Self-adhesion modified asphalt waterproofing coil coating material, preparation method thereof and passive special self-adhesion asphalt waterproofing coil for buildings

A technology of bitumen waterproofing membrane and waterproofing membrane, which is applied in the direction of bituminous material adhesive, building insulation material, roofing using flexible materials, etc. Longevity and quality of life, improved stability and high temperature resistance, effect of increased stability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In the embodiment of the present invention, the preparation method of the self-adhesive modified bitumen waterproof membrane coating material comprises:

[0054] Heat the mixed asphalt to a molten state, control the system temperature at 140°C, add polyethylene wax and stir evenly; control the system temperature ≤ 150°C, add stabilizers, and react for 30 minutes; control the system temperature at 150°C, add powder SBR modification in turn agent and linear SBS modifier; control the temperature of the system at 180°C, after the powder SBR modifier and linear SBS modifier are completely swollen, add tackifying resin, and after complete dissolution, add inorganic filler and stir evenly to obtain the described Self-adhesive modified bitumen waterproof membrane coating material. Among them, the preparation method of the mixed asphalt is as follows: below 160°C, add 90# petroleum asphalt and minus three softening oil in sequence, and stir slowly for 5min-10min below 160°C, so ...

Embodiment 1

[0056] This embodiment provides a self-adhesive modified asphalt waterproof membrane coating material, a preparation method thereof, and a self-adhesive asphalt waterproof membrane.

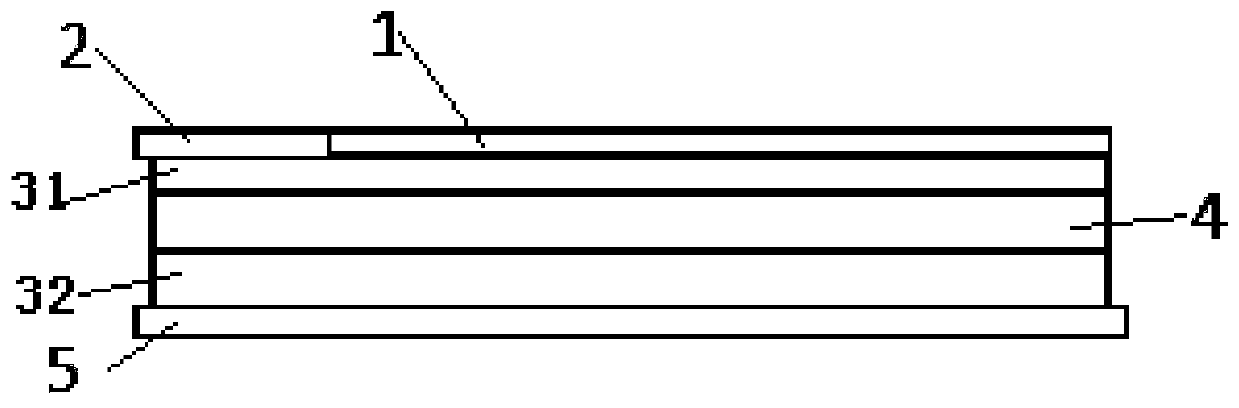

[0057] Among them, the width of the coil is 1000mm, the thickness is 3mm, and the length is 10m;

[0058] The isolation material 1 on the upper surface of the coil is LDPE film with a thickness of 0.1mm;

[0059] Self-adhesive asphalt waterproofing membrane overlapping part isolation side membrane 2 is PE material surface coated with silicon oil film, the width is 120mm, the thickness is 0.035mm;

[0060] The reinforced tire base layer 4 is a polyester glass fiber reinforced tire (purchased from Bona High Performance Materials (Changzhou) Co., Ltd.), with a thickness of 1.0mm and a mass per unit area of 270g / m 2 .

[0061] The isolation bottom film 5 is made of PE and coated with silicone oil, with a thickness of 0.035mm and a width of 1040mm.

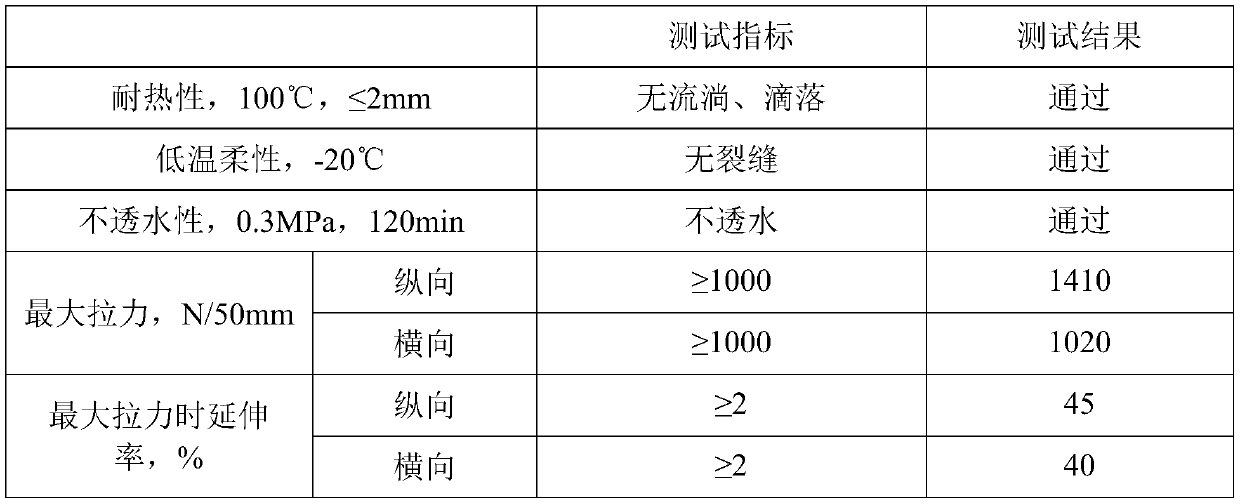

[0062] The first self-adhesive asphalt waterpr...

Embodiment 2

[0068] This embodiment provides a self-adhesive modified asphalt waterproof membrane coating material, a preparation method thereof, and a self-adhesive asphalt waterproof membrane.

[0069] Among them, the width of the coil is 1000mm, the thickness is 3mm, and the length is 10m;

[0070] The isolation material 1 on the upper surface of the coil is LDPE film with a thickness of 0.1mm;

[0071] Self-adhesive asphalt waterproofing membrane overlapping part isolation side membrane 2 is PE material surface coated with silicon oil film, width is 150mm, thickness is 0.030mm;

[0072] The reinforced tire base layer 4 is a polyester glass fiber reinforced tire PYG (purchased from Bona High Performance Materials (Changzhou) Co., Ltd.), with a thickness of 1.15mm and a mass per unit area of 272g / m 2 .

[0073] The isolation bottom film 5 is made of PE and coated with silicone oil, with a thickness of 0.035mm and a width of 1040mm.

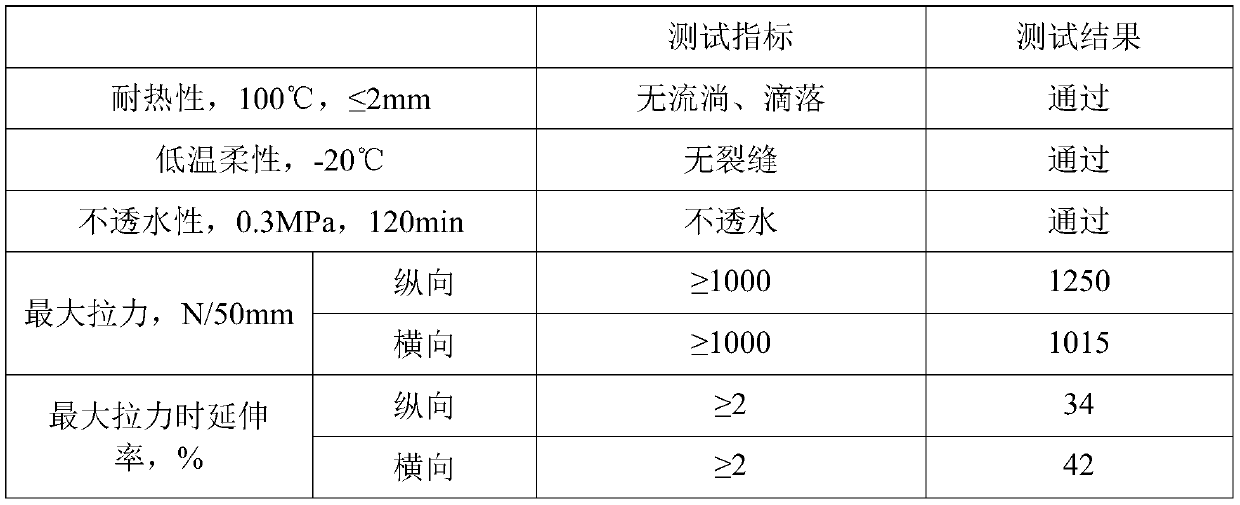

[0074] The first self-adhesive asphalt waterproof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com