Sealing assembly for a rolling bearing

A sealing device, rolling bearing technology, applied in the direction of ball bearings, bearing elements, shafts and bearings, etc., to achieve the effect of chemical resistance, simple manufacturing and installation, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

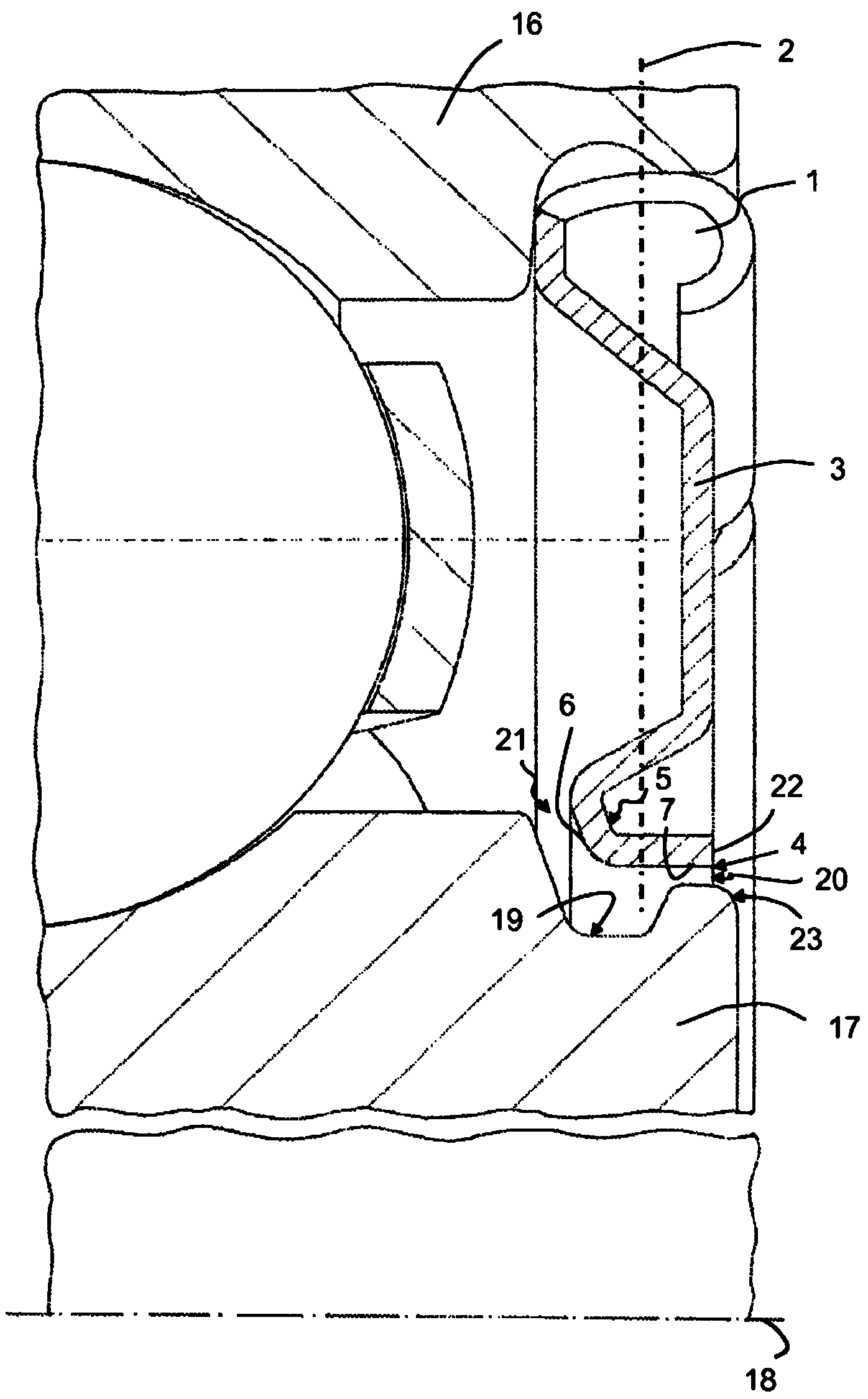

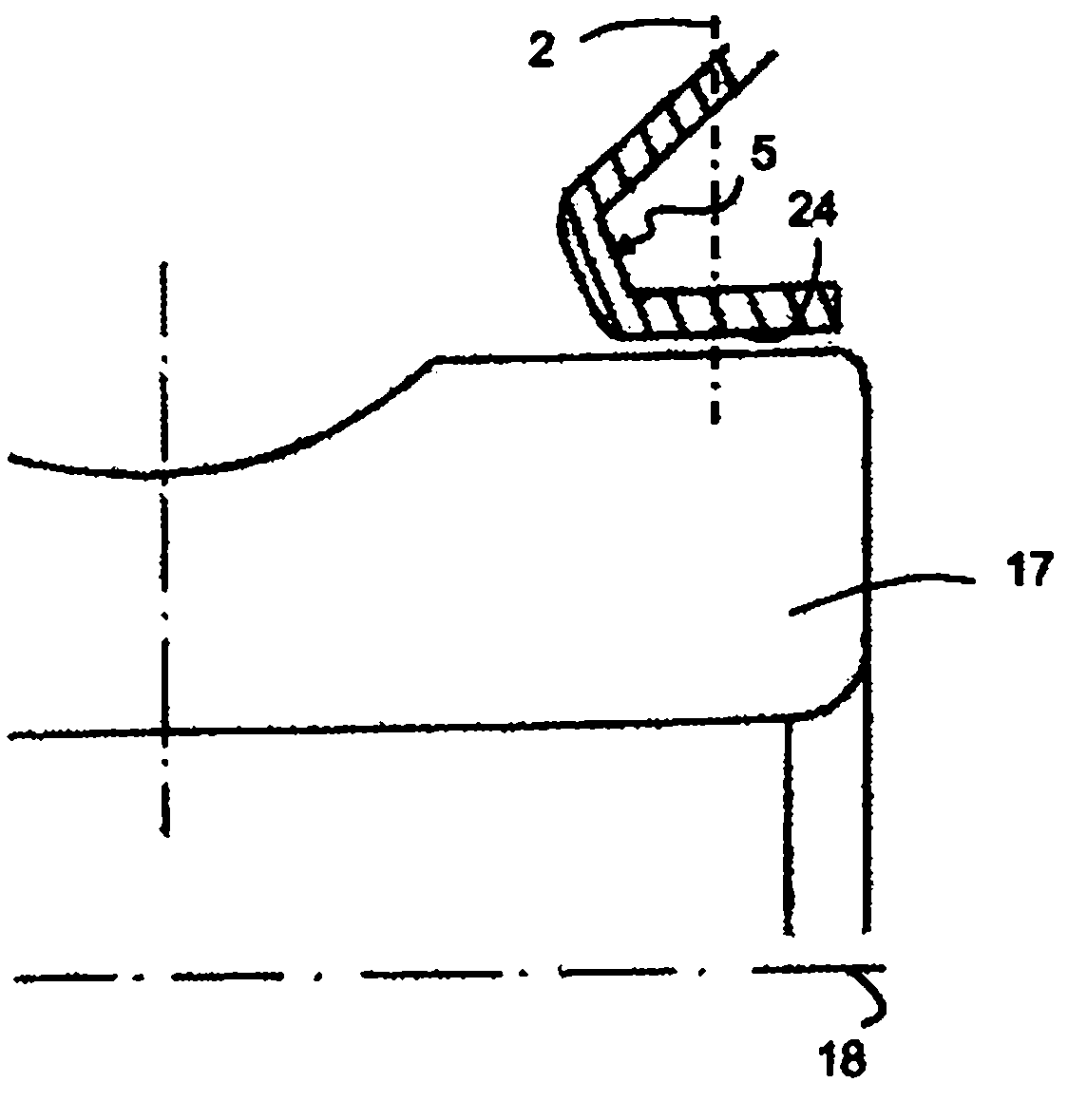

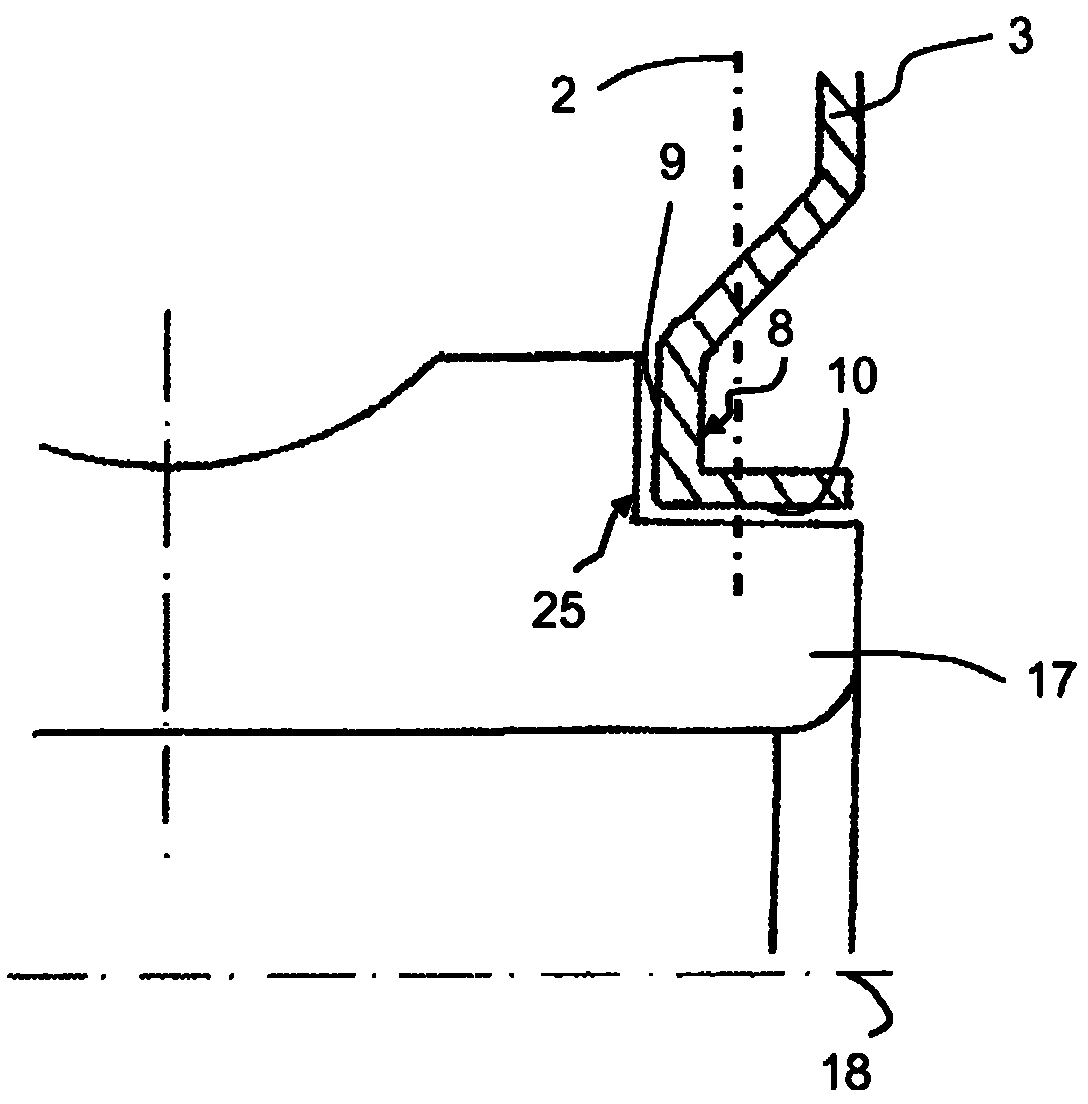

[0023] figure 1A radial deep groove ball bearing is shown in partial section. Between the outer bearing ring 16 and the inner bearing ring 17 , the rolling bodies enclosed in the rolling-element cage each rotate on raceways configured as raceways. The bearing gaps formed between the bearing rings 16 , 17 are each covered on the axial outer sides of the rolling bearing by the annularly encircling cover 1 according to the invention along a covering plane 2 , which is perpendicular to the rolling bearing axis 18 and in the radial direction Extend up. In this case, the cover part 1 has an inner side axially facing the bearing interior to be sealed and an outer side facing axially away from said inner side and the bearing interior. The cover part 1 is designed as a one-piece cover made of sheet metal. The cover has a disk-shaped base 3 extending in the radial direction in the mounted state, the disk plane of which extends parallel to the cover plane 2 . Radially outwardly from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com