Aluminum plate coil coating and preparation method thereof

A technology of coil coating and aluminum plate, applied in the direction of polyester coating, coating, etc., to achieve the effect of simple production, beautiful effect and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

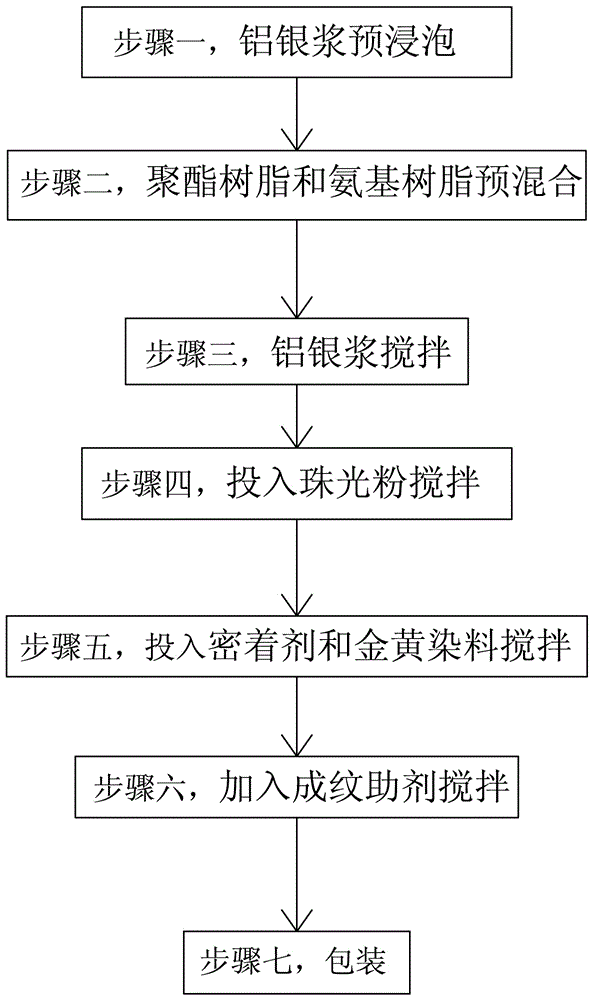

[0051] like figure 1 Shown, a kind of preparation method of aluminum coil coating is characterized in that: comprise the following steps,

[0052] Step 1: Pre-soak the aluminum-silver paste; take the aluminum-silver paste according to the weight percentage and add the solvent to soak it, stir it at a slow speed and place it for 3-5 hours, such as: leave it for 4 hours, continue to stir it evenly, take a sample, fully wet it and set aside ;

[0053] Step 2: pre-mixing; adding the polyester resin and amino resin into the dispersion kettle by weight percentage, and stirring evenly;

[0054] Step 3: Use a mixer to stir at a speed of 80-120 RPM, such as: stir at a speed of 100 RPM. During the stirring process, put the aluminum silver paste wetted in the above step 1 into the dispersion kettle, and stir for 8-15 minutes, such as: stir 10 minutes;

[0055] Step 4: Put the pearlescent powder into the dispersing kettle according to the weight percentage, and use the mixer to stir ev...

Embodiment 1

[0060] Embodiment 1: a kind of coating for aluminum sheet coil, it is coated with golden flash diamond three-dimensional shell pattern paint as coil roll, comprises following component and important percentage thereof: polyester resin 72%, adhesive agent 2%, aluminum silver paste 8% , 0.5% defoamer, 6% solvent, 1% texture aid, 6% amino resin, 2% golden dye, 2% pearl powder, and 0.5% catalyst.

[0061]The above polyester resin is a medium molecular weight polyester with a solid content of 80% and a viscosity of 5000-6000pa.s / 25°C. The aluminum silver paste is a silver round aluminum silver paste with an inner diameter of 35um. The solvent is a mixed solvent of butyl ester and PMA. The ratio is 3:1; the amino group is permethylether melamine formaldehyde resin, the adhesive is epoxy-modified phosphate polymer, the defoamer is acrylic polymer, and the graining aid is silicone Modified compound; the golden yellow dye is an organic aromatic compound, and the pearl powder is a white...

Embodiment 2

[0062] Embodiment 2: a kind of coating for aluminum plate coil, it is coated with golden flash diamond three-dimensional shell pattern paint as coil roll, comprises following each component and mass percentage: polyester resin 70%, aluminum silver paste 6%, solvent 7%, Amino resin 8%, Adhesive 2%, Defoamer 0.5%, Texturing aid 2%, Golden dye 2.5%, Pearl powder 2%.

[0063] The performance test of coating film of the present invention is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com