Plastic remanufacturing method

A technology of remanufacturing and plastic products, applied in the preparation of test samples, etc., can solve problems such as environmental pollution, harm to health, death of plastic animals, etc., and achieve the effect of saving oil resources and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations of the present invention are now described.

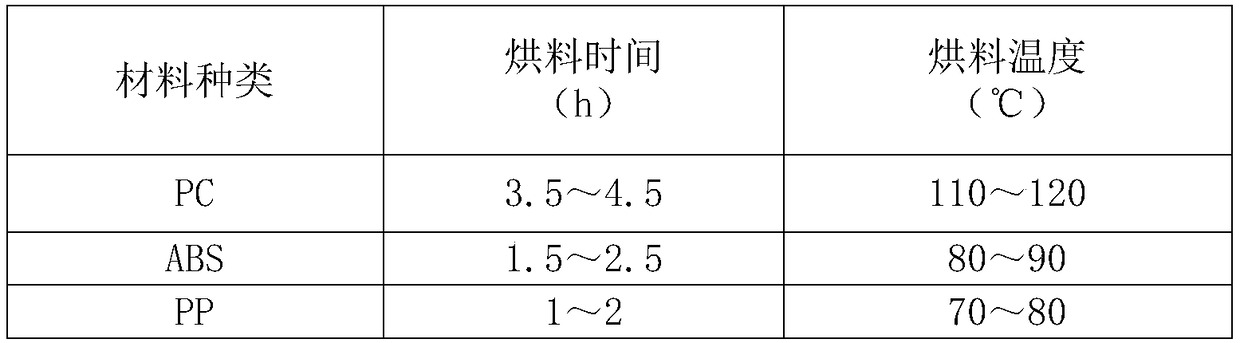

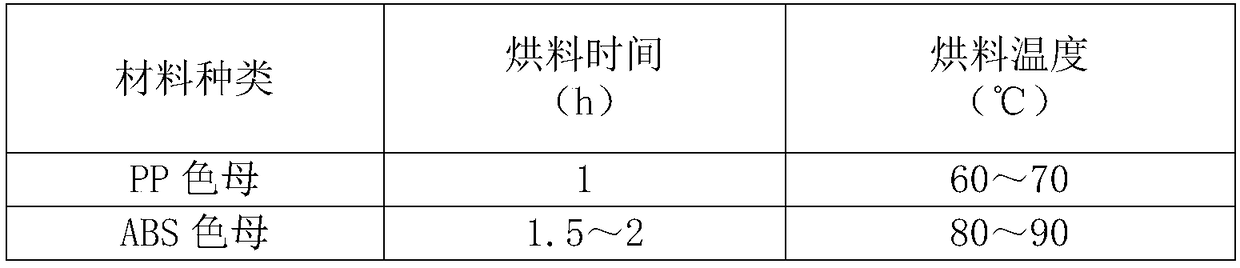

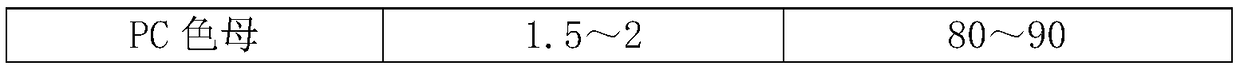

[0020] A method for remanufacturing plastics. First, waste plastics are classified according to their material type and color, and a large amount of oil stains, screws, nuts, stones, paper labels and other non-plastic sundries need to be sorted out before crushing. Then, the classified plastics are crushed and cleaned by a crusher to obtain broken plastic particles; then, the broken plastic particles are dried by a dryer to make their moisture content lower than 0.02%; during processing, they can be The moisture content of the broken plastic particles is measured by the JT-K8 new halogen moisture analyzer. The drying treatment not only effectively removes the moisture in the broken plastic particles, but also can be preheated to facilitate subsequent injection molding. The technical requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com