Production process of solar heat collecting plate and heat collecting panel utilized by same

A solar heat collector plate and a production process technology, applied in the field of solar heat collection, to achieve the effects of easy installation, increased thermal conductivity, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

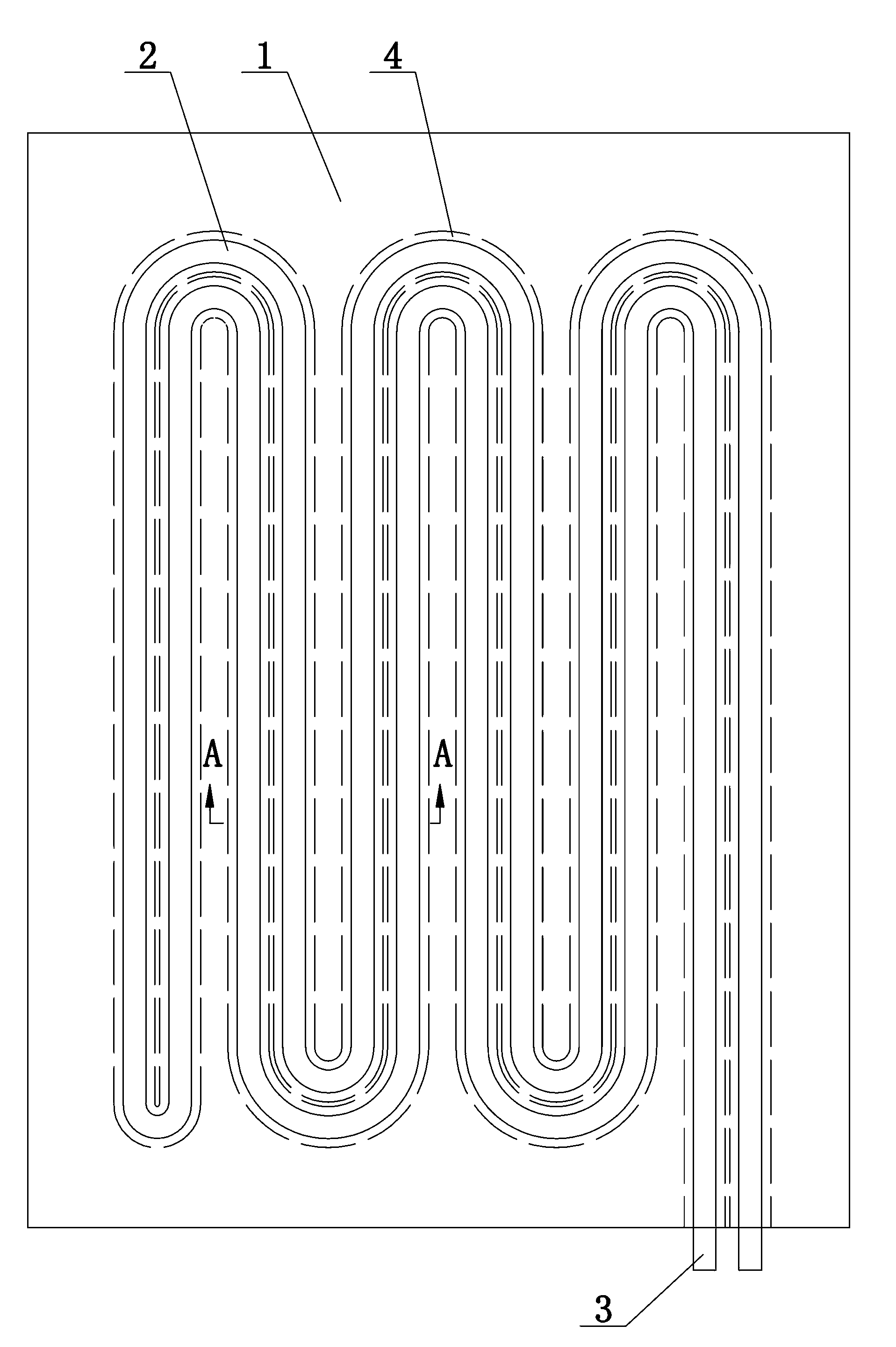

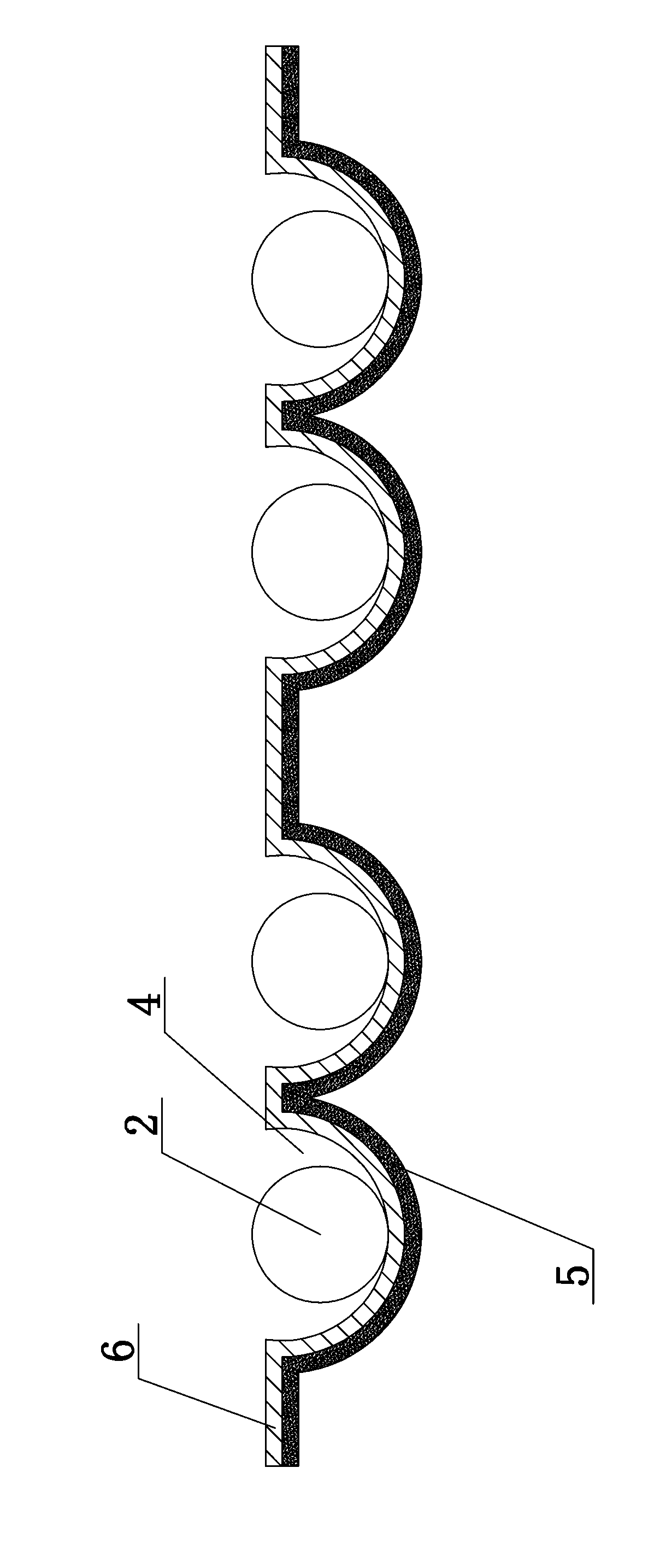

[0039] Such as figure 1 , figure 2 As shown, a solar thermal collector includes a thermal collector panel 1, a heat pipe 2 and a joint 3. The thermal collector panel 1 includes a metal substrate 6 and a glassy inorganic composite coating 5. The metal substrate 6 is stamped from a low-carbon steel plate. The vitreous inorganic composite coating 5 is enamelled on the lighting surface of the metal substrate 6, and the thickness of the vitreous inorganic composite coating 5 is 0.1 mm. The backlight surface of the metal base 6 is provided with a groove 4, and the heat pipe 2 is arranged in the groove 4. The groove 4 and the heat pipe 2 are both S-shaped coiled on the backlight surface of the metal base 6. The water inlet and outlet of the heat pipe 2 The nozzles are all provided with joints 3, and the heat pipe 2 is equipped with a superconducting medium.

[0040] A production process of the above-mentioned heat collecting panel, comprising the following process steps:

[0041...

Embodiment 2

[0056] Repeat Example 1, with the following differences: the thickness of the vitreous inorganic composite coating 5 is 0.2mm, and the production process of the heat collecting panel comprises the following process steps:

[0057] a, the making of metal substrate 6

[0058] After cutting the low-carbon steel plate, it is punched and formed to obtain a metal matrix parison. The parison is subjected to oil burning→acid washing→water washing→coating with nickel→water washing→neutralization→drying→inspection and then ready for use to complete the production of the metal matrix 6;

[0059] In the oil burning process, put the metal matrix parison into a kiln at 650-750°C and heat it for 5-10 minutes;

[0060] In the pickling process, soak the oil-burned metal matrix parison in a sulfuric acid solution with a concentration of 8% for 3 to 8 minutes;

[0061] In the nickel-coating process, the metal matrix parison washed with clean water is put into a nickel sulfate solution with a co...

Embodiment 3

[0072] Repeat Example 1, with the following differences: the thickness of the vitreous inorganic composite coating 5 is 0.15mm, and the production process of the heat collecting panel comprises the following process steps:

[0073] a, the making of metal substrate 6

[0074] After cutting the low-carbon steel plate, it is punched and formed to obtain a metal matrix parison. The parison is subjected to oil burning→acid washing→water washing→coating with nickel→water washing→neutralization→drying→inspection and then ready for use to complete the production of the metal matrix 6;

[0075] In the oil burning process, put the metal matrix parison into a kiln at 650-750°C and heat it for 5-10 minutes;

[0076] In the pickling process, soak the oil-burned metal matrix parison in a sulfuric acid solution with a concentration of 7% for 3 to 8 minutes;

[0077] In the nickel-coating process, the metal matrix parison washed with clean water is put into a nickel sulfate solution with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com