Precoated coil coating for adhering polyester film and using method thereof

A technology of coil coating and polyester film, which is applied in the direction of polyester coating, coating, and the device for coating liquid on the surface, etc. It can solve the problems that cannot meet the use requirements, and achieve simple and practical use methods and good adhesion , the effect of firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

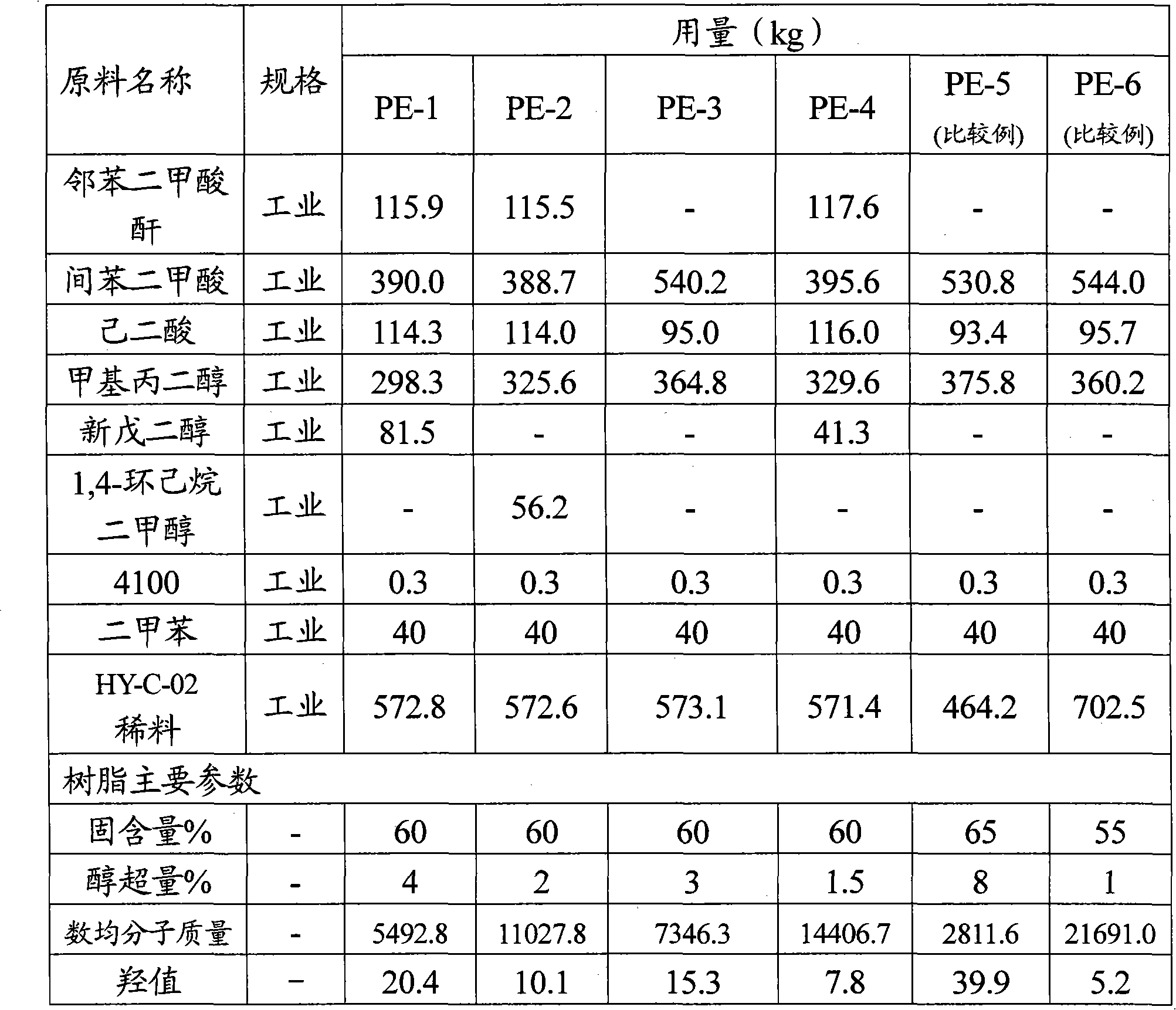

[0018] Embodiment 1 prepares the polyester resin PE-1~PE-6 that has hydroxyl functional group

[0019] 1. The formula and main parameters are shown in Table 1

[0020] Table 1

[0021]

[0022] Note 1: HY-C-02 thinner is the product brand of Jiangsu Hongye Coating Technology Industry Co., Ltd.;

[0023] 4100 is the brand name of domestic dibutyltin oxide esterification catalyst;

[0024] Note 2: The acids and alcohols used to prepare polyester resins with hydroxyl functional groups are not limited to the raw materials listed in Table 1;

[0025] 2. Synthesis process

[0026] In the four-neck flask equipped with stirring, thermometer, water separator, fractionating column, and inert gas inlet, add the remaining raw materials except HY-C-02 thinner according to the formula in Table 1, and feed inert gas from the inert gas inlet. Slowly raise the temperature under the protection of inert gas, reflux reaction at 140°C, heat up to 230°C in 4 to 5 hours, and keep the tem...

Embodiment 2

[0027] Example 2 Preparation of Precoated Coil Coatings 1-6 for Adhesive Polyester Film

[0028] (1) The formula of coatings 1-6: it is composed of the following components, and the mass percentage of each component is as follows:

[0029] The film-forming resin is 20% to 35% in solid terms, the additive is 0.5% to 5%, the pigment and filler is 20% to 35%, and the solvent is 25% to 50%. Among them, the film-forming resin is composed of number average molecules It is composed of polyester resin with hydroxyl functional group and cross-linked resin with a quality of 3500-20000 and a hydroxyl value of 6-35. In terms of resin solids, the polyester resin with hydroxyl functional group is 70%-95%, and the cross-linked resin is 5%. %~30%, the specific formula is shown in Table 2.

[0030] Table 2

[0031] components

raw material name

Raw material specification

Dosage, g

Paint 1

Dosage, g

Paint 2

Dosage...

Embodiment 3

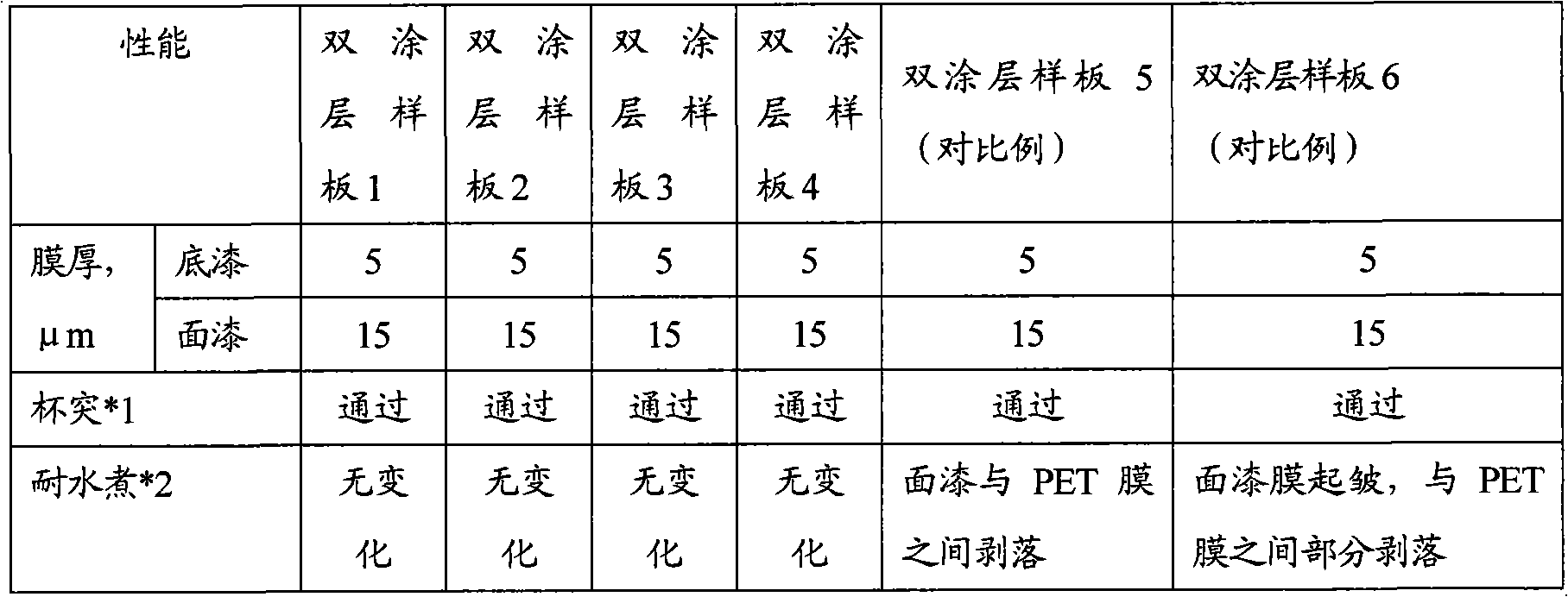

[0048] Embodiment 3 uses precoated coil material coating thermal lamination bonding polyester film of the present invention to prepare polyester film laminated precoated coil sample:

[0049] (1) coating the precoated coil coating of the present invention on the precoated coil surface with primer

[0050] How to use it

[0051] 1. Take a cold-rolled steel plate of 12cm×15cm×0.5mm, wash it, and treat it with chromium treatment solution according to the existing method;

[0052] 2. Bake in an oven at 120°C for 30s and take it out;

[0053] 3. On the dried steel plate, use 10 # Scratch coat the wire rod with HY-JD-101-3 white primer, dry it, and its dry film thickness is 4-6 μm;

[0054] 4. Use 26 on the white primer film # The pre-coated coil coating of the present invention prepared in Example 2 of wire bar scraping is dried after drying (furnace temperature: 280 ℃; baking time: 45~46s; board temperature: 216~232 ℃), after taking out from oven, its The total thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com