Packing for substrate plating jig and the substrate plating jig using same

A substrate and gasket technology, applied in the field of gaskets for plating fixtures, can solve problems such as damage to the sealing effect, step difference, etc., and achieve the effects of high sealing effect, low manufacturing cost, and high elastic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the gasket for a plating jig of the present invention and a plating jig using the same will be described in detail based on the drawings. In addition, the present invention is not limited by these embodiments.

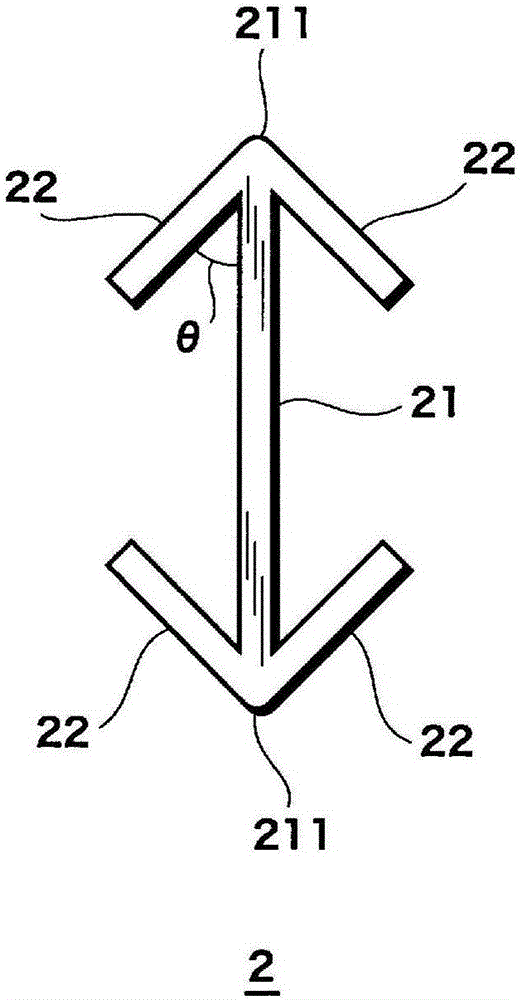

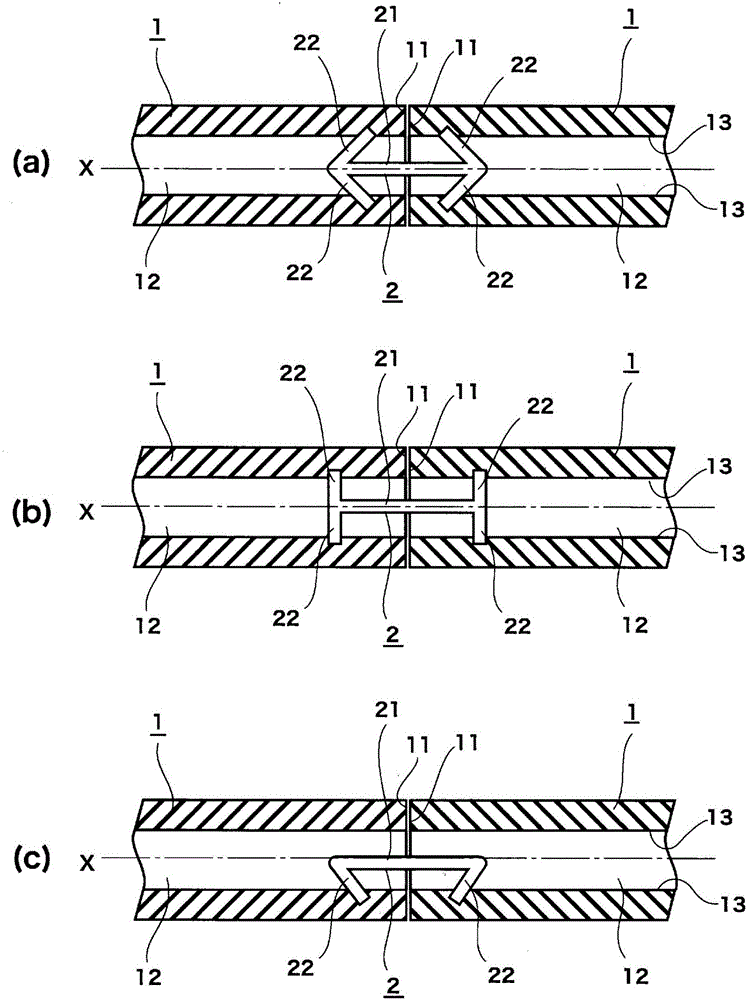

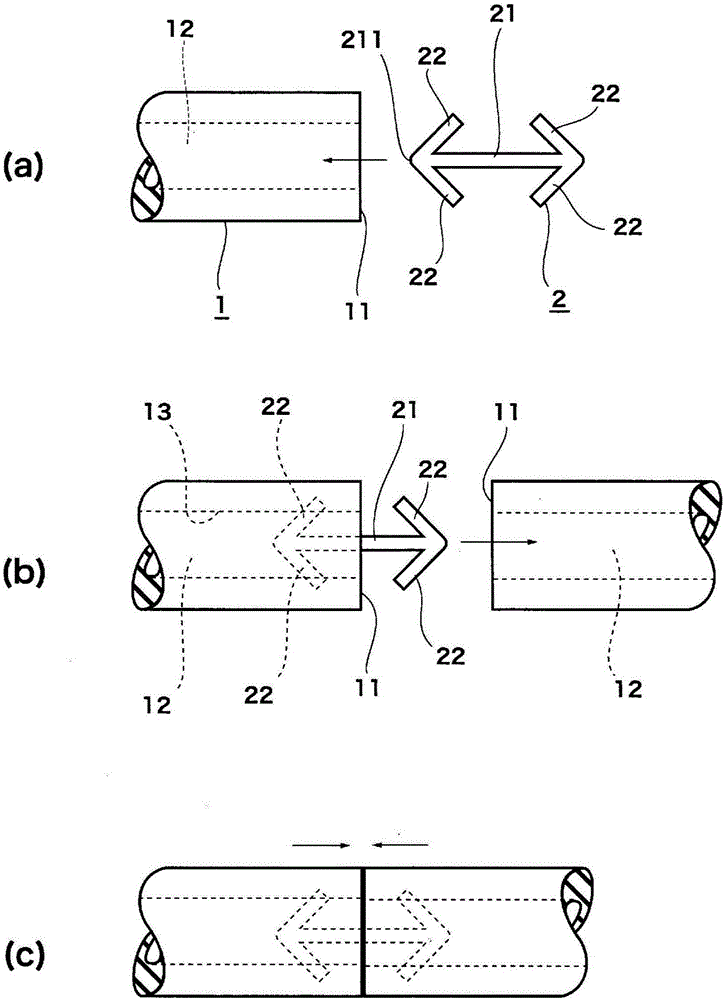

[0028] The gasket of the present invention is a tubular or rope-shaped gasket body 1 formed of a long strip of elastic material with ends, and a connection for connecting the two ends of the gasket body 1 (hereinafter referred to as "connection ends"). Component 2 is constructed. The pad main body 1 is preferably manufactured by extrusion molding which is also advantageous in terms of manufacturing cost, but the manufacturing method is not limited thereto. The two connection ends of the gasket main body 1 are connected and fixed to each other by the connection member 2, so that it can be used as an endless ring or quadrangular or other shaped sealing member. Thereby, since it is originally a single end member, it is possible to arbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com