PC/ABS alloy material with excellent chemical substance resistance, and preparation method thereof

An alloy material, chemical resistance technology, applied in the field of PC/ABS alloy material and its preparation, can solve the problems of poor chemical resistance, corrosion, etc., and achieve the effect of excellent hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

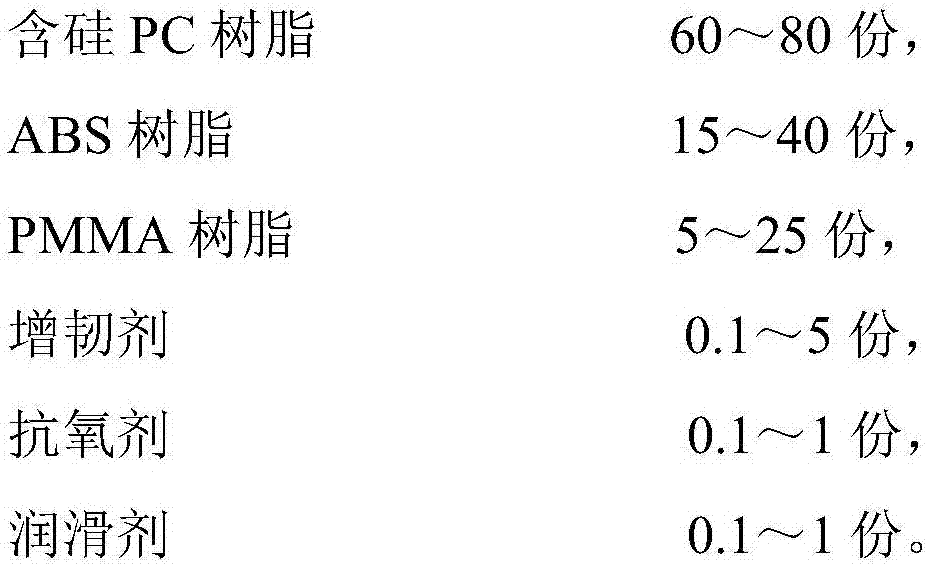

Method used

Image

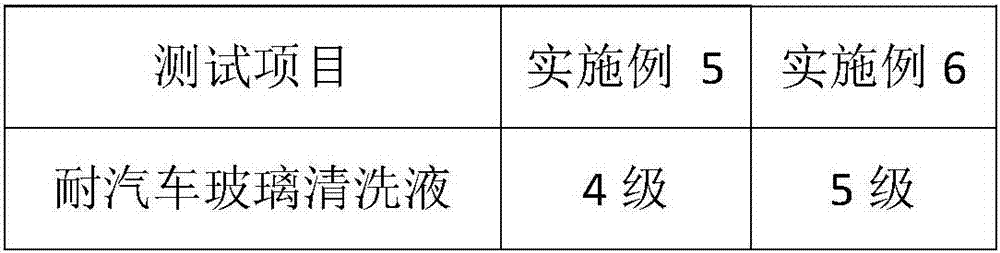

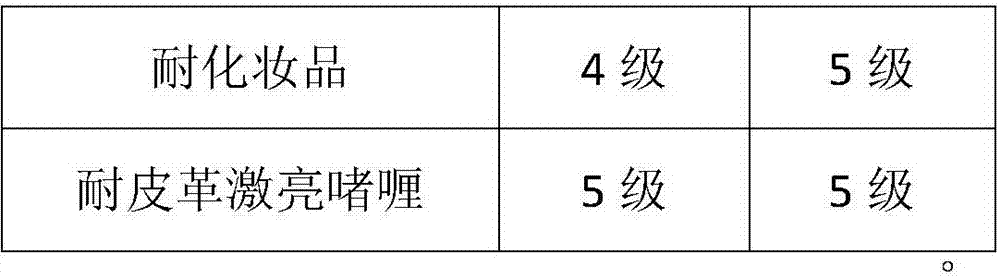

Examples

Embodiment 1

[0026] A PC / ABS alloy material with excellent chemical resistance and a preparation method thereof, the method comprising the following steps:

[0027] (1) Weigh each component by weight: silicon-containing PC: 60kg; ABS: 25kg; PMMA: 15kg; toughening agent: 5; antioxidant: 0.2; lubricant: 0.3;

[0028] (2) Mix the components with a mixer and feed them from the main feeding port, melt and extrude at 200-260°C, the screw extruder speed is 500rpm, the pressure is 2MPa, after melt extrusion, granulation to obtain the product .

Embodiment 2

[0030] A PC / ABS alloy material with excellent chemical resistance and a preparation method thereof, the method comprising the following steps:

[0031] (1) Weigh each component by weight: silicon-containing PC: 60kg; ABS: 15kg; PMMA: 25kg; toughening agent: 5; antioxidant: 0.2; lubricant: 0.3;

[0032] (2) Mix the components with a mixer and feed them from the main feeding port, melt and extrude at 200-260°C, the screw extruder speed is 500rpm, the pressure is 2MPa, after melt extrusion, granulation to obtain the product .

Embodiment 3

[0034] A PC / ABS alloy material with excellent chemical resistance and a preparation method thereof, the method comprising the following steps:

[0035] (1) Weigh each component by weight: silicon-containing PC: 60kg; ABS: 40kg; toughening agent: 5; antioxidant: 0.2; lubricant: 0.3;

[0036] (2) Mix the components with a mixer and feed them from the main feeding port, melt and extrude at 200-260°C, the screw extruder speed is 500rpm, the pressure is 2MPa, after melt extrusion, granulation to obtain the product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com