A kind of lignin modified urea-formaldehyde resin adhesive and its preparation method and application

A urea-formaldehyde resin, lignin technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of high raw material cost, poor boiling water resistance, complex process, etc., and achieve quality control methods. Simple, good boiling water resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

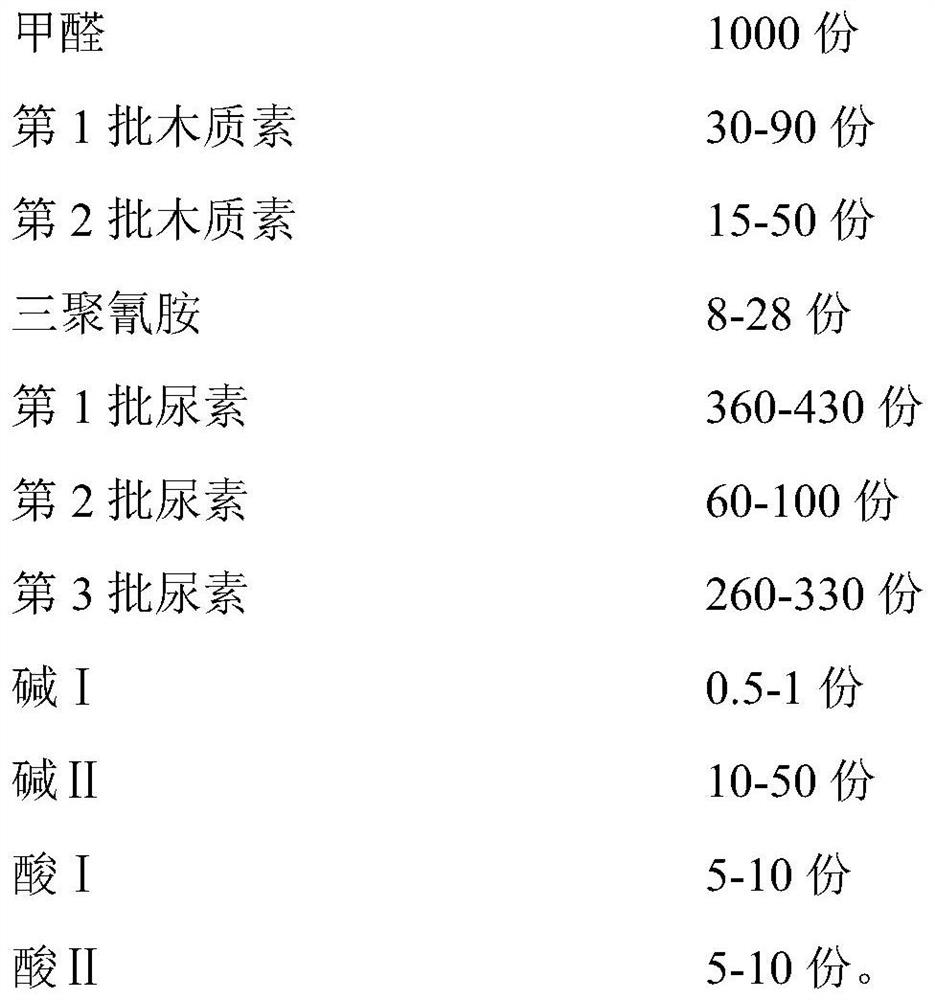

Method used

Image

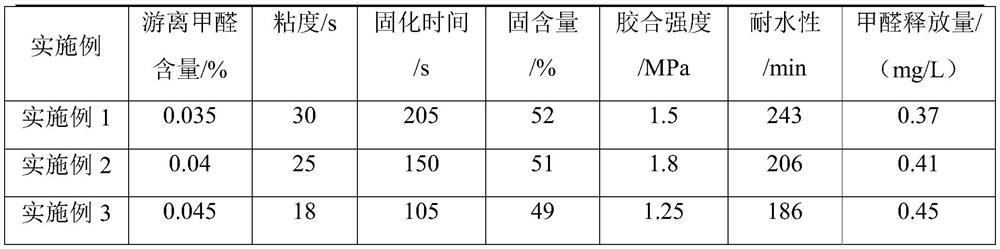

Examples

Embodiment 1

[0037]A preparation method of a lignin-modified urea-formaldehyde resin adhesive is as follows: add lignin in two batches, add urea in three batches, first add formaldehyde, the first batch of lignin and melamine for addition reaction; then add the first The first batch of urea and the second batch of lignin are subjected to the first polycondensation reaction; the second batch of urea is then added for the second polycondensation reaction; finally the third batch of urea is added for the third polycondensation reaction to obtain a lignin-modified urea-formaldehyde resin adhesive. Specifically include the following steps:

[0038] (1) Add 1000kg of formaldehyde into the reaction kettle, adjust the pH value to 7.3 with 0.7kg of sodium hydroxide solution, then add 35kg of the first batch of lignin and 17kg of melamine, raise the temperature to 70°C, keep it warm for 10min, and then adjust the pH with 7kg of formic acid The value is 6.5, and it is kept at 70°C for 27 minutes;

...

Embodiment 2

[0043] A preparation method of a lignin-modified urea-formaldehyde resin adhesive is as follows: add lignin in two batches, add urea in three batches, first add formaldehyde, the first batch of lignin and melamine for addition reaction; then add the first The first batch of urea and the second batch of lignin are subjected to the first polycondensation reaction; the second batch of urea is then added for the second polycondensation reaction; finally the third batch of urea is added for the third polycondensation reaction to obtain a lignin-modified urea-formaldehyde resin adhesive. Specifically include the following steps:

[0044] (1) Add 1000kg of formaldehyde into the reaction kettle, adjust the pH value to 7.2 with 0.8kg of ammonia water, then add 90kg of the first batch of lignin and 20kg of melamine, heat up to 50°C, keep it warm for 20min, and then adjust the pH value with 8kg of sulfuric acid solution 6.3, keep warm at 69°C for 28 minutes;

[0045] (2) Add 360kg of th...

Embodiment 3

[0049] A preparation method of a lignin-modified urea-formaldehyde resin adhesive is as follows: add lignin in two batches, add urea in three batches, first add formaldehyde, the first batch of lignin and melamine for addition reaction; then add the first The first batch of urea and the second batch of lignin are subjected to the first polycondensation reaction; the second batch of urea is then added for the second polycondensation reaction; finally the third batch of urea is added for the third polycondensation reaction to obtain a lignin-modified urea-formaldehyde resin adhesive. Specifically include the following steps:

[0050] (1) Add 1000kg formaldehyde into the reaction kettle, adjust the pH value to 7.3 with 0.8kg triethanolamine, then add 55kg of the first batch of lignin and 10kg melamine, heat up to 60°C, keep it warm for 15min, and then adjust the pH value with 7kg formic acid 6.7, keep warm at 68°C for 30 minutes;

[0051] (2) Add 430kg of the first batch of urea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com