Coil coating with imitated velvet effect and preparation method thereof

A technology of coil coating and velvet, applied in the field of building decoration materials, can solve the problems of color steel plate and aluminum plate satisfying individualization, lack of aesthetics, and constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

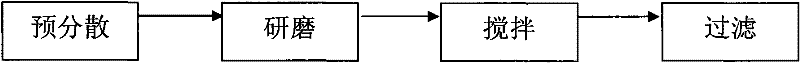

[0030] Embodiment one: the preparation method of a kind of velvet-like coil coating of the present invention adopts following process steps: its prescription ratio is calculated in parts by weight:

[0031] Take 36.0 parts of branched chain saturated polyester resin, 1.0 parts of polymer block copolymerization dispersant, 15.0 parts of colored pigment, 16.0 parts of 5000 mesh quartz powder, 4.0 parts of 100# hydrocarbon solvent, 2.0 parts of cyclohexanone, dibasic acid 2.0 parts of ester, put the above raw materials into the container tank in sequence, disperse for 30 minutes with a high-speed disperser, grind 3 to 5 times with a sand mill until the fineness is ≤15 microns, then pour the slurry into the mixing tank and add linear polymer 16 parts of ester polyol elastic resin, 1.6 parts of blocked isophorone polyisocyanate, 3.0 parts of methyl etherified melamine resin, 1.2 parts of blocked p-toluenesulfonic acid, 1.0 parts of polyethylene wax, 1.0 parts of fluorine-modified ac...

Embodiment 2

[0032] Embodiment two: the preparation method of a kind of imitation velvet coil coating of the present invention adopts following process steps: its prescription ratio is calculated by weight parts:

[0033] Take 38.0 parts of branched chain saturated polyester resin, 0.8 parts of polymer block copolymerization dispersant, 10.0 parts of colored pigment, 23.0 parts of 5000 mesh quartz powder, 3.0 parts of 100# aromatic hydrocarbon solvent, 1.5 parts of cyclohexanone, dibasic acid ester 2.0 parts, put the above raw materials into the container tank in sequence, disperse for 30 minutes with a high-speed disperser, grind 3 to 5 times with a sand mill until the fineness is ≤15 microns, then take out the slurry and pour it into the mixing tank and add linear polymer 13.0 parts of ester polyol elastic resin, 2.0 parts of blocked isophorone polyisocyanate, 3.5 parts of methyl etherified melamine resin, 2.0 parts of blocked p-toluenesulfonic acid, 0.9 parts of polyethylene wax, 0.8 par...

Embodiment 3

[0034] Embodiment three: the preparation method of a kind of imitation velvet coil coating of the present invention adopts following process steps: its prescription ratio is calculated by weight parts:

[0035] Take 28 parts of branched chain saturated polyester resin, 1.25 parts of polymer block copolymerization dispersant, 28 parts of colored pigment, 6.0 parts of 5000 mesh quartz powder, 4.5 parts of 100# hydrocarbon solvent, 2.5 parts of cyclohexanone, dibasic acid 2.5 parts of ester, put the above raw materials into the container tank in sequence, disperse for 30 minutes with a high-speed disperser, grind 3 to 5 times with a sand mill until the fineness is ≤15 microns, then take out the slurry and pour it into the mixing tank to add linear 18 parts of polyester polyol elastic resin, 2 parts of blocked isophorone polyisocyanate, 2.8 parts of methyl etherified melamine resin, 1.4 parts of blocked p-toluenesulfonic acid, 1.6 parts of polyethylene wax or tetrafluoroethylene wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com