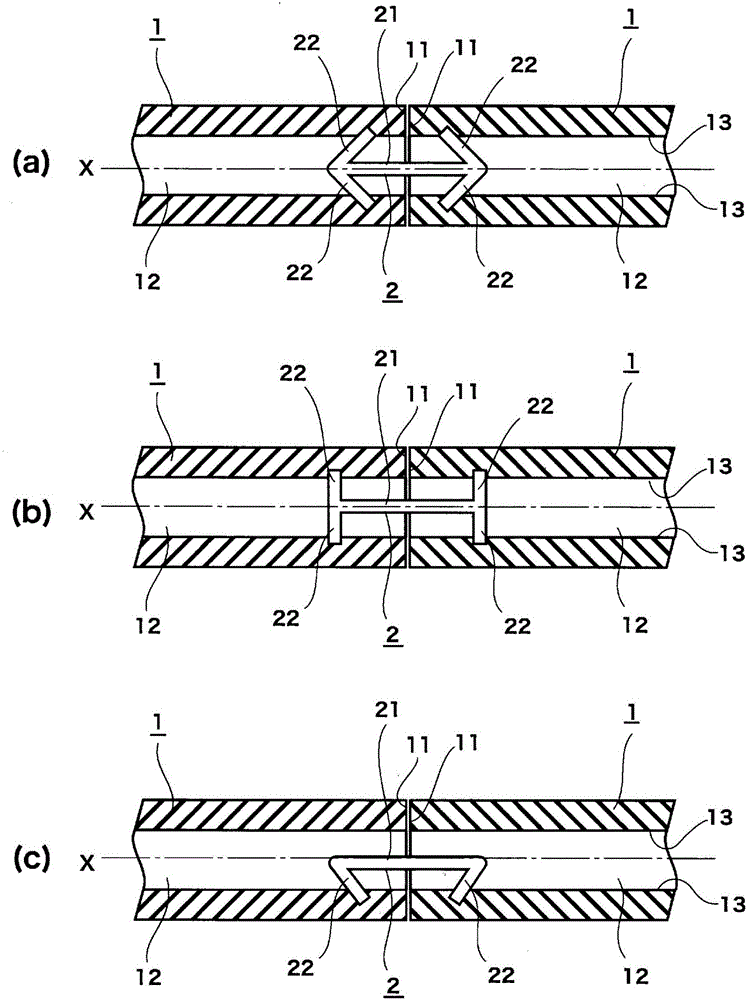

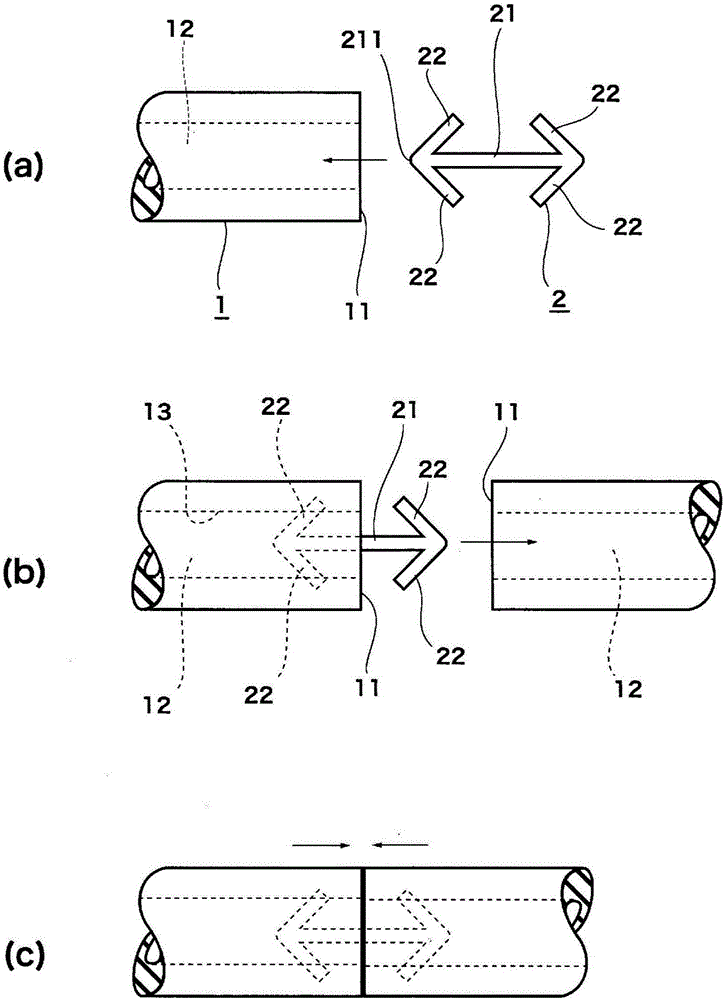

The problem addressed by the present invention is providing packing for a substrate plating jig that is more advantageous in terms of cost than O-rings and can handle various dimensions and shapes for a substrate jig and the substrate plating jig that uses the packing. The packing is attached to the plating jig and is for sealing conductive members for electrifying the substrate and parts of the substrate surface in contact with the conductive members from plating fluid. The packing is provided with a packing main body formed from an elastic material that has an elongated shape and an end, and a connecting member for making a non-ending shape by connecting and affixing connecting ends of both end parts of the packing main body to each other. The connecting member is formed from a shaft part and a plurality of hooks provided so as to protrude at a prescribed angle from the shaft part. The connecting member is provided inside and extends within the packing main body in both directions from the connecting point within a prescribed range so as to extend over the connecting point where the connection ends are linked when the two ends of the packing main body are linked.

Owner:JCU CORP

Container room machining method

InactiveCN108000062AReasonable balance of strength and weightWaterproof up toNon-macromolecular adhesive additivesLarge containersCorrosionFiber

The invention relates to the field of machining methods and discloses a container room machining method. The container room machining method is characterized in that firstly cast steel liquid is placed into a machining mold, and protecting gas is injected to the periphery of the mold; then cooling is performed till room temperature is achieved, and plate pieces A are obtained; polishing and burr removing then are performed on the plate pieces A; the two plate pieces A are stacked, and carbon fibers are placed between the plate pieces A so that fiber cloth can be formed in a weaving manner; then the stacked faces of the two plate pieces A are coated with an adhering agent and are subjected to adhering, the back sides of the two plate pieces A are coated with corrosion preventing coating, and a composite plate C is made; finally, the composite plate C is subjected to trimming and grinding, and two or more roughly made composite plate pieces C after trimming and grinding are made into a top cover, floor and side walls of a container in a spliced manner; and the problems that an existing container has strength and weight balance, and can be affected by an acidic environment during daily use are solved.

Owner:成都龙泉马龙机械厂

A PC/ABS composite material having chemical resistance at high temperature and a preparing method thereof

InactiveCN108912640AGood chemical resistance at high temperatureImprove mechanical propertiesMethyl celluloseCopolyester

The invention provides a PC / ABS composite material having chemical resistance at high temperature and a preparing method thereof, relating to the technical field of polymer materials. The composite material is prepared from modified PC resin, ABS resin, copolyester, poly(methyl methacrylate), a filler, a nucleating auxiliary, hydroxypropyl methyl cellulose, a toughening agent, polysiloxane powder,white mineral oil, and a compatibilizer. The composite material has good chemical resistance at high temperature, and the modified PC resin improves compactness of a surface of the material, and is used for resisting corrosion of acids, alkalis and hot oil on a PC / ABS composite material substrate at high temperature, thus greatly improving chemical resistance at high temperature of the compositematerial. The composite material has excellent mechanical properties and adaptability in complex chemical corrosive environments, and is especially suitable for use in peripheral parts of engines to improve the safety of automobiles.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

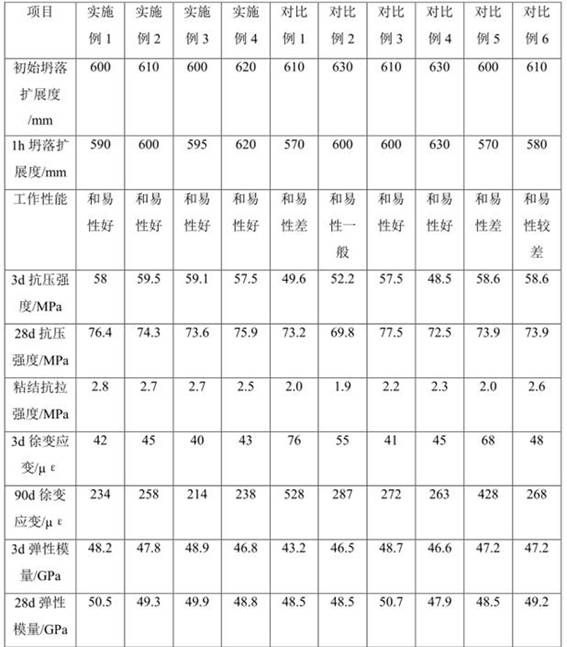

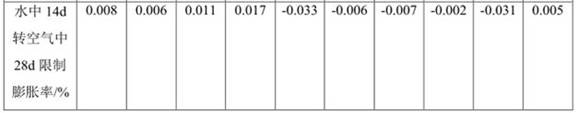

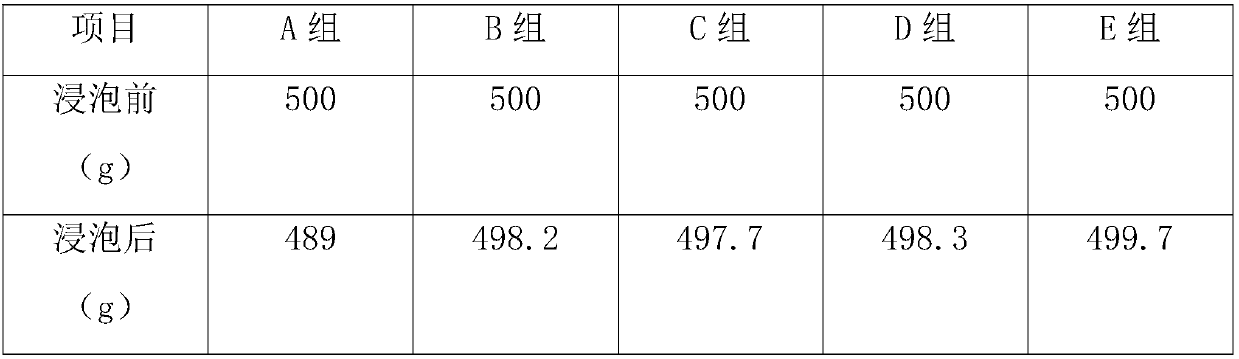

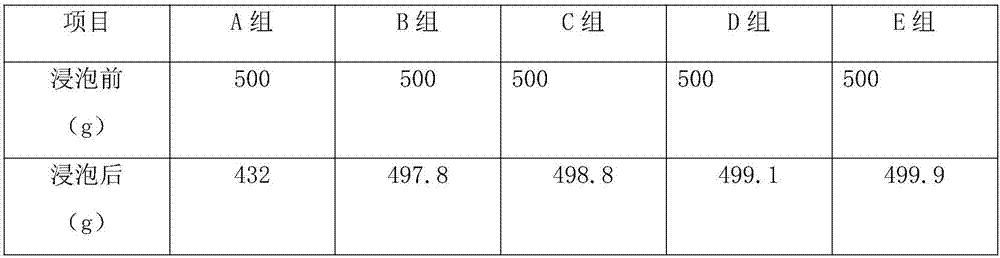

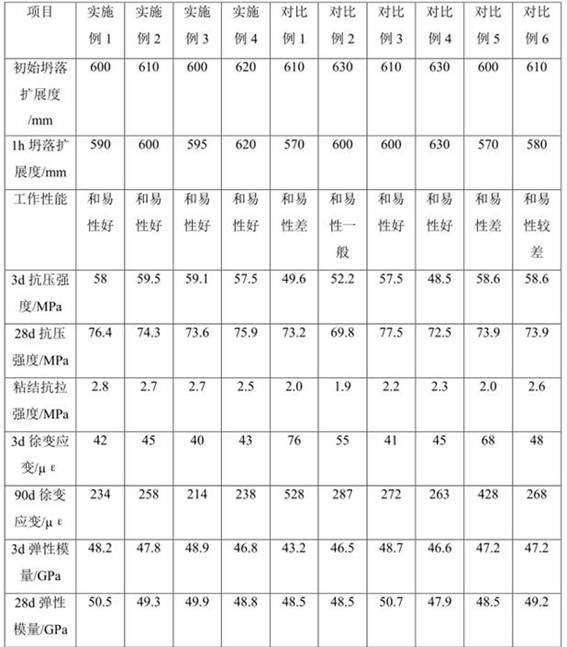

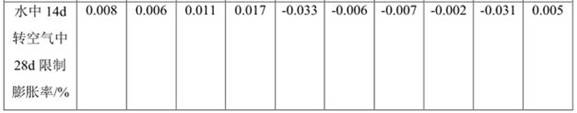

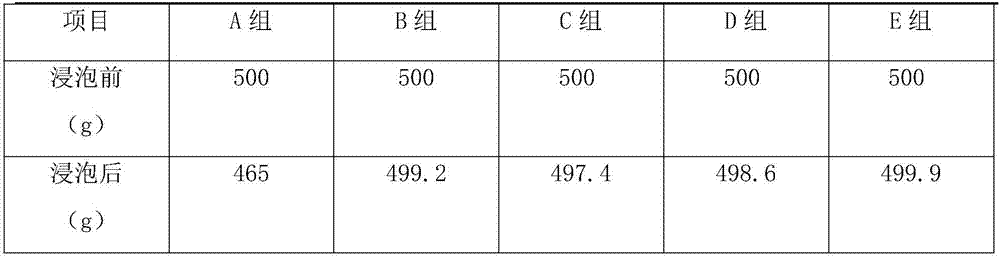

Low-shrinkage low-creep concrete composite additive suitable for early-age prestress tensioning

ActiveCN112194404AImprove early strength and elastic modulusImprove compactnessSilica fumeSilicate Cement

The invention discloses a low-shrinkage low-creep concrete composite additive suitable for early-age prestress tensioning. The composite additive is composed of anhydrous calcium sulfoaluminate clinker, calcium sulfate, silica fume, lithium carbonate, a styrene polymer, triisopropanolamine, an anti-settling agent and the like, is used in concrete taking ordinary Portland cement as a cementing material, and provides ettringite crystals through hydration reaction of anhydrous calcium sulfoaluminate and calcium sulfate. The forming speed of ettringite in a hydration product is increased by utilizing the seed crystal effect of silica fume and the early strength effect of lithium carbonate and triisopropanolamine, the purposes of micro-expansion, early strength, low shrinkage and low creep areachieved, meanwhile, the workability of concrete is improved through an anti-settling agent, and the later strength of silica fume is improved through a volcanic ash reaction; the concrete added withthe composite additive has the characteristics of early strength, micro-expansion and low creep, is suitable for concrete early-age prestress tensioning engineering, saves time and shortens the construction period.

Owner:湖南固特邦土木科技发展有限公司

Mechanical processing alkali corrosion resistant paint

InactiveCN107805428AWaterproof up toAchieve moisture resistanceConjugated diene hydrocarbon coatingsAnti-corrosive paintsDiborideMoisture resistance

The invention relates to the field of mechanical processing protective coatings, and discloses a mechanical processing anti-alkaline corrosion coating. Pearl powder, dispersant, deionized water, azole compounds, vanadium diboride, tributyl phosphate, polyvinyl alcohol and polysilicone, can be formed on the surface of mechanical metal by using titanium dioxide and butadiene-styrene copolymer emulsion A waterproof diaphragm, with water as the carrier, reacts with the alkaline substances outside the organic diaphragm by means of the penetration of water, and acts along or against the direction of water pressure, so as to achieve the purpose of waterproof, moisture-proof and chemical corrosion resistance. It solves the problem that the existing protective paint is corroded by the alkaline environment, which causes the mechanical surface to be exposed to the external environment and reduces its service life.

Owner:成都龙泉马龙机械厂

High-performance industrial composite glycerin and preparation method thereof

The invention discloses a high-performance industrial composite glycerin. The high-performance industrial composite glycerin comprises the following raw materials by weight: 55-65 parts of glycerin, 10-20 parts of an alloy assistant liquid, 3-7 parts of Si powder, 5-15 parts of a reinforcing agent and 2-6 parts of rutile type nano-titanium dioxide. According to the invention, the alloy assistant liquid is added into glycerin to improve the adaptability of glycerin at a high temperature and adapt to the temperature change so as to reach a yellowing-resistant effect, the alloy assistant liquid adopts methyl phenyl silicone oil as a matrix liquid, methyl phenyl silicone oil itself has weather resistance, heat resistance, chemical resistance and other excellent properties, and by adding nickelpowder, titanium carbide powder and magnesium borate powder, on the one hand, methyl phenyl silicone oil can serve as bridging liquid to make nickel powder, titanium carbide powder and magnesium borate powder better integrate into glycerin, the nickel powder can play a repairing role, so that glycerin can adapt to the temperature timely at the high temperature, the yellowing resistance effect isimproved, and the titanium carbide powder and magnesium borate powder can improve the temperature resistant effect of glycerin.

Owner:安徽诚宁油脂科技有限公司

Luminous road surface and preparation method thereof

ActiveCN110395952BTo achieve the artistic effect of appreciationBeautiful art deco effectBrickArchitectural engineering

The present invention provides a luminous pavement material, which includes a surface material and a base material in sequence from top to bottom, wherein the base material includes the following components in parts by weight: 120-240 parts of cement; 10 parts of recycled micropowder from construction waste ‑70 parts; 500‑900 parts of recycled coarse aggregate from construction waste; 200‑600 parts in recycled fine aggregate from construction waste; 60‑140 parts in water; The following components: 120-240 parts of white cement; ≤80 parts of coloring powder; 200-600 parts of recycled fine aggregate from construction waste; 60-140 parts of water; ≤6 parts of water reducing agent. The present invention further provides a luminescent road surface. The invention provides a luminous pavement and a preparation method thereof. Construction waste is used to make a luminous art road. Luminous aggregates and brick aggregates can be inlaid according to a certain pattern. After being polished, it has an artistic effect, and the appreciation effect is better at night.

Owner:TONGJI UNIV

Alkali-resistant concrete for manufacturing jacking pipes

The invention relates to the field of manufacturing of jacking pipes and discloses alkali-resistant concrete for manufacturing jacking pipes. The technical key point is as follows: the alkali-resistant concrete is prepared from the following components in parts by weight: 50-70 parts of high-aluminum white cement, 10-15 parts of kaolin, 40-50 parts of stone powder, 30-50 parts of machine-made sand, 2-8 parts of water-retaining agents, 2-8 parts of organosilicone water repellents, 2-6 parts of polyvinyl alcohol, 10-20 parts of silicon powder, 4-8 parts of naphthalene sulfonic acid-formaldehyde condensate sodium salt, 0.2-0.8 part of hydroxypropyl methyl cellulose, 1-5 parts of tributyl phosphate, 1-2 parts of defoaming agents and 2.4-3.2 parts of polysilicone. Through the alkali-resistant concrete for manufacturing jacking pipes, the purposes of permanently resisting water, resisting moisture and resisting chemical corrosion can be achieved; the problem that the existing jacking pipes manufactured by ordinary concrete have cracks and are corroded in the alkali soil can be solved.

Owner:成都金玉雄辉建筑工程有限公司

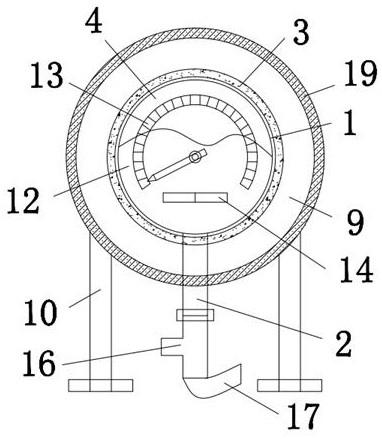

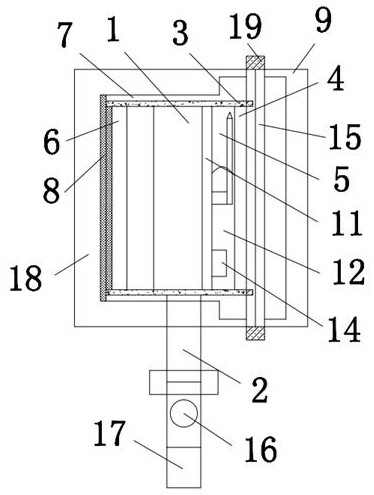

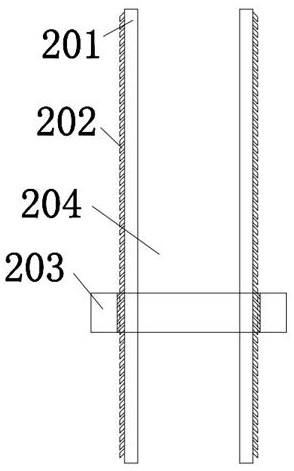

Industrial boiler pressure gauge structure

InactiveCN111855075AGuaranteed stabilityAccurate measurementFluid pressure measurementToughened glassPressure measurement

The invention discloses an industrial boiler pressure gauge structure, and belongs to the technical field of instruments. The peripheral side of the pressure gauge body is fixedly connected with a fixing cylinder, first tempered glass is fixedly connected to the front end of the interior of the fixing cylinder, a cavity is formed between the first tempered glass and the pressure gauge body, a rearcover is fixedly connected to the rear end of the interior of the fixing cylinder, the pressure gauge body is fixed in the fixing cylinder and protected by the rear cover and the first tempered glass, then the fixing cylinder is placed in a groove of the shell, double protection is carried out on the pressure gauge body by matching a sealing mechanism with a pipe hoop, and when the pressure gaugebody needs to be replaced or maintained, the shell and the sealing mechanism can be separated through the pipe hoop, so that the pressure gauge body is replaced or maintained. Boilers of different types can be subjected to pressure measurement through a communicating mechanism, then the device is installed on the boiler through an installing mechanism, and the stability is guaranteed.

Owner:李良德

A kind of anti-alkali concrete for making jacking pipe

The invention relates to the field of manufacturing of jacking pipes and discloses alkali-resistant concrete for manufacturing jacking pipes. The technical key point is as follows: the alkali-resistant concrete is prepared from the following components in parts by weight: 50-70 parts of high-aluminum white cement, 10-15 parts of kaolin, 40-50 parts of stone powder, 30-50 parts of machine-made sand, 2-8 parts of water-retaining agents, 2-8 parts of organosilicone water repellents, 2-6 parts of polyvinyl alcohol, 10-20 parts of silicon powder, 4-8 parts of naphthalene sulfonic acid-formaldehyde condensate sodium salt, 0.2-0.8 part of hydroxypropyl methyl cellulose, 1-5 parts of tributyl phosphate, 1-2 parts of defoaming agents and 2.4-3.2 parts of polysilicone. Through the alkali-resistant concrete for manufacturing jacking pipes, the purposes of permanently resisting water, resisting moisture and resisting chemical corrosion can be achieved; the problem that the existing jacking pipes manufactured by ordinary concrete have cracks and are corroded in the alkali soil can be solved.

Owner:成都金玉雄辉建筑工程有限公司

Spraying method for anti-acidic-corrosion coating for mechanical component

InactiveCN108031638ASimple processEasy to operateAnti-corrosive paintsSpecial surfacesEtchingMechanical components

The invention relates to the field of machining protecting spraying agents and discloses a spraying method for anti-acidic-corrosion coating for a mechanical component. According to the key points ofthe spraying method, the surface of the mechanical component is cleaned firstly and dried, and the mechanical component is subjected to sand blasting treatment after drying; then undercoat is sprayed,the undercoat is evenly sprayed on the surface of the mechanical component through a spray gun after the undercoat is stirred evenly, and the undercoat surface is polished; and finally, anti-acidic-corrosion finishing coat is sprayed on the polished undercoat surface, wherein the undercoat is waterborne alkyd resin, amino resin, film-forming resin, calcium lignin sulfonate, a water-retaining agent, an organic silicon water repellent and deionized water. The problem that as for a product machined through an existing metal etching technique, usually, the spraying effect is not ideal, or the unqualified position exists in the coating sprayed face, protecting coating suffers from acidic corrosion, thus the mechanical surface is exposed in the exterior environment, and thus the service life ofthe product is shortened are solved.

Owner:成都龙泉马龙机械厂

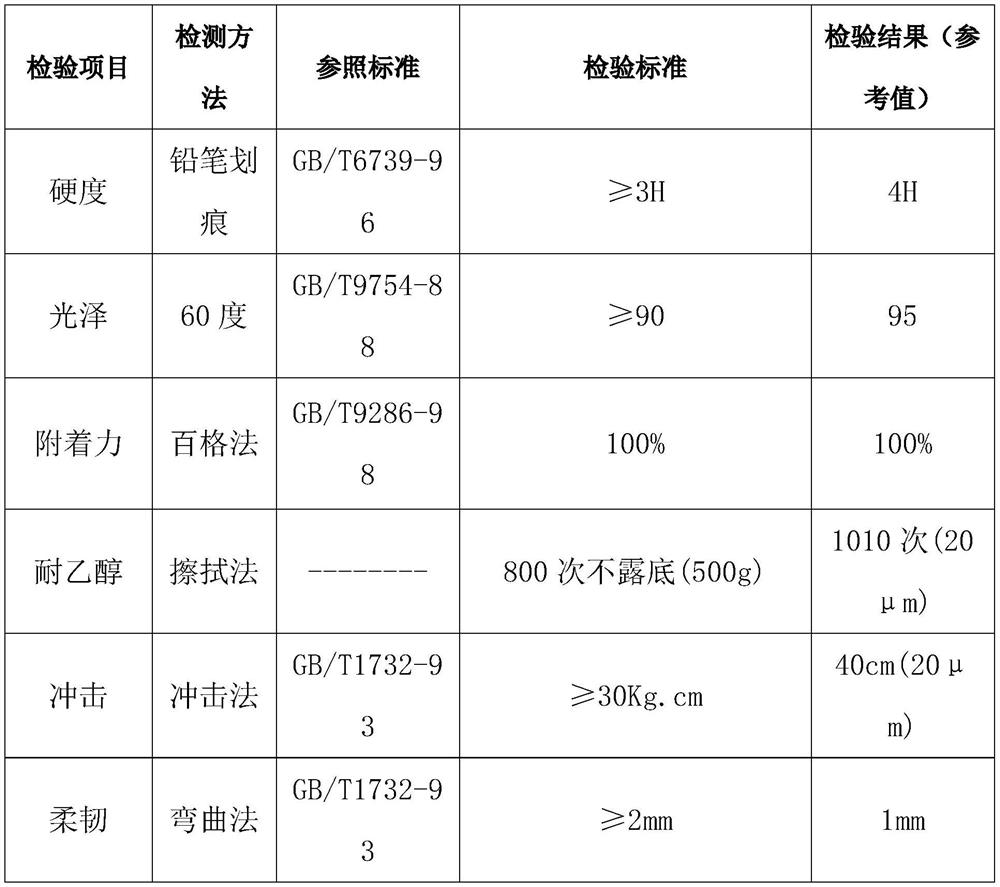

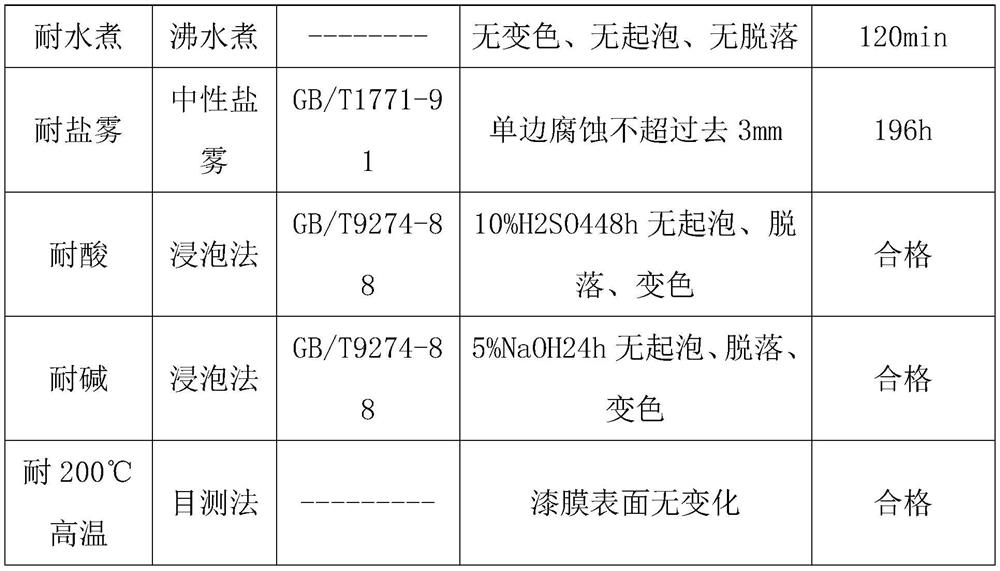

Special odorless modified acrylic acid stoving varnish coating

The invention discloses a special odorless modified acrylic acid stoving varnish coating, and relates to the technical field of coatings. The special odorless modified acrylic acid varnish stoving varnish coating comprises the following components in parts by weight: 60 parts of HE61, 11 parts of nano black paste, 0.5 part of fumed silica, 0.2 part of BYK333, 0.1 part of TEGO410, 0.2 part of TEGO245, 5.7 parts of DBE, 2 parts of Z-6040, 13 parts of Bayer 3175 curing agent, 3 parts of Cytec 303, 0.3 part of a cooling agent and 4 parts of 704 epoxy resin. According to the special odorless modified acrylic acid stoving varnish coating, the resin is selected from high-solid-content and low-viscosity resin, a high-boiling-point and low-odor type solvent is selected as a solvent of the matrix resin, during film forming at the high temperature of 160-180 DEG C, paint film forming reaction is fast, volatile gas is little, solvent volatilization is little, the odorless and environment-friendly effects are achieved during production and construction, The varnish coating can be applied to industrial stoving varnish, household appliance stoving varnish, electric cookers, electric frying pans and the like.

Owner:珠海市卓和化工科技有限公司

Coil coating with imitated velvet effect and preparation method thereof

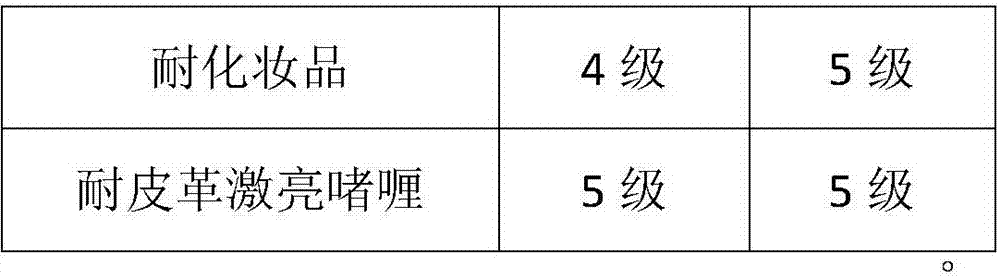

InactiveCN101705045BMeet any processing and forming requirementsAchieve chemical resistancePolyester coatingsEthylenediamineCyclohexanone

The invention relates to a coil coating with imitated velvet effect and a preparation method thereof and the coil coating is a colour paint coating used for colour steel and colour aluminum for architectural decoration. According to the technical scheme provided by the invention, the coil coating with imitated velvet effect comprises the following components in parts by weight: 35-40 parts of branched saturated polyester resin, 0.3-1.5 parts of macromolecular block copolymer, 5-30 parts of coloring pigment, 5-25 parts of filler, 3-5 parts of 100# aromatic solvent, 1-3 parts of cyclohexanone, 1-3 parts of dibasic ester, 5-20 parts of polyester polyol resin, 1-3 parts of enclosed type polyurethane curing agent, 2-5 parts of methylated melamine resin, 0.6-1.8 parts of enclosed type p-toluenesulfonic acid, 0.5-1.5 parts of polyethylene wax, 0.15-1.5 parts of triethylamine or ethylenediamine and 0.3-1.5 parts of fluorine modified acrylic leveling agent. The paint capability of the coating of the invention can fully reach all kinds of requirements of forming and can also meet the requirements of good look, newfangled, personality, and the like.

Owner:无锡银星涂层板有限公司

Method and application of dye residue for preparing cement floor color paste and cement curing enhancer

The invention discloses a method and application for preparing cement floor color paste and cement solidification enhancer from dye residue. The method comprises the following steps: using dye residue to prepare mother liquor; mixing 70-85 parts by weight of mother liquor, polyether polyol 2~6 parts by weight, 2~8 parts by weight of triethanolamine, 6~10 parts by weight of lithium silicate, 3~10 parts by weight of urea and 3~10 parts by weight of diethylene glycol are mixed together and stirred evenly, and the stirring time is After 60 to 120 minutes, the cement floor color paste and cement curing enhancer are obtained, which are sealed and stored. If the specific gravity value of the dye residue is 1.15-1.17, it is used as mother liquor; if the specific gravity is lower than 1.15-1.17, the following steps are included: extracting polyacrylamide by 0.5-2% of the weight of the dye residue, adding an appropriate amount Dilution water dissolves polyacrylamide into a solution, the solution is added to the dye residue and stirred, then precipitated, and the upper part of the liquid close to water is removed, and when the specific gravity reaches 1.15~1.17, it is used as the mother liquor. The invention has the beneficial effects of simple method, convenient processing, effectively solving dye discharge and beautifying buildings.

Owner:HANGZHOU ZUONA IND CO LTD

Method for preparing cement floor color paste and cement curing enhancer from dye residual paste and application

The invention discloses a method for preparing cement floor color paste and a cement curing enhancer from dye residual paste and application. The method comprises the following steps: preparing mother liquor from the dye residual paste; mixing 70-85 parts by weight of mother liquor, 2-6 parts by weight of polyether polyol, 2-8 parts by weight of triethanolamine, 6-10 parts by weight of lithium silicate, 3-10 parts by weight of urea and 3-10 parts by weight of diethylene glycol, evenly stirring for 60-120 minutes to obtain the cement floor color paste and the cement curing enhancer, sealing, and storing. If the specific gravity value of the dye residual paste is 1.15-1.17, the dye residual paste is used as mother liquor; and if the specific gravity value is lower than 1.15-1.17, following steps are executed: extracting polyacrylamide according to 0.5-2% of the weight of the dye residual paste, adding a proper amount of dilution water to prepare polyacrylamide into a solution, adding the dye residual paste into the solution, stirring, precipitating, removing the upper part of the liquid similar with water, and taking the liquid as a mother liquor when the specific gravity value is 1.15-1.17. The method has the beneficial effects that the method is simple, processing is convenient, dye emission is effectively solved, and buildings are beautified.

Owner:HANGZHOU ZUONA IND CO LTD

Anti-corrosion coating for container

InactiveCN107189649AAchieve waterproofAchieve moisture resistanceAnti-corrosive paintsPolyester coatingsEpoxySodium salt

The invention relates to the field of container protection, and discloses an anti-corrosion coating for a container. The anti-corrosion coating is technically characterized by being prepared from the following components in parts by weight: 35 to 50 parts of unsaturated polyester resin, 20 to 30 parts of modified alkyd resin, 9 to 21 parts of palm kernel ester, 13 to 21 parts of an organic silicon water repellent, 30 to 45 parts of titanium dioxide, 19 to 23 parts of calcium sulfate, 2 to 6 parts of epoxy resin, 5 to 10 parts of a fluorocarbon emulsion, 4 to 8 parts of sodium sulfonate condensation sodium salt, 0.2 to 0.8 part of hydroxypropyl methyl cellulose, 1 to 5 parts of tributyl phosphate, 1 to 2 parts of a defoaming agent and 2.4 to 3.2 parts of butyl cellosolve. The problem, in the existing common coating, that inner objects are wetted by seepage due to ocean transportation and long-time solarization treatment of the container is solved.

Owner:成都协恒科技有限公司

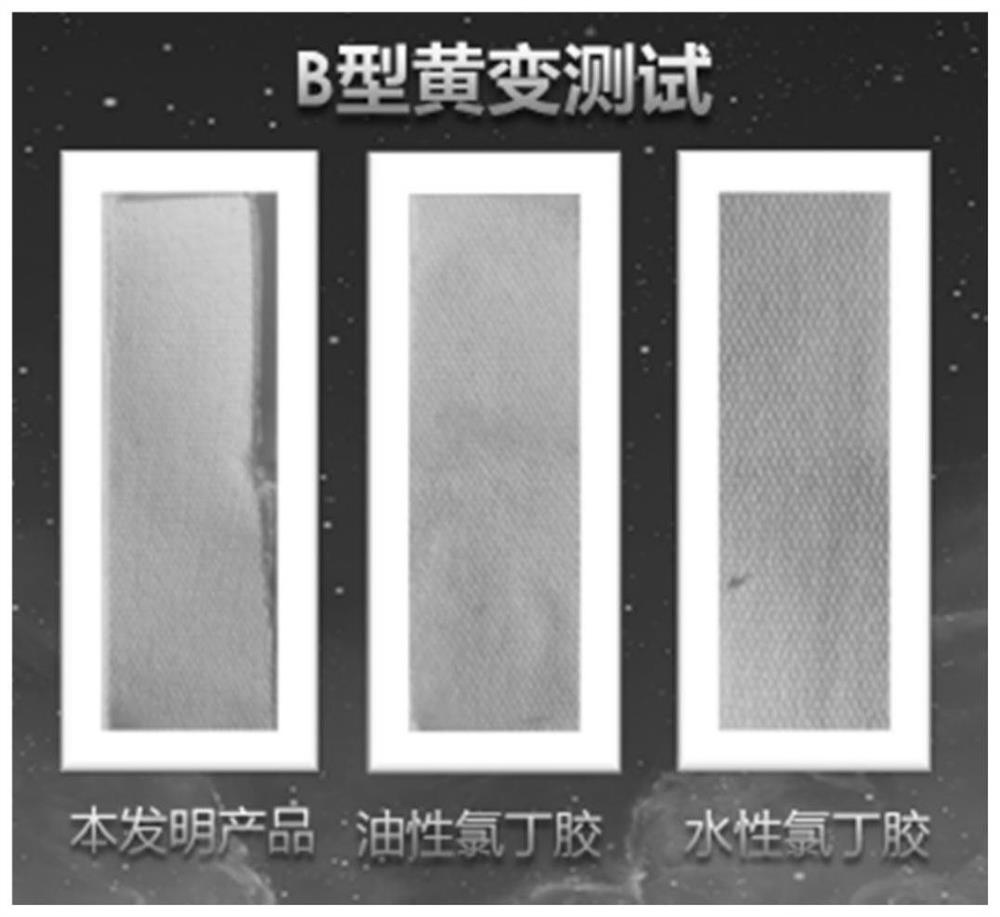

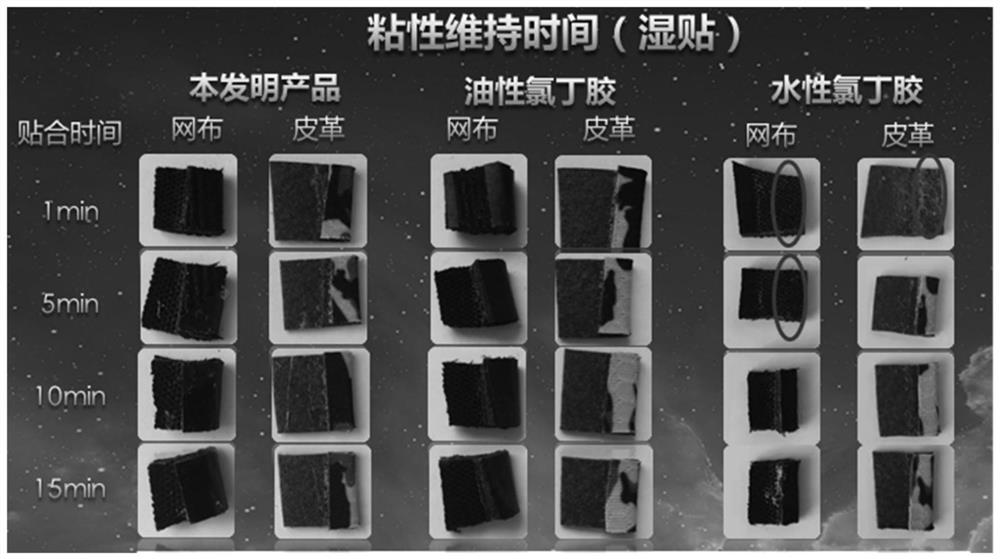

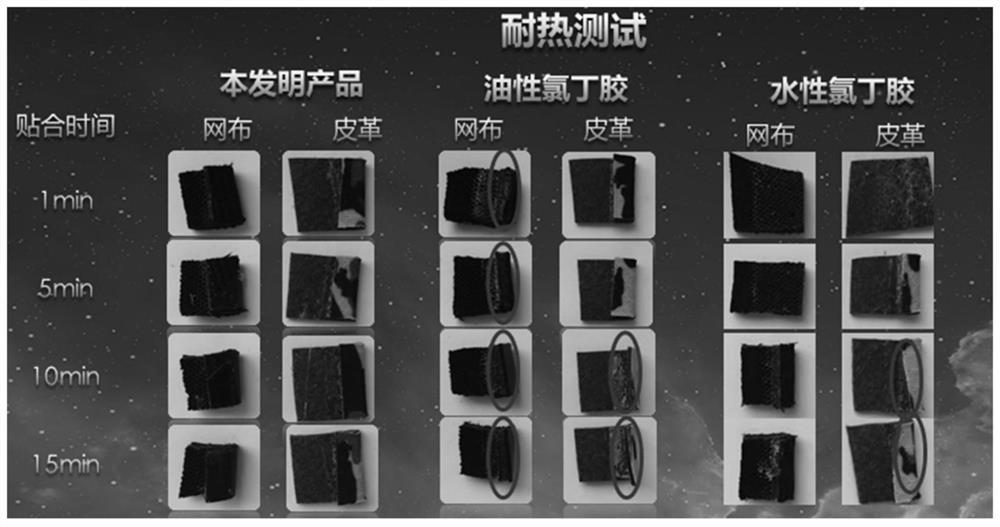

Anti-yellowing water-based adhesive as well as preparation method and application thereof

PendingCN112831306AIncrease adhesion and strengthGood film properties and water solubilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesActive agentAntifoam agent

The invention belongs to the technical field of adhesives, and discloses an anti-yellowing water-based adhesive as well as a preparation method and application thereof. The anti-yellowing water-based adhesive comprises the following components: a water-based polyurethane emulsion, a defoaming agent, a plasticizer, a cross-linking agent, a thickening agent and a surfactant. By adding the organic silicon defoaming agent and the surfactant, the problem of wettability of the existing sewing machine flanging adhesive is solved; by adding the cross-linking agent, the binding power and the strength of the adhesive are changed; and the viscosity is increased through the thickening agent.

Owner:南宝树脂(佛山)有限公司

A low-shrinkage and low-creep concrete composite additive suitable for early-age prestressed tension

ActiveCN112194404BImprove anti-settling performanceIncrease resistance to dehydrationHydration reactionClinker (cement)

The invention discloses a low-shrinkage and low-creep concrete composite additive suitable for early-age prestressed tension. The composite additive is composed of anhydrous calcium sulfoaluminate clinker, calcium sulfate, silica fume, lithium carbonate, styrene polymer, triisopropanolamine, anti-settling agent and other components, and is used for ordinary portland cement In the concrete used as cementitious material, ettringite crystals are provided through the hydration reaction of anhydrous calcium sulfoaluminate and calcium sulfate, and the seed crystal effect of silica fume and the early strength effect of lithium carbonate and triisopropanolamine are used to accelerate The formation speed of ettringite in the hydration product achieves the purpose of micro expansion, early strength, low shrinkage and low creep. At the same time, the anti-settling agent improves the workability of concrete, and silica fume improves the later strength through pozzolanic reaction; Concrete with composite additives has the characteristics of early strength, micro-expansion, and low creep, and is suitable for prestressed tensioning projects in the early age of concrete, saving time and shortening the construction period.

Owner:湖南固特邦土木科技发展有限公司

Acid-resistant acrylic material for manufacturing of toilets

The invention relates to the field of toilet manufacture, and discloses an acid-resistant acrylic used for making toilets. The technical points are as follows: 35-50 parts of unsaturated polyester resin, 20-30 parts of glass microspheres, lignin 9-21 parts of calcium sulfonate, 13-21 parts of borax, 30-45 parts of calcium carbonate, 19-32 parts of calcium sulfate, 2-6 parts of epoxy resin, 5-10 parts of fluorocarbon emulsion, 4-8 parts of antibacterial masterbatch 0.2-0.8 parts of hydroxypropyl methylcellulose, 1-5 parts of tributyl phosphate, 1-2 parts of polyvinyl alcohol, and 2.4-3.2 parts of silver-based inorganic bacteria powder. To achieve permanent waterproof, moisture-proof, chemical corrosion resistance purposes. The invention solves the problem of cracks and corrosion in the acidic environment of existing toilets made of acrylic materials.

Owner:成都金宝马数码技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com