Acid-resistant acrylic material for manufacturing of toilets

An acrylic and acid-resistant technology, used in toilet manufacturing, it can solve problems such as corrosion and cracks, and achieve the effect of high water resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

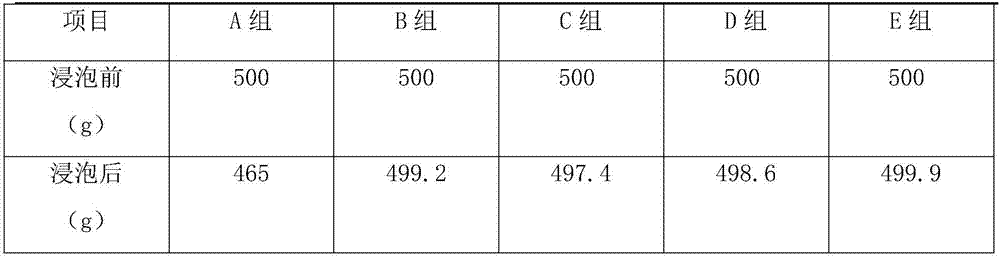

[0022] Choose an acrylic plate made of ordinary acrylic, take 500g of acrylic plate, put it into 10% dilute sulfuric acid with a pH of 5, soak it for 1 month, weigh it again, count the weight data, and mark it as A.

Embodiment 2

[0024] Select the acrylic board prepared by the following ratio, acrylic is composed of the following weight ratio, 43 parts of unsaturated polyester resin, 25 parts of glass beads, 16 parts of calcium lignosulfonate, 17 parts of borax, 39 parts of calcium sulfate, carbonic acid Calcium 25 parts. Take a 500g acrylic plate, put it into 10% dilute sulfuric acid with a pH of 5, soak it for 1 month, weigh it again, count the weight data, and mark it as B.

Embodiment 3

[0026] Select the acrylic board prepared in the following proportions. The acrylic is composed of the following weight proportions: 35 parts of unsaturated polyester resin, 20 parts of glass beads, 9 parts of calcium lignosulfonate, 13 parts of borax, 30 parts of calcium sulfate, carbonic acid Calcium 19 parts. Take 500g of acrylic board, put it into 10% dilute sulfuric acid with a pH of 5, soak it for 1 month, weigh it again, count the weight data, and mark it as C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com