Coil coating bonded with PVC film and preparation method thereof

A PVC film and coil coating technology, applied in the field of coatings, can solve problems such as failure to meet requirements, and achieve the effects of excellent adhesion, excellent mechanical properties, and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

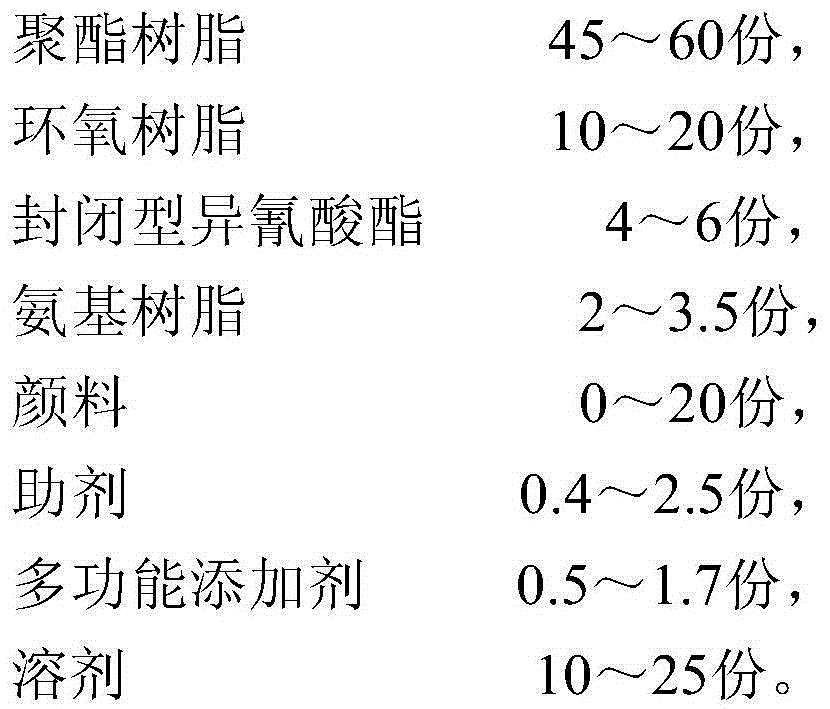

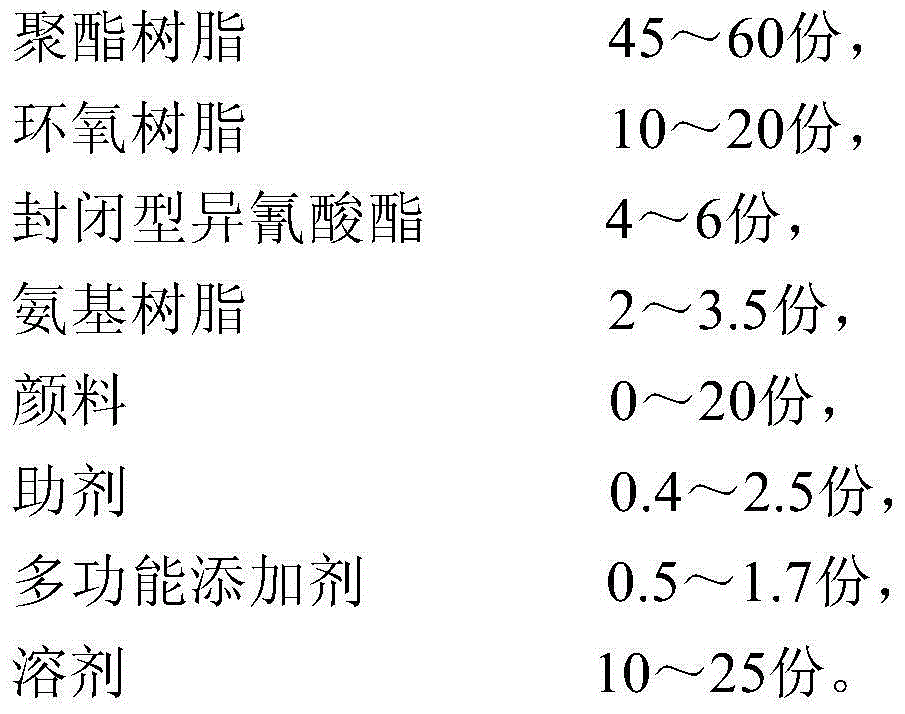

Method used

Image

Examples

Embodiment 1

[0039] a) Weigh 300 grams of polyester resin, 70 grams of rutile titanium dioxide, and 7 grams of iron oxide red powder. 16 grams of iron oxide yellow powder, 0.1 gram of carbon black powder, 9 grams of calcium ion exchange silica type antirust pigment, 45 grams of cyclohexanone, 35 grams of S-150 aromatic solvent, 10 grams of butyl acetate, 5.6 grams of low molecular weight non Saturated polycarboxylic acid polymer dispersant is commercially available BYK, stir evenly, and then grind to a fineness of less than 15 μm to form a color paste for later use.

[0040] b) Weigh 210 grams of polyester resin, 130 grams of bisphenol A epoxy resin, 42 grams of blocked methylene diisocyanate, 25 grams of highly methylated melamine resin, 12 grams of Nochet PAE206, acrylate leveling agent 3 gram, 2 grams of acrylate defoamer, 15 grams of cyclohexanone, 15 grams of S-150 aromatic hydrocarbon solvent, 15 grams of butyl acetate, 5 grams of dibasic acid ester and mix well.

[0041] c) Slowly ...

Embodiment 2

[0051] A coil coating for bonding PVC films, comprising the steps of:

[0052] Take by weighing 300 grams of polyester resin, 140 grams of rutile titanium dioxide, 9 grams of calcium ion exchange silica type antirust pigments, 45 grams of cyclohexanone, 35 grams of S-150 aromatic solvent, 10 grams of butyl acetate, 3 Gram of commercially available P-104S of low molecular weight unsaturated polycarboxylic acid polymer dispersant, stir evenly, then grind to fineness below 15 μ m to form color paste, standby.

[0053] 210 grams of the remaining polyester resin, 130 grams of bisphenol A epoxy resin, 42 grams of blocked methylene diisocyanate, 25 grams of highly methylated melamine resin, 12 grams of Nochet PAE206, 3 grams of acrylate leveling agent , 2 grams of acrylate defoamer, 15 grams of cyclohexanone, 15 grams of S-150 aromatic hydrocarbon solvent, 15 grams of butyl acetate, 5 grams of dibasic acid ester, mix well, and slowly add the ground color paste under stirring In the ...

Embodiment 3

[0058] A coil coating for bonding PVC films, comprising the steps of:

[0059] Weigh 300 grams of polyester resin, 20 grams of rutile titanium dioxide, 2 grams of carbon black powder, 9 grams of calcium ion exchange silica type antirust pigments, 35 grams of cyclohexanone, 35 grams of S-150 aromatic solvent, 15 grams Butyl acetate, 8 grams of low-molecular-weight unsaturated polycarboxylic acid polymer dispersant, stirred evenly, then ground to a fineness of 15 μm or less to form a color paste, set aside.

[0060] 150 grams of the remaining polyester resin, 160 grams of bisphenol A epoxy resin, 42 grams of blocked methylene diisocyanate, 15 grams of highly methylated melamine resin, 9.5 grams of Nochet PAE206, acrylate leveling agent 3 grams, 2 grams of acrylate defoamer, 15 grams of cyclohexanone, 15 grams of S-150 aromatic hydrocarbon solvent, 15 grams of butyl acetate, mix well, and slowly add the ground color paste to the above premixed one under stirring In the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com