Anti-corrosion coating for container

A corrosion-resistant, container-based technology, applied in the direction of anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of internal objects such as wetness and leakage, and achieve high water resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

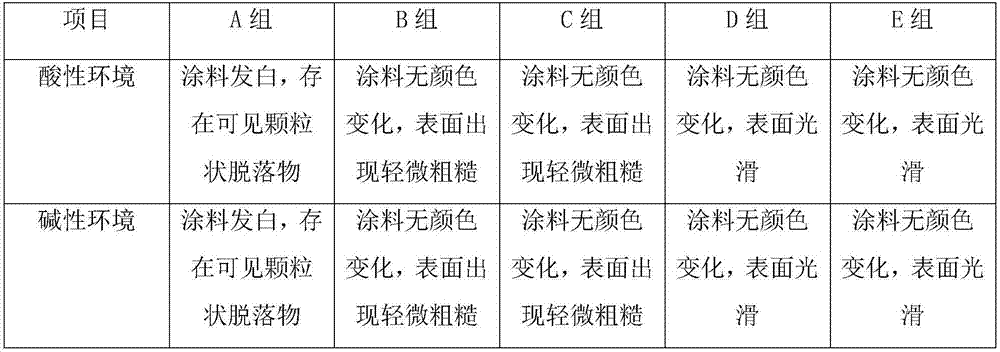

[0023] Use ordinary paint to coat the surface of the container and mark it as group A, spray 10% dilute sulfuric acid with a pH of 5, place it for 48 hours under a light intensity of 1000 lux, count the surface conditions, and spray 10% NaOH with a pH of 9 , placed under the light intensity of 1000 lux for 48 hours, and the surface conditions were counted.

Embodiment 2

[0025] Select the coating prepared from the following ratio, and the coating is composed of the following weight ratio, 43 parts of unsaturated polyester resin, 25 parts of modified alkyd resin, 16 parts of palm kernel ester, 17 parts of silicone water repellent, 39 parts of calcium sulfate parts, 25 parts of titanium dioxide. The coating is applied on the surface of the container and marked as group B, spraying 10% concentration of dilute sulfuric acid with a pH of 5, and placing it for 48 hours under the light intensity of 1000 lux, counting the surface conditions, spraying 10% concentration of NaOH with a pH of 9, Under the light intensity of 1000 lux, it was placed for 48 hours, and the surface conditions were counted.

Embodiment 3

[0027] Select the coating prepared from the following ratio, and the coating is composed of the following weight ratio: 35 parts of unsaturated polyester resin, 20 parts of modified alkyd resin, 9 parts of palm kernel ester, 13 parts of silicone water repellent, 30 parts of calcium sulfate parts, 19 parts of titanium dioxide. The coating is applied on the surface of the container and marked as group C. Spray 10% dilute sulfuric acid with a pH of 5, place it for 48 hours under the light intensity of 1000 lux, and count the surface conditions. Spray 10% NaOH with a pH of 9. Under the light intensity of 1000 lux, it was placed for 48 hours, and the surface conditions were counted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com