Modified polypropylene special resin and preparation method thereof

A polypropylene, terpene resin technology, applied in the direction of graft polymer adhesives, polyurea/polyurethane coatings, adhesive types, etc., can solve the problem of poor weather resistance, low polyolefin content, and poor coating adhesion. stability and other issues to achieve the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

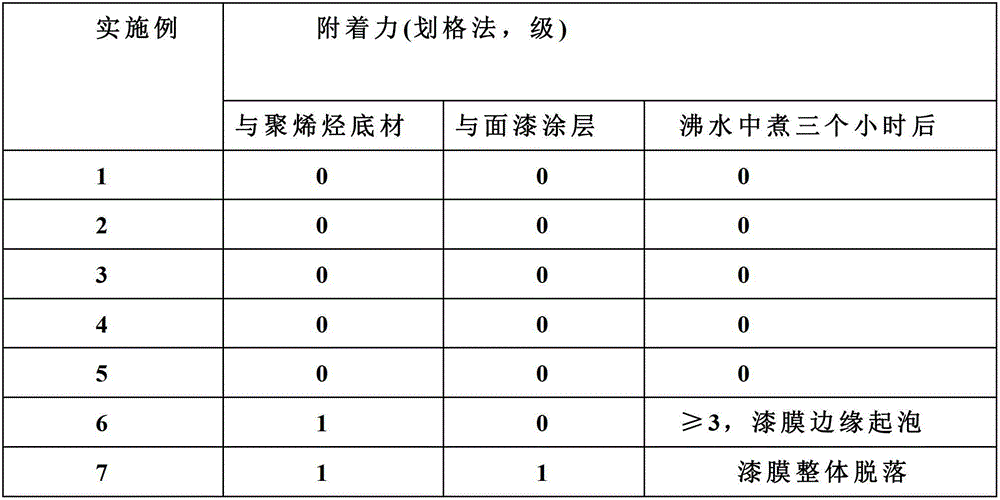

Examples

Embodiment 1

[0025] In a 1000ml four-necked bottle equipped with stirring, a thermometer, and a condenser tube, 150 g of chlorinated polypropylene (atactic body, chlorine content 30%) and 445 g of xylene were added, and the temperature was slowly raised to 50° C. to fully dissolve the material, and the temperature was raised to 100° C. ℃, add SBS 30g, methyl methacrylate 100g, cyclohexyl methacrylate 20g, terpene resin 3.5g, benzoyl peroxide 0.3g and 1.5GAIMW, stir and react for 10 hours. Cool down, filter and fill.

[0026] Add appropriate amount of alkyd resin, rutile titanium dioxide, calcium carbonate, superfine talcum powder, solvent, auxiliary agent, etc. to the obtained resin according to the formula in Table 1 (except modified chlorinated polyolefin resin, all other raw materials are Commercially available product), after high-speed dispersion and grinding to a fineness of less than 30 microns, after spraying and molding, after baking at 80°C for 2 hours, the performance of the pre...

Embodiment 2

[0030] Same as the method of Example 1, the difference is that chlorinated polypropylene (random body, chlorine content 30%) is changed into equal weight low molecular weight polypropylene wax.

Embodiment 3

[0032] In a 1000ml four-necked bottle equipped with stirring, a thermometer, and a condenser tube, 150 g of chlorinated polypropylene (atactic body, chlorine content 30%) and 420 g of xylene were added, and the temperature was slowly raised to 50° C. to fully dissolve the material, and the temperature was raised to 100 ℃, add SBS 30g, methyl methacrylate 80g, cyclohexyl methacrylate 20g, glycidyl methacrylate 20g, toluene 25g, terpene resin 3.5g and benzoyl peroxide 0.3g, benzoyl peroxide After 1.5 g, stir and react for 10 hours. Cool down, filter, and fill. The following operations are exactly the same as in Example 1. The obtained resin is poured into acetone to precipitate a white precipitate, which is filtered by suction and fully washed 3 times with acetone , after vacuum drying, obtain graft sample, its infrared spectrum (Shimadzu PTIR-8300 type Fourier Transform Infrared Spectroscopy). As can be seen, the absorption peak at 1714cm-1 is the acid anhydride peak of grafting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com