Tough soybean protein adhesive as well as preparation method and application thereof

A soybean protein and adhesive technology, used in the preparation of protein adhesives, animal glue or gelatin, and adhesives, etc., can solve the problems of poor bonding ability, poor water resistance, excessive formaldehyde content, etc. The effect of increasing the homogenization time and improving the water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of soybean meal dispersion

[0030] The preparation method is as follows:

[0031] (1) pulverizing the soybean meal to pass 200 meshes, then dispersing the soybean meal powder in water to prepare a soybean meal dispersion liquid with a mass concentration of 10%;

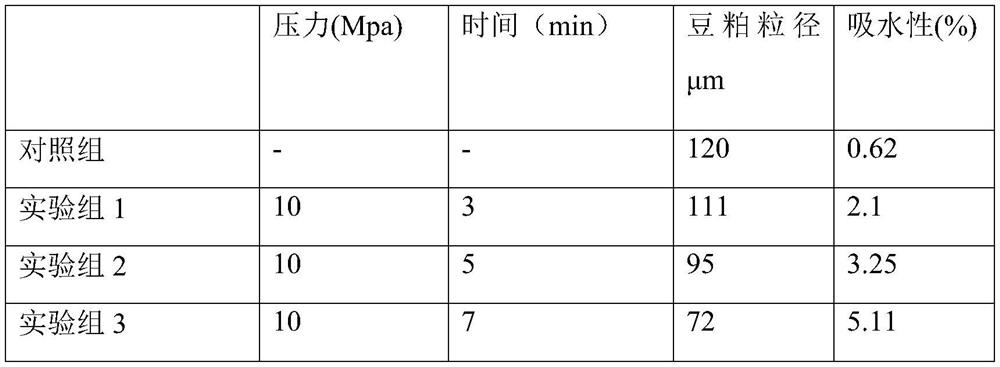

[0032] (2) utilize the homogenizer of high pressure shearing to process the soybean meal dispersion, and the homogenization pressure and time are as shown in Table 1;

[0033] (3) Measure the particle size and water absorption of soybean meal in the soybean meal dispersion obtained in each experimental group.

[0034] Table 1

[0035]

[0036]

[0037] Among them, the control group is the soybean meal dispersion without treatment.

[0038] The water absorption test method is as follows:

[0039] Step 1. Dry the samples of each experimental group in Table 1 to obtain the solidified protein samples and weigh them;

[0040] Step 2. Put the cured protein sample in a constant tempe...

Embodiment 2-5

[0049] Embodiments 2-5 relate to a tough soybean protein adhesive and a preparation method.

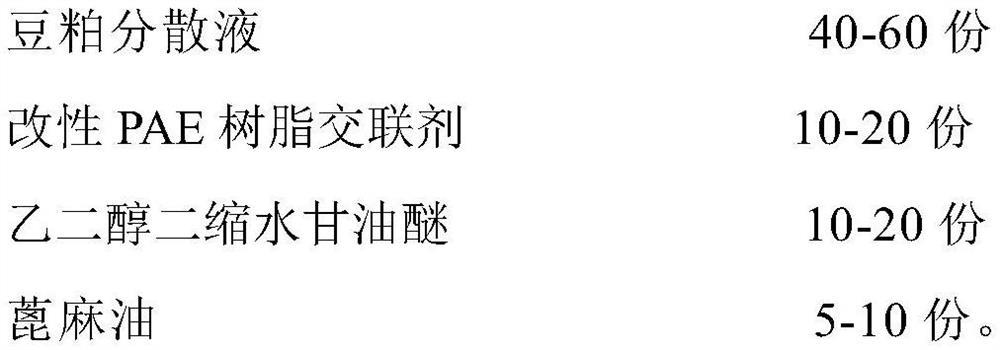

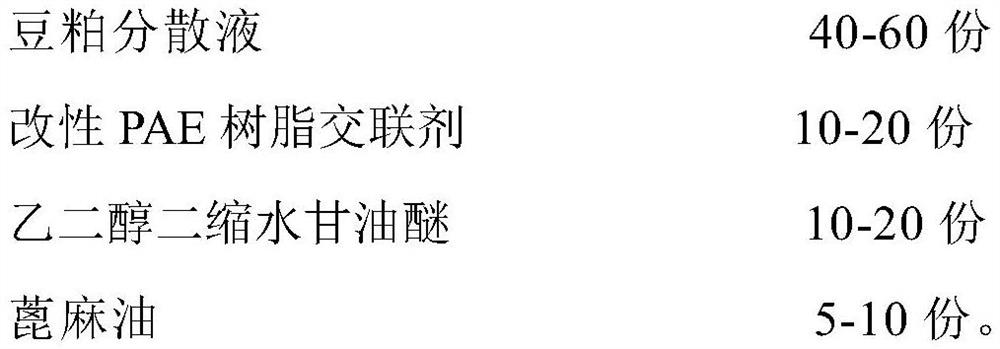

[0050] 1. Tough soybean protein adhesive formula

[0051] The components and amounts of the tough soybean protein adhesives of Examples 2-6 are shown in Table 1, and "-" in Table 1 indicates that they are not added.

[0052] Table 1 (unit: parts by weight)

[0053]

[0054] Among them, the soybean meal dispersion was prepared by the method provided in Test Group 7 of Example 1.

[0055] The preparation method of the modified PAE resin crosslinking agent comprises the following steps:

[0056] Step 1, preparation of polyamide polyamine intermediate: add adipic acid and diethylene triamine into the reaction kettle, after the raw materials are completely mixed, stir evenly, heat up to 150-180 ° C, and evaporate the water in the solution , after evaporating the water to dryness, immediately stop heating, add a certain proportion of water to adjust the solid content to 20-30wt% when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com