Fireproof door middle seam provided with flame-retardant straw fire prevention boards

A fire door and straw board technology, applied in the field of fire doors, can solve problems such as non-thermal conductivity, achieve good environmental performance, improve flatness, compactness, waterproofness, and improve bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

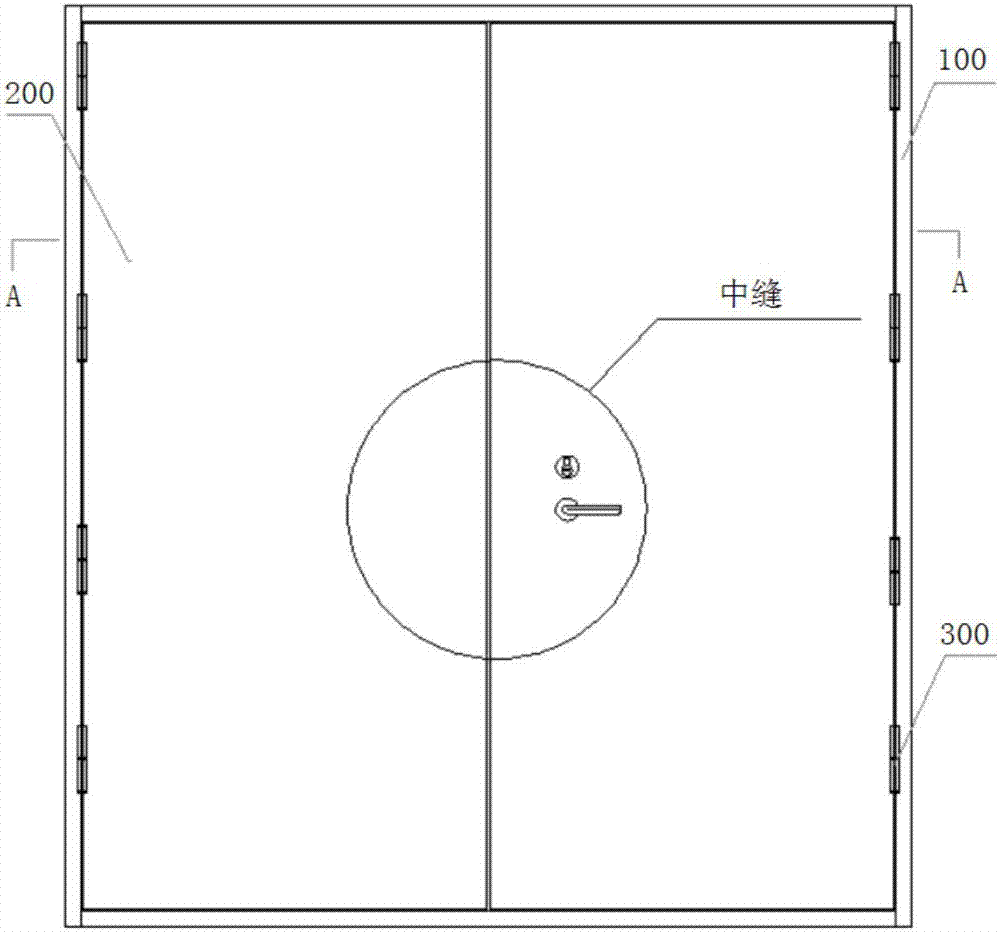

[0037] refer to figure 1 , figure 1 It is a schematic diagram of the overall structure of the fireproof door in the embodiment of the present invention, including a door frame 100, a door leaf 200, and a hinge 300. The door frame and the door leaf are connected by hinges. The face forms a seam.

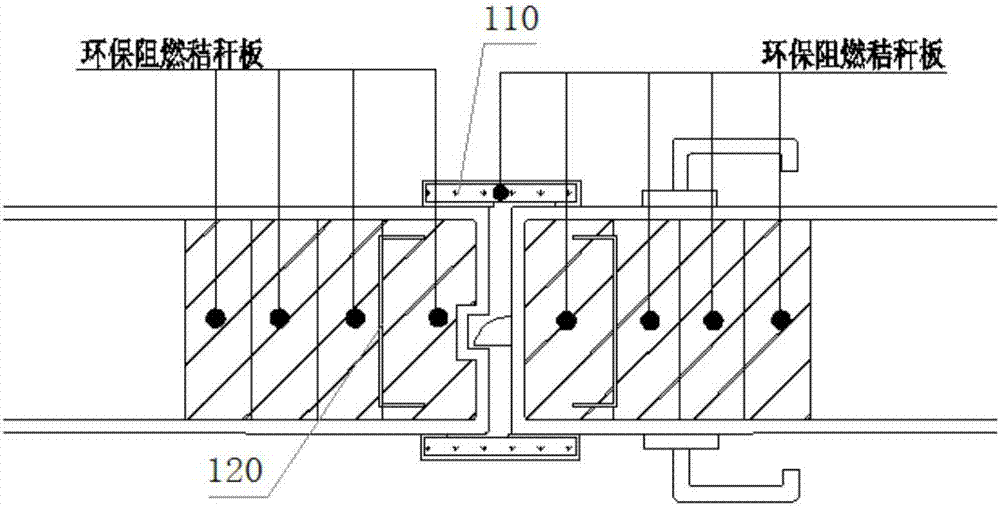

[0038] refer to figure 2 , figure 2 For the embodiment of the present invention figure 1 A-A sectional view of the fire door. The contact surfaces of the left and right door leaves of the fire door form a middle seam, and a cover seam plate 110 is arranged between the middle seam, and the seam cover plate 110 is cut from a fireproof and flame-retardant straw board; the left and right door leaves are respectively provided with four fire-proof and flame-retardant panels on the side close to the middle seam Straw boards, the other parts connected with the above-mentioned flame-retardant and fire-proof straw boards are set as steel profiles; the four flame-retardant and fire-proof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com