Alkali-resistant concrete for manufacturing jacking pipes

A concrete and alkali-resistant technology, applied in the field of alkali-resistant concrete, can solve problems such as corrosion and cracks, and achieve high water resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

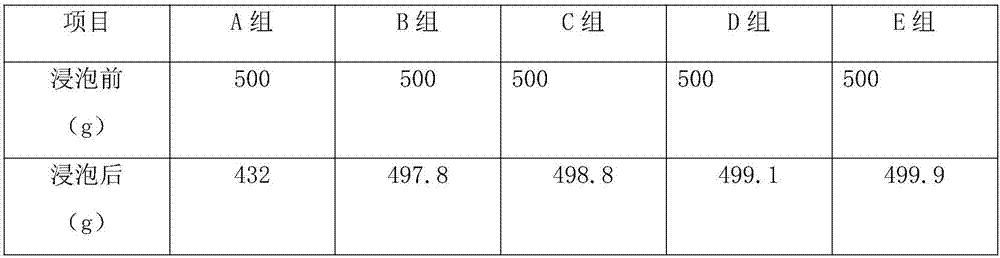

[0022] Choose the pipe jacking made of ordinary concrete, destroy the pipe jacking, take 500g pipe jacking block, put it into the simulated alkaline soil test solution, the pH of the alkaline soil test solution is 7.5-8, and extract it from the alkaline loess soil of the Loess Plateau. Soak it for 1 month, weigh it again, count the weight data, and mark it as A.

Embodiment 2

[0024] The pipe jacking prepared by the following ratio is selected, and the concrete is composed according to the following weight ratio: 50 parts of high-alumina white cement, 10 parts of kaolin, 40 parts of stone powder, 30 parts of machine-made sand, 2 parts of water-retaining agent, and 2 parts of silicone water-repellent agent . Destroy the pipe jacking, take 500g pipe jacking block, put it into the simulated alkaline soil test solution, the pH of the alkaline soil test solution is 7.5-8, and extract it from the alkaline loess cotton soil on the Loess Plateau, soak it for 1 month, and weigh it again. Quantity, statistical weight data, marked as B.

Embodiment 3

[0026] The pipe jacking prepared by the following ratio is selected, and the concrete is composed of the following weight ratio: 70 parts of high-alumina white cement, 15 parts of kaolin, 50 parts of stone powder, 50 parts of machine-made sand, 8 parts of water-retaining agent, and 8 parts of silicone water-repellent agent . Destroy the pipe jacking, take 500g pipe jacking block, put it into the simulated alkaline soil test solution, the pH of the alkaline soil test solution is 7.5-8, and extract it from the alkaline loess cotton soil on the Loess Plateau, soak it for 1 month, and weigh it again. Quantities, statistical weight data, marked C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com