Luminous road surface and preparation method thereof

A pavement material and surface layer technology, which is applied in the field of making luminous art road pavement and its preparation using construction waste, can solve the problems of secondary pollution, waste of resources, less than 10%, and achieve good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

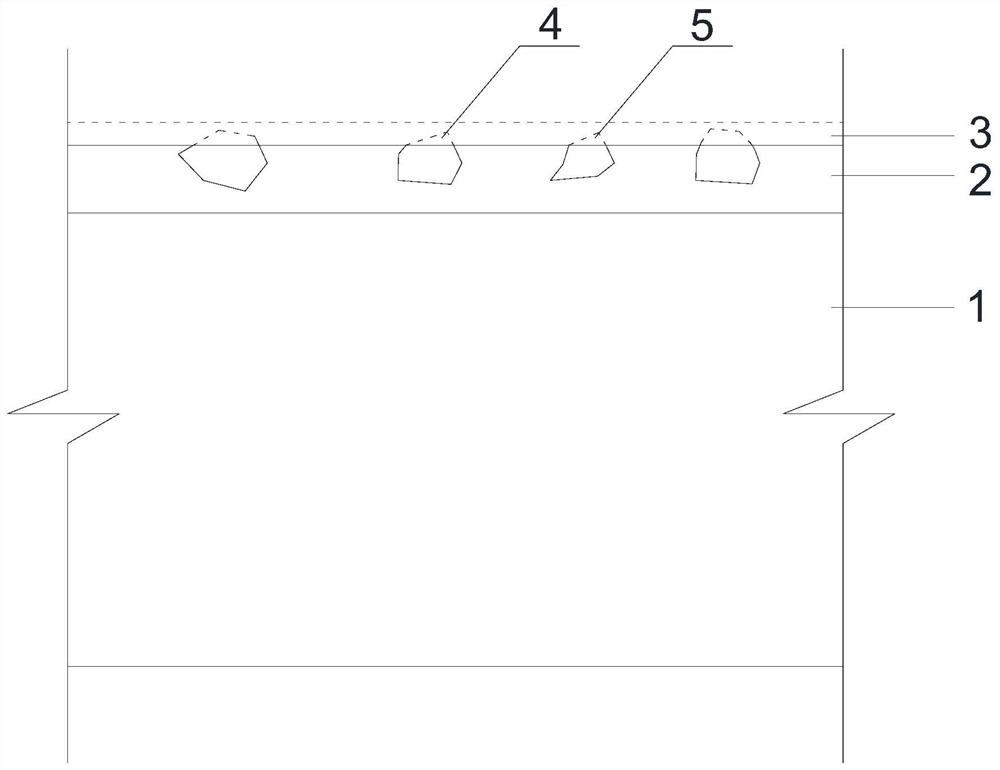

Image

Examples

Embodiment 1

[0086] The components in the base material are measured by weight and then stirred and mixed to obtain a semi-dry base material, wherein the base material includes the following components by weight: 150 parts of cement, 20 parts of construction waste recycled micropowder, construction 600 parts of recycled coarse aggregate from garbage, 300 parts of recycled fine aggregate from construction waste, 80 parts of water, and 0 parts of water reducing agent. Then pave the grassroots mixture on the road and solidify it as the grassroots. The strength grade of the solidified grassroots is C30, and the thickness of the solidified grassroots is 200mm.

[0087] Stir and mix the components in the surface layer material in parts by weight to obtain a semi-dry surface layer mixture, wherein the surface layer material includes the following components in parts by weight: 150 parts of white cement, 10 parts of coloring powder 300 parts of recycled fine aggregate from construction waste, 80 p...

Embodiment 2

[0090] Stir and mix the components in the base material according to parts by weight to obtain a semi-dry base material mixture, wherein the base material includes the following components by parts by weight: 210 parts of cement, 60 parts of recycled micropowder of construction waste, construction 800 parts of recycled coarse aggregate from garbage, 500 parts of recycled fine aggregate from construction waste, 120 parts of water, and 5 parts of water reducing agent. Then pave the grassroots mixture on the road and solidify it as the grassroots. The strength grade of the solidified grassroots is C20, and the thickness of the solidified grassroots is 200mm.

[0091] Stir and mix the components in the surface layer material in parts by weight to obtain a semi-dry surface layer mixture, wherein the surface layer material includes the following components in parts by weight: 210 parts of white cement, 60 parts of coloring powder 500 parts of recycled fine aggregate from constructio...

Embodiment 3

[0094] The components in the base material are measured by weight and then stirred and mixed to obtain a semi-dry base mixture, wherein the base material includes the following components by weight: 210 parts of cement, 20 parts of construction waste recycled micropowder, construction 600 parts of recycled coarse aggregate from garbage, 300 parts of recycled fine aggregate from construction waste, 100 parts of water, and 3 parts of water reducing agent. Then pave the grassroots mixture on the road and solidify it as the grassroots. The strength grade of the solidified grassroots is C25, and the thickness of the solidified grassroots is 200mm.

[0095] Stir and mix each component in the surface layer material by weight to obtain a semi-dry surface layer mixture, wherein the surface layer material includes the following components by weight: 210 parts of white cement, 5 parts of coloring powder 350 parts of recycled fine aggregate from construction waste, 120 parts of water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com