Vegetable oil-based flame-retardant polyurethane acrylate prepolymer as well as preparation method and application thereof

A polyurethane acrylate and vegetable oil-based technology, which is applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, applications, etc., can solve the problems of flammability hindering the use of coatings and limiting the scope of application, and achieve good acid resistance Alkali and boiling water resistance, expanded application range, and improved crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the vegetable oil-based flame-retardant polyurethane acrylate prepolymer of the present embodiment comprises the steps:

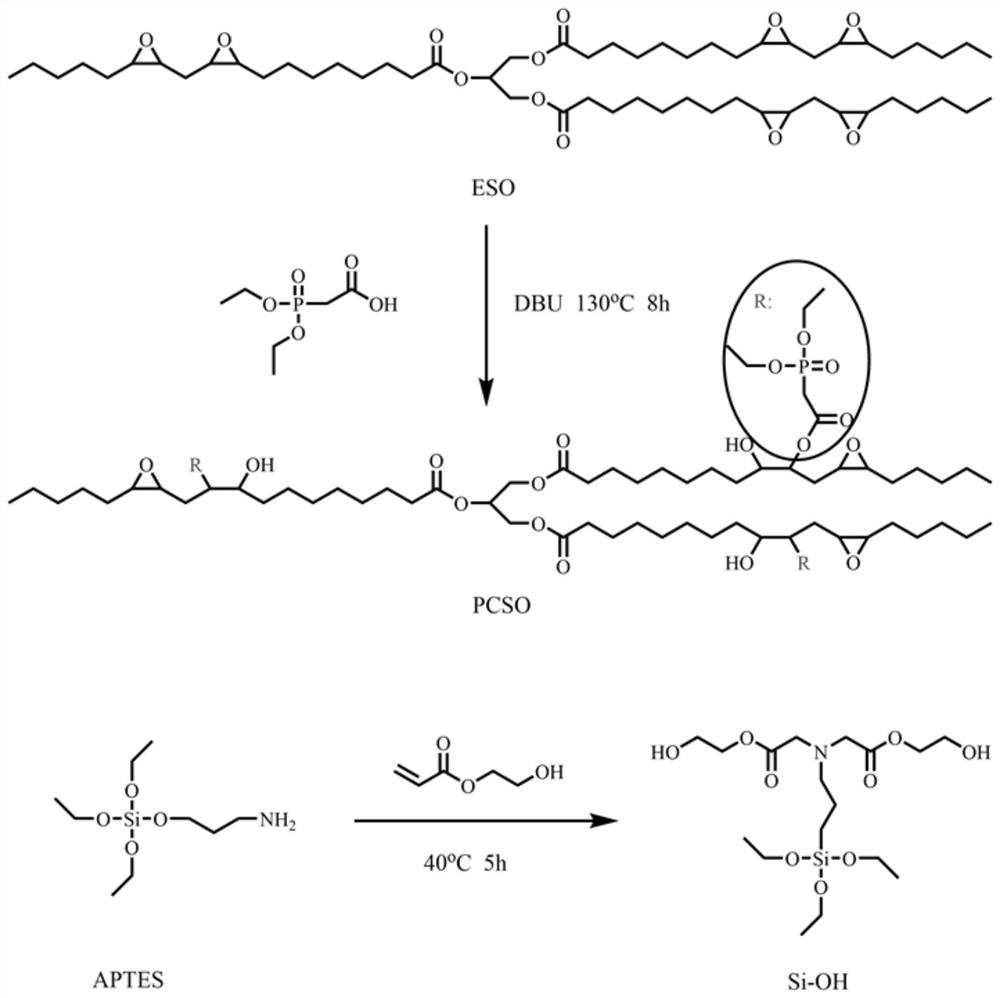

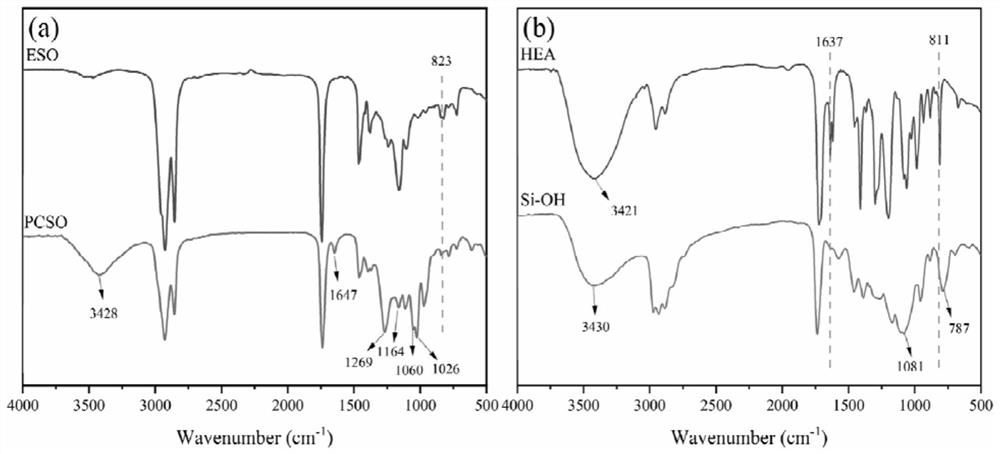

[0041] (1) in reactor, add 10.00g epoxidized soybean oil (ESO), 6.03g diethylphosphonoacetic acid and the catalyst 1 of 1% of total feeding weight 1,8-diazabicycloundec-7-ene ( DBU), the molar ratio between the epoxy group in epoxidized soybean oil and the carboxylic acid group in diethylphosphoacetic acid is 1:3, stir evenly and heat up to 130°C, react for 8h, and obtain bio-based Phosphorus polyol (PCSO).

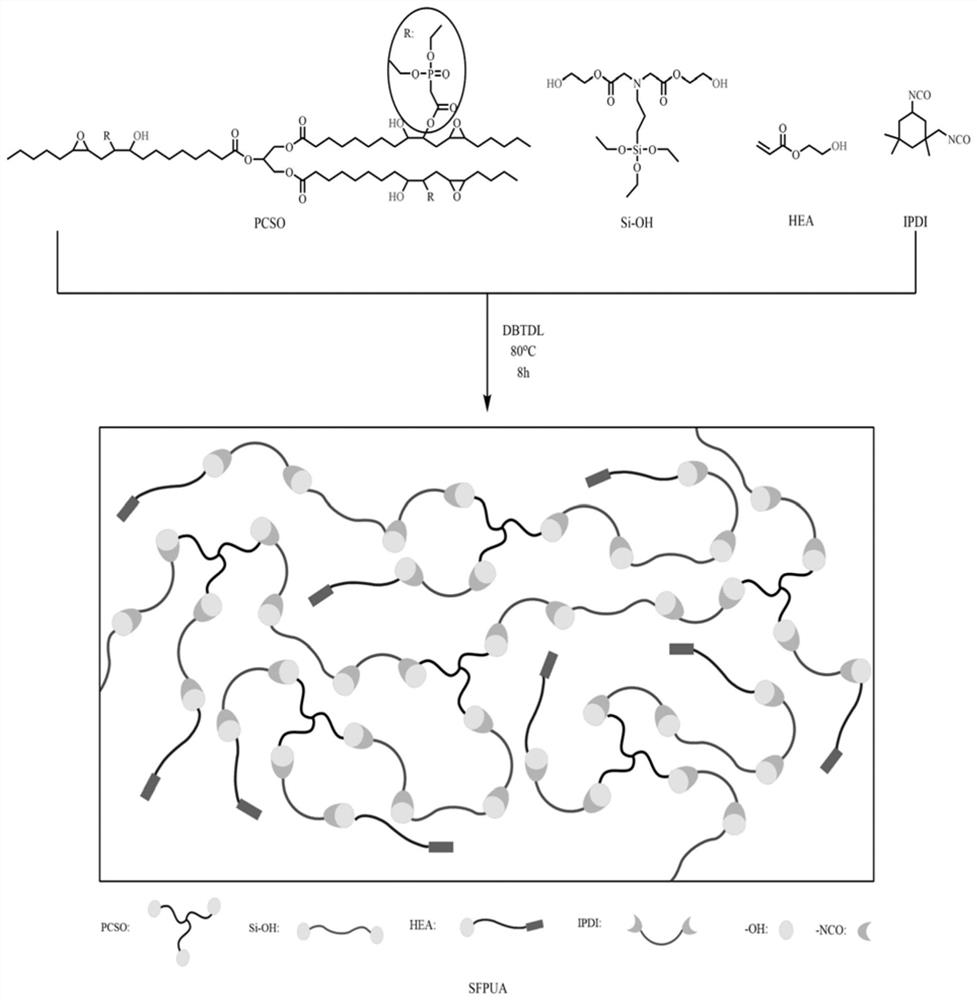

[0042] (2) At room temperature, mix 1g of hydroxyethyl acrylate (HEA) with 13.46g of the bio-based phosphorus-containing polyol (PCSO) obtained in step (1), and then mix 3.83g of isophorone diisocyanate (IPDI) And the catalyst dibutyltin dilaurate (DBTDL) of 1% of total feed weight is slowly dripped, then add the polymerization inhibitor hydroquinone of 0.5% of total feed weight, stir, the isophorone diisocyanate isocy...

Embodiment 2

[0044] The preparation method of the vegetable oil-based flame-retardant polyurethane acrylate prepolymer of the present embodiment comprises the steps:

[0045] (1) in reactor, add 10.00g epoxidized soybean oil (ESO), 6.03g diethylphosphonoacetic acid and the catalyst 1 of 1% of total feeding weight 1,8-diazabicycloundec-7-ene ( DBU), the molar ratio between the epoxy group in epoxidized soybean oil and the carboxylic acid group in diethylphosphoacetic acid is 1:3, stir evenly and heat up to 130°C, react for 8h, and obtain bio-based Phosphorus polyol (PCSO).

[0046] (2) Add 10.00g 3-aminopropyltriethoxysilane (APTES) and 10.49g hydroxyethyl acrylate (HEA) in the reactor, the primary amino group in 3-aminopropyltriethoxysilane and The molar ratio between the double bond groups in hydroxyethyl acrylate is 1:2, stir evenly and raise the temperature to 40°C, react for 5h, and obtain the silicon-containing monomer (Si-OH).

[0047] (3) At room temperature, mix 1g of hydroxyethy...

Embodiment 3

[0050] The preparation method of the vegetable oil-based flame-retardant polyurethane acrylate prepolymer of the present embodiment comprises the steps:

[0051] (1) in reactor, add 10.00g epoxidized soybean oil (ESO), 6.03g diethylphosphonoacetic acid and the catalyst 1 of 1% of total feeding weight 1,8-diazabicycloundec-7-ene ( DBU), the molar ratio between the epoxy group in epoxidized soybean oil and the carboxylic acid group in diethylphosphoacetic acid is 1:3, stir evenly and heat up to 130°C, react for 8h, and obtain bio-based Phosphorus polyol (PCSO).

[0052] (2) Add 10.00g 3-aminopropyltriethoxysilane (APTES) and 10.49g hydroxyethyl acrylate (HEA) in the reactor, the primary amino group in 3-aminopropyltriethoxysilane and The molar ratio between the double bond groups in hydroxyethyl acrylate is 1:2, stir evenly and raise the temperature to 40°C, react for 5h, and obtain the silicon-containing monomer (Si-OH).

[0053] (3) At room temperature, mix 1g of hydroxyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com