Coil coating body vehicle for site operation of multilayer composite waterproof layer

An on-site construction and multi-layer composite technology, which is applied to the tools used in roofing engineering, roofing, construction, etc., can solve the problem of incomplete guarantee of vehicle moving speed and waterproof construction speed, difficulty in keeping the same moving speed and construction speed, and inability to achieve multiple Problems such as synchronous construction of waterproof layer structure and other issues, to achieve the effect of reducing process flow and process time, improving construction efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention is further described below, but the scope of protection is not limited.

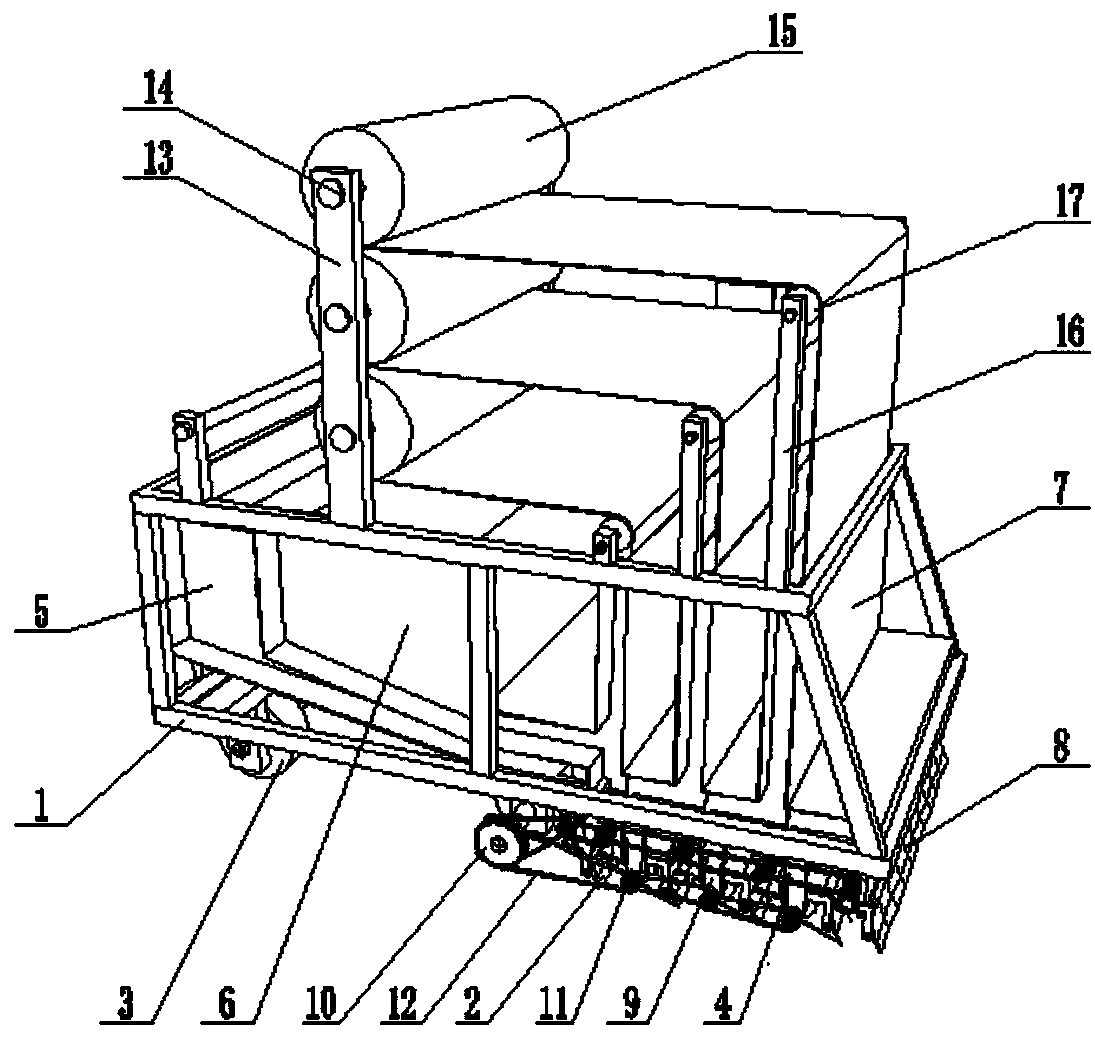

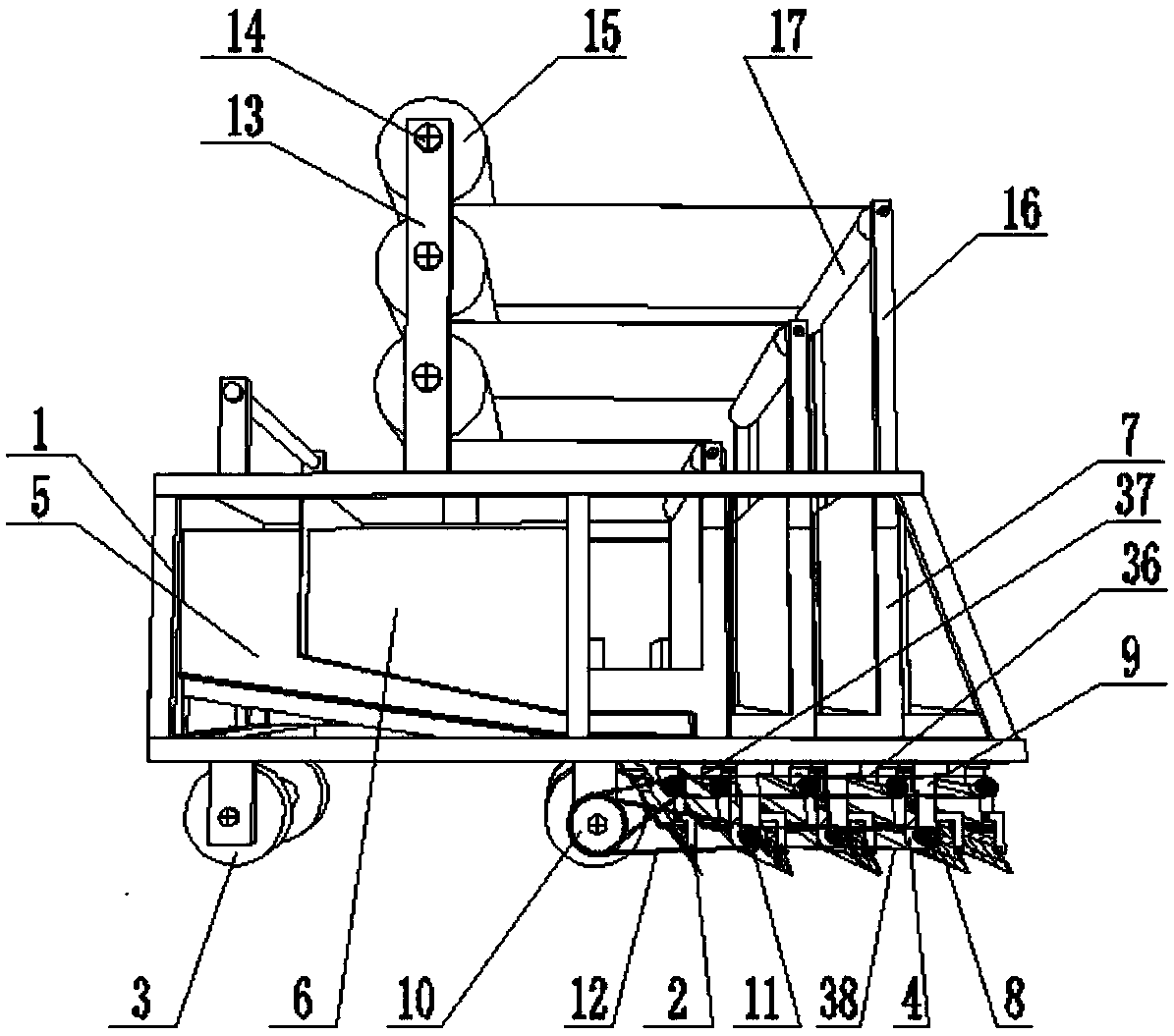

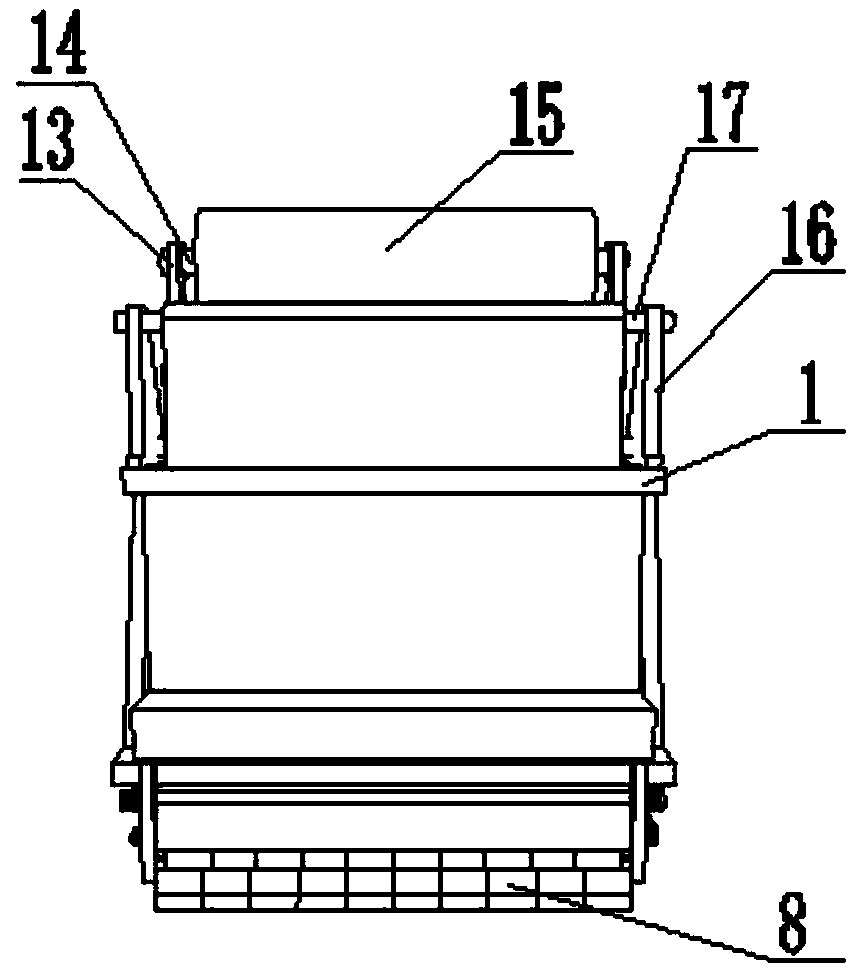

[0050] like Figure 1 to Figure 8 As shown, the present invention provides a kind of roll-coating body car that is used for multi-layer composite waterproof layer on-site construction, comprises paint silo, tire base supply device and coating device, paint silo, tire base supply device and coating device are all Installed on the coil coating car, the tire base supply device and the coating device are both connected to the paint silo.

[0051] Adopting the technical scheme of the present invention, by simultaneously coating the coating layer and laying the tire base reinforcement layer to form a waterproof layer with a multi-layer composite structure that is firmly bonded to the base surface and has good continuity, the waterproof layer of the multi-layer composite waterproof layer is realized. Simultaneous laying and one-time molding ensure the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com