A semi-closed submerged arc furnace top charging device

A feeding device and submerged arc furnace technology, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of easy grinding, leakage, overflow and damage of material pipes, so as to avoid shutdown of the furnace, continuous detection of material quantity, and reduction The effect of small shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

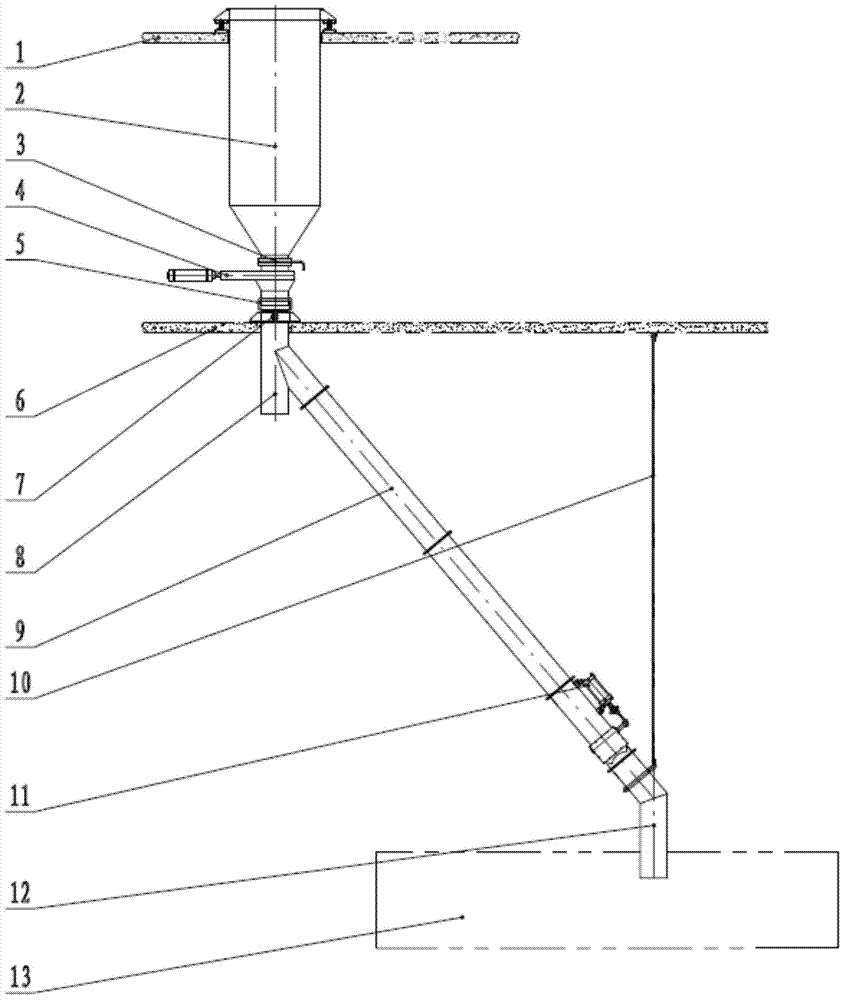

[0027] The present invention will be further described below in conjunction with drawings and embodiments. It is implemented as a 2×30MW multi-circuit DC manganese-silicon alloy electric furnace top charging device. Furnace top charging device, including weighing bin 2, finger valve 3, hydraulic flapper valve 4, herringbone feeding pipe 8, inclined feeding pipe 9 and feeding nozzle 10, weighing bin 2 is fixedly connected to weighing bin On the floor 1, there is a flange on the upper opening of the weighing bin 2, and a load cell is set under the upper flange of the weighing bin 2, and the weighing sensor is supported under the upper flange of the weighing bin 2 and connected to the weighing material. Between the warehouse floors 1, the lower port of the weighing bin 2 is sequentially connected with the finger valve 3 and the hydraulic slide valve 4; the herringbone material pipe 8 is composed of a vertical pipe and an inclined pipe located in the middle of the vertical pipe. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com