Anti-yellowing water-based adhesive as well as preparation method and application thereof

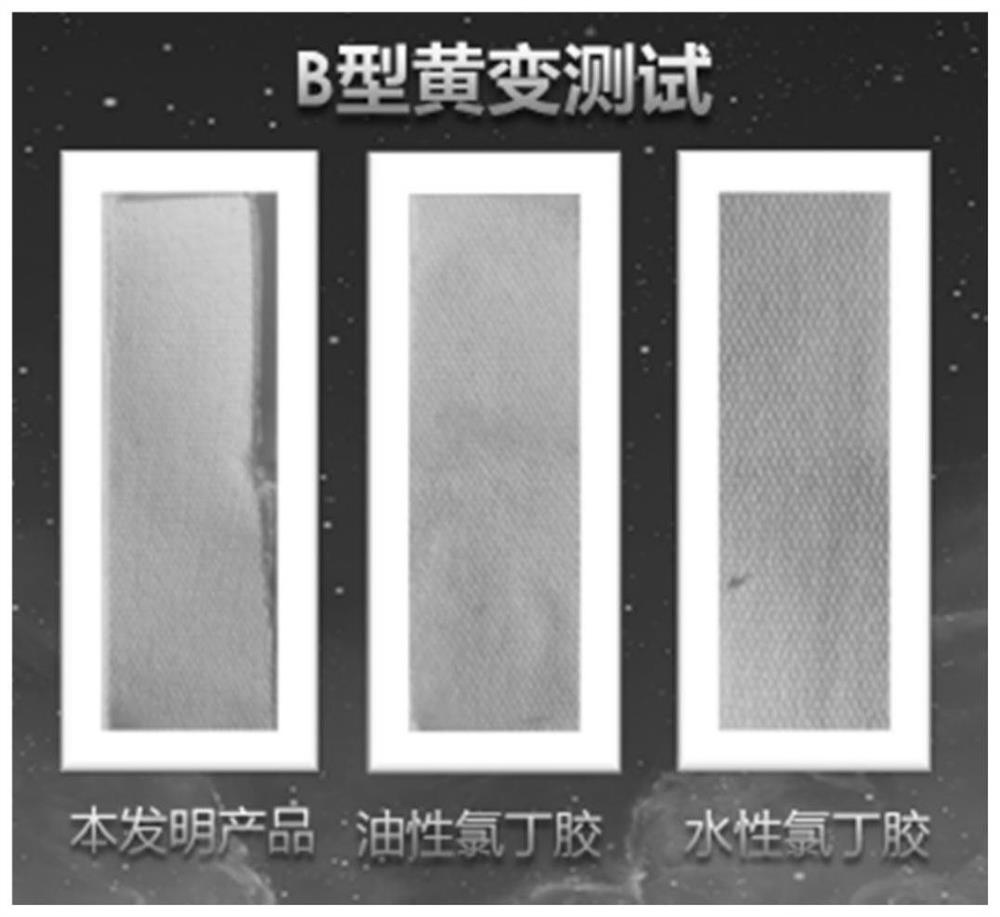

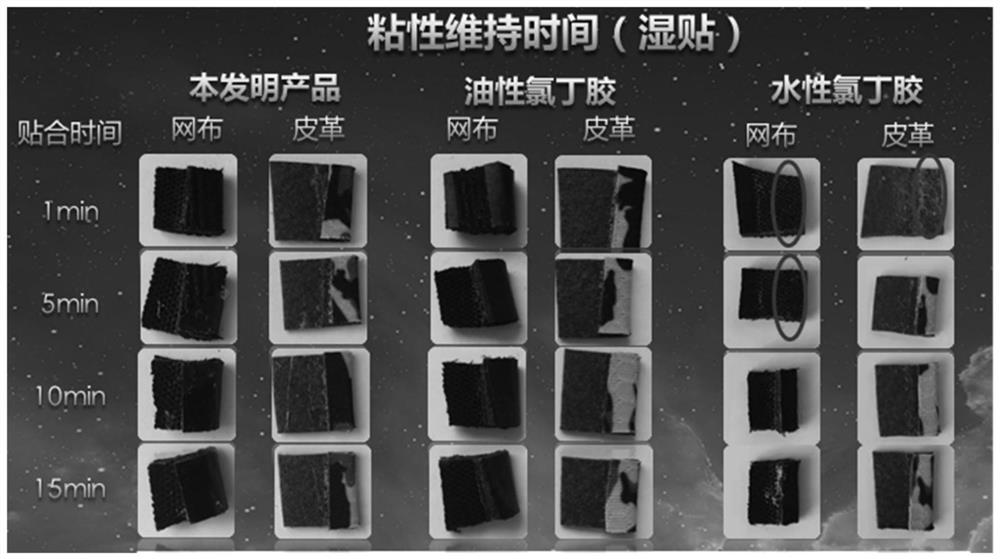

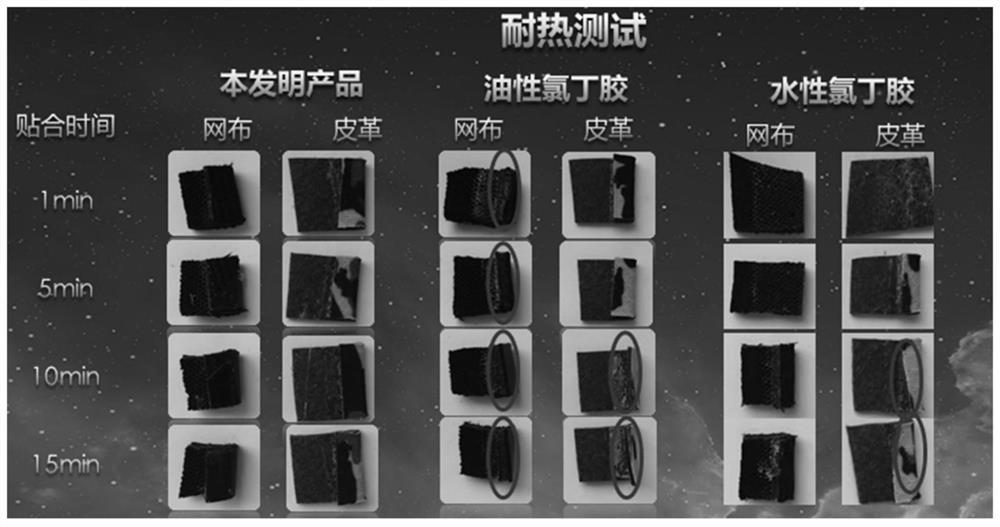

A technology of water-based adhesives and water-based polyurethanes, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve problems such as yellowing film, shorten production time, increase adhesion and strength, and have no risk of explosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]The moisture-resistant adhesive of the present embodiment comprises a component of the following weight parts: 100 parts of aqueous polyurethane resin, 0.05 parts of polyether alkylphenol polyoxyethylene ether, 5 parts of terephthalate, 5 Nipphenylene terephthalate, 0.2 parts of 1- (3-dimethylaminopropyl) -3-ethyl carbon diimide hydrochloride, 0.5 parts of polyurethane association thickened VesMody U601, 0.1 parts sodium dodecyl sulfate and 0.2 parts of alkylphenol polyoxyethylene ether.

[0042]In this example, a yellow-wreattable adhesive is prepared, and the specific process is:

[0043](1) Configure aqueous polyurethane emulsion: mix the aqueous polyurethane and solvent to obtain aqueous polyurethane emulsion;

[0044](2) The polyether alkylphenol polyoxyethylene ether was added to the aqueous urethane emulsion for 10 minutes, and terephthalate, terephthalate (2-ethylhexyl) ester, 1- (3-dimethylaminopropyl) -3-ethyl carbon diimide hydrochloride, dodecyl sulfate and alkylphenol poly...

Embodiment 2

[0047]The 黄 水性 水黏 剂剂, includes a component of the following weight parts: 100 parts of aqueous polyurethane resin, 0.05 parts of polyether alkylphenol polyoxyethylene ether, 10 parts of terephthalate, 10 Nipphenylene terephthalate, 0.2 parts of 1- (3-dimethylaminopropyl) -3-ethyl carbon diimide hydrochloride, 0.5 parts of polyurethane association thickened VesMody U601, 0.1 parts sodium dodecyl sulfate and 0.2 parts of alkylphenol polyoxyethylene ether.

[0048]In this example, a yellow-wreattable adhesive is prepared, and the specific process is:

[0049](1) Configure aqueous polyurethane emulsion: mix the aqueous polyurethane and solvent to obtain aqueous polyurethane emulsion;

[0050](2) The polyether alkylphenol polyoxyethylene ether was added to the aqueous urethane emulsion for 10 minutes, and terephthalate, terephthalate (2-ethylhexyl) ester, 1- (3-dimethylaminopropyl) -3-ethyl carbon diimide hydrochloride, dodecyl sulfate and alkylphenol polyoxyethylene ether, increase the stirring ...

Embodiment 3

[0053]The 黄 水水 水性 胶剂, includes a component of the following weight parts: 100 parts of aqueous polyurethane resin, 0.05 parts of polyether alkylphenol polyoxyethylene ether, 2 parts of terephthalate, 3 Nipphenylene terephthalate, 0.2 parts of 1- (3-dimethylaminopropyl) -3-ethyl carbon diimide hydrochloride, 0.5 parts of polyurethane association thickened VesMody U601, 0.1 parts sodium dodecyl sulfate and 0.2 parts of alkylphenol polyoxyethylene ether.

[0054]In this example, a yellow-wreattable adhesive is prepared, and the specific process is:

[0055](1) Configure aqueous polyurethane emulsion: mix the aqueous polyurethane and solvent to obtain aqueous polyurethane emulsion;

[0056](2) The polyether alkylphenol polyoxyethylene ether was added to the aqueous urethane emulsion for 10 minutes, and terephthalate, terephthalate (2-ethylhexyl) ester, 1- (3-dimethylaminopropyl) -3-ethyl carbon diimide hydrochloride, dodecyl sulfate and alkylphenol polyoxyethylene ether, increase the stirring sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com