Device for retaining a component to be secured to a support part, system, and use of a device for retaining a component

A technology of bearing parts and components, which is applied in the field of component devices, can solve problems such as gaps between holding elements and difficulties in fixture manufacturing, and achieve the effect of improving abutment and reliable holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

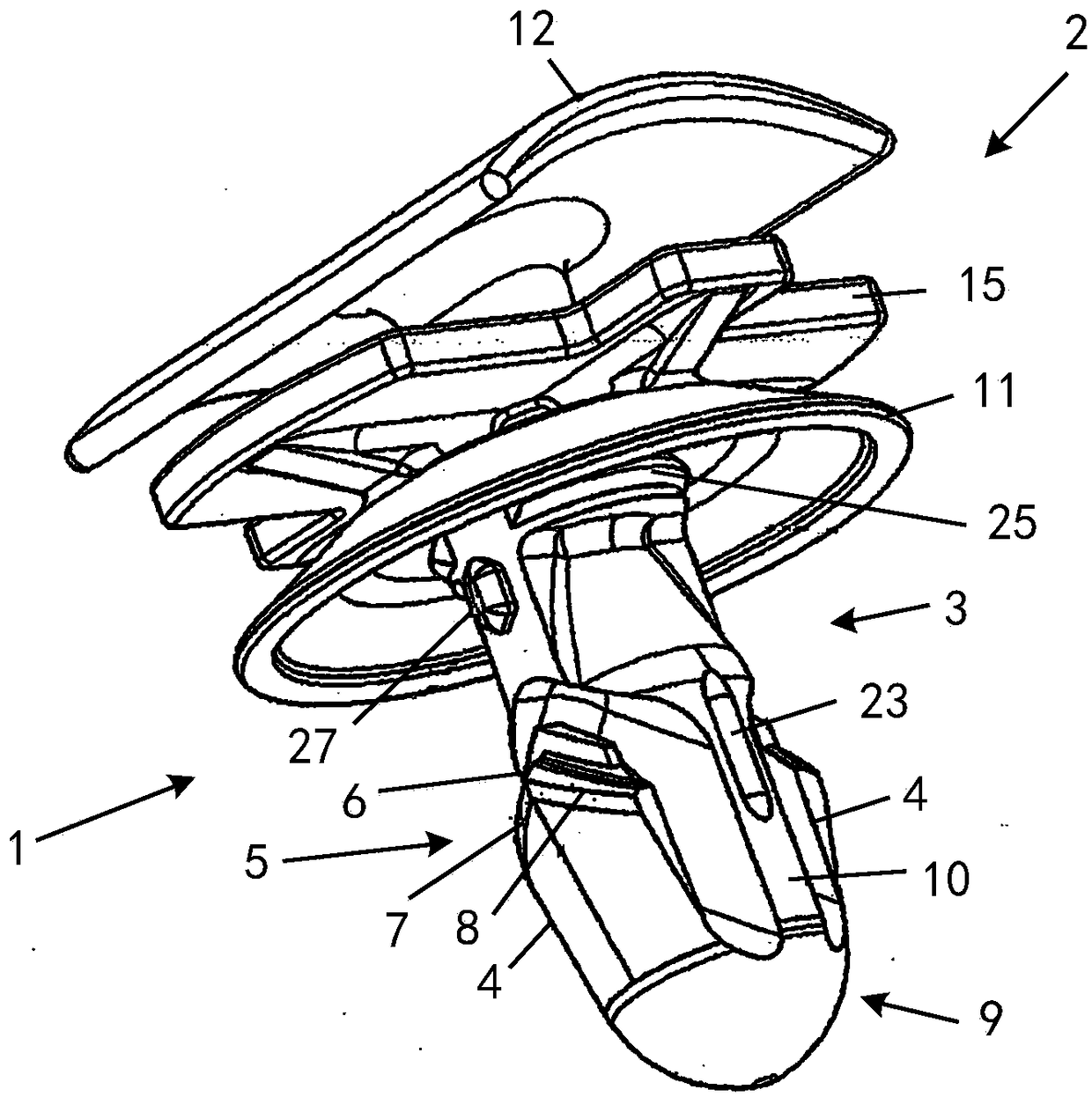

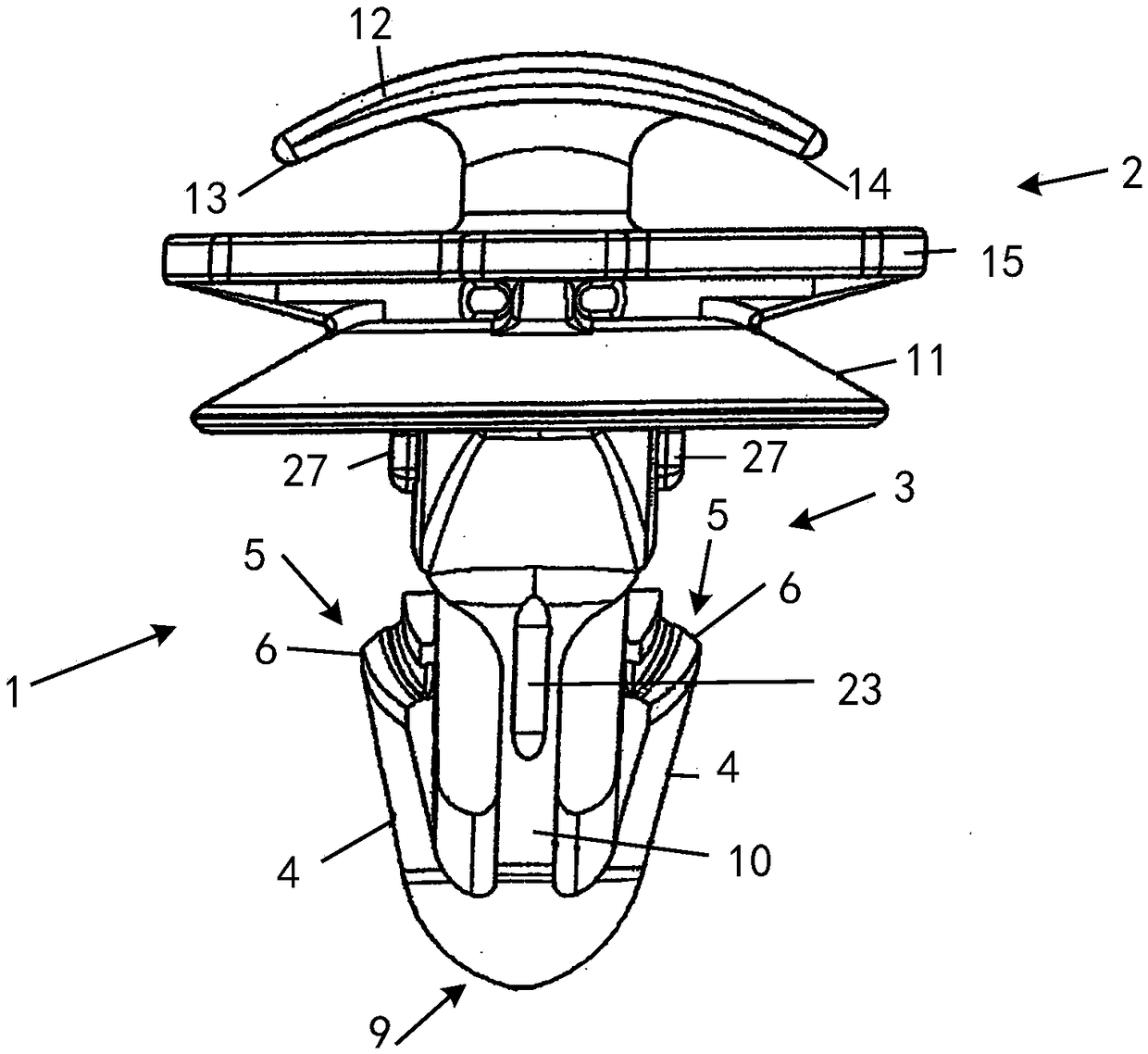

[0058] figure 1 and figure 2 An isometric view of a device 1 according to the invention is shown. The device 1 has a head 2 and a pin 3 . The pin portion 3 extends in the longitudinal direction of the head 2 . The pin part 3 has two anchoring elements 4 which extend radially from the pin part 3 . Each anchoring element 4 has a structure 5 pointing substantially in the direction of the head 2 . The structure 5 has a shape that tapers in the direction of the head 2 .

[0059] exist figure 1 and figure 2 In the illustrated embodiment, the structure 5 having a tapered shape has a top end 6 formed by two sides 7 , 8 enclosing an angle with the longitudinal direction of the pin portion 3 . exist figure 1 and figure 2 In the illustrated embodiment, the structure 5 is formed symmetrically by sides 7 , 8 extending symmetrically about the pin axis.

[0060] The structure 5 of the anchoring element 4 tapers radially away from the pin portion 3 . The structure 5 slopes from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com