Preparation method of boiling water-resistant super-hydrophobic fabric for oil-water separation

An oil-water separation, super-hydrophobic technology, applied in separation methods, immiscible liquid separation, liquid separation and other directions, can solve the problems of complicated preparation steps, poor practicability and high production cost of super-hydrophobic materials, and achieve good super-hydrophobicity and cost. The effect of low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

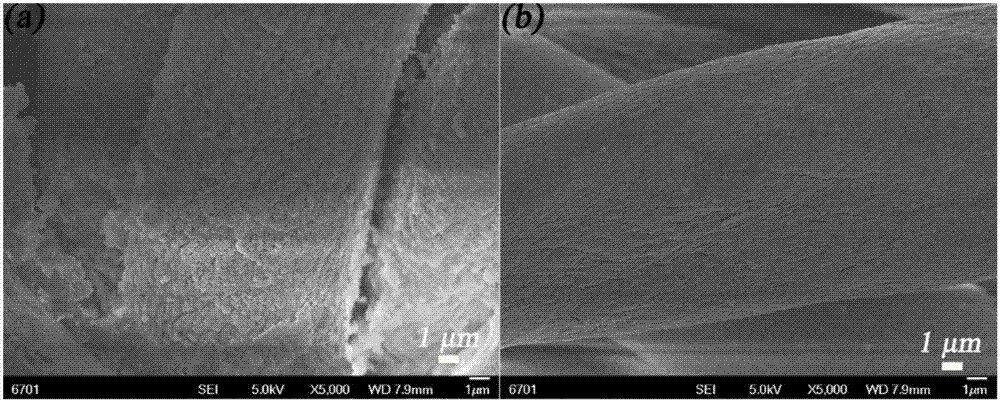

[0025] (1) Preparation of super-hydrophobic fabric: Dissolve 2 mL of tetraethyl orthosilicate in 30 mL of absolute ethanol, form a transparent solution under magnetic stirring, and then add 3 mL of 0.2M hydrochloric acid solution, and then add 0.05 g of dopamine powder Add it, stir evenly, add 4mL hexamethyldisilazane, then add 2mL concentrated ammonia water and 2mL water, add the fabric, and then react at room temperature for 24h. After the reaction is completed, take out the fabric and wash it with ethanol and dry it. Thus, the preparation of superhydrophobic fabric is completed. The scanning electron microscope picture of the obtained superhydrophobic fabric is as follows: figure 1 As shown, it can be found that the fabric fibers are tightly packed.

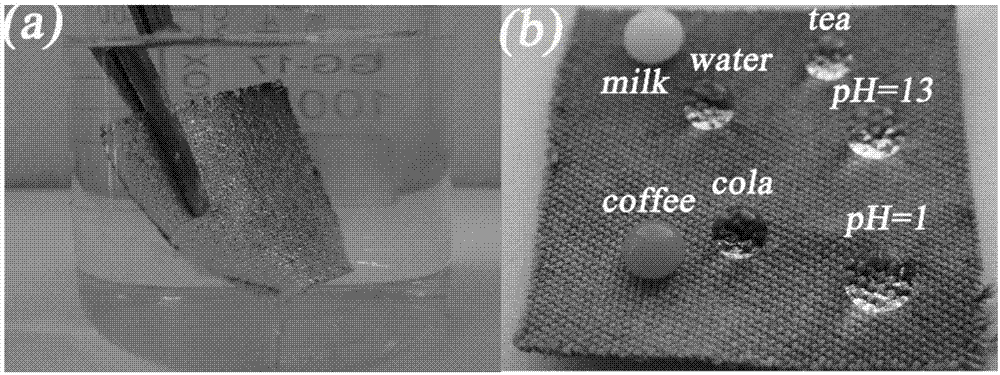

[0026] (2) Superhydrophobic properties of the prepared superhydrophobic fabric: the superhydrophobic fabric has good hydrophobic properties, such as figure 2 As shown, picture (a) is a picture of the silver mirror phenomeno...

Embodiment 2

[0031] Preparation of superhydrophobic fabric: Dissolve 10mL tetraethyl orthosilicate in 50mL absolute ethanol, form a transparent solution under magnetic stirring, after that, add 6mL 0.2M hydrochloric acid solution, and then add 0.1g dopamine powder, After stirring evenly, add 3mL hexamethyldisilazane to it, then add 4mL concentrated ammonia water and 2mL water, add the fabric, then react at room temperature for 24h, after the reaction is completed, take out the fabric and wash it with ethanol and dry it to complete the super Preparation of hydrophobic fabrics.

Embodiment 3

[0033] Preparation of superhydrophobic fabric: Dissolve 1mL tetraethyl orthosilicate in 20mL absolute ethanol, form a transparent solution under magnetic stirring, after that, add 1mL0.1M hydrochloric acid solution to it, and then add 0.05g dopamine powder to it, After stirring evenly, add 2mL hexamethyldisilazane to it, then add 2mL concentrated ammonia water and 2mL water, add the fabric, then react at room temperature for 24h, after the reaction is completed, take out the fabric and wash it with ethanol and dry it to complete the super Preparation of hydrophobic fabrics.

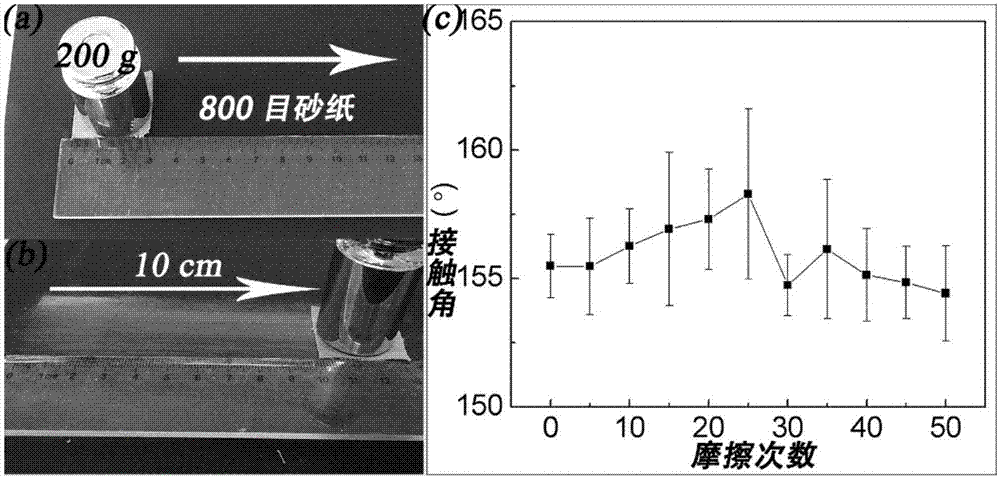

[0034] The present invention includes a one-pot process for preparing superhydrophobic fabrics. The superhydrophobic fabric has good stability, the contact angle to water is greater than 150°, and the rolling angle is less than 10°. It also has good anti-wetting ability for common water-based liquids in daily life, and can last a long time in boiling water. maintain superhydrophobic properties. The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com