Efficient ozone contact and reaction device for advanced wastewater treatment and treatment process

An advanced treatment, ozone contact technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high civil construction cost, low ozone utilization rate and incomplete ozone attenuation in contact pools, so as to reduce operating costs and improve low utilization rate. , Improve the effect of contact transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

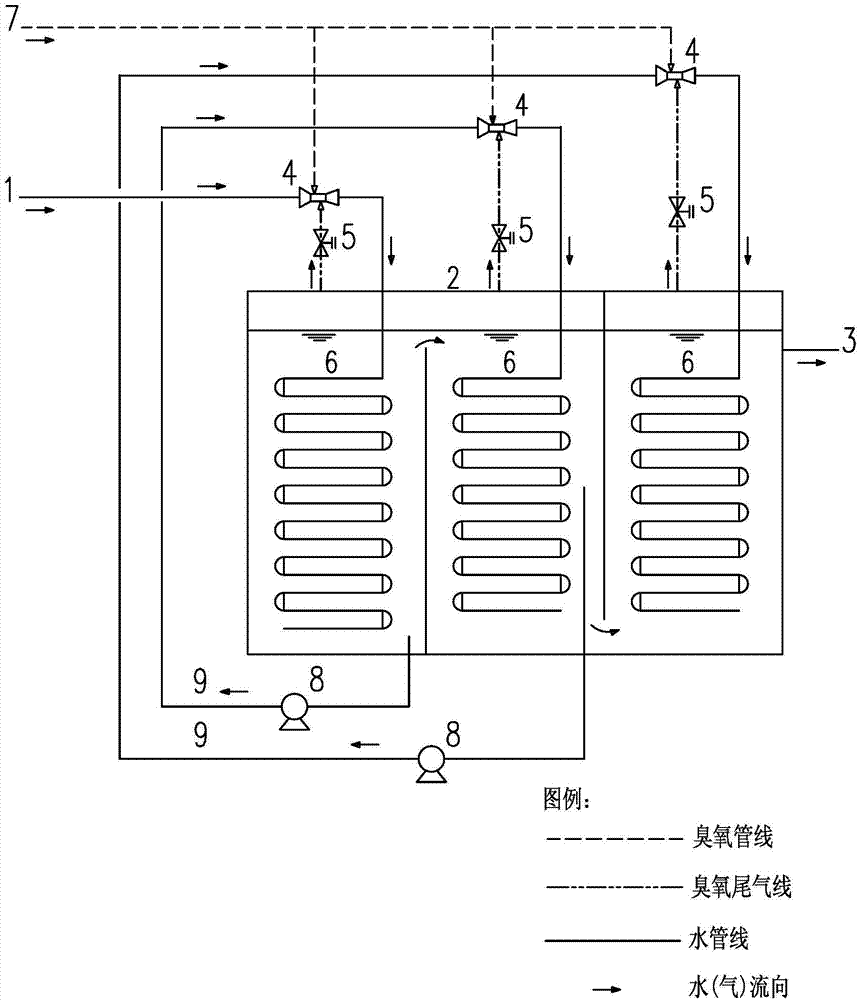

[0016] like figure 1 As shown, a kind of high-efficiency ozone contact reaction device for the advanced treatment of sewage of the present invention comprises ozone contact tank 2 and ozone pipeline 7, and described ozone contact tank 2 is provided with water inlet pipe 1 and water outlet pipe 3, and each section of reaction tank The tops are respectively equipped with an ozone tail gas outlet. In the ozone contact pool 2, N baffles are arranged sequentially from the side of the water inlet pipe 1 to the side of the outlet pipe 3, and the N baffles are at least two baffles, and the N baffles are at least two baffles. The baffle divides the ozone contact pool 2 into N+1 segment reaction pools, and the outlets of the N baffles are arranged alternately up and down, thus forming an up and down baffle in the ozo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com