Gear transmission apparatus using flexible belts as engagement medium

A technology of gear transmission mechanism and flexible belt, which is applied in the direction of gear transmission device, belt/chain/gear, transmission device, etc., can solve the problems such as the difficulty of reusing the tooth body, high processing and manufacturing costs, and affecting the life of the gear. The effect of environmental protection, low cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

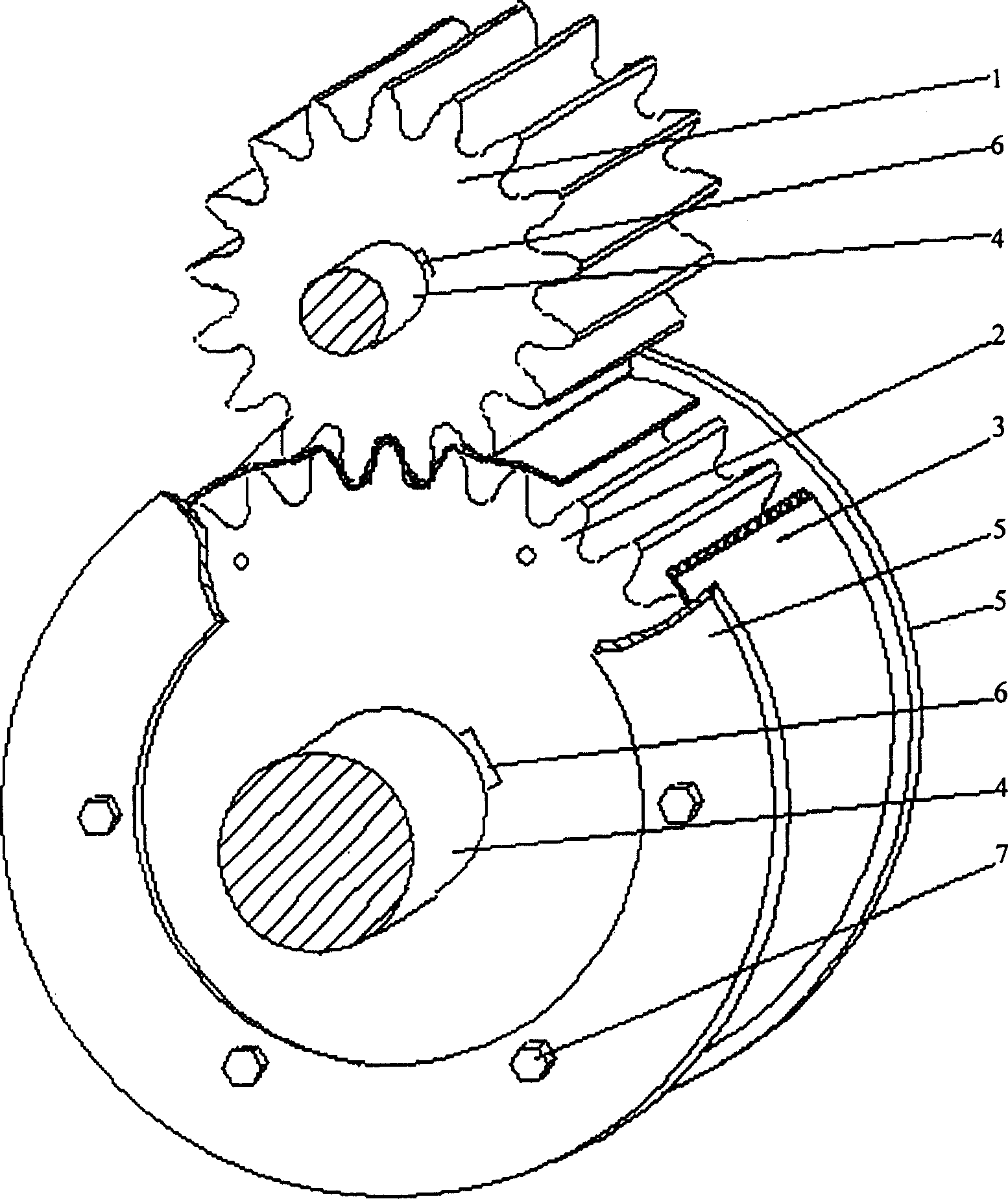

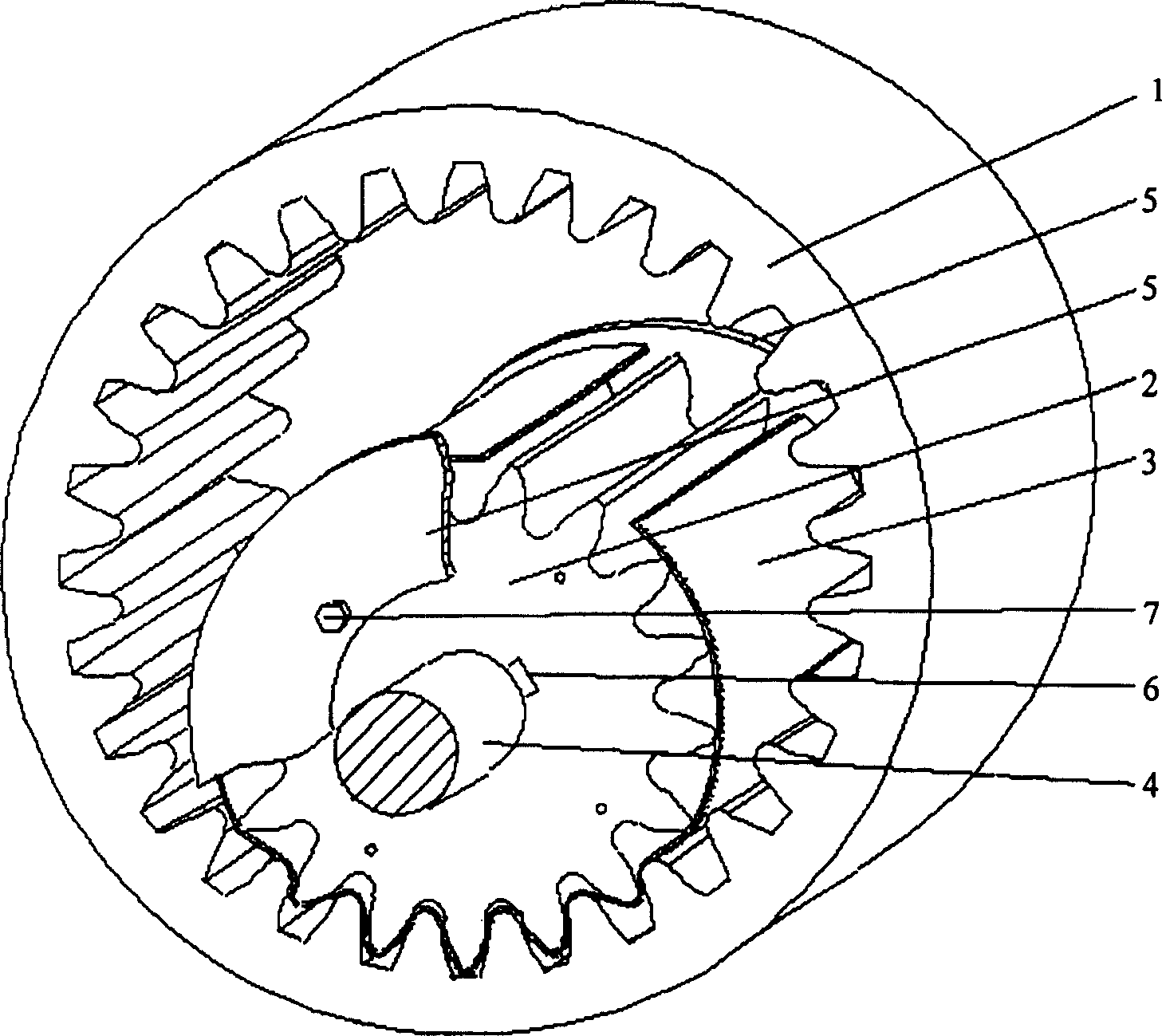

[0026] Such as figure 1 As shown, the gear A1 with the coupling 6 and the gear shaft 4 conjugate meshes with the gear B2 of the coupling 6 and the gear shaft 4. The gear teeth of the gear shaft B2 are sheathed with a movable closed flexible belt 3, which is equipped with flexible The retaining ring 5 provided on both sides of the gear B2 with 3 is connected with the gear B2 by screws 7.

[0027] figure 2 , The gear A1 is conjugated with the gear B2 of the coupling 6 and the gear shaft 4, the teeth of the gear B2 are covered with a flexible closed belt 3 that is movable, and the gear B2 with the flexible belt 3 is equipped with a retaining ring 5 provided on both sides of the gear B2 Connect with gear B2 with screws 7.

[0028] Above figure 1 , figure 2 Middle: The flexible belt 3 is in a closed ring shape. During operation, the flexible belt 3 is gradually embedded between the two meshing tooth surfaces by the gear A1 without the flexible belt. On both sides of the gear B2 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com