Glossy impregnated paper and manufacturing method thereof

A technology of impregnated paper and high gloss, applied in the field of impregnated paper, can solve the problem of insufficient surface gloss, and achieve the effects of good wetting effect, good printing effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

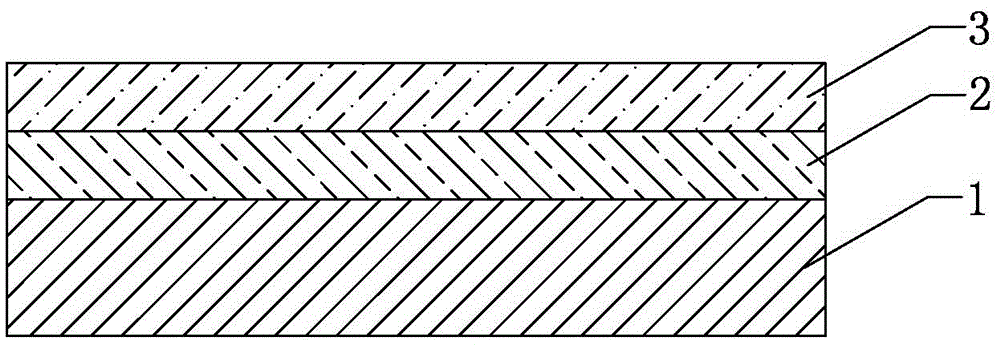

[0046] See figure 1 , a high-gloss impregnated paper, comprising a base paper layer 1, a printed wood grain layer 2 attached to the upper surface of the base paper layer 1, and a high-gloss adhesive layer 3 attached to the upper surface of the printed wood grain layer 2.

[0047] The printed wood grain layer 2 is made by printing with water-based ink.

[0048] The water-based ink is composed of the following raw materials in weight percentage: 3% water-based resin, 0.15% dispersant, 0.15% wetting agent, 8% pigment, 4% other additives, and the balance of water.

[0049] The water-based resin is a mixture of water-soluble acrylic resin and maleic rosin modified acrylic resin with a weight ratio of 2:1; the dispersant is composed of sodium hexametaphosphate, polyacrylamide and sodium lauryl sulfate The mixture that weight ratio 1.8:0.8:1 is formed; Described wetting agent is by polyoxyethylene alkylphenol ether, polyoxyethylene fatty alcohol ether and polyoxyethylene polyoxyprop...

Embodiment 2

[0062] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0063] The water-based ink is composed of the following raw materials in weight percentage: 4% water-based resin, 0.2% dispersant, 0.2% wetting agent, 9% pigment, 6% other additives, and the balance of water.

[0064] The water-based resin is a mixture of water-soluble acrylic resin and maleic rosin modified acrylic resin with a weight ratio of 2.5:1; the dispersant is composed of sodium hexametaphosphate, polyacrylamide and sodium lauryl sulfate A mixture of weight ratio 2:0.9:1; the wetting agent is made of polyoxyethylene alkylphenol ether, polyoxyethylene fatty alcohol ether and polyoxyethylene polyoxypropylene block copolymer in a weight ratio of 1:0.8: The mixture of 1.6 composition; Described pigment is at least one in cobalt phosphate violet, phthalocyanine blue, phthalocyanine green, carbon black, permanent red and benzidine yellow; Described other auxiliary agent is made of level...

Embodiment 3

[0074] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0075] The water-based ink is composed of the following raw materials in weight percentage: 5% water-based resin, 0.25% dispersant, 0.25% wetting agent, 10% pigment, 8% other additives, and the balance of water.

[0076] The water-based resin is a mixture of water-soluble acrylic resin and maleic rosin modified acrylic resin with a weight ratio of 3:1; the dispersant is composed of sodium hexametaphosphate, polyacrylamide and sodium lauryl sulfate The mixture that weight ratio 2.2:1:1 forms; Described wetting agent is to be by polyoxyethylene alkylphenol ether, polyoxyethylene fatty alcohol ether and polyoxyethylene polyoxypropylene block copolymer with weight ratio 1:1: The mixture of 1.8 composition; Described pigment is at least one in cobalt phosphate violet, phthalocyanine blue, phthalocyanine green, carbon black, permanent red and benzidine yellow; Described other auxiliary agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com