Self-crosslinking water-borne wood paint emulsion and synthetic method thereof

A water-based wood paint, self-crosslinking technology, used in latex paints, coatings, polyurea/polyurethane coatings, etc., can solve the problem that water-based wood coatings cannot meet the requirements of high quality, high content of volatile organic compounds, and endanger human health. and other problems, to achieve the effects of excellent gloss and color retention, low volatile organic compound content, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

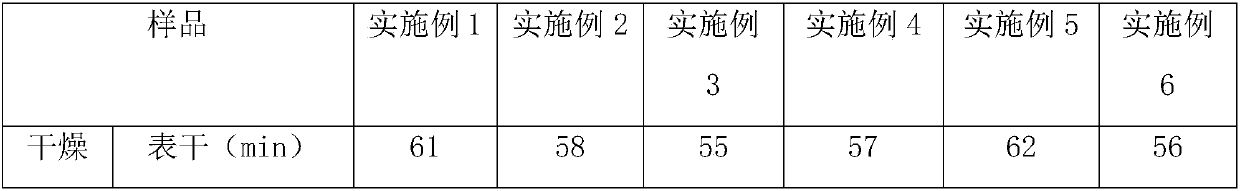

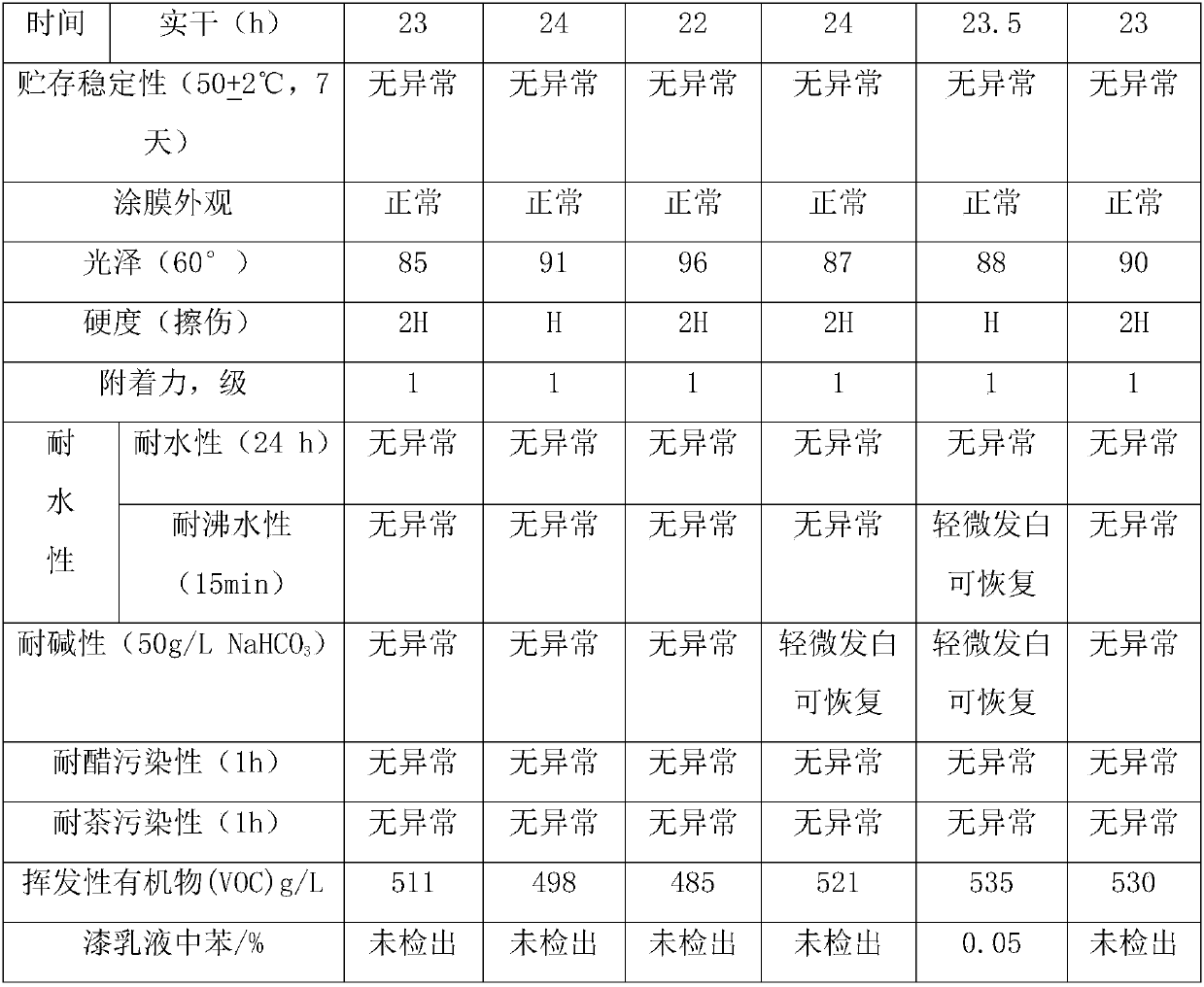

Examples

Embodiment 1

[0021] The self-crosslinking water-based wood paint emulsion of this embodiment includes the following raw materials in weight percentage: 60% of self-crosslinking type acrylic emulsion, 2% of isophorone diisocyanate, 2% of glyceryl triacetate, 10% of acrylic monomer, water-based 20% of polyurethane resin emulsion, 0.2% of sodium lauryl sulfate, 3% of nanocellulose, 0.2% of defoamer, and the balance is deionized water.

[0022] Among them, the nanocellulose is a mixture of powdered nanofibril cellulose, nanocrystalline cellulose in the form of an aqueous dispersion, and anionic nanofibrillar cellulose in the form of an aqueous dispersion; the acrylic acid monomer is acrylic acid; the defoaming agent is Polyether-modified siloxane copolymer defoamer containing fumed silica;

[0023] The synthetic method of present embodiment self-crosslinking water-based wood paint emulsion, comprises the following steps:

[0024] S1, weighing each raw material according to weight percentage; ...

Embodiment 2

[0028] The self-crosslinking water-based wood paint emulsion of this embodiment includes the following raw materials in weight percentage: 25% of self-crosslinking type acrylic emulsion, 6% of isophorone diisocyanate, 7% of glyceryl triacetate, 15% of acrylic monomer, water-based Polyurethane resin emulsion 35%, fatty acid polyoxyethylene ester 2%, nanocellulose 6%, defoamer 1.5%, and the balance is deionized water.

[0029] Among them, the nanocellulose is a mixture of nano-microcrystalline cellulose in the form of an aqueous dispersion and anionic nanofibrillar cellulose in the form of an aqueous dispersion; the acrylic monomer is methacrylic acid; the defoaming agent is fumed silica Polyether modified siloxane copolymer defoamer;

[0030] The synthetic method of present embodiment self-crosslinking water-based wood paint emulsion, comprises the following steps:

[0031] S1, weighing each raw material according to weight percentage;

[0032] S2. Put self-crosslinking acryl...

Embodiment 3

[0036] The self-crosslinking water-based wood paint emulsion of this embodiment includes the following raw materials in weight percentage: 25% of self-crosslinking type acrylic emulsion, 3% of isophorone diisocyanate, 3% of glyceryl triacetate, 15% of acrylic monomer, water-based Polyurethane resin emulsion 50%, alkylphenol polyethoxy ether ammonium sulfate 0.5%, powdered nanofibril cellulose 4%, defoamer 0.5%, and the balance is deionized water.

[0037] Wherein, the acrylic monomer is acrylic acid; the defoamer is a polyether-modified siloxane copolymer defoamer containing fumed silica;

[0038] The synthetic method of present embodiment self-crosslinking water-based wood paint emulsion, comprises the following steps:

[0039] S1, weighing each raw material according to weight percentage;

[0040] S2. Put self-crosslinking acrylic emulsion, isophorone diisocyanate, acrylic monomer, water-based polyurethane resin emulsion and deionized water into the mixer and mix them evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com