Patents

Literature

33 results about "Schrader valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Schrader valve (also called American valve) is a type of pneumatic tire valve used on virtually every motor vehicle in the world today. The Schrader company, for which it was named, was founded in 1844 by August Schrader. The original Schrader valve design was invented in 1891, and patented in the United States in 1893.

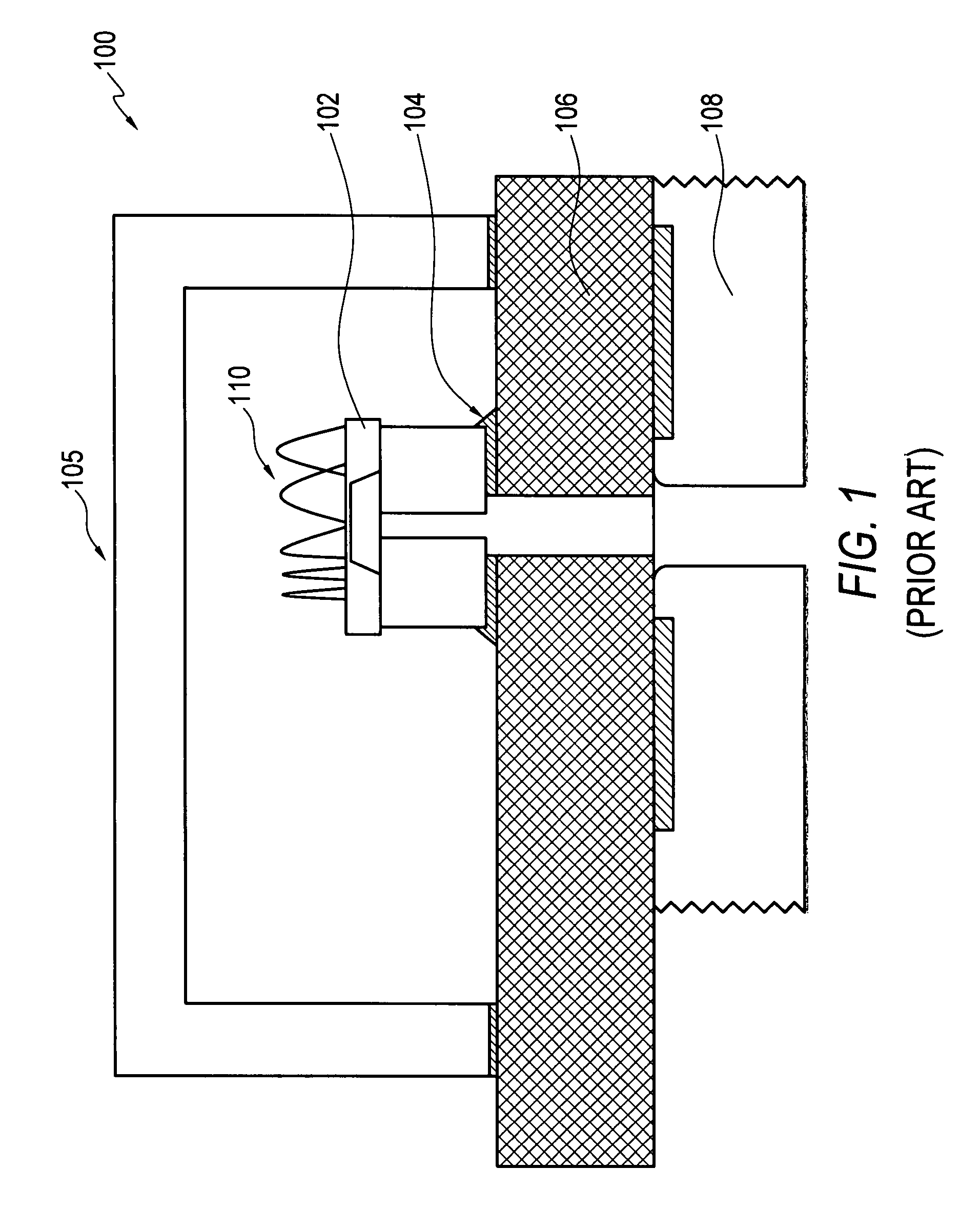

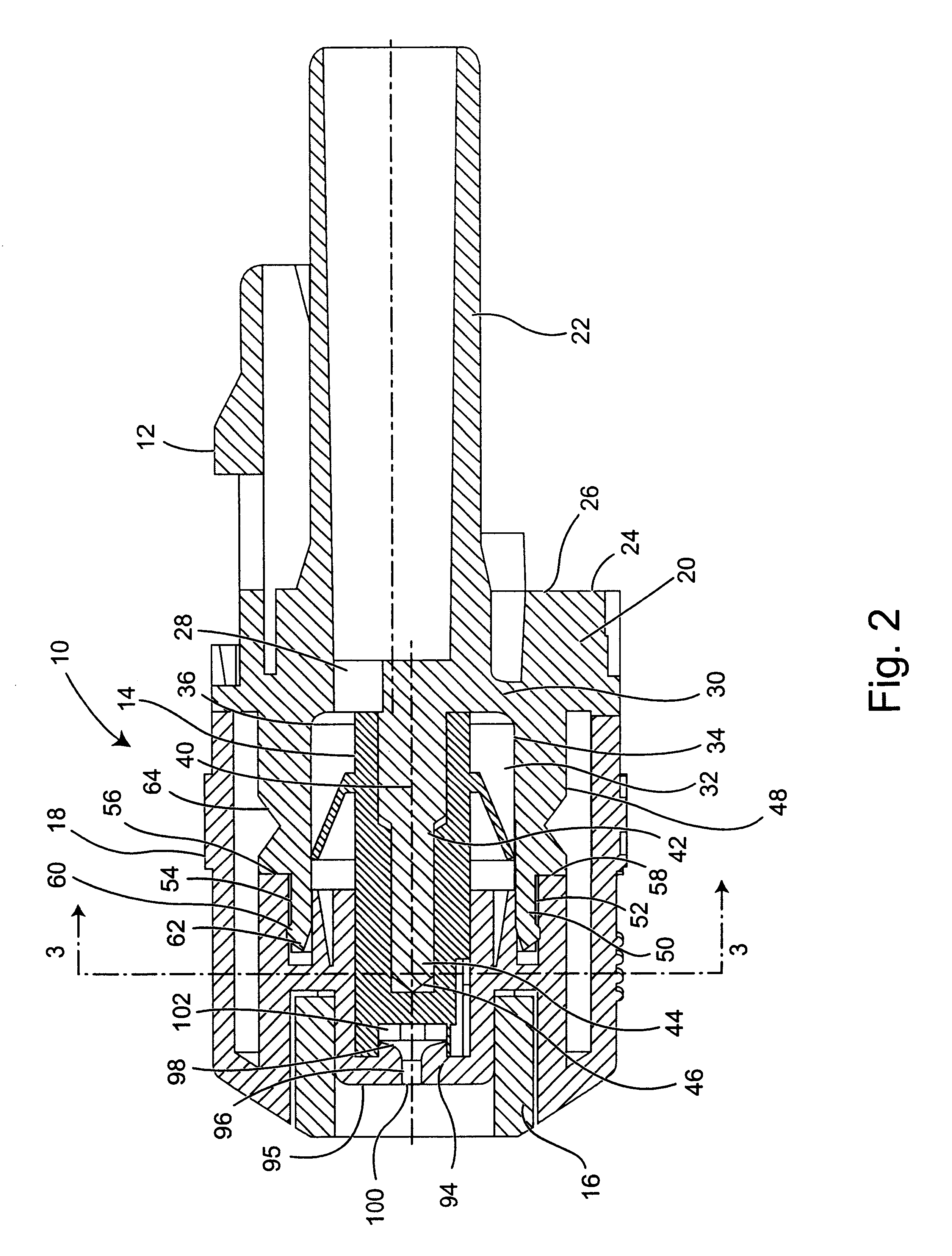

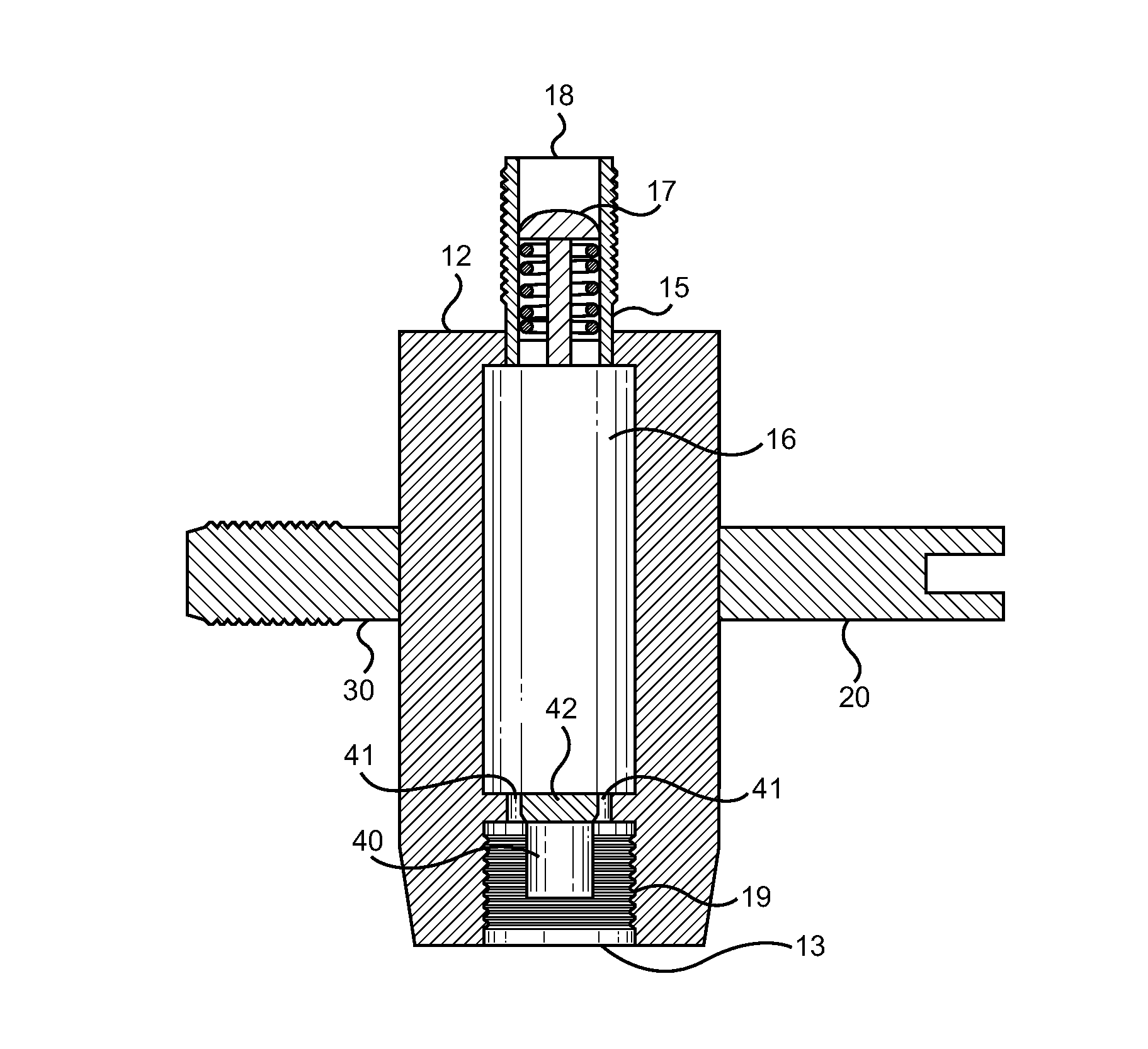

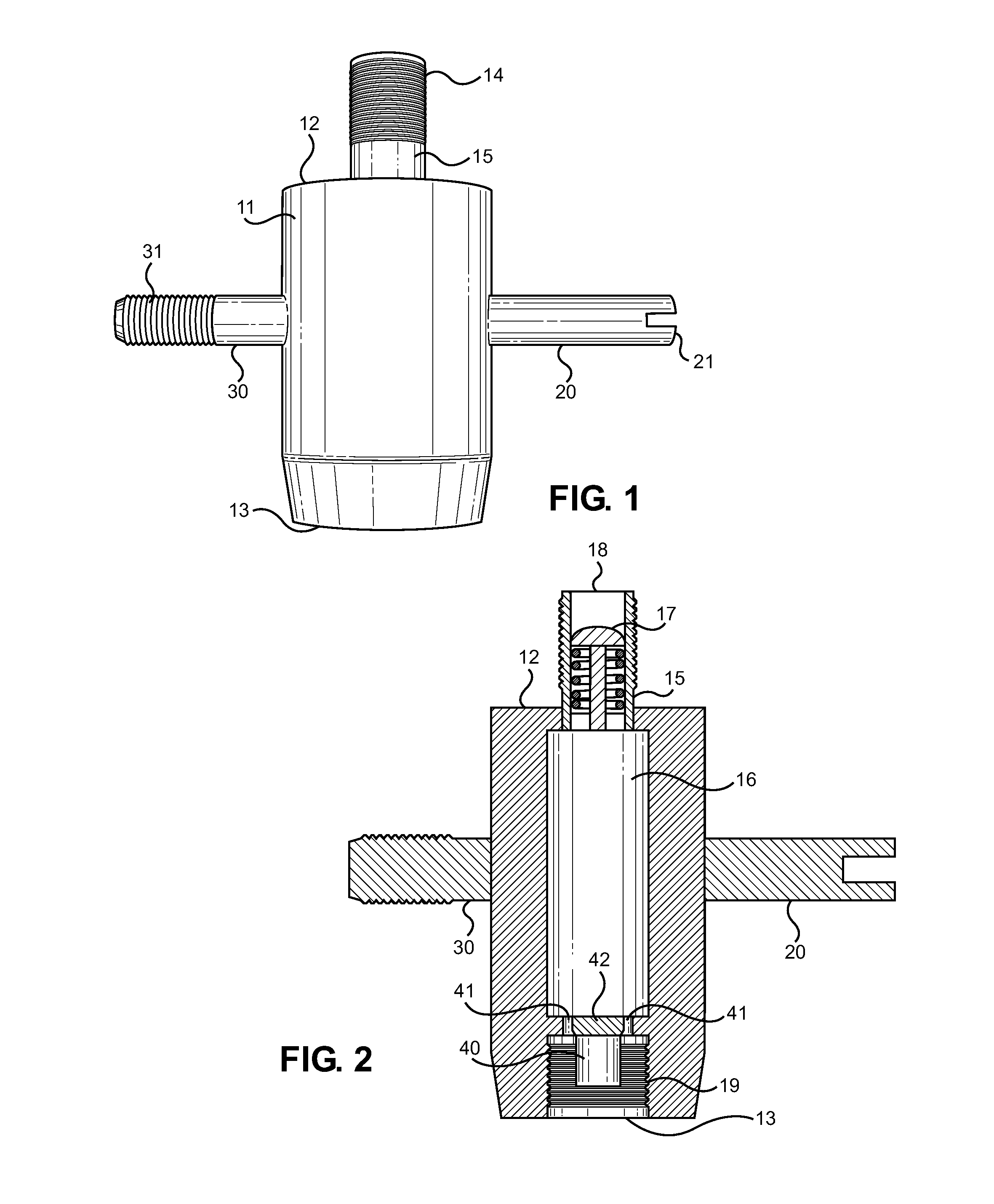

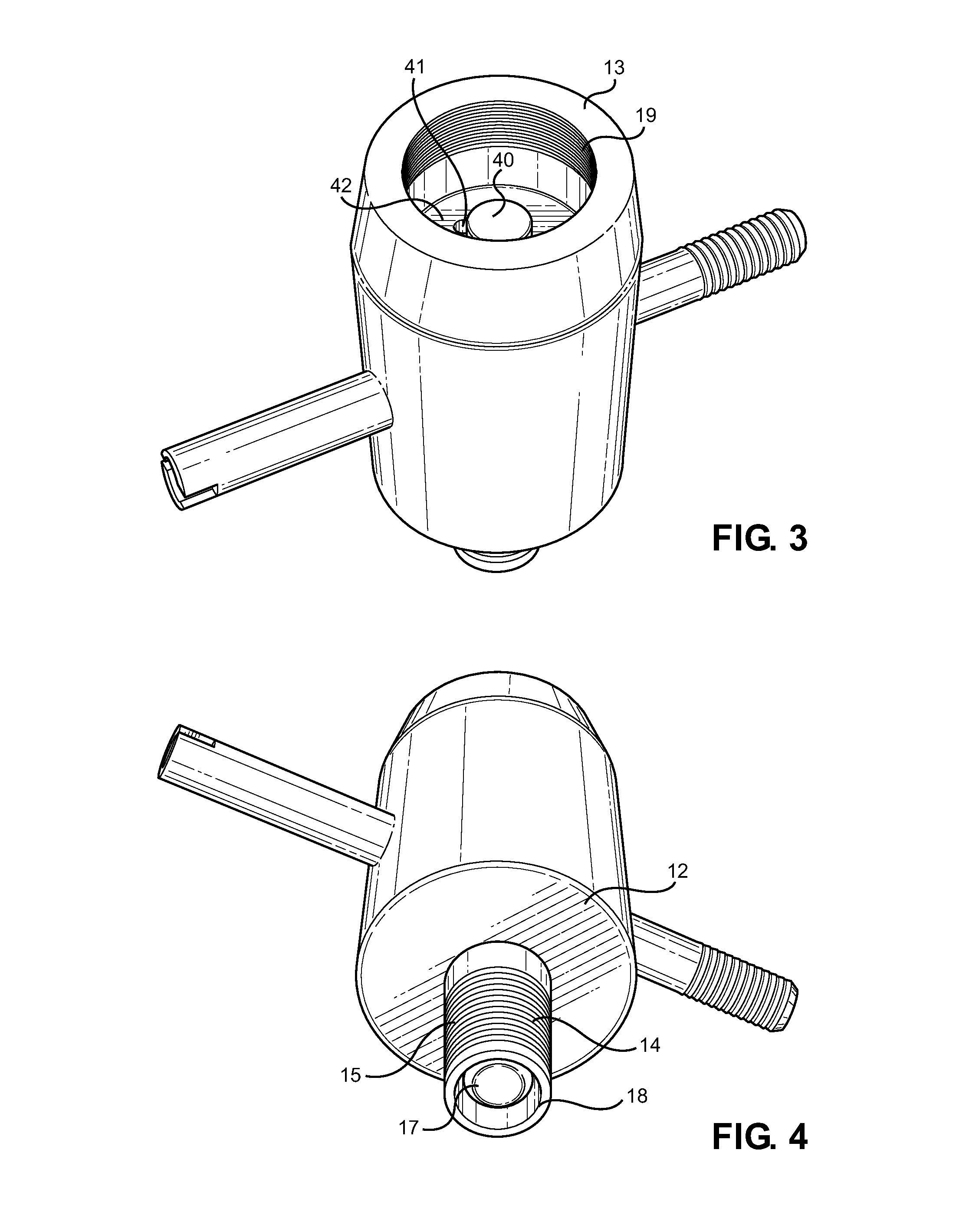

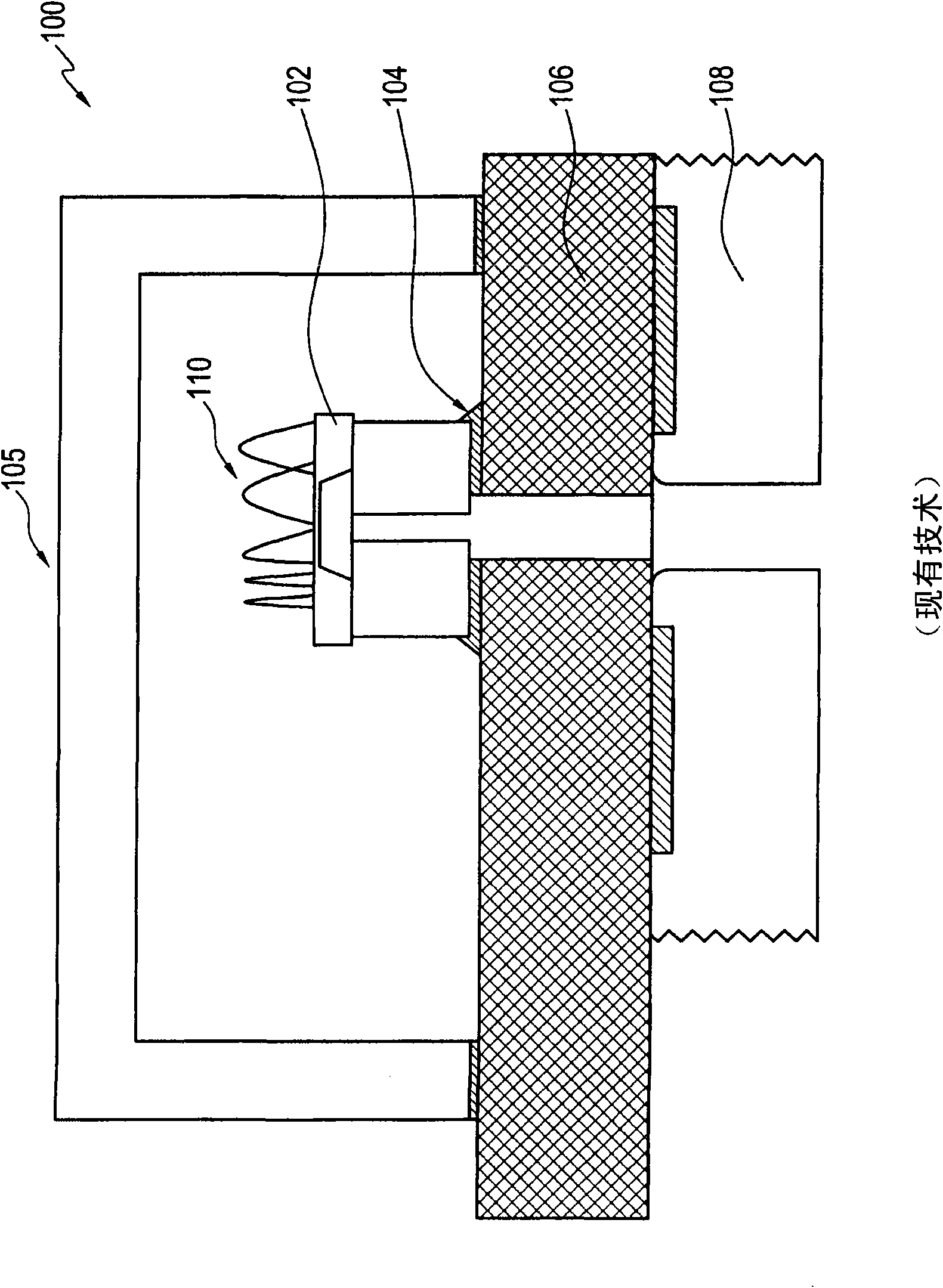

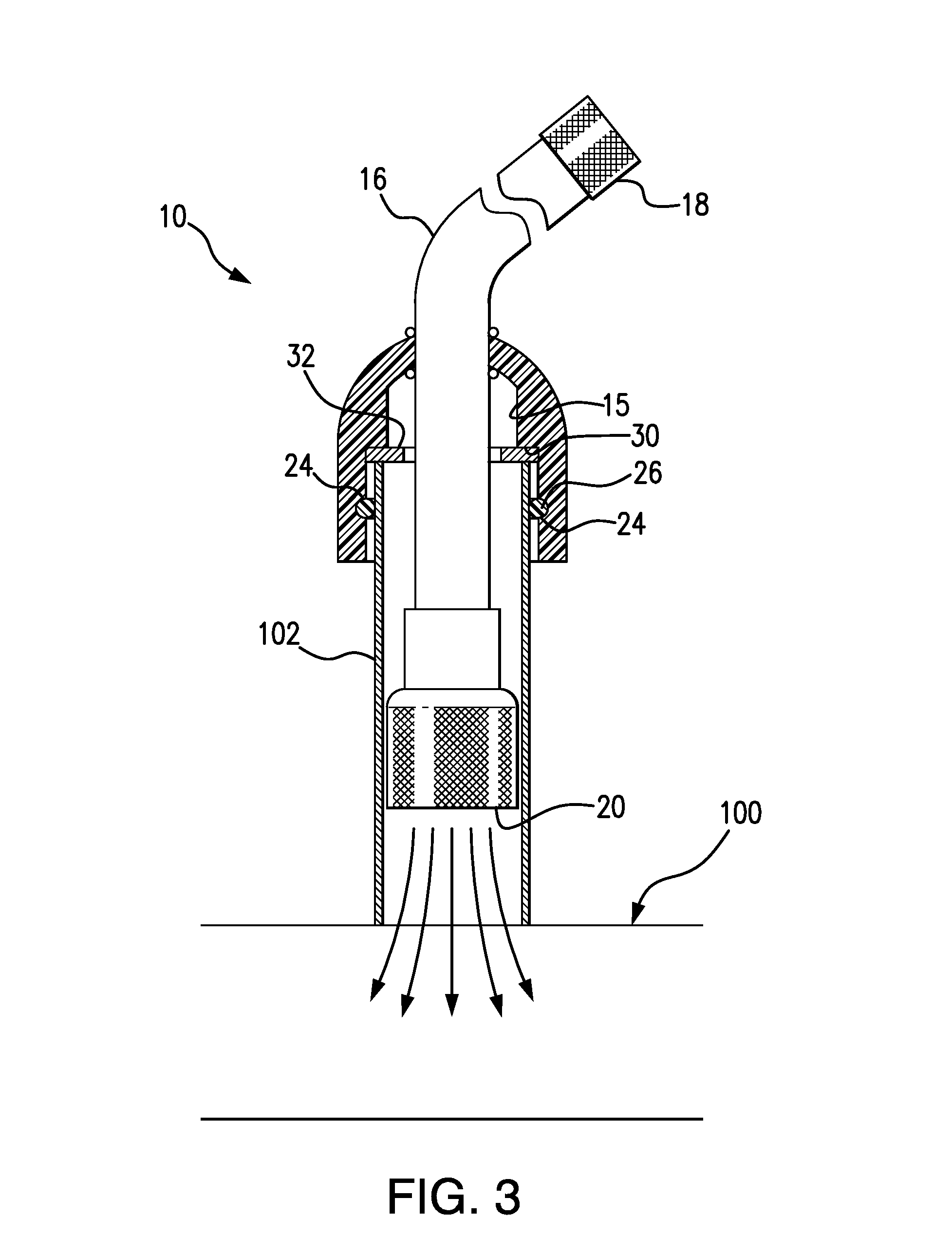

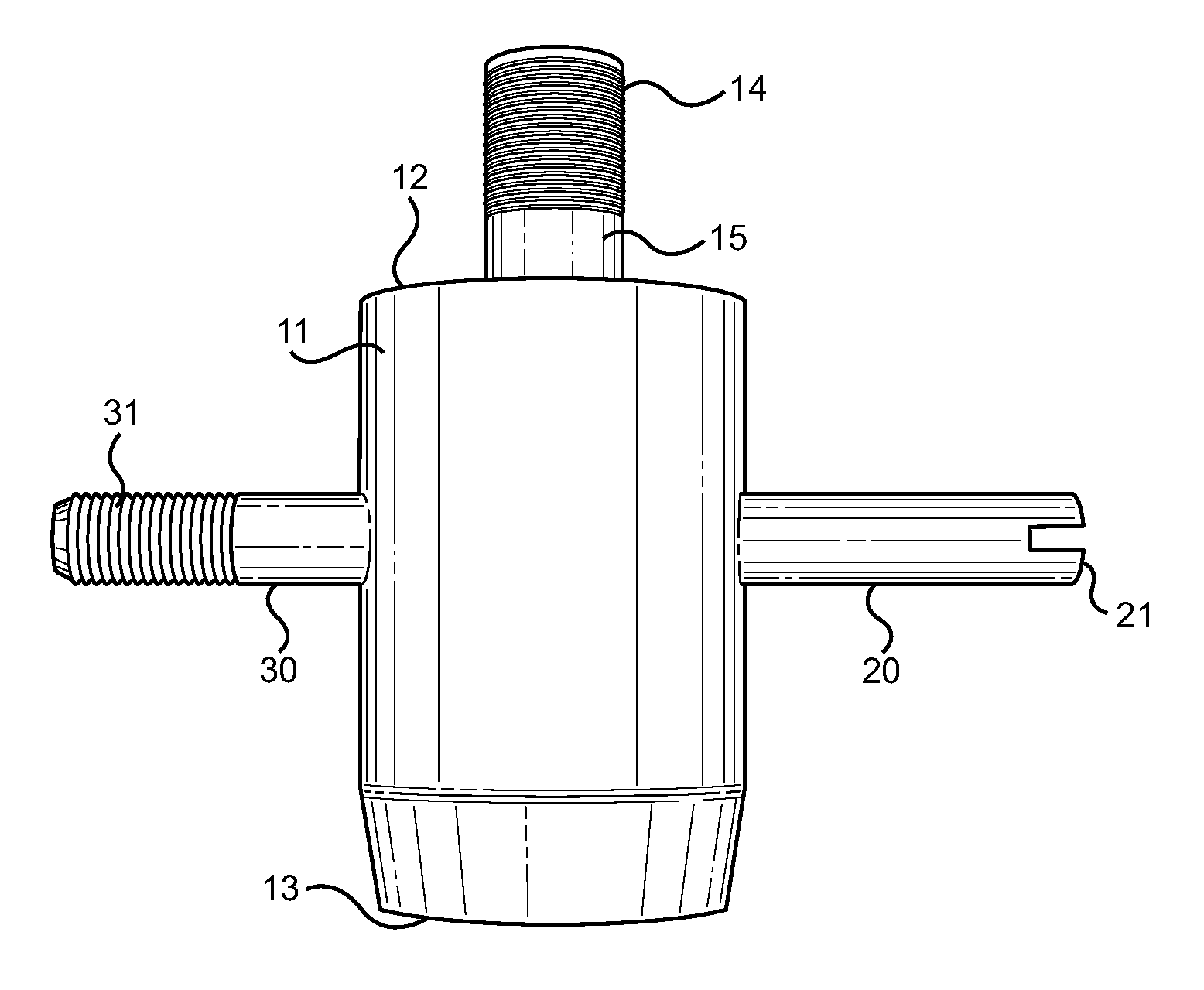

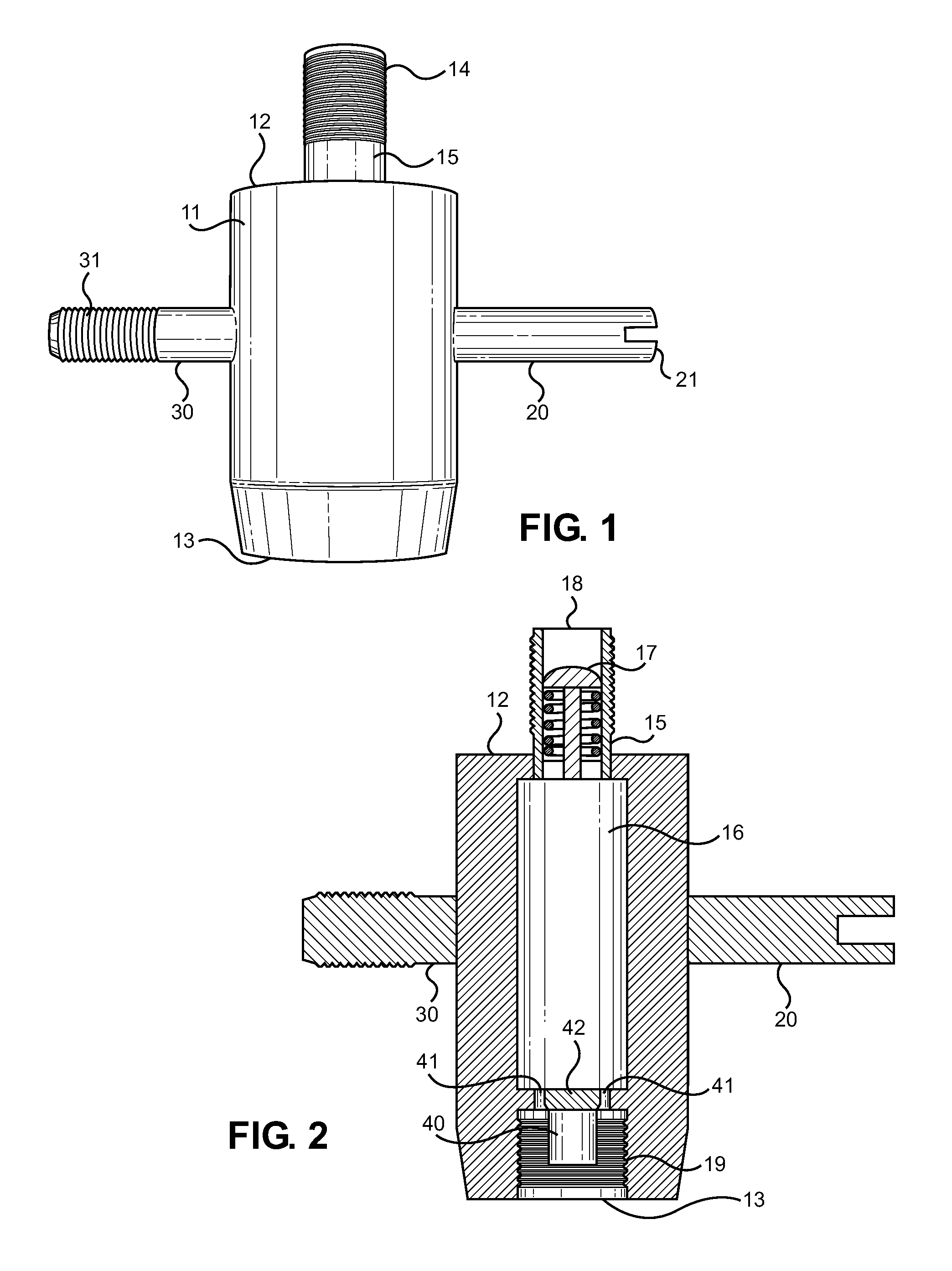

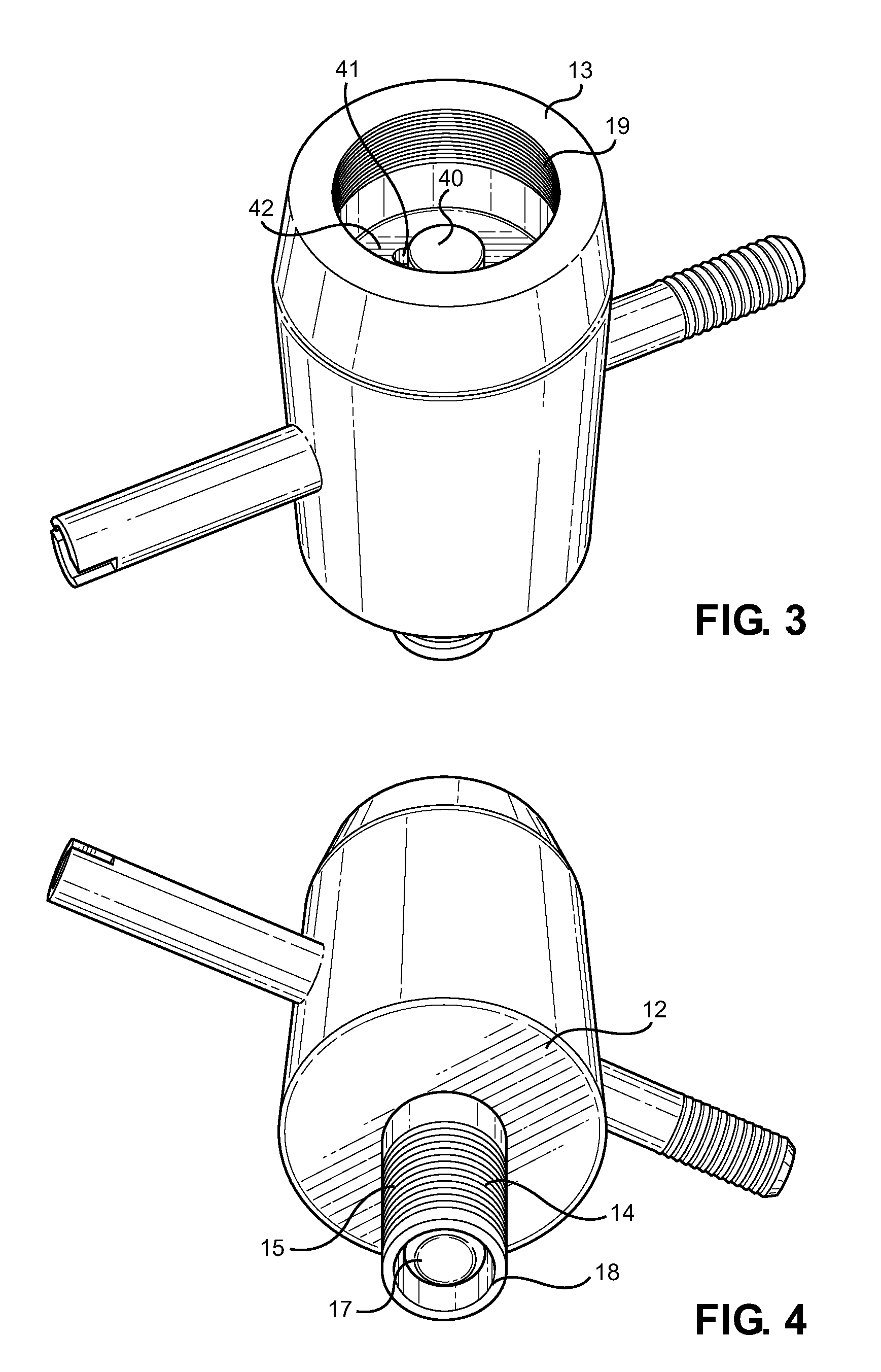

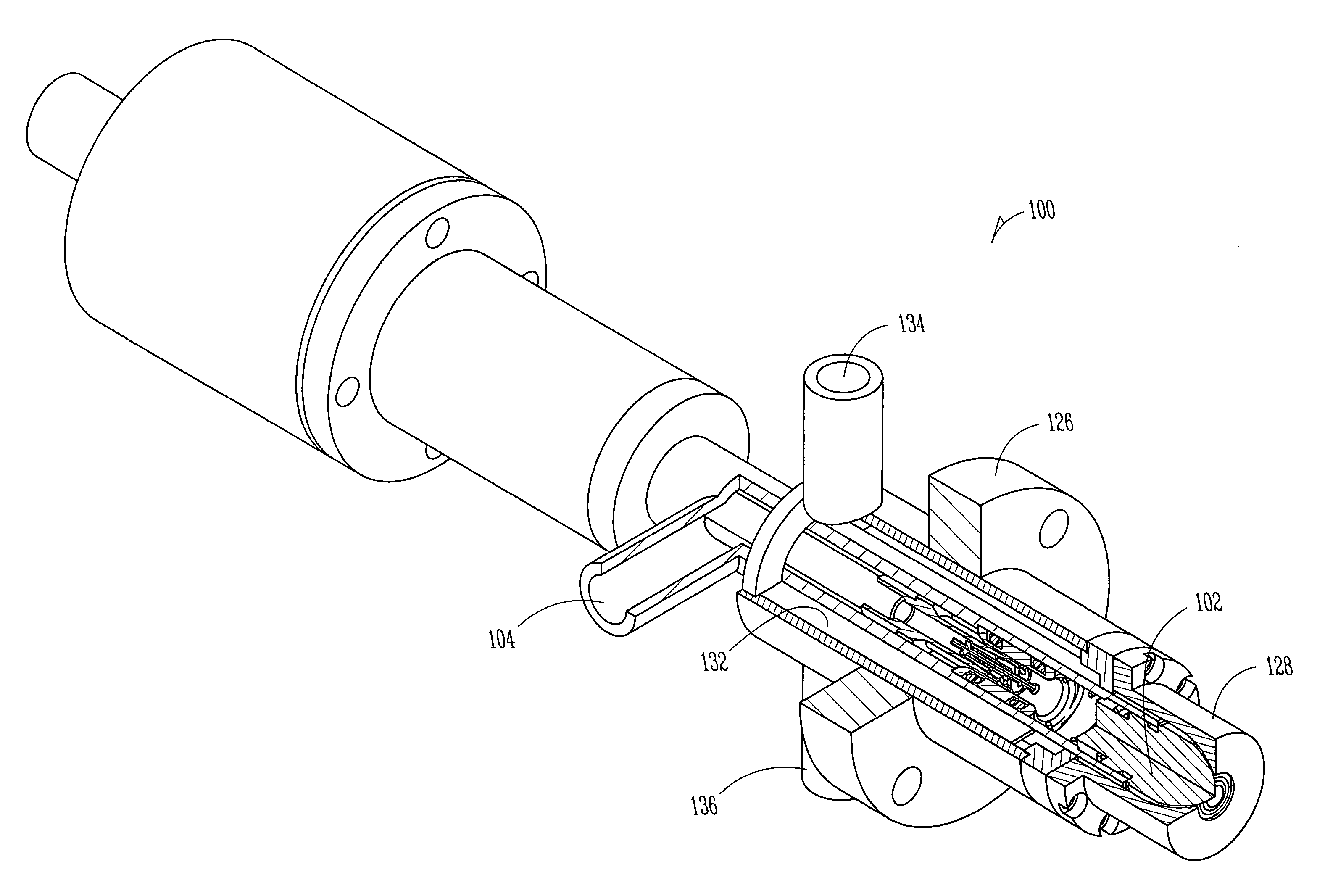

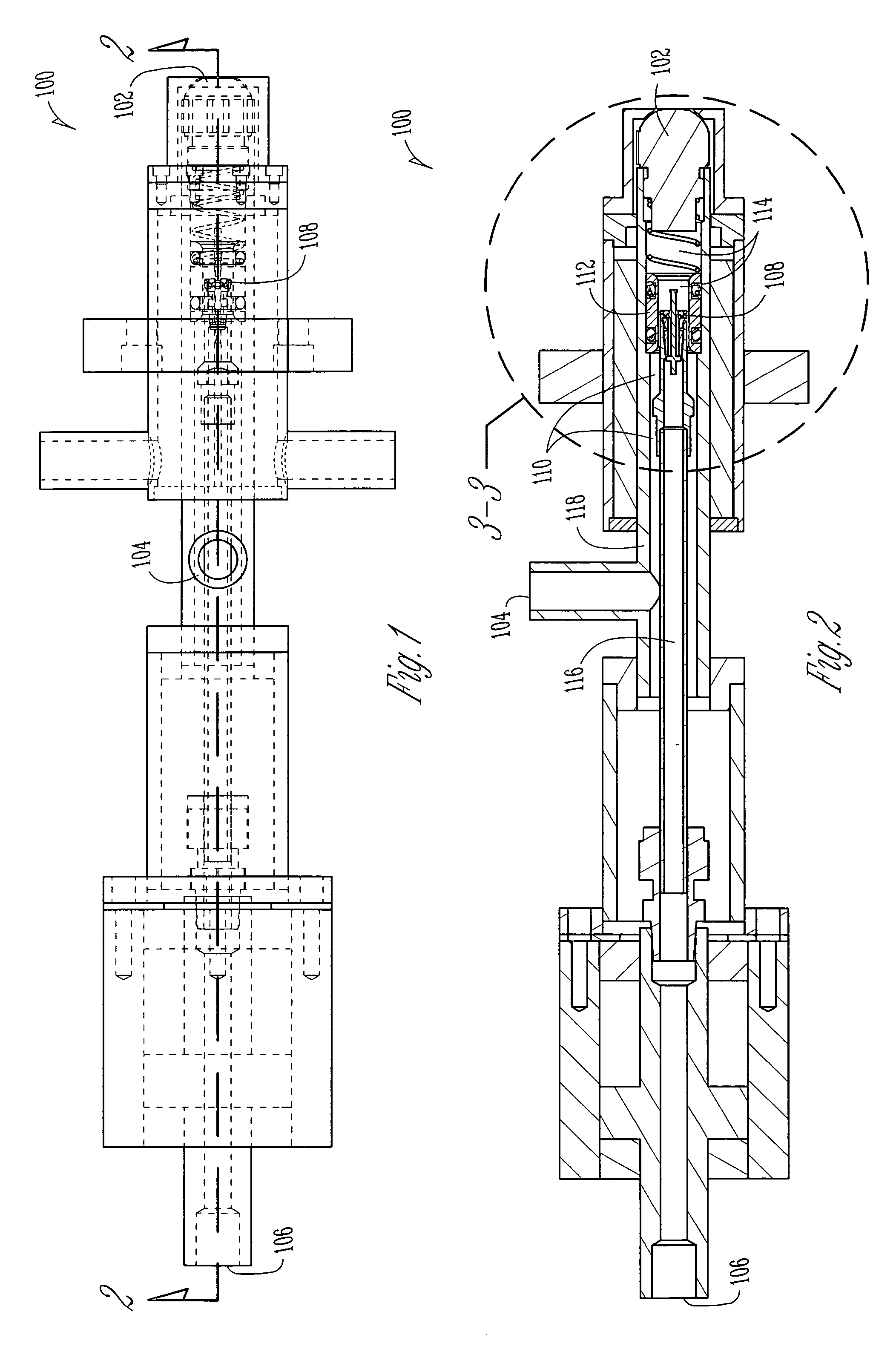

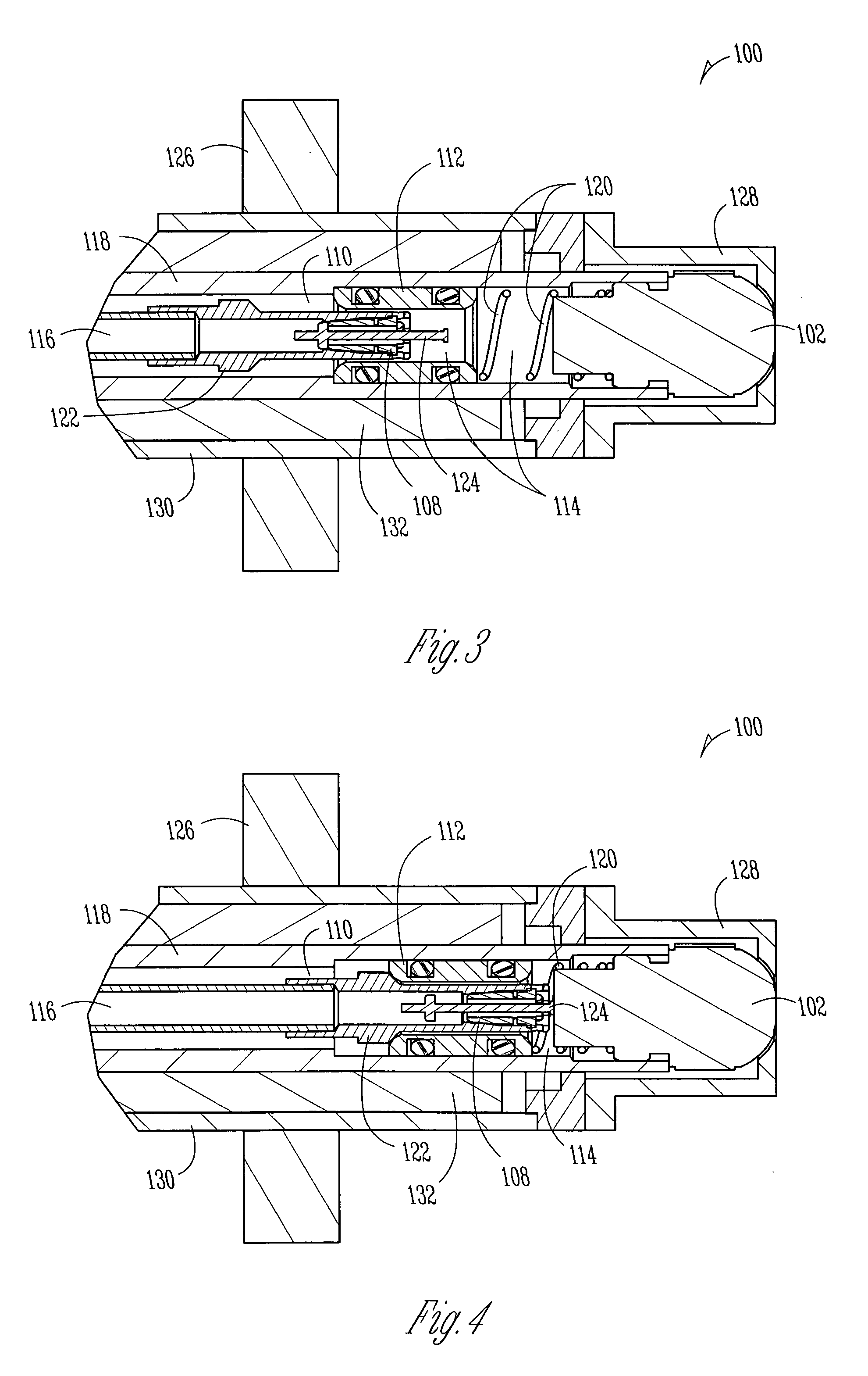

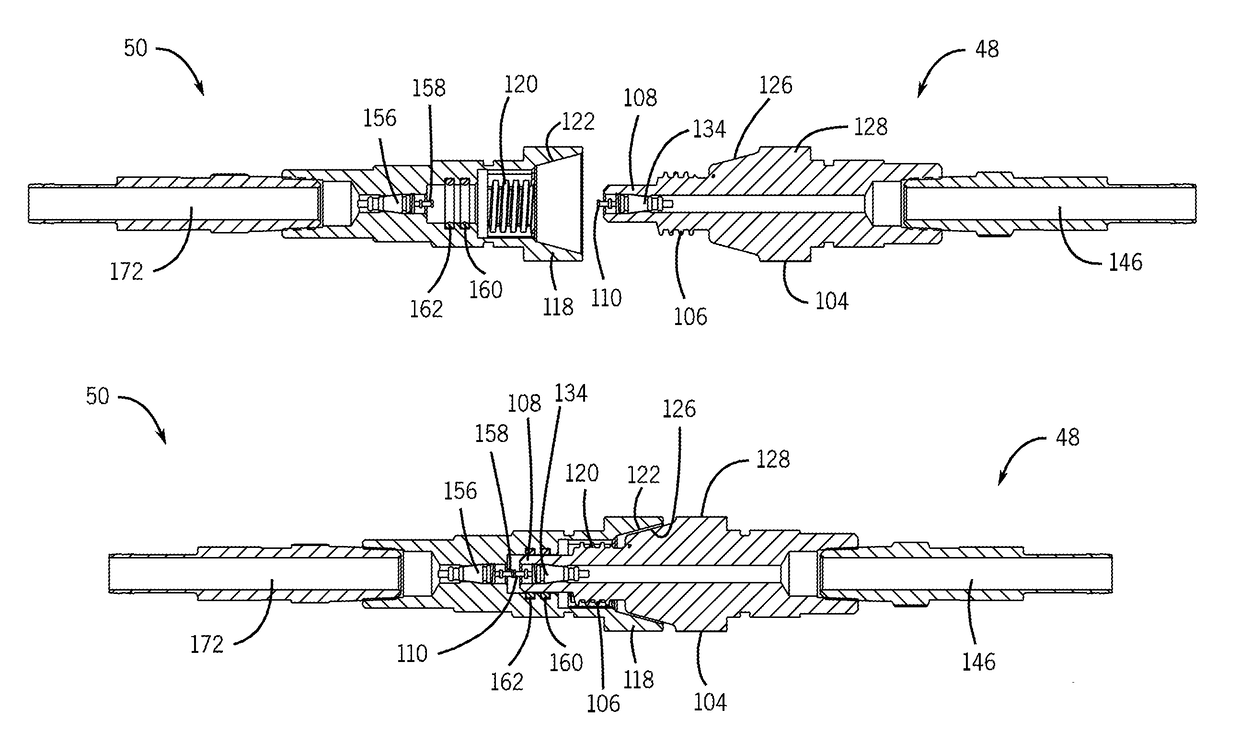

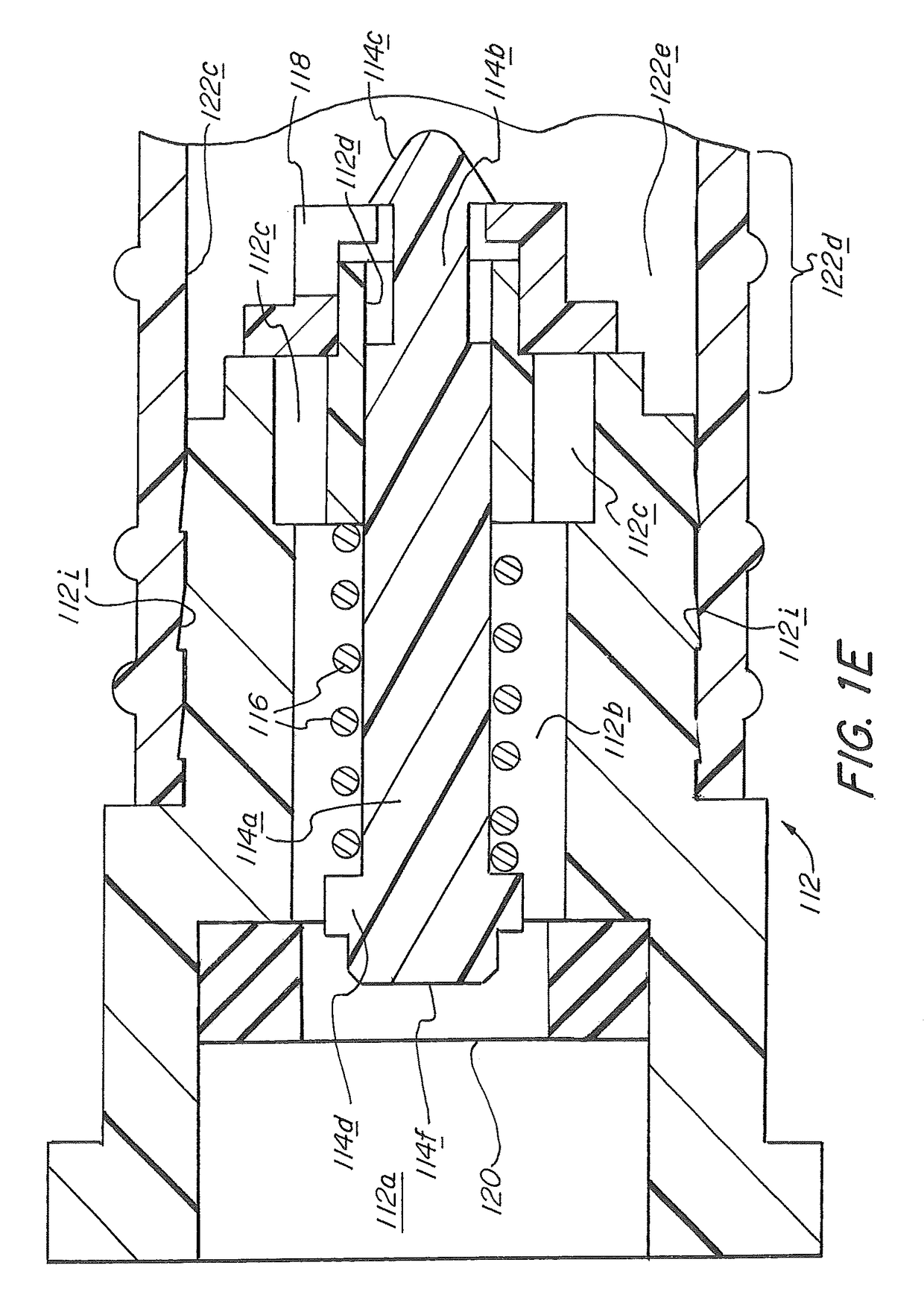

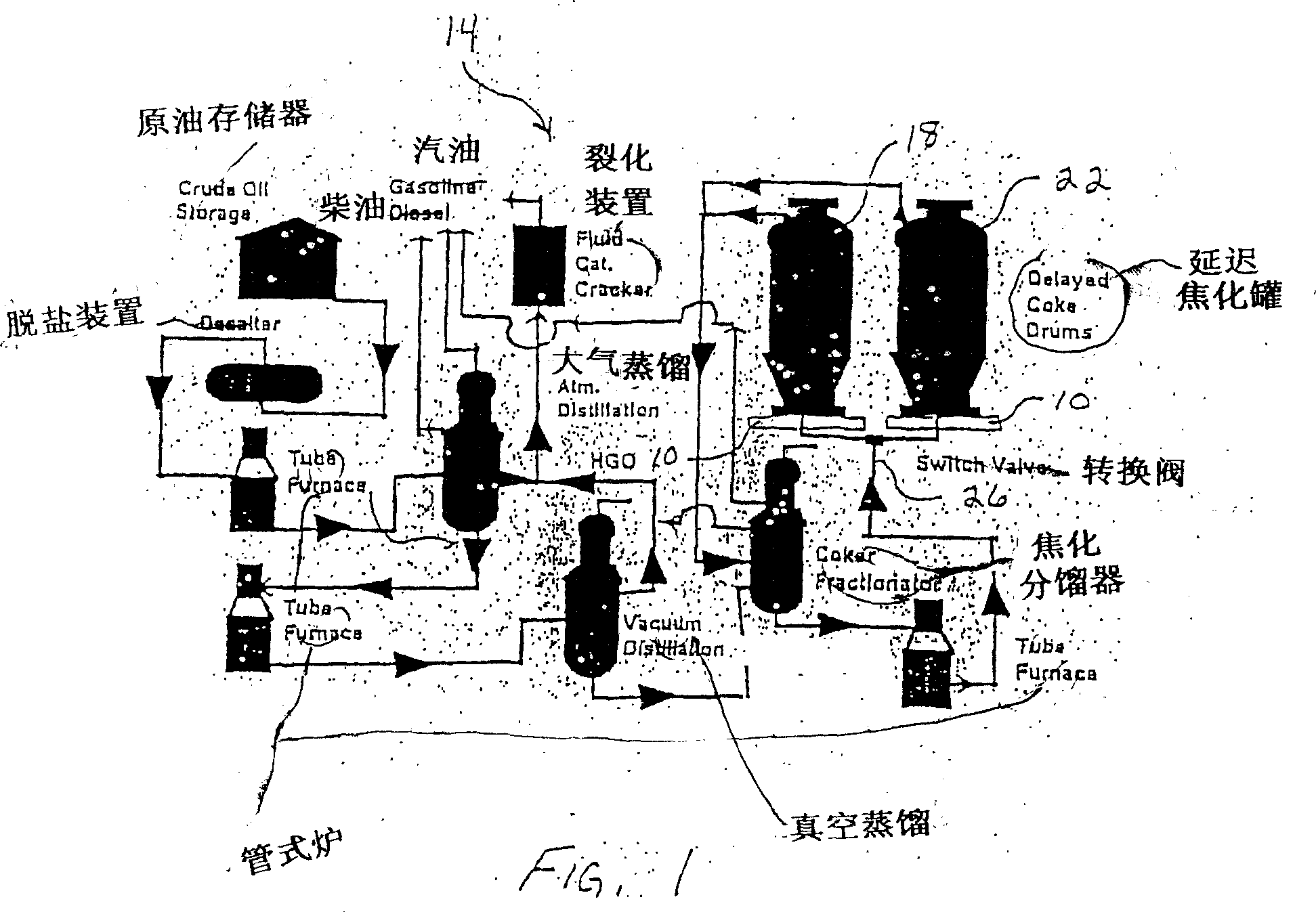

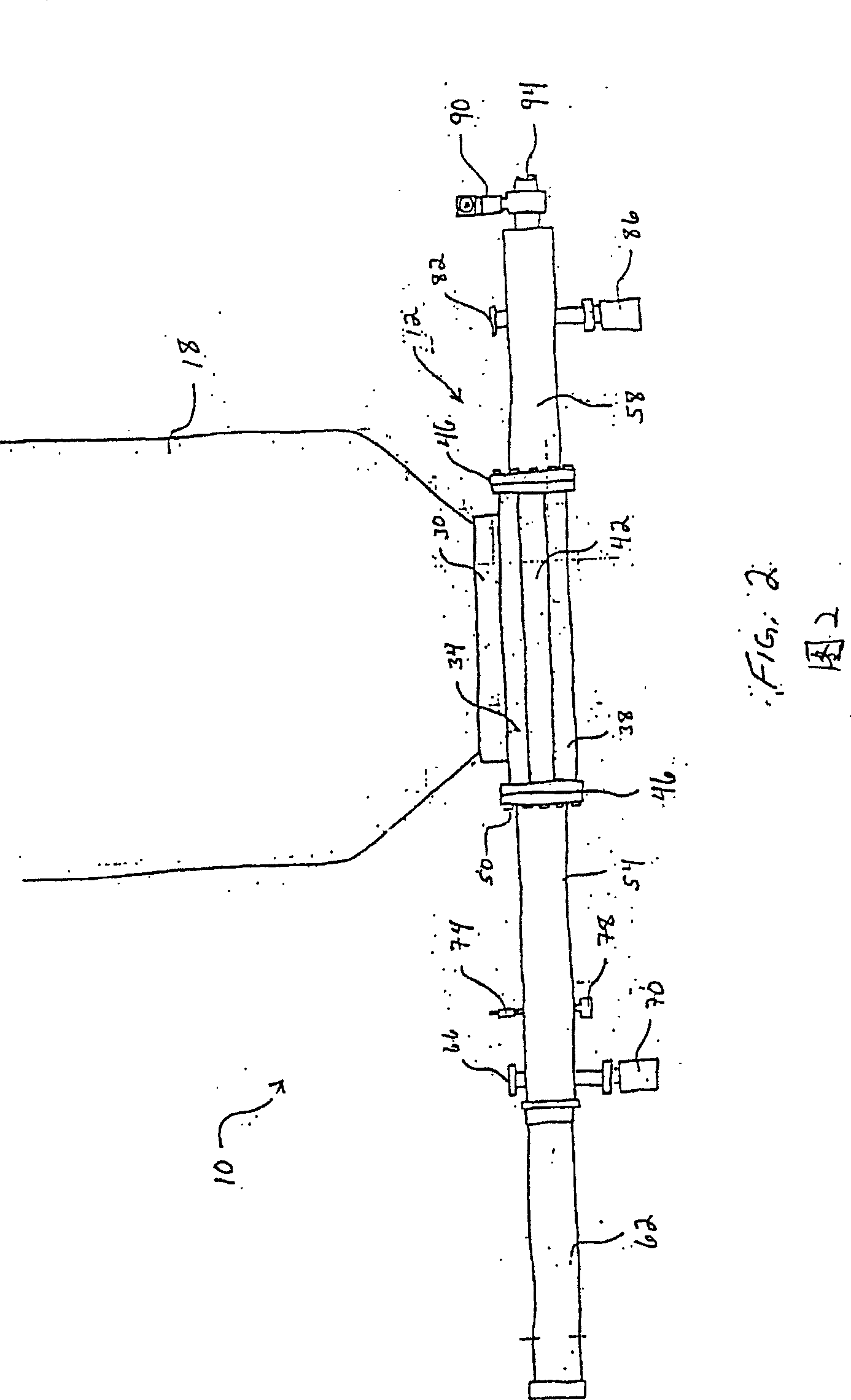

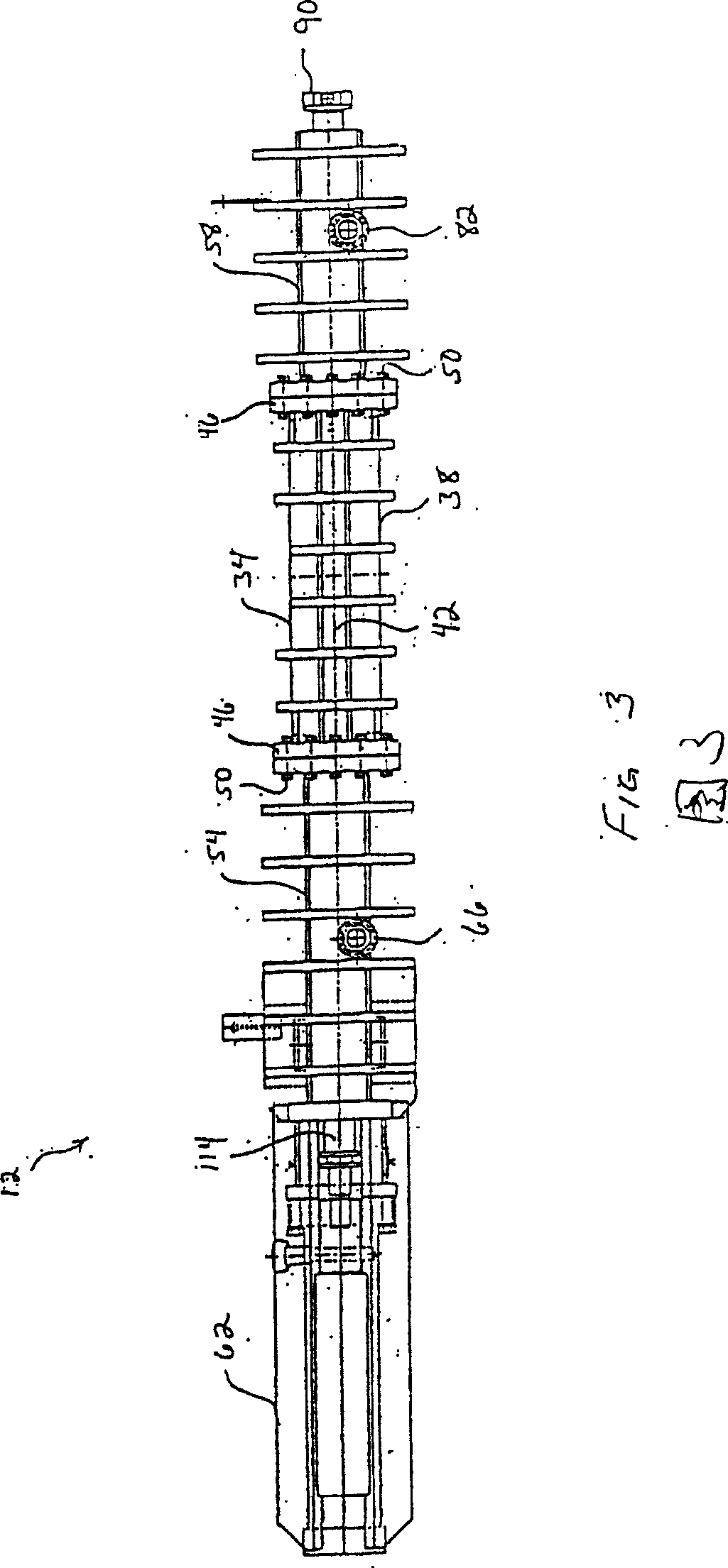

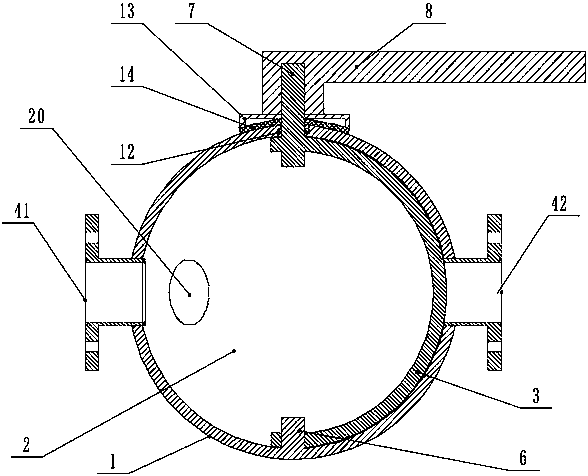

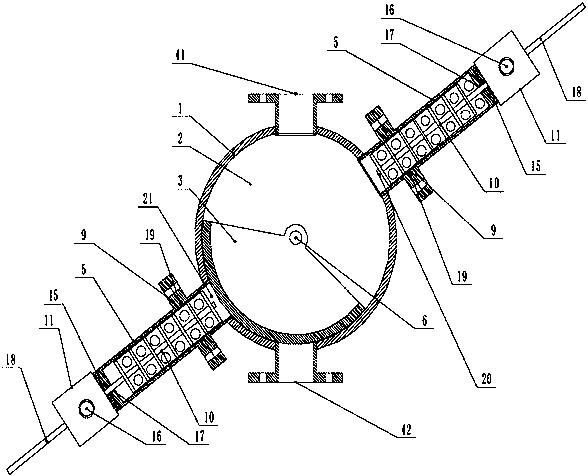

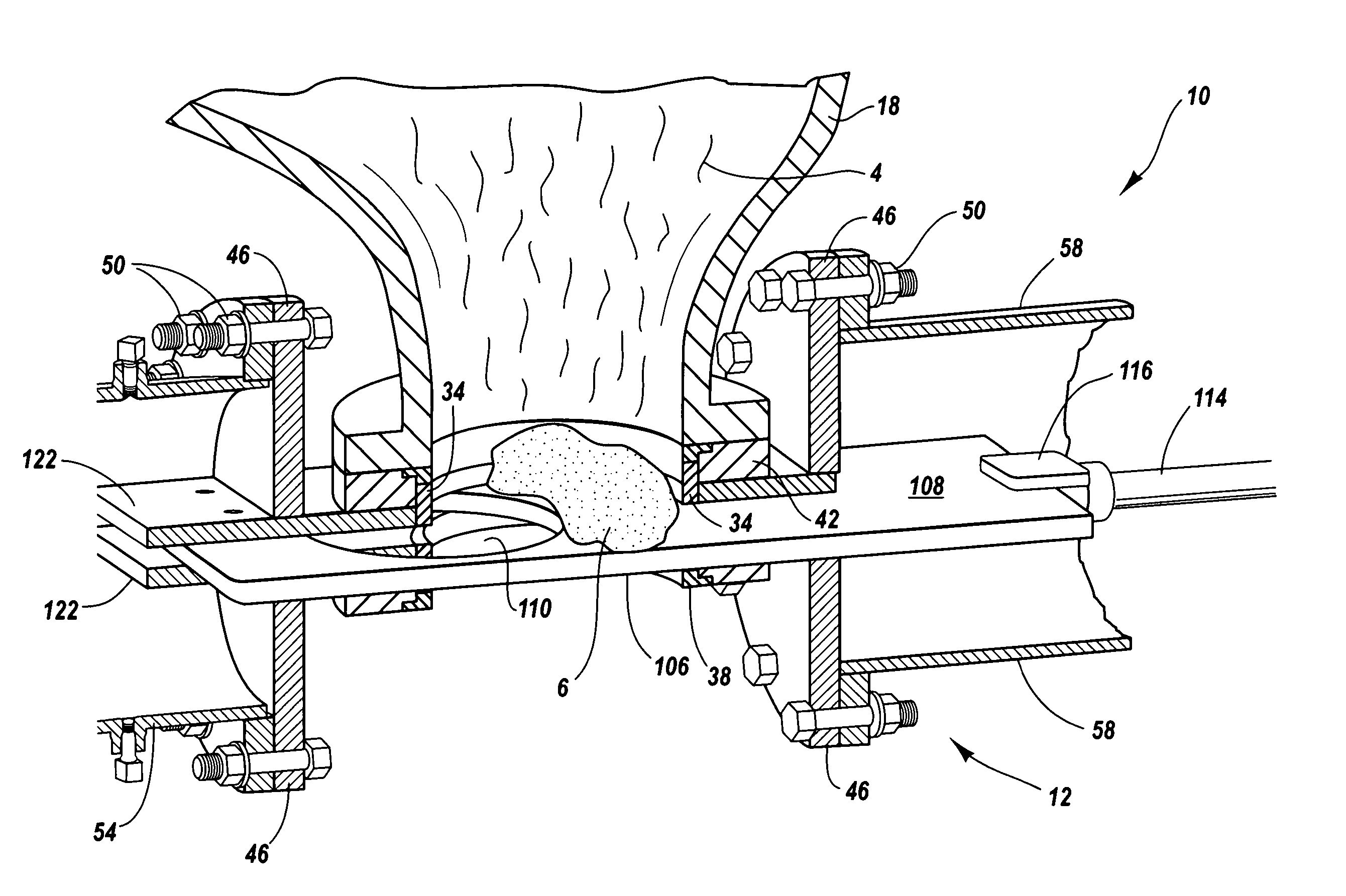

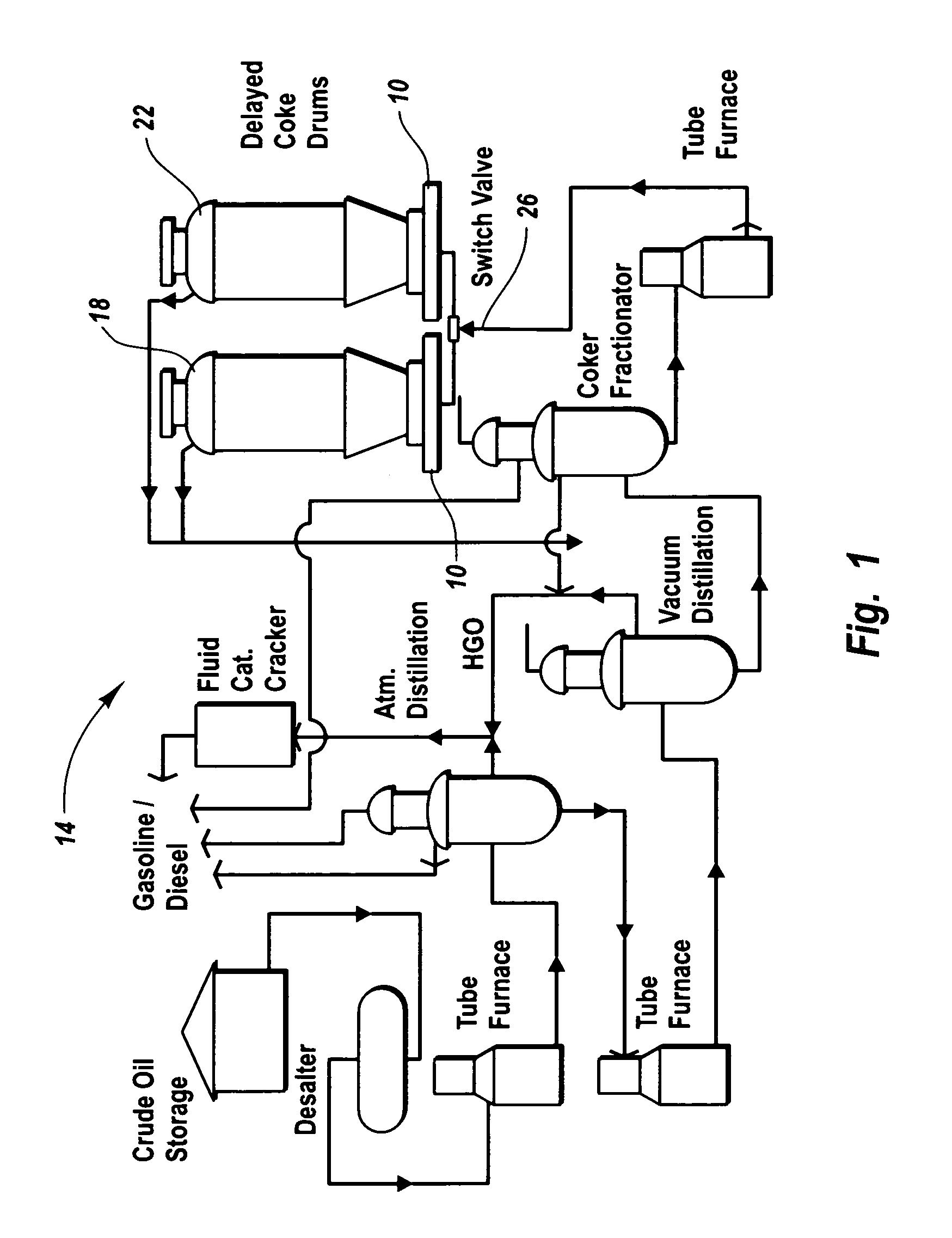

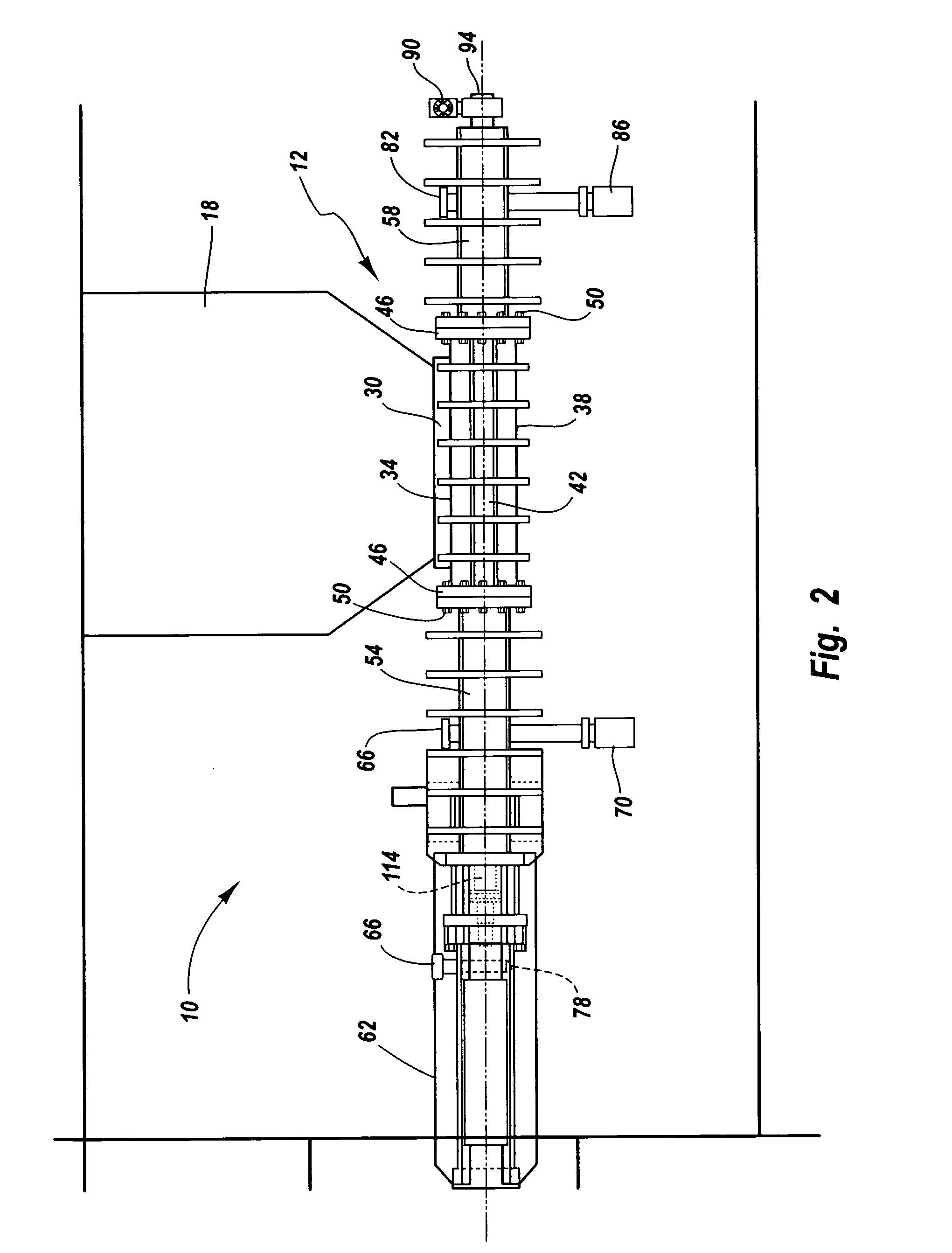

Coke drum bottom de-heading system

InactiveUS6964727B2Efficient and cost-effective and safeSimplified and reliableCharging-discharging device combinationsMan-operated mechanismWindow shutterComputer module

The present invention features a coke drum de-heading system comprising (a) at least one coke drum having an orifice therein; (b) a de-header valve removably coupled to the coke drum designed to de-head the coke drum; and (c) an exchange system, including an upper and lower bonnet and other elements and members adapted to integrate the de-heading system, and particularly the de-header valve, into the manufacturing system. The de-header valve itself comprises (1) a main body having an orifice dimensioned to align with and couple to, in a concentric relationship, the orifice of the coke drum; (2) a live loaded seat assembly coupled to the main body and comprising a dynamic, live loaded seat, a live seat adjustment mechanism coupled to the main body and designed to control and adjust the force and resulting seat load of the dynamic, live loaded seat, and a force transfer module in juxtaposition to the dynamic, live loaded seat for transferring the force from the live loaded seat adjustment mechanism to the dynamic, live loaded seat; (3) a static seat positioned opposite from and counteracting or counterbalancing the dynamic, live loaded seat; and (4) a blind or sliding blind capable moving in a linear, bi-directional manner within the de-header valve and between the dynamic, live loaded seat and the static seat, such that upon actuation of the blind from a closed position to an open position, the coke drum is de-headed.

Owner:DELTAVALVE

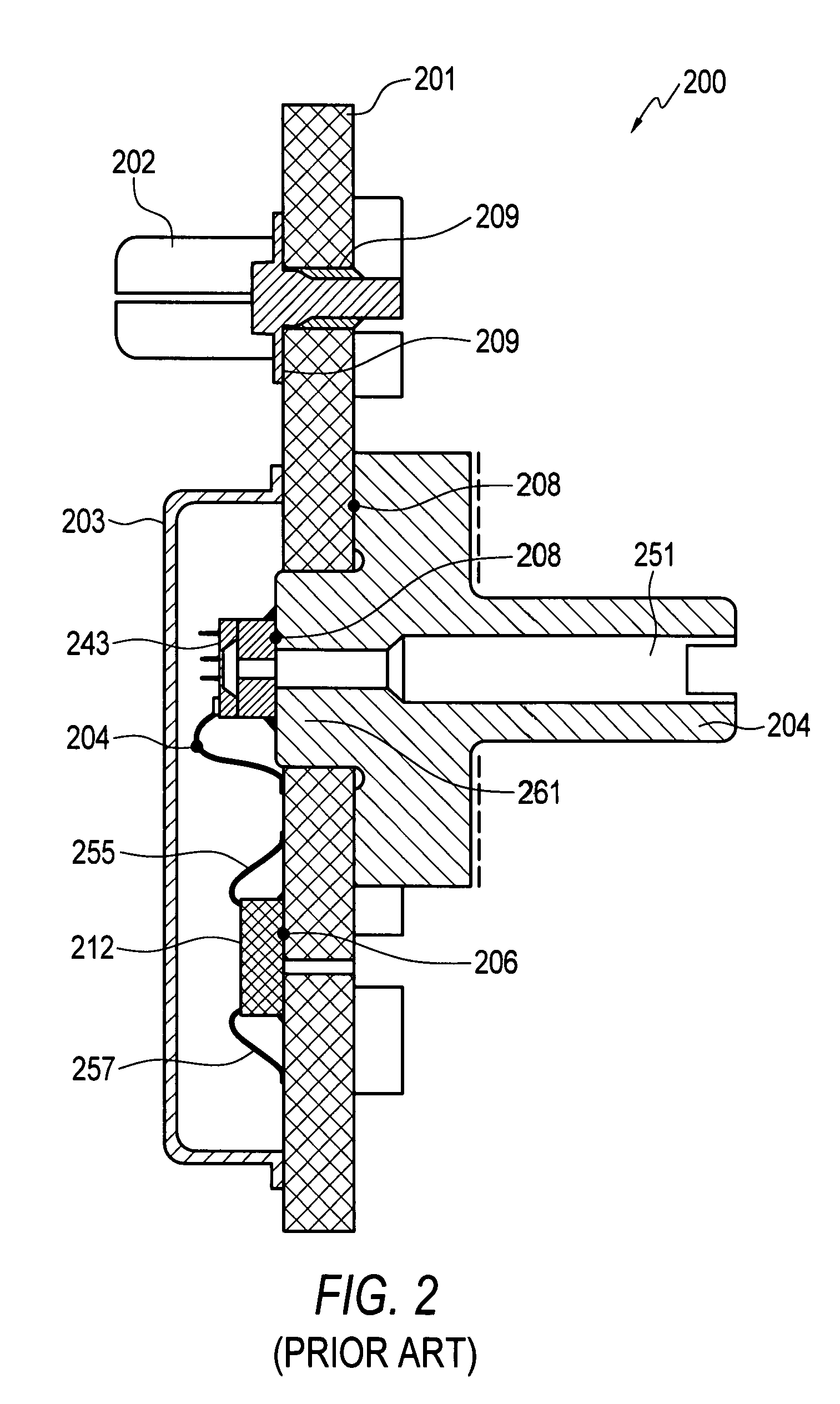

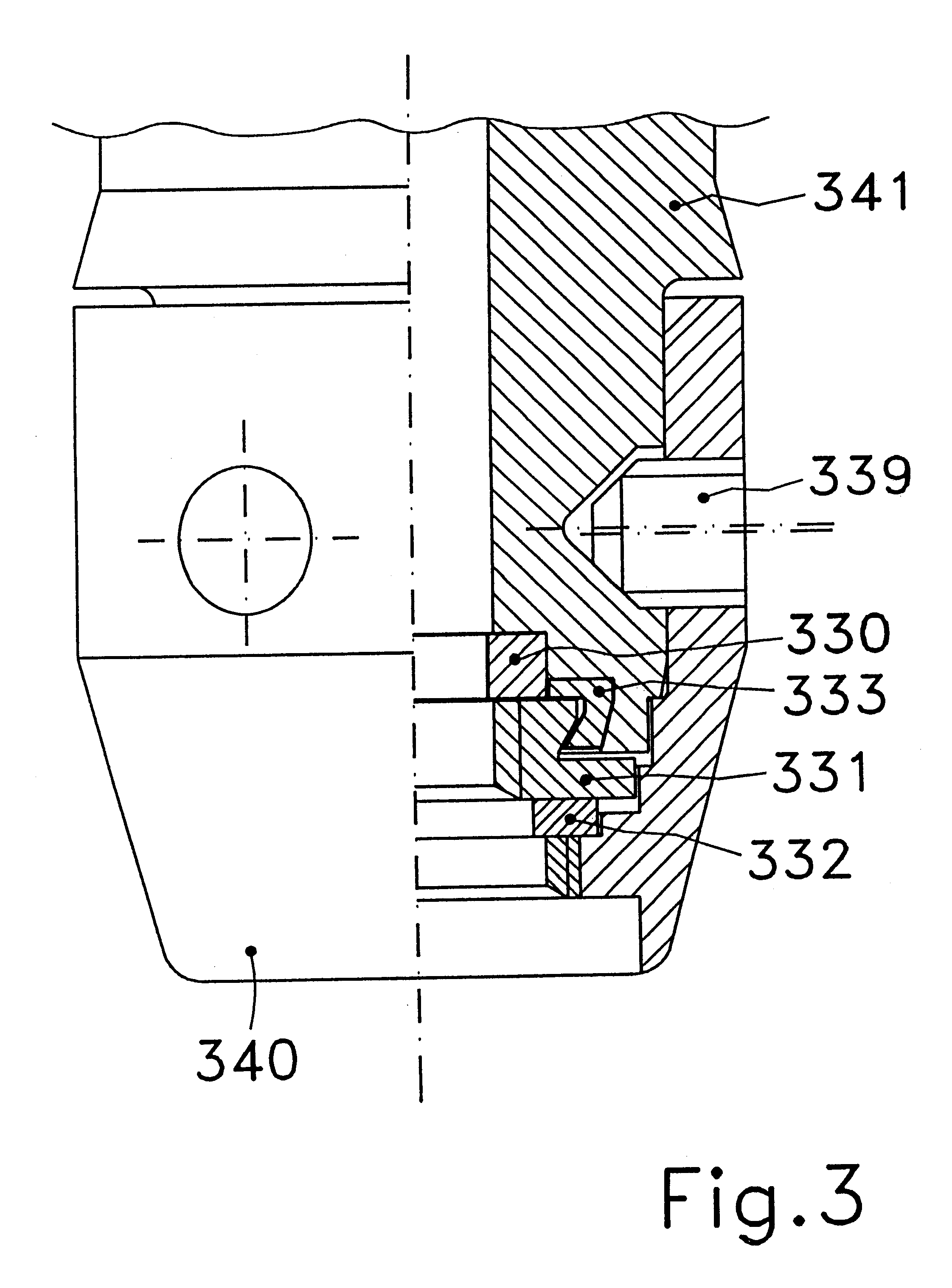

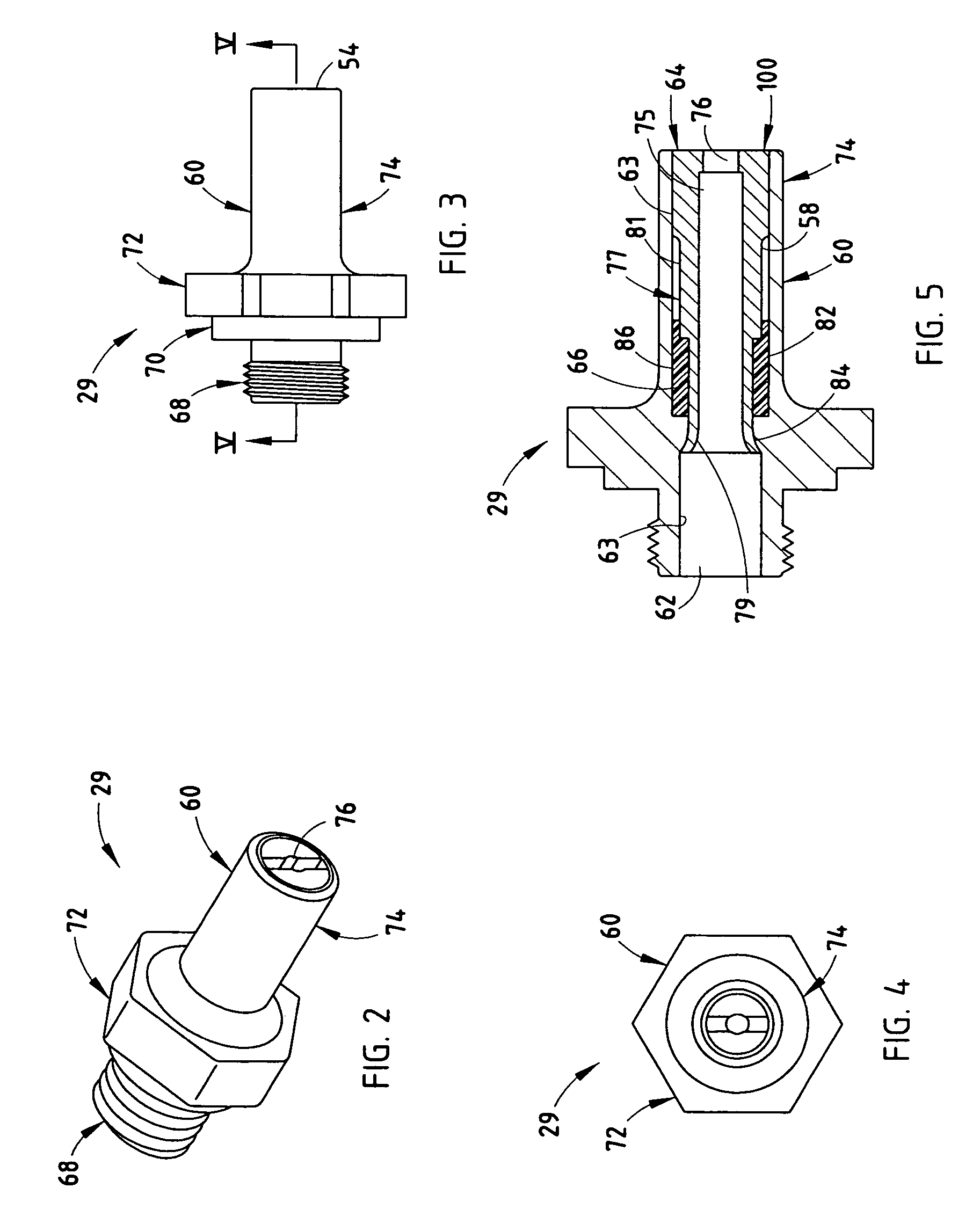

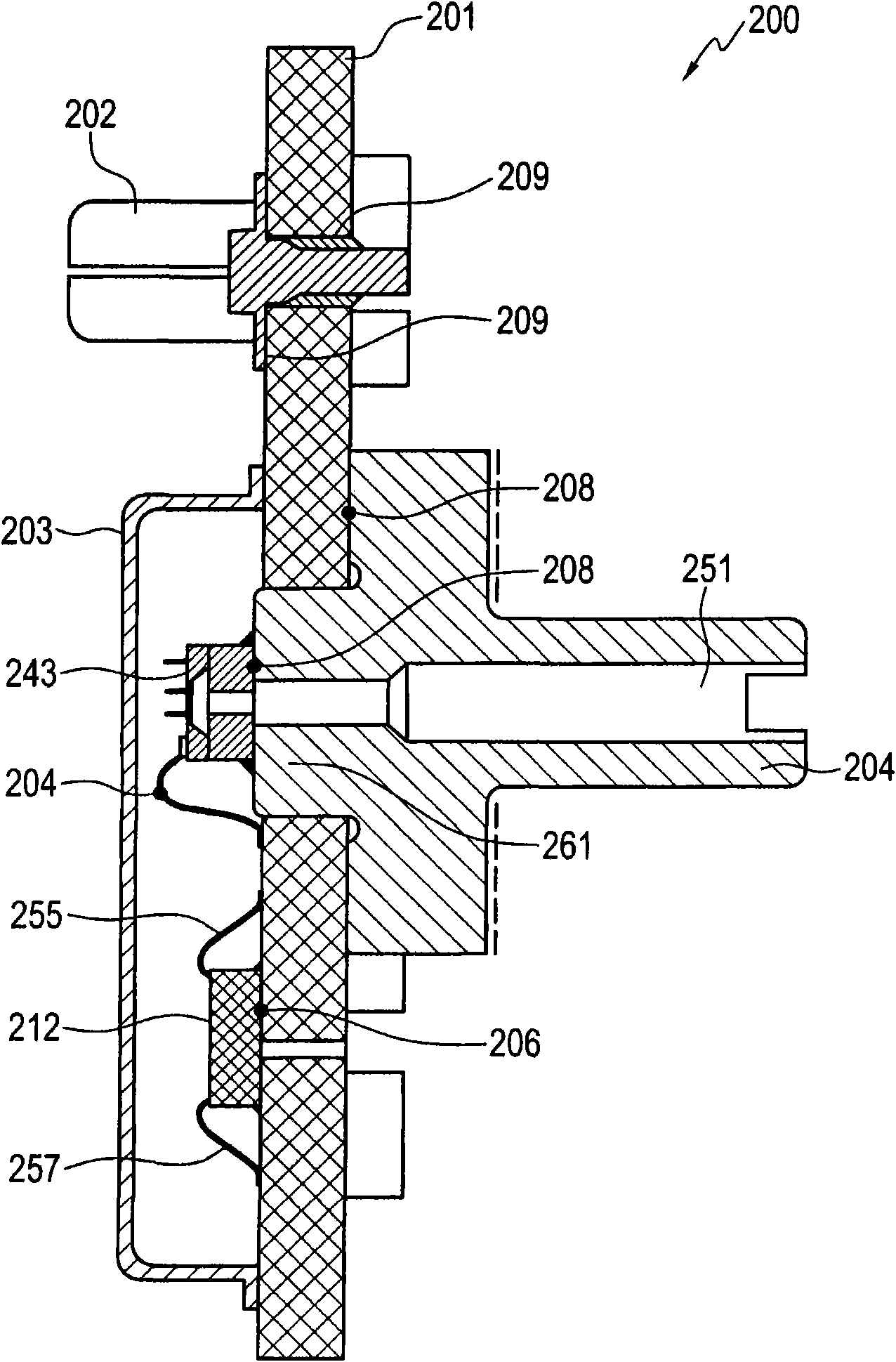

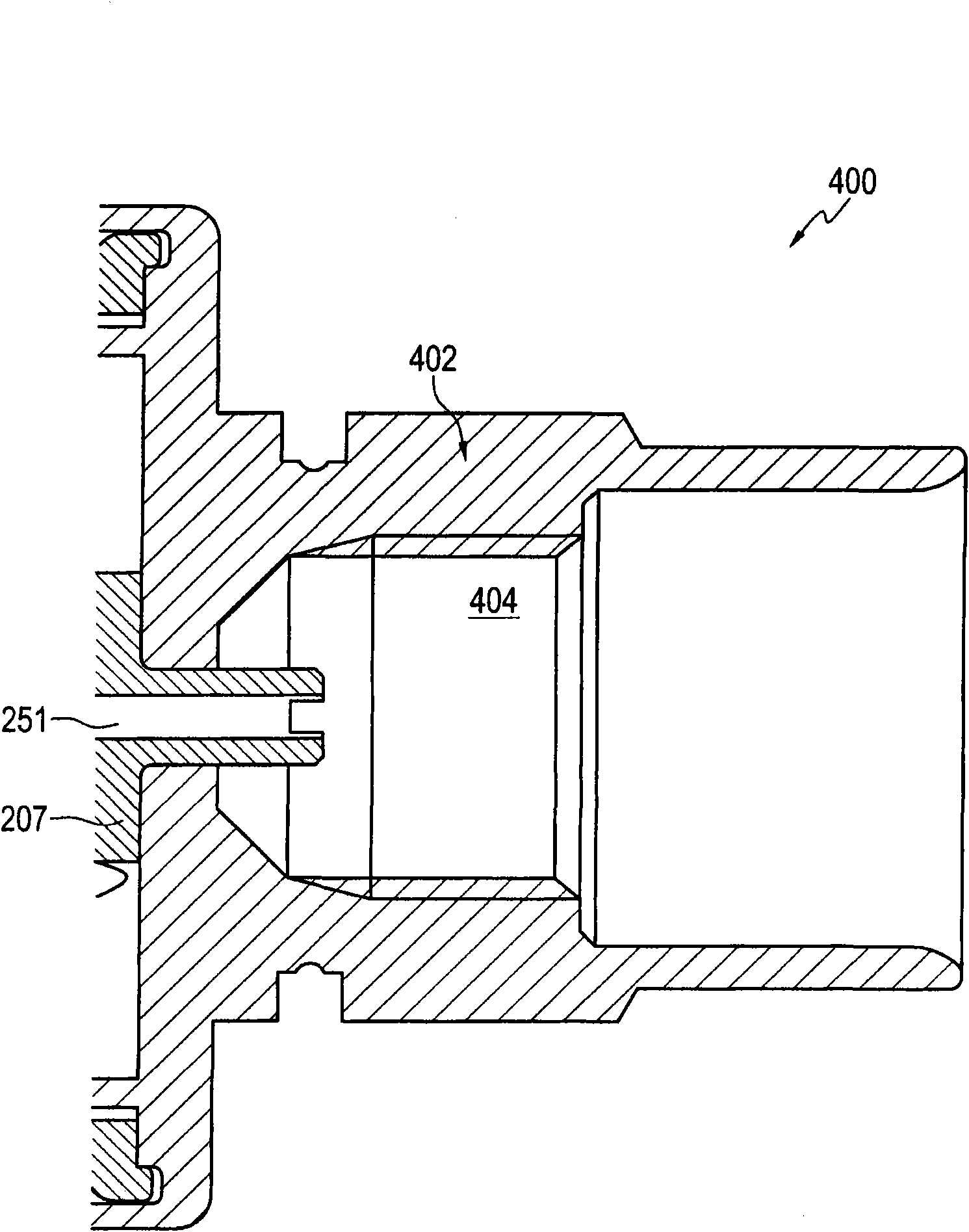

Pressure sensor method and apparatus

ActiveUS7377177B1Easy to understandSolid-state devicesFluid pressure measurement by mechanical elementsContact pressureOn board

A pressure sensor apparatus and a method of forming the same. A substrate (e.g., PCB) can be provided that includes a top side and a bottom side. A pressure transducer can be directly bonded to the top side of the substrate, wherein the substrate comprises substrate walls forming a plated through-hole that allows for the passage of a sensed media to contact a back side of the pressure transducer. Thereafter, a metal carrier with an integral port is bonded to the bottom side of the substrate, thereby forming a chip-on-board pressure sensor in which the need for a plating or coating to allow adhesion between the pressure transducer and the metal carrier is eliminated. The pressure transducer may comprise, for example, silicon or silicon bonded to glass. The metal carrier can be provided with a feature that mates with a valve such as a Schrader valve.

Owner:HONEYWELL INT INC

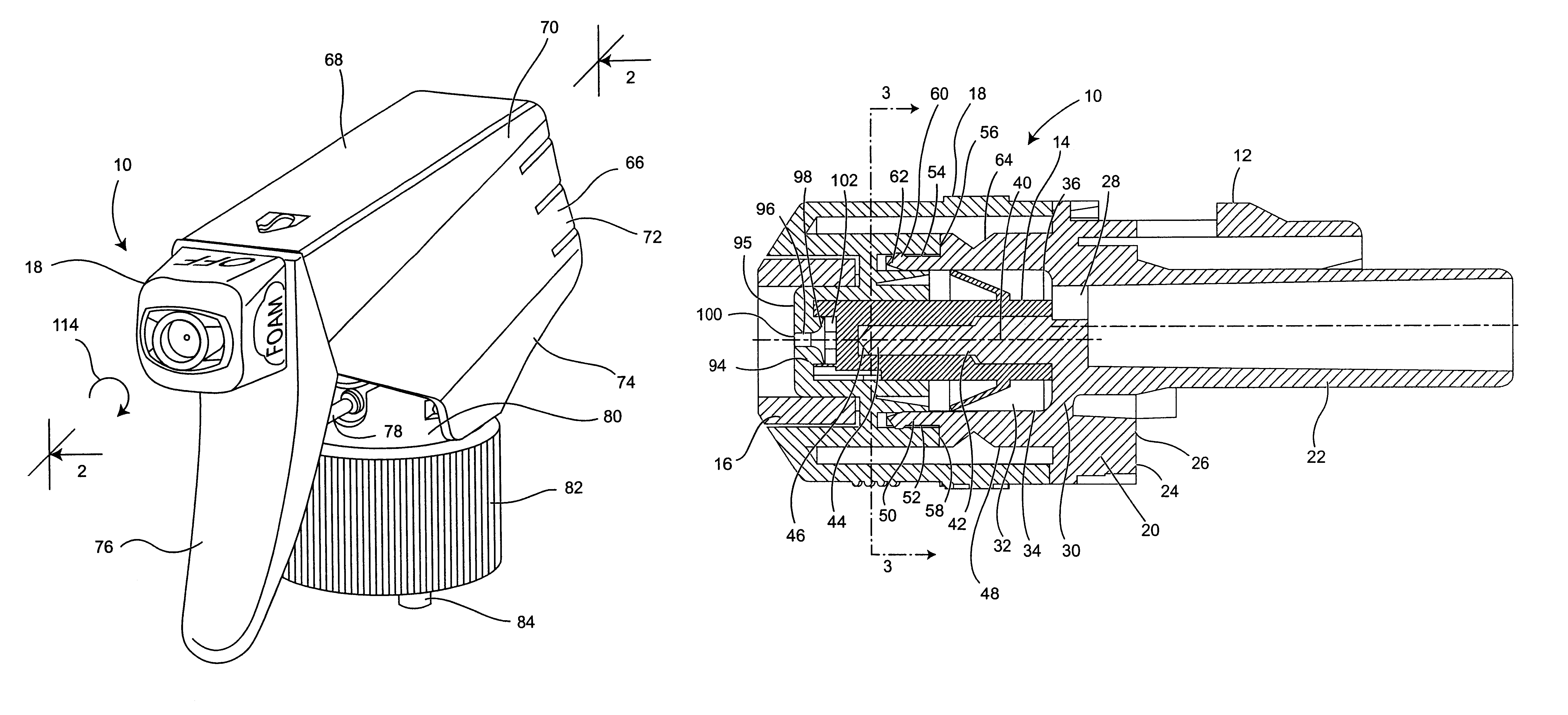

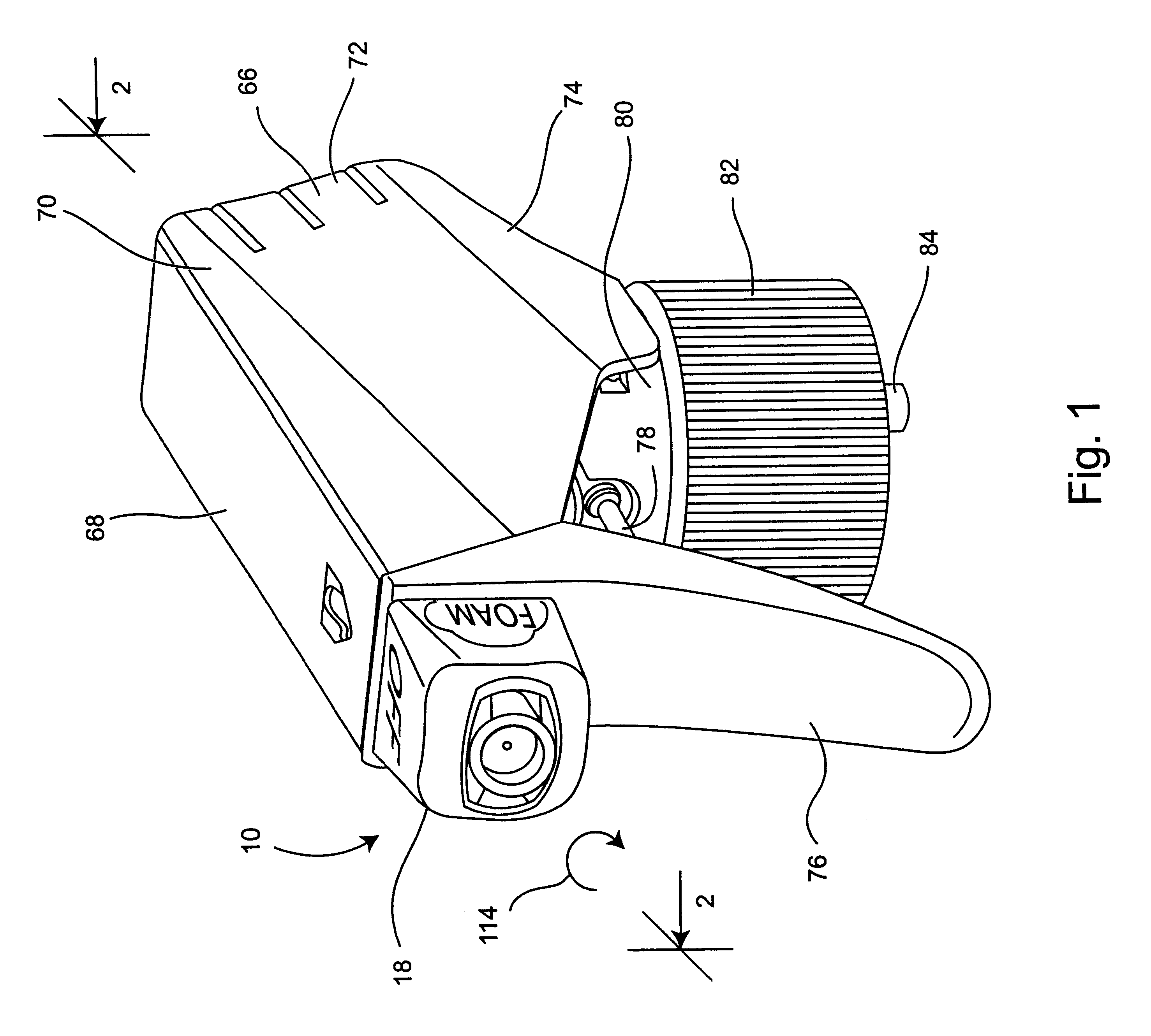

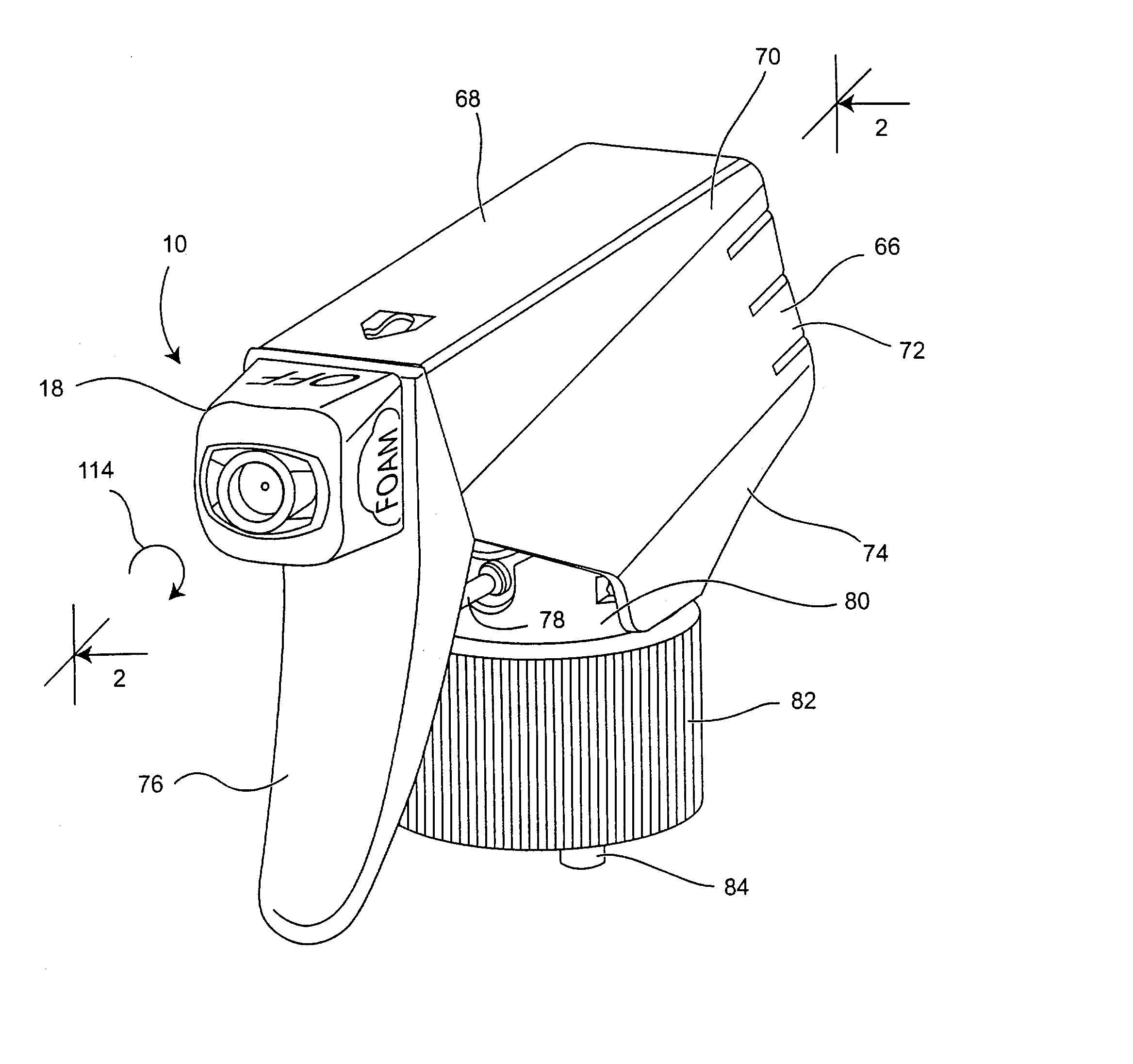

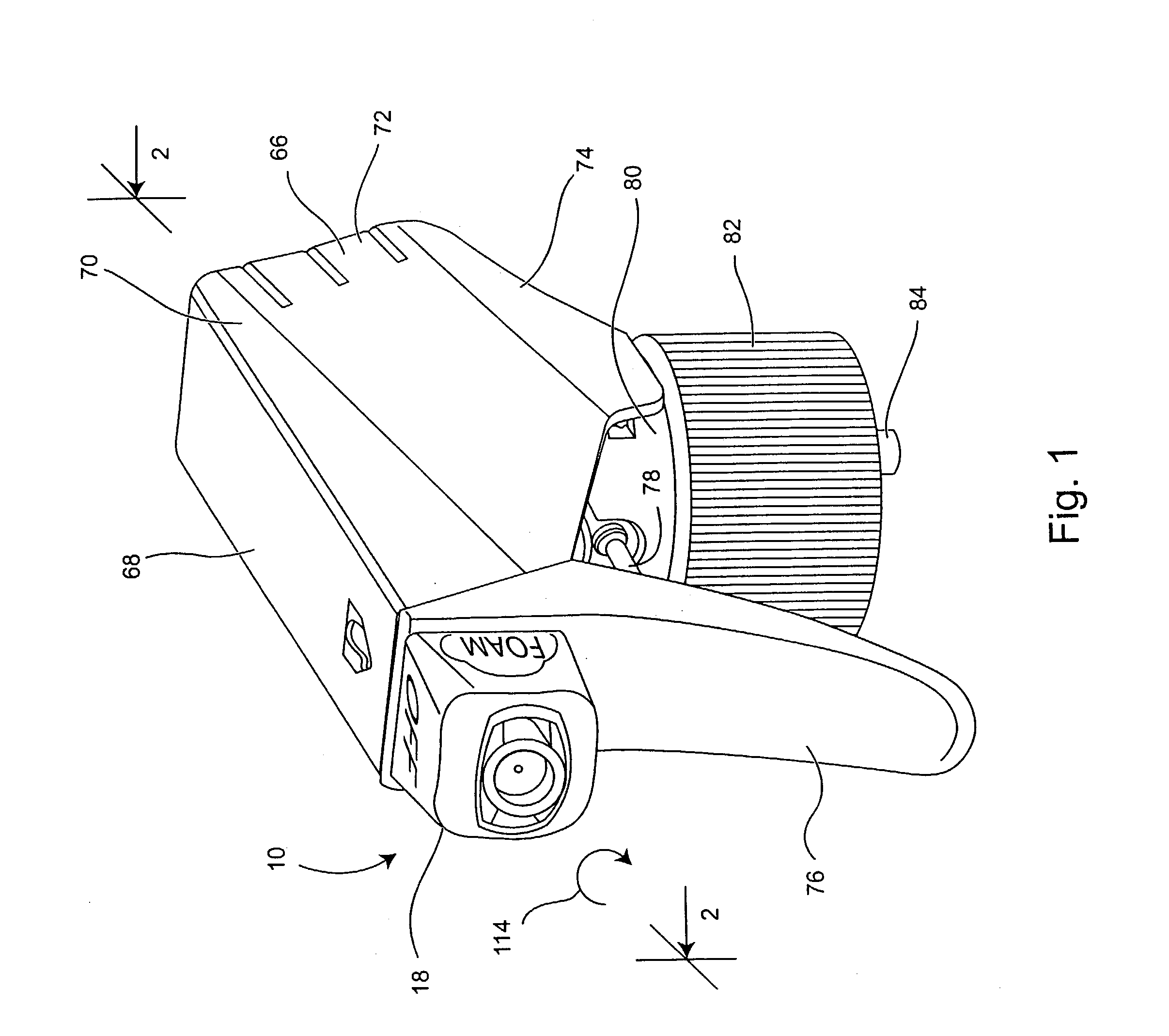

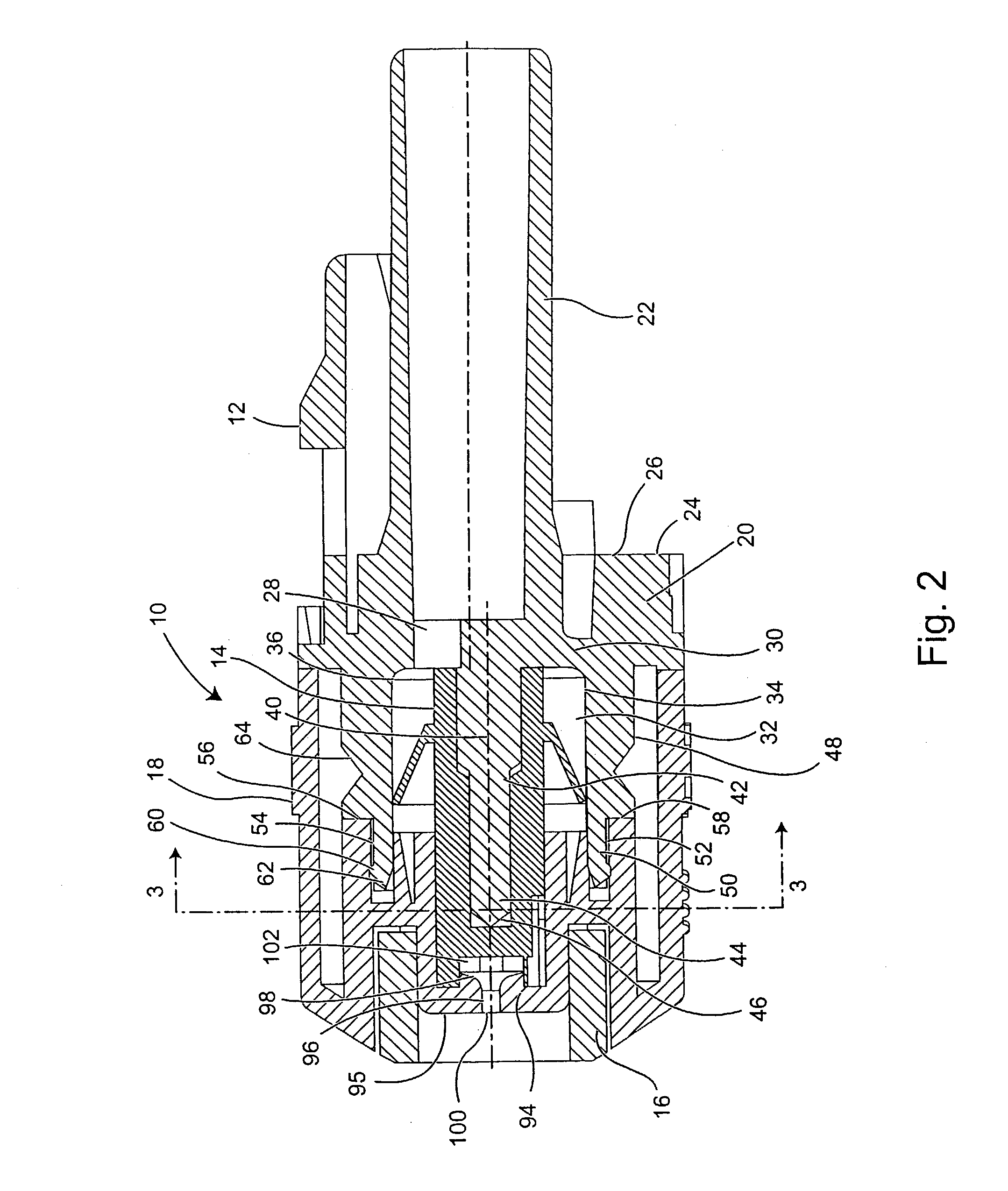

Manually operable trigger sprayer with rearwardly located sprayer valve

A trigger sprayer valve assembly that has a conical flange that controls the flow of liquid in a downstream direction through a liquid passage of the trigger sprayer. The valve is constructed with an elongate stem or shaft that facilities the assembly of the valve into the trigger sprayer and a positioning plug that solely holds the valve in a centered position in the liquid passage of the trigger sprayer.

Owner:WESTROCK DISPENSING SYST

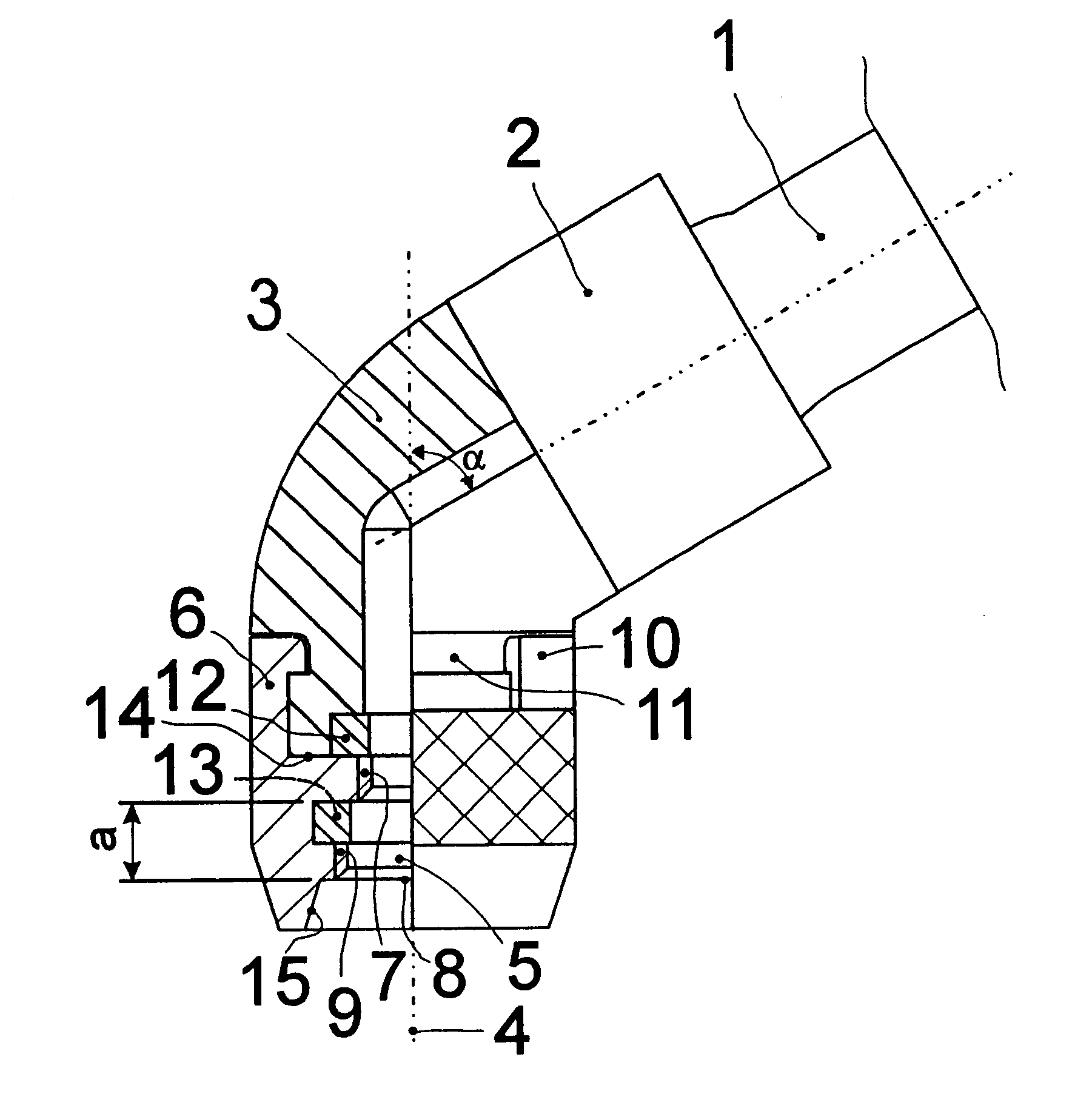

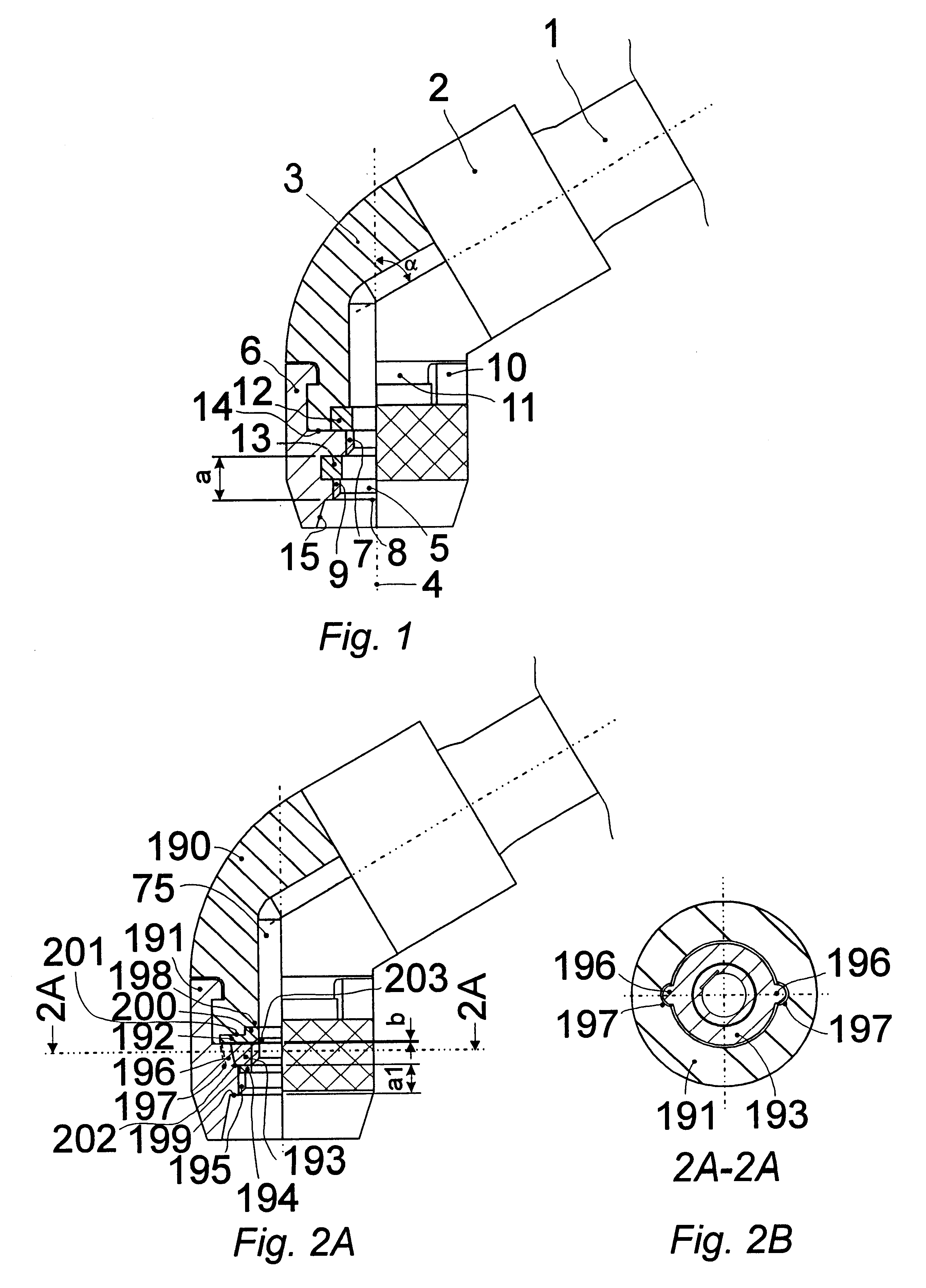

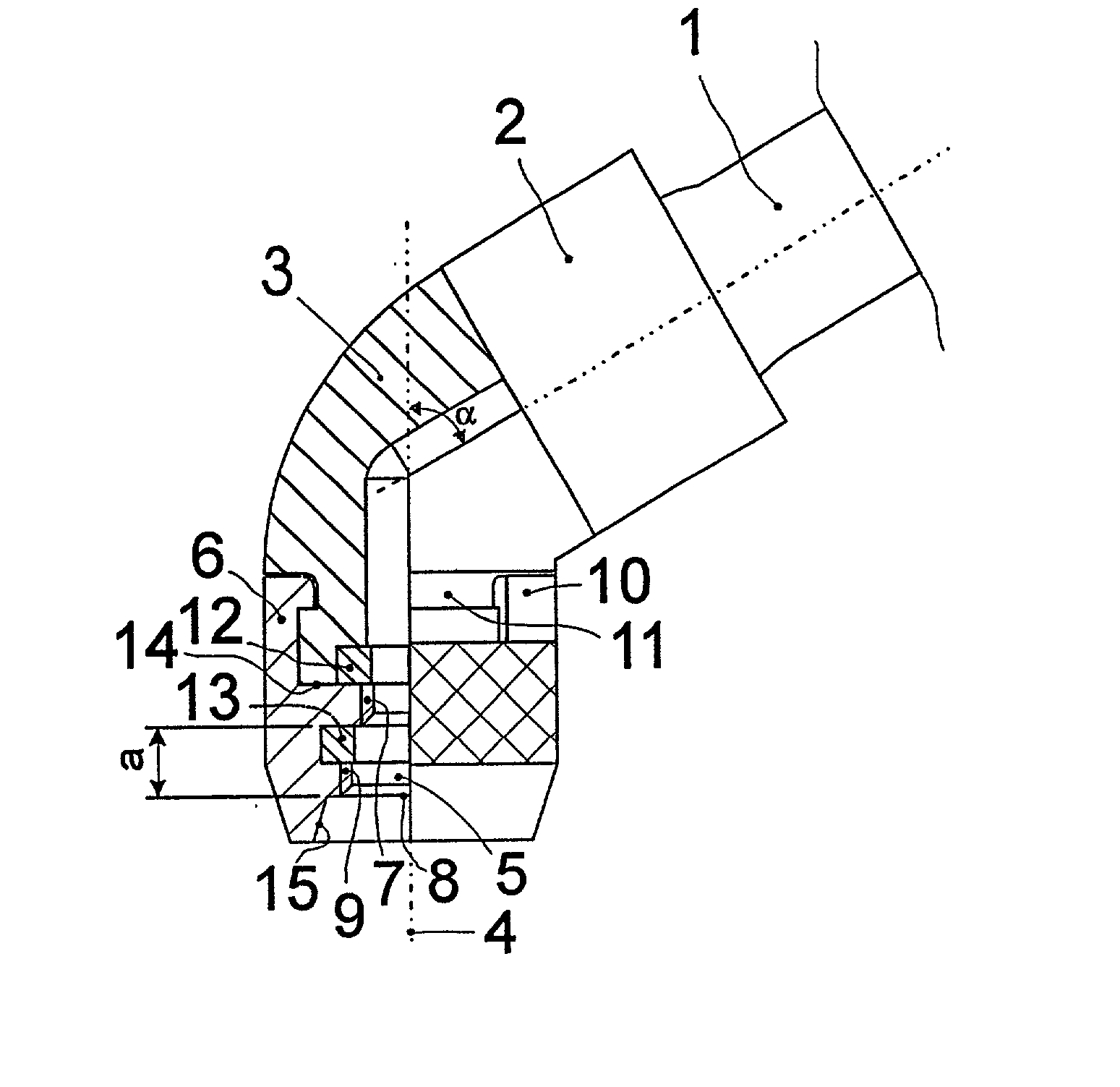

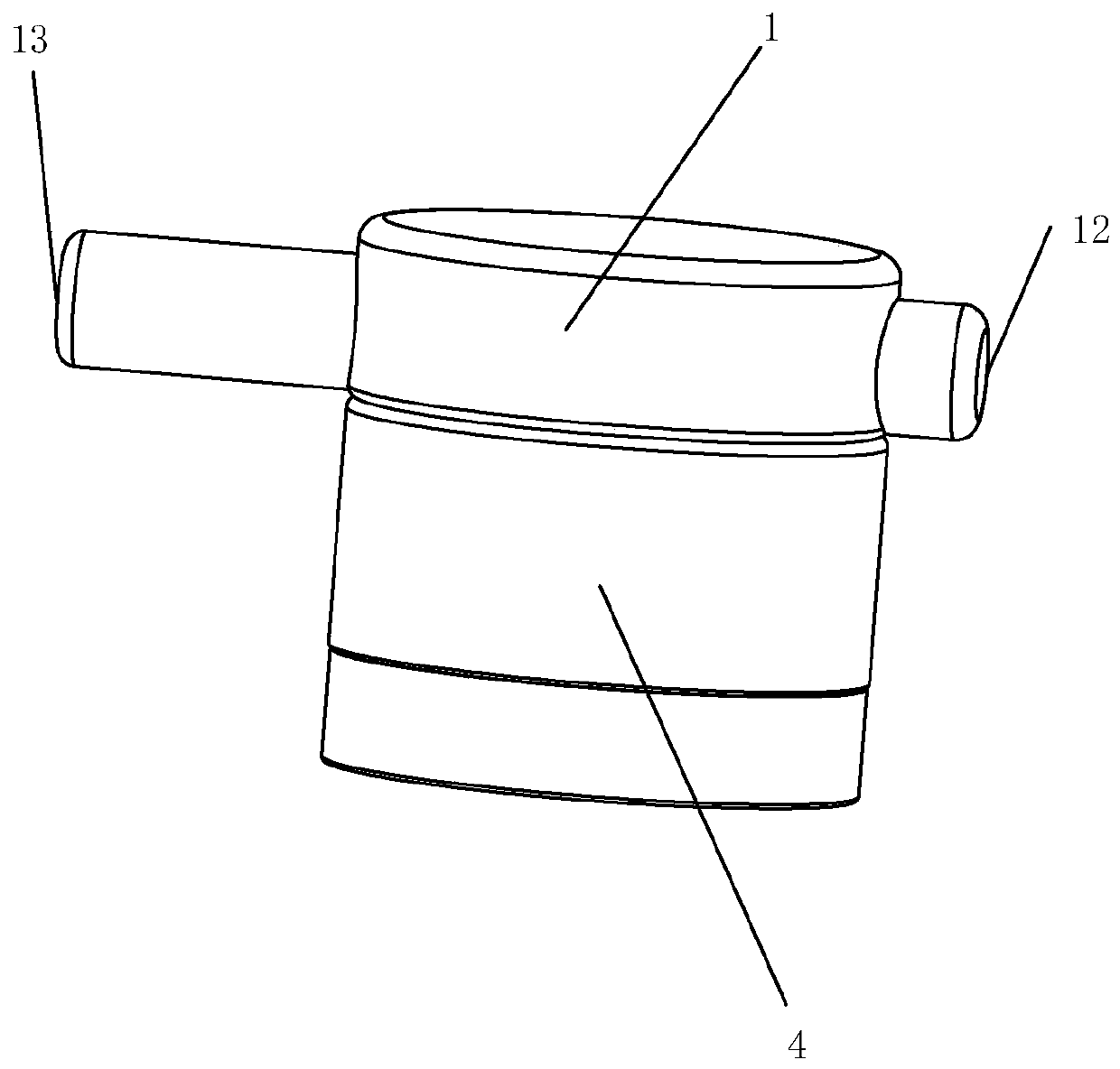

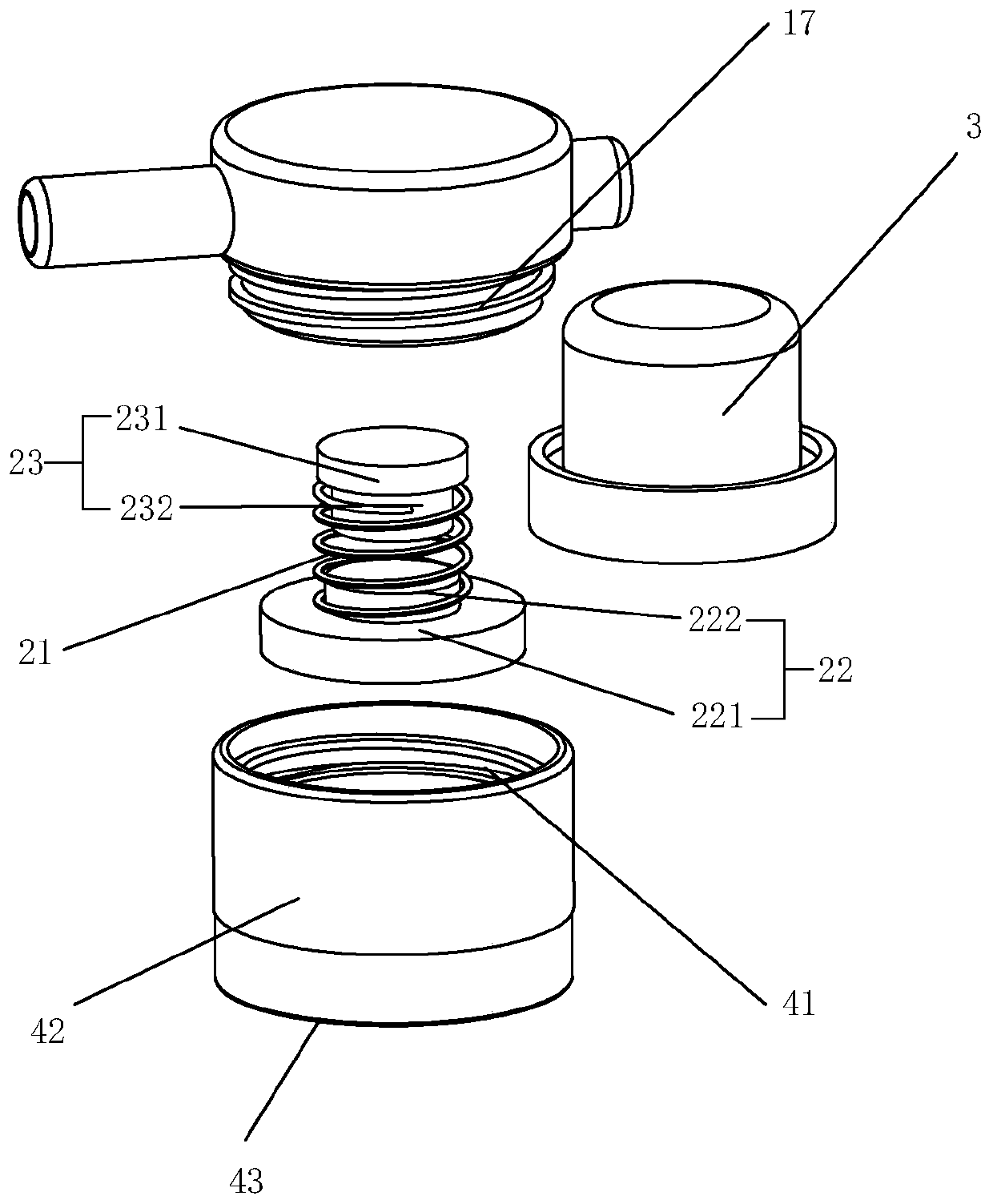

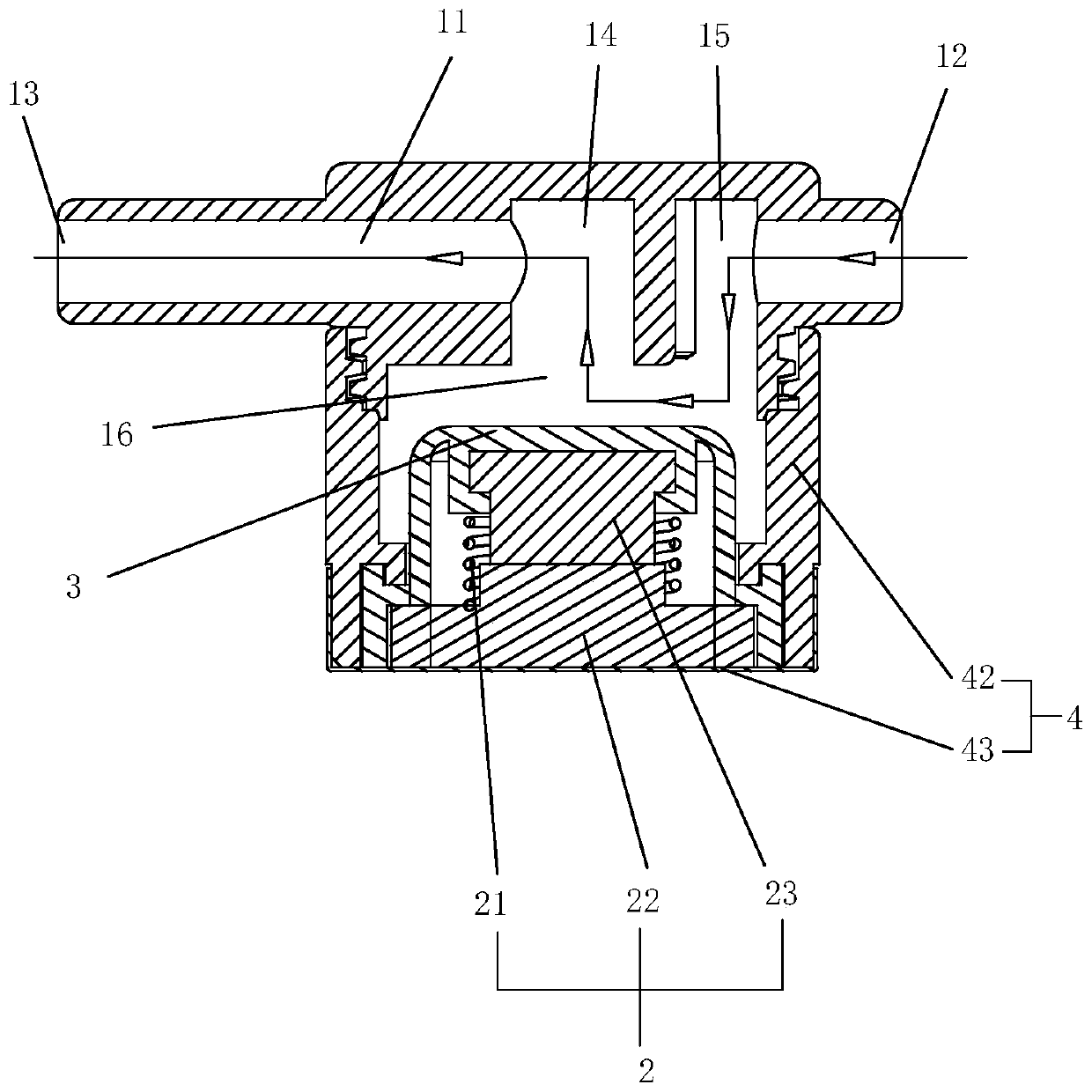

Valve connector

By a universal valve connector for inflation valves of vehicle types (Sclaverand, Dunlop-Woods, or Schrader), whose connector consists of a connector housing (368), which partly is connected to a pressure source, preferably a hand or foot pump, and which partly has a coupling hold (5) with a diameter corresponding to the diameter of the valve, which is to be connected, where the coupling hole is equipped with a securing means for securing on the valve, plus a sealing means against valves of different sizes. This is achieved by the sealing means (366) being mounted coaxially in the connector housing (368) and being established on at least two parallel, separate levels, having the centre line (4) of the connector housing (368), which is coaxial to the centre line of the valve, as its normal, where the minor diameters of the sealing means approximately correspond to the major diameter of the current valve dimensions, on which the connector is mounted when used, that the sealing means (366), closest to the opening (8) of the coupling hole (5) in the connector housing (368) has the biggest minor diameter, while the sealing means (366) farthest from the opening (8) of the coupling hole in the connector housing (368) has the smallest minor diameter, and diameters between the extremes are lying corresponding separate distance between these extremes. The valve connector has the possibility of automatically adjust itself to the valve in question and if needed to activate the central core of a Schrader valve. Also, it is possible to use the connector with existing pumps.

Owner:NVB INT AS

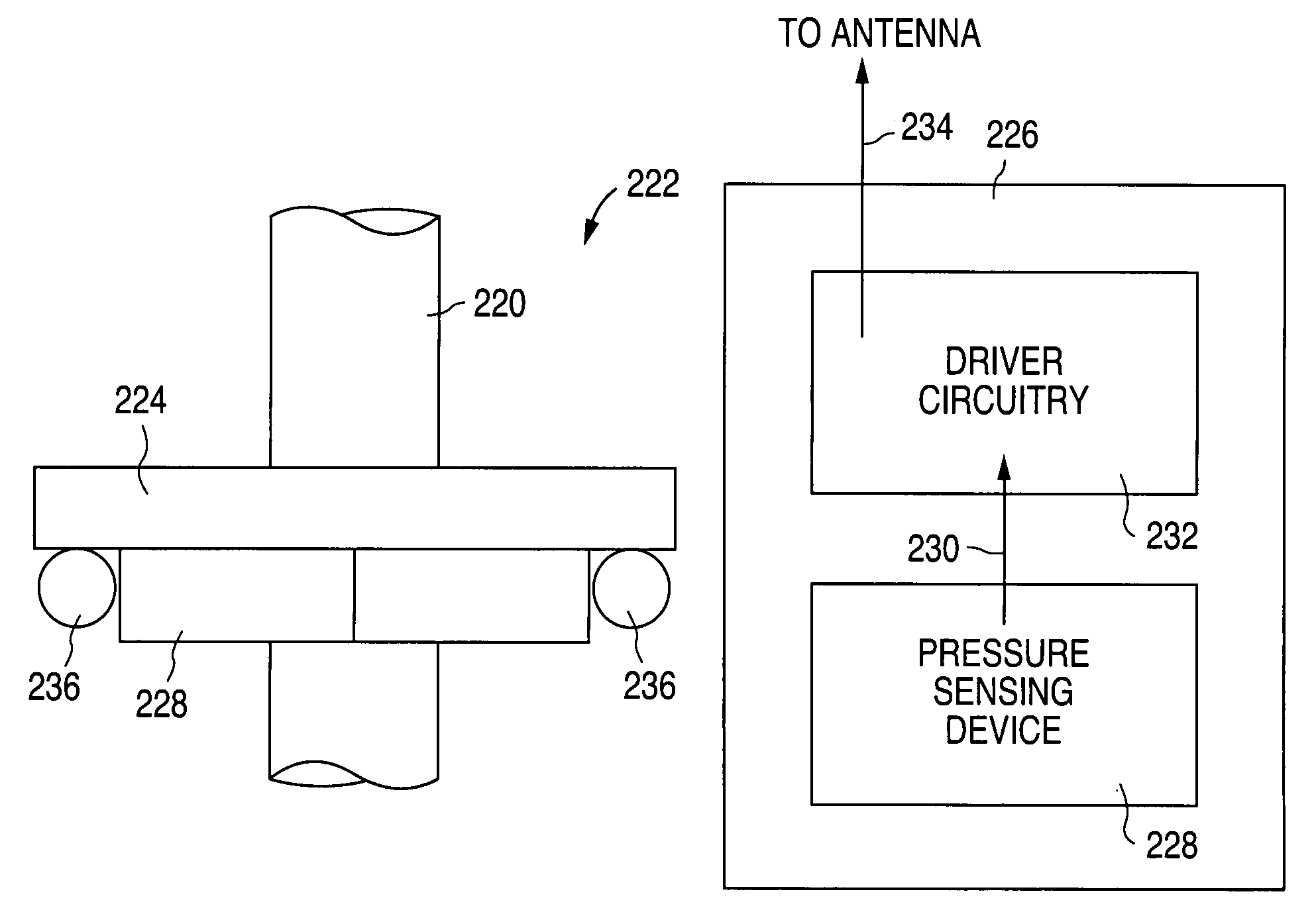

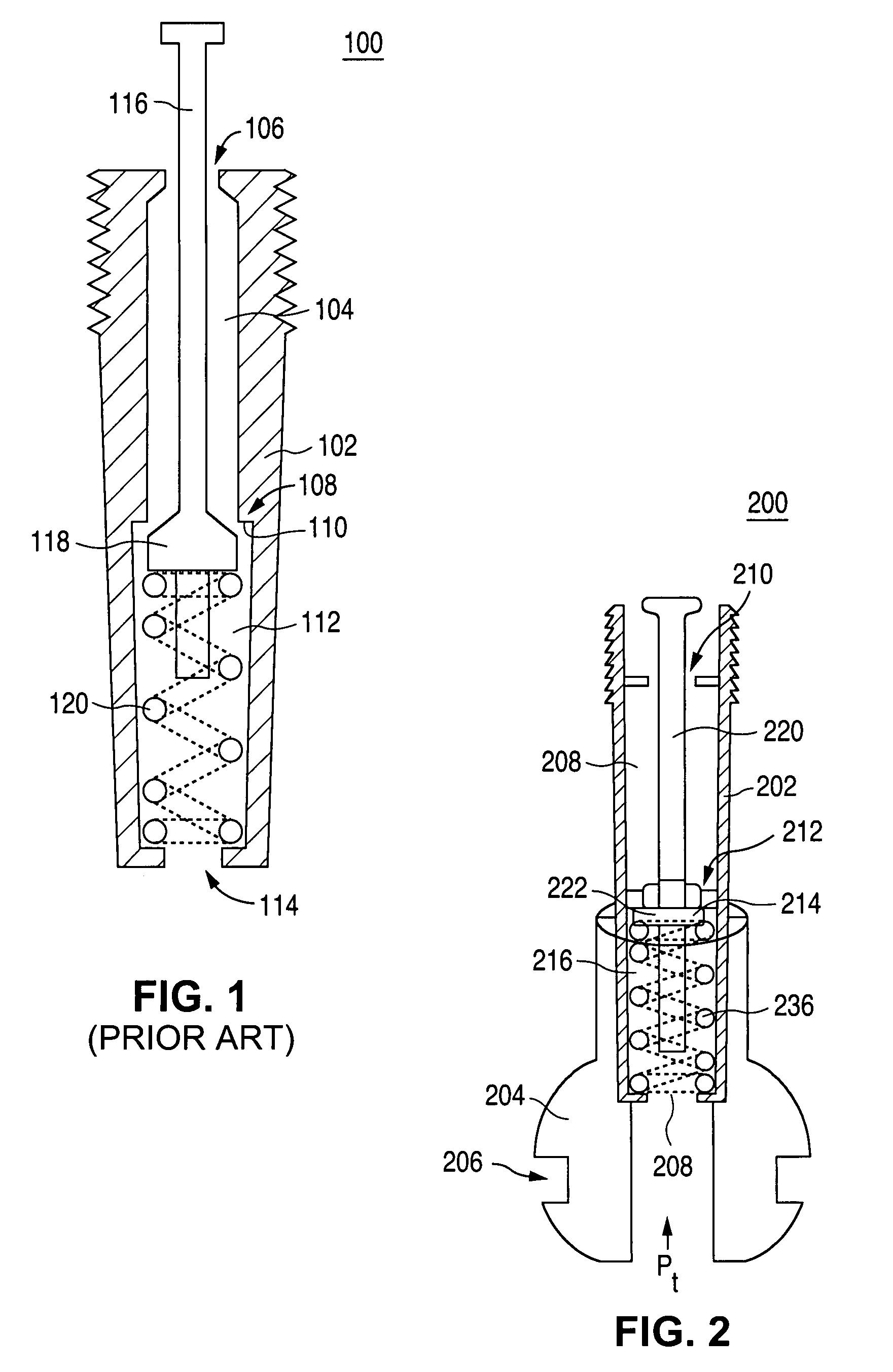

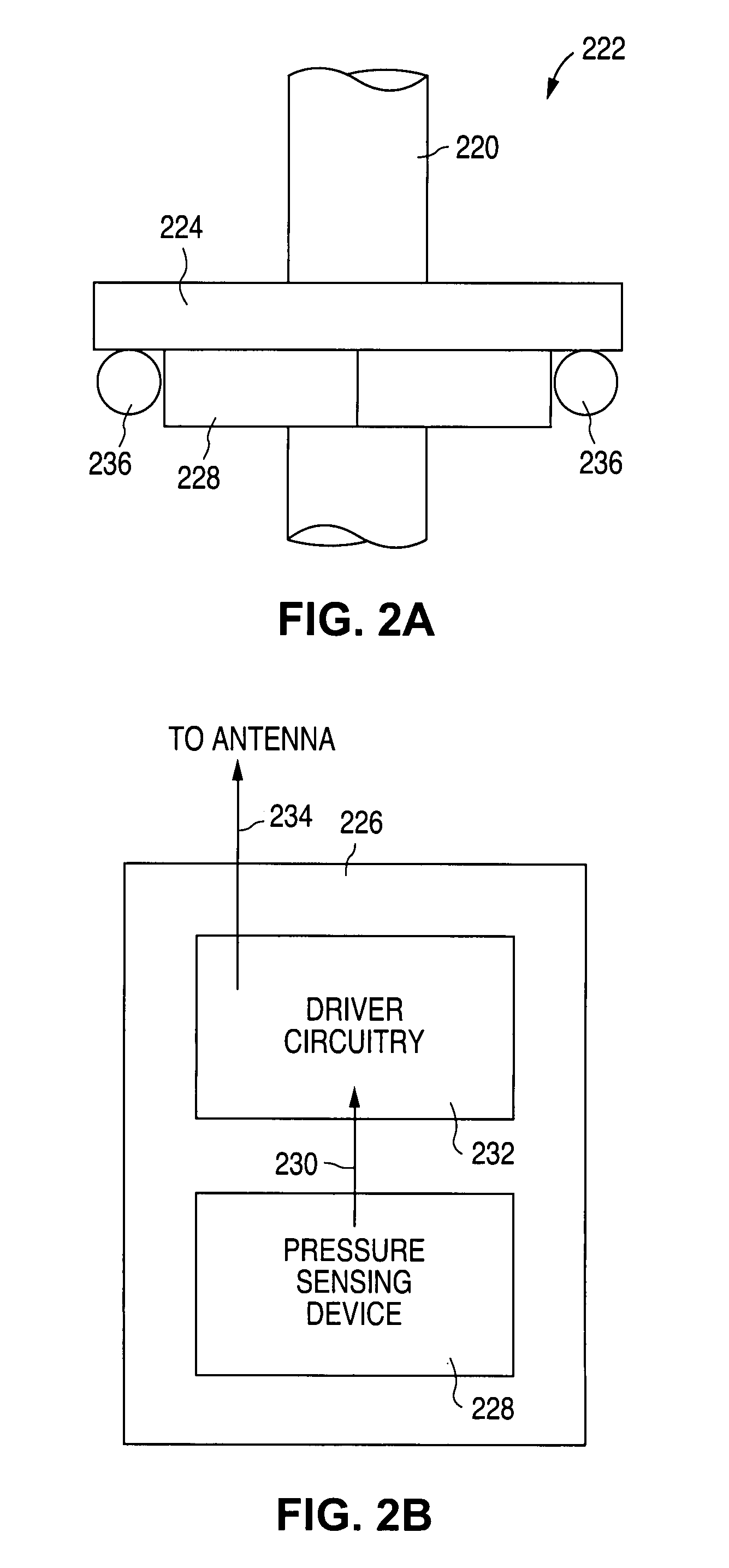

Wireless pressure sensing Schrader valve

A wireless tire pressure sensing system based upon a Schrader valve design is provided. The system includes a valve body, a valve pin and a compression element for sealing engaging the valve body and the valve pin to maintain tire pressure. A pressure sensing device mounted within the valve body and connected to valve pin senses the pressure within the tire and provides its signal to the valve pin. The valve pin is adapted as a component of an antenna that transmits a wireless pressure signal to a remote receiver / transmitter mounted on the vehicle. The receiver / transmitter transmits a corresponding signal to a vehicle control system that generates a warning signal when the tire pressure is below a threshold safety value.

Owner:NAT SEMICON CORP

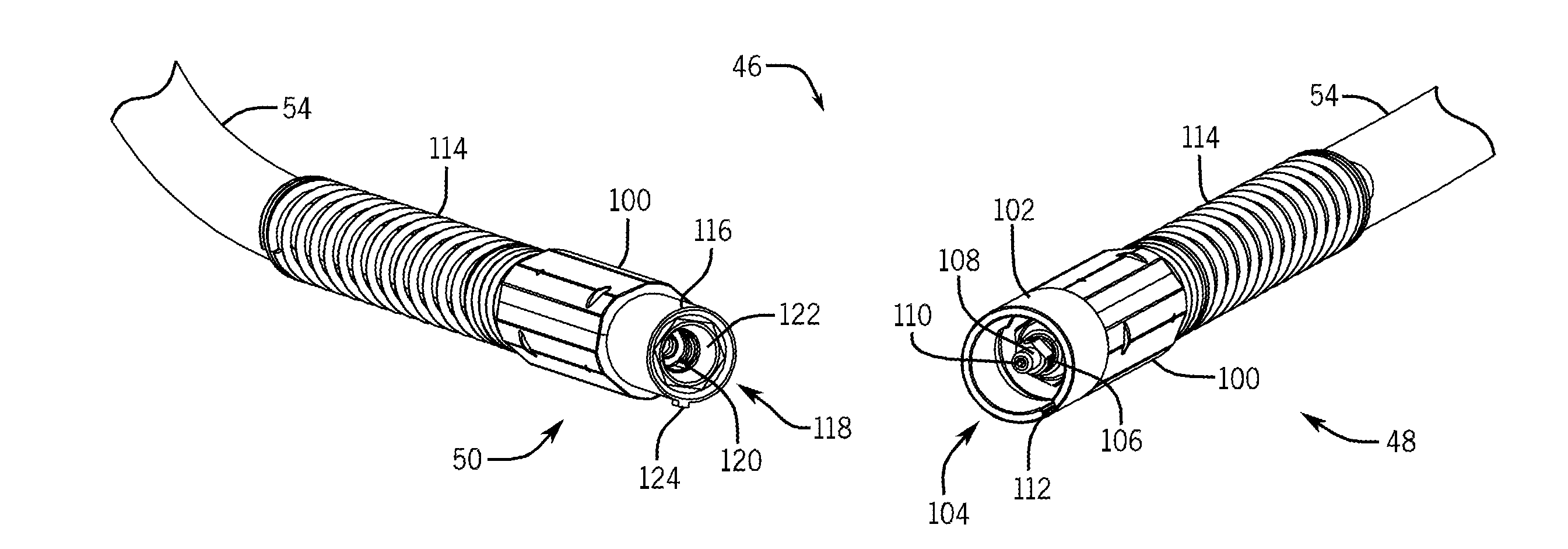

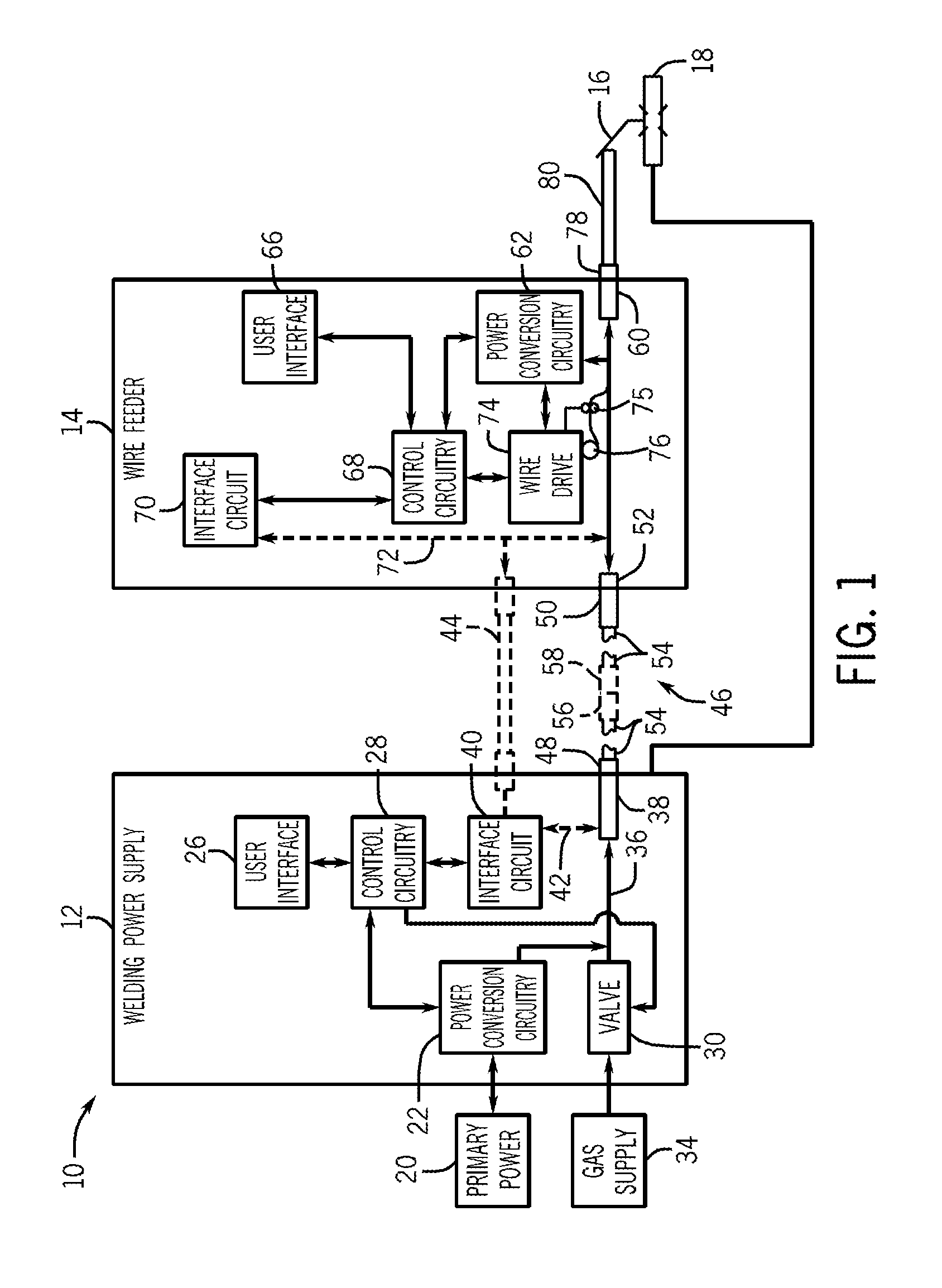

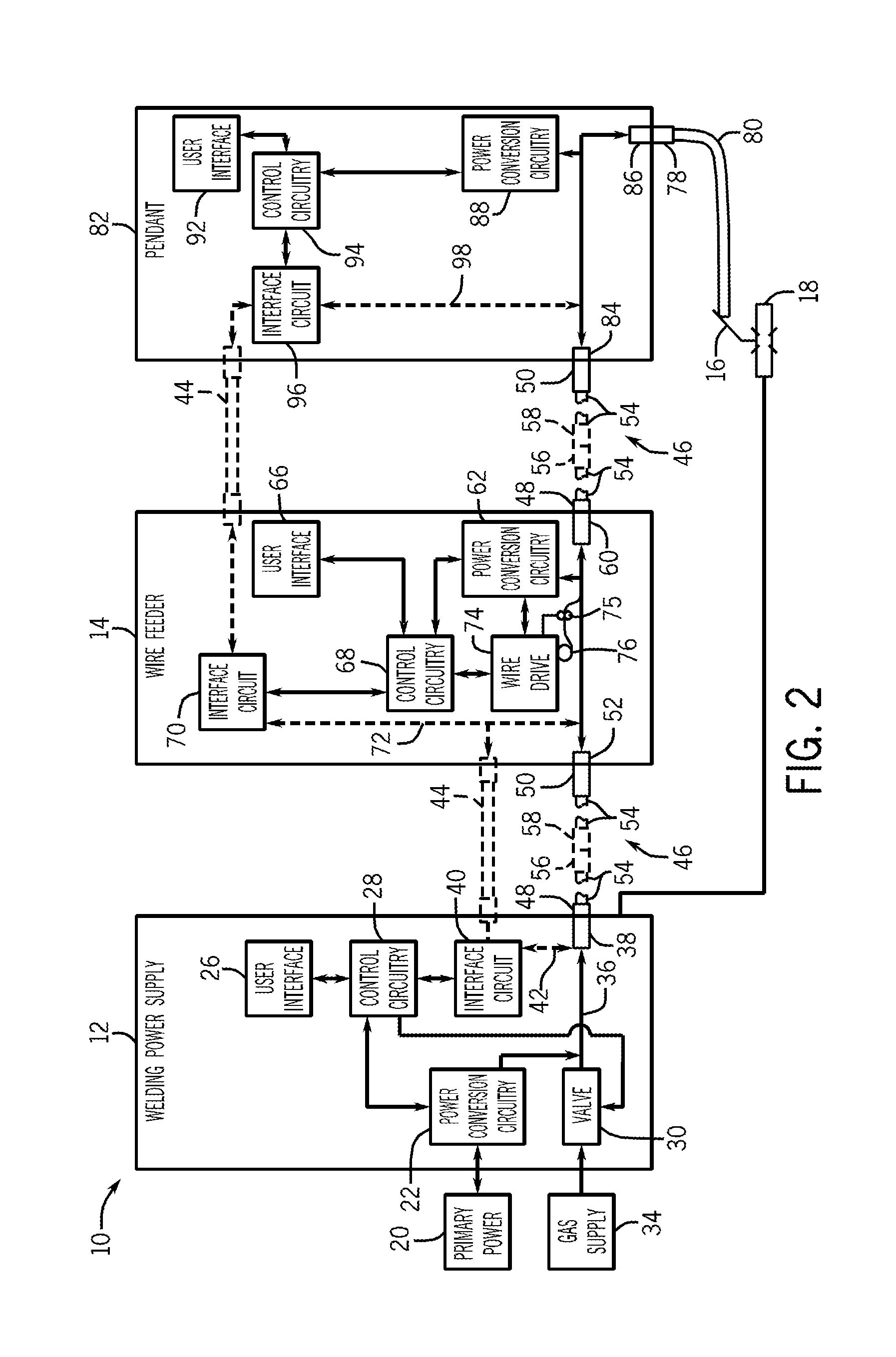

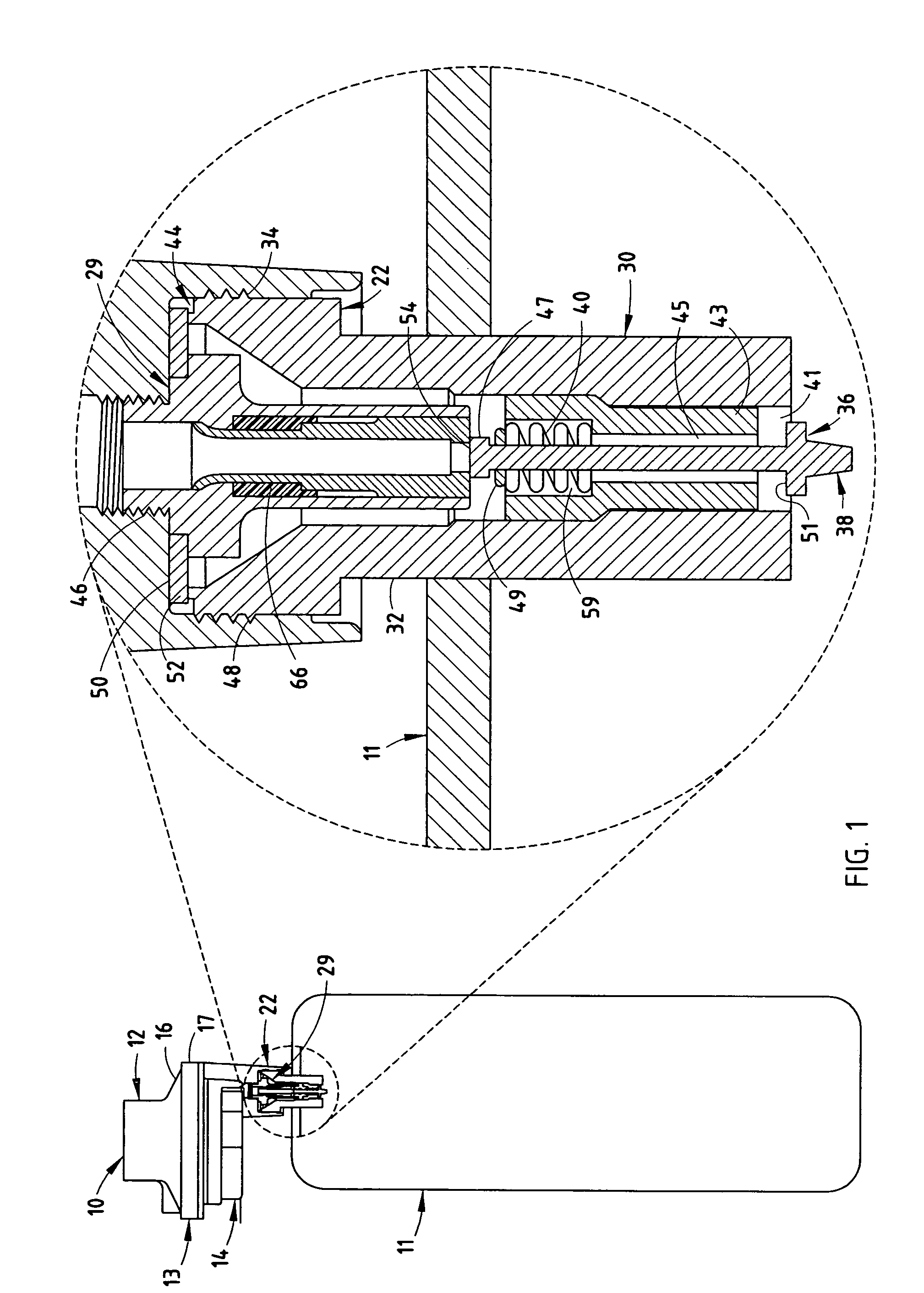

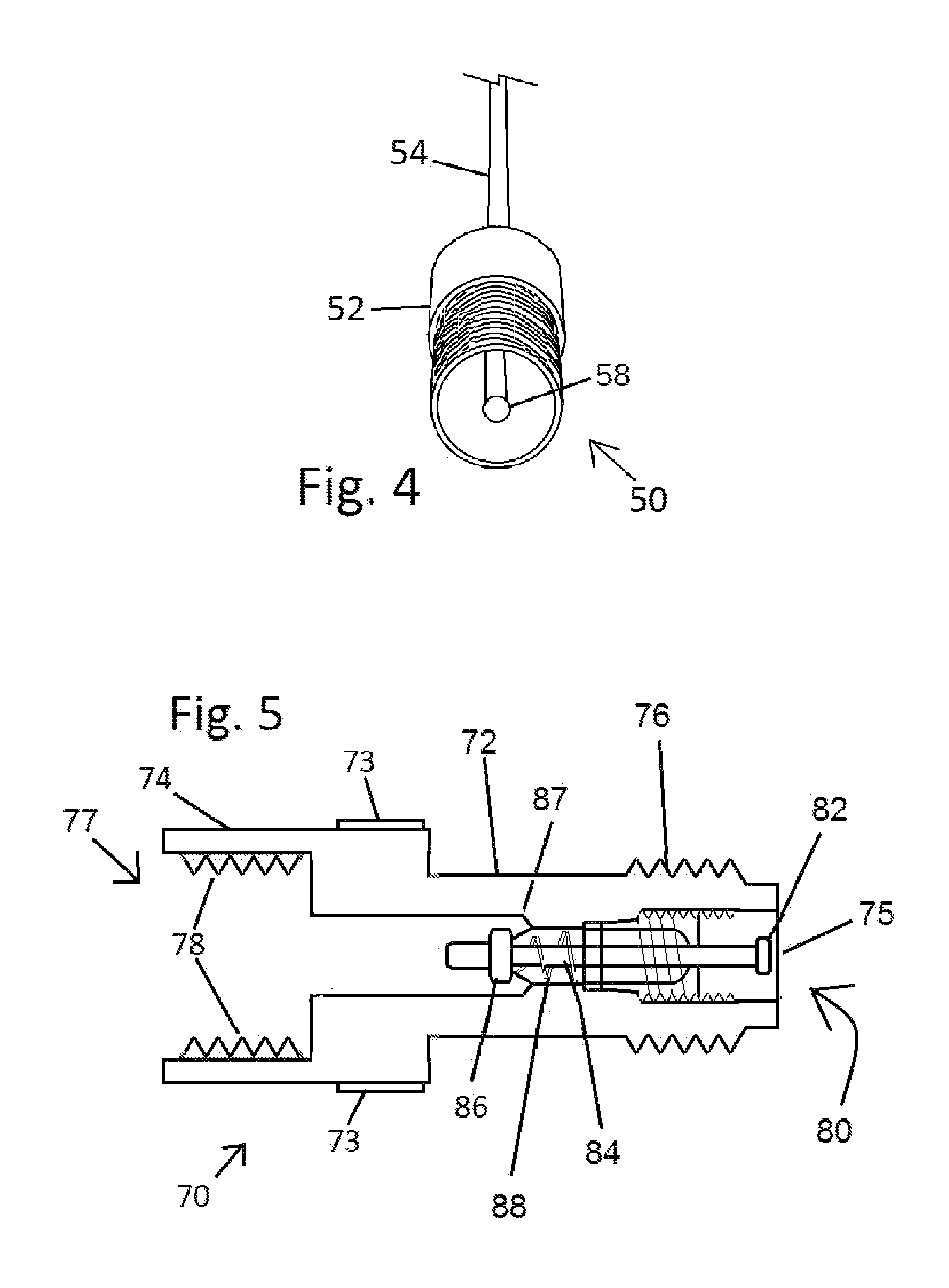

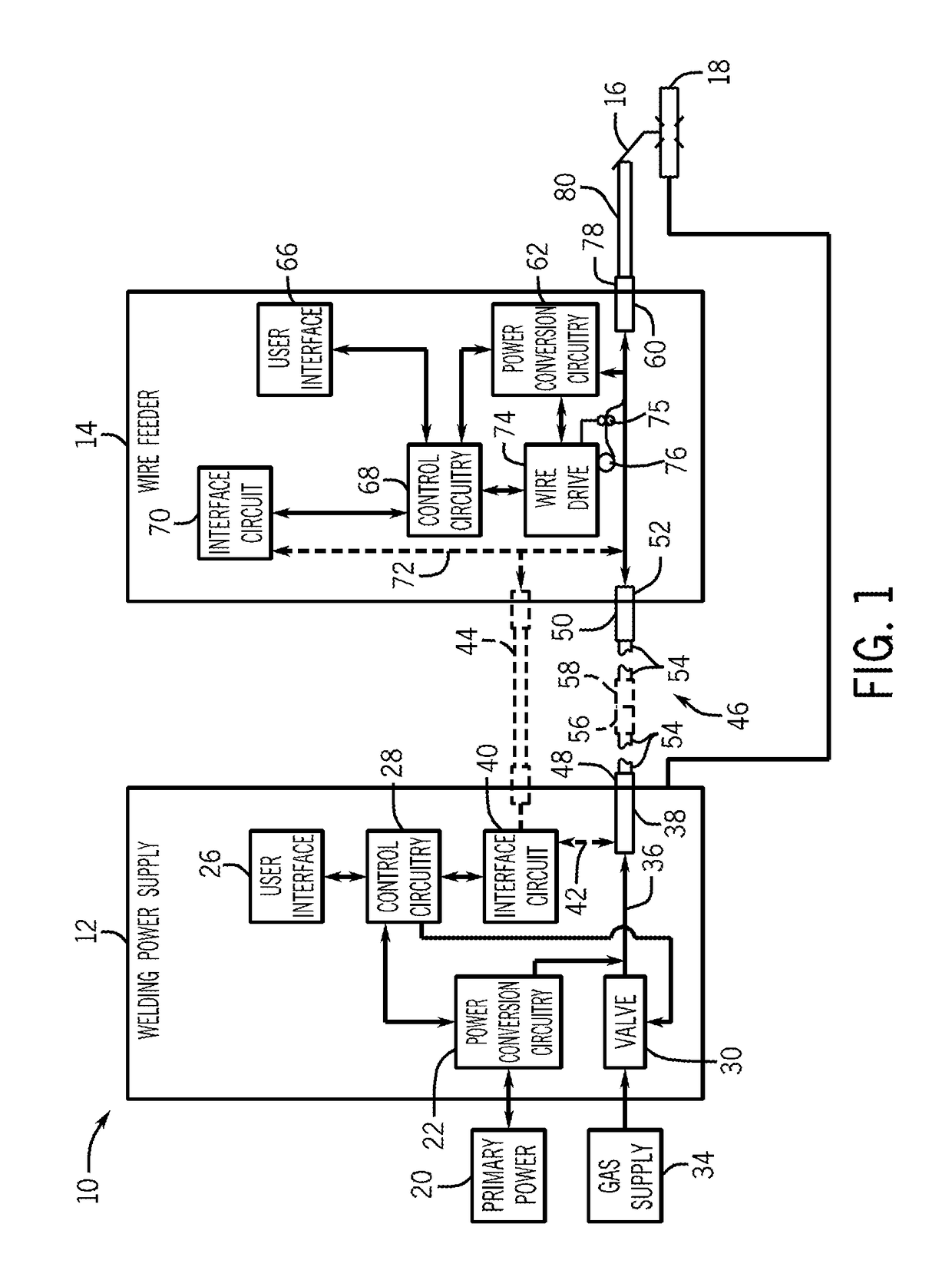

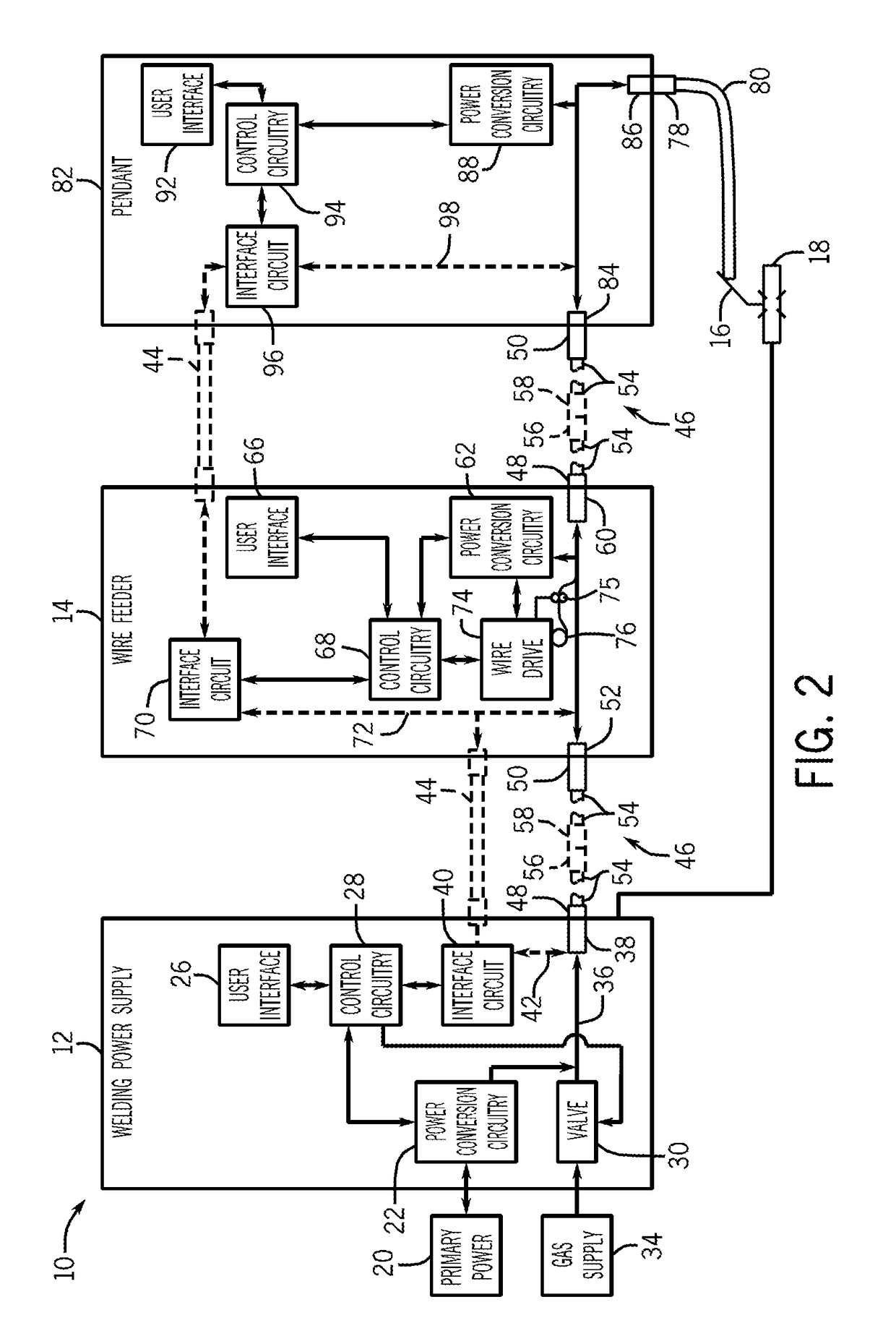

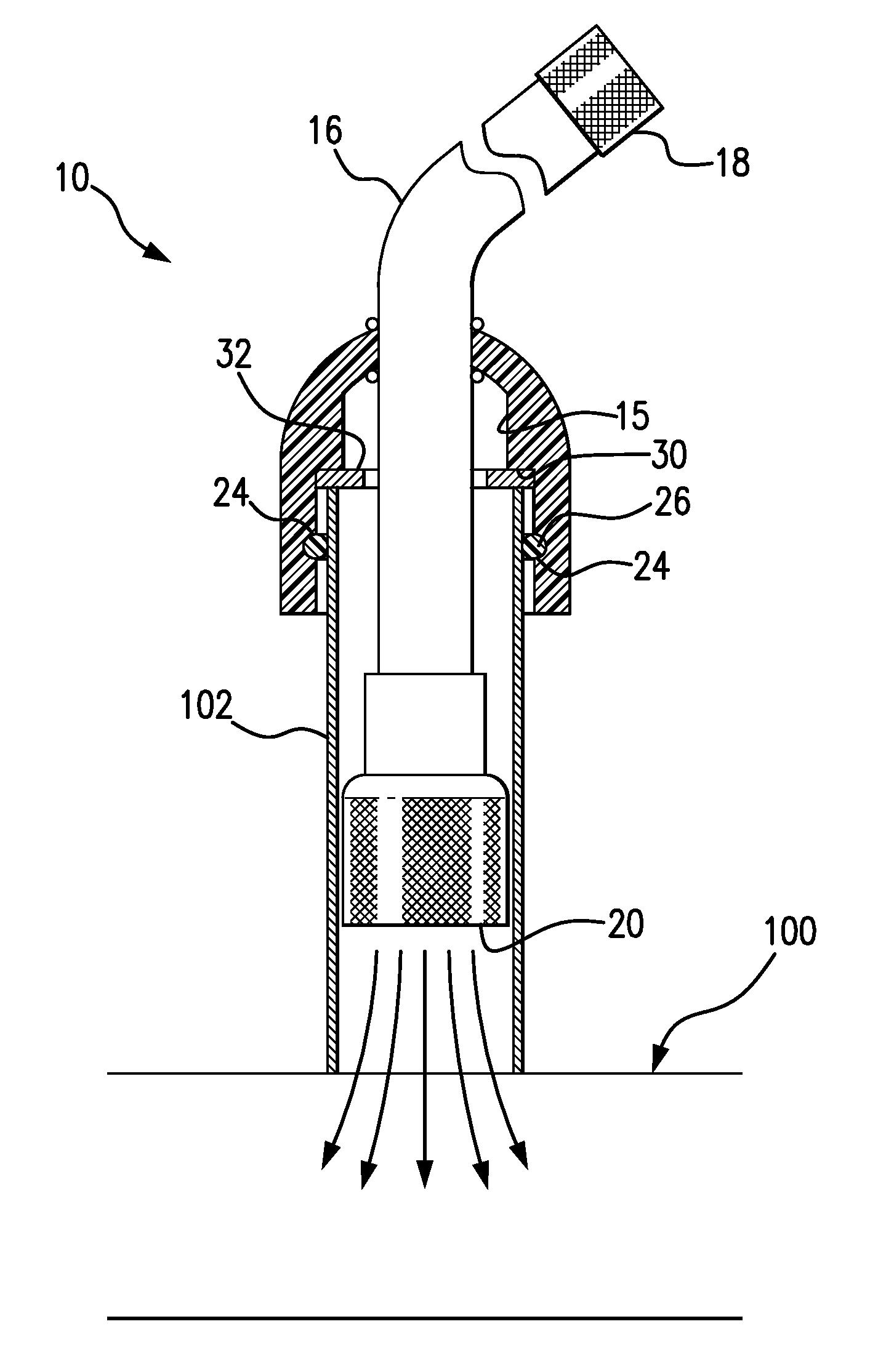

Weld electrical and gas connector with sealed gas flow

A welding cable connector system having a male connector and a female connector. The male connector includes a first conductive body for conveying welding power. The male connector also includes a first sealed passageway disposed coaxially of the first conductive body for conveying shielding gas, and a first Schrader valve configured to stop flow of shielding gas when the male connector is not engaged. The female connector includes a second conductive body for conveying welding power. The female connector also includes a second sealed passageway disposed coaxially of the conductive body for conveying shielding gas, and a second Schrader valve configured to stop flow of shielding gas when the female connector is not engaged. The male and female connectors are mutually engageable to conduct welding power and shielding gas therethrough. The first and second Schrader valves seal the flow of shielding gas when the connectors are not mutually engaged.

Owner:ILLINOIS TOOL WORKS INC

Liquid fuel injection

InactiveUS7150416B2Eliminate needSafer means to deliverBurnersLiquid fuel feeder/distributionLiquid fuelEngineering

Liquid fuel injectors are provided. The liquid fuel injectors allow the injection of a fine spray of liquid fuel. The liquid fuel injectors utilize a schrader valve movable between an open position and a closed position. When the schrader valve is in the closed position fuel flow is blocked and purge gas is allowed to flow through the fuel injectors. When the schrader valve is in the open position, the flow of purge gas is blocked and fuel is allowed to flow through the fuel injector. In this manner, the fuel injectors provide for an immediate and automatic purge of the fuel lines when the fuel flow is shut off.

Owner:KERR MCGEE CHEM CORP

Manually operable trigger sprayer with rearwardly located sprayer valve

A trigger sprayer valve assembly that has a conical flange that controls the flow of liquid in a downstream direction through a liquid passage of the trigger sprayer. The valve is constructed with an elongate stem or shaft that facilities the assembly of the valve into the trigger sprayer and a positioning plug that solely holds the valve in a centered position in the liquid passage of the trigger sprayer.

Owner:WESTROCK DISPENSING SYST

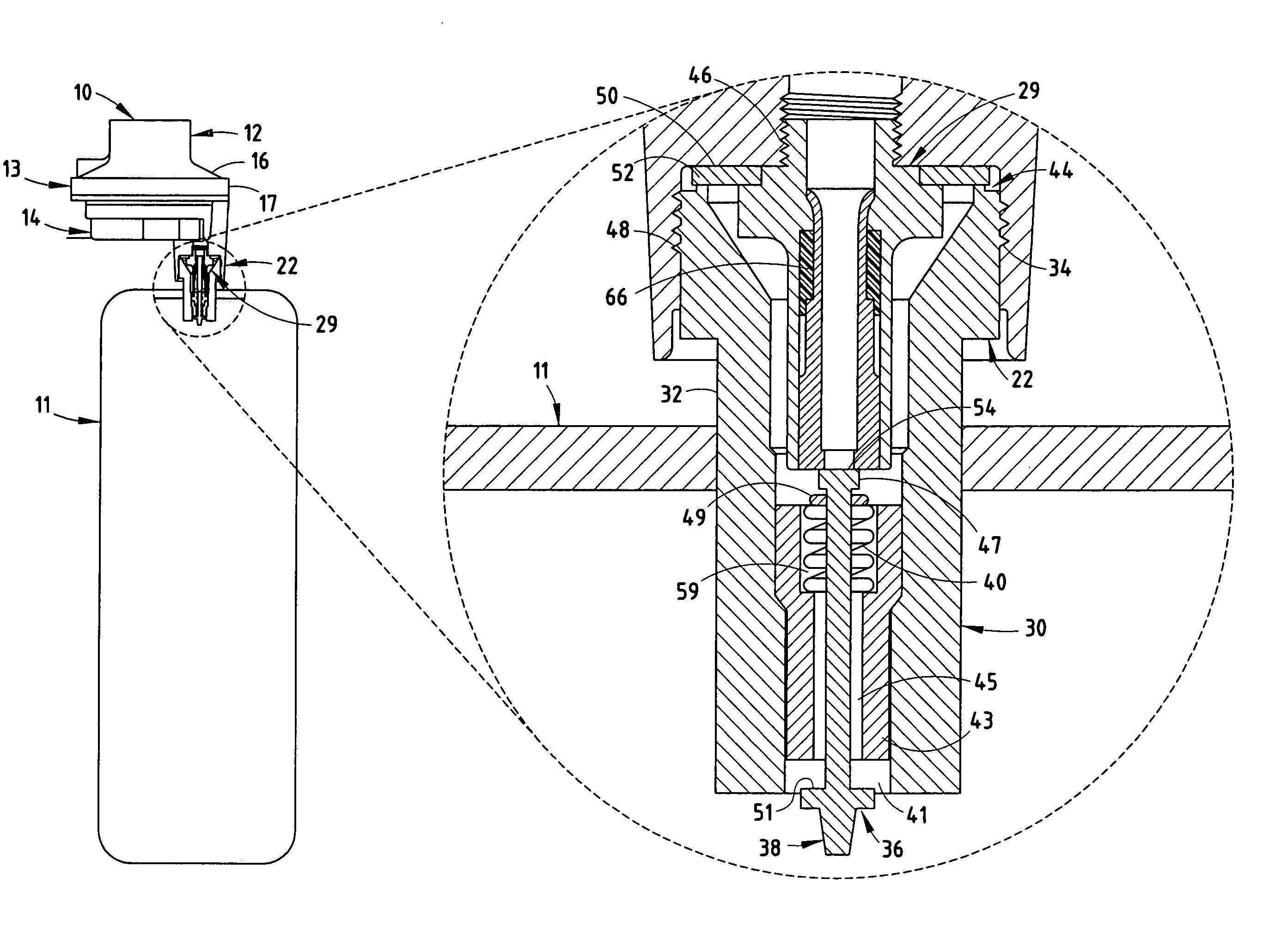

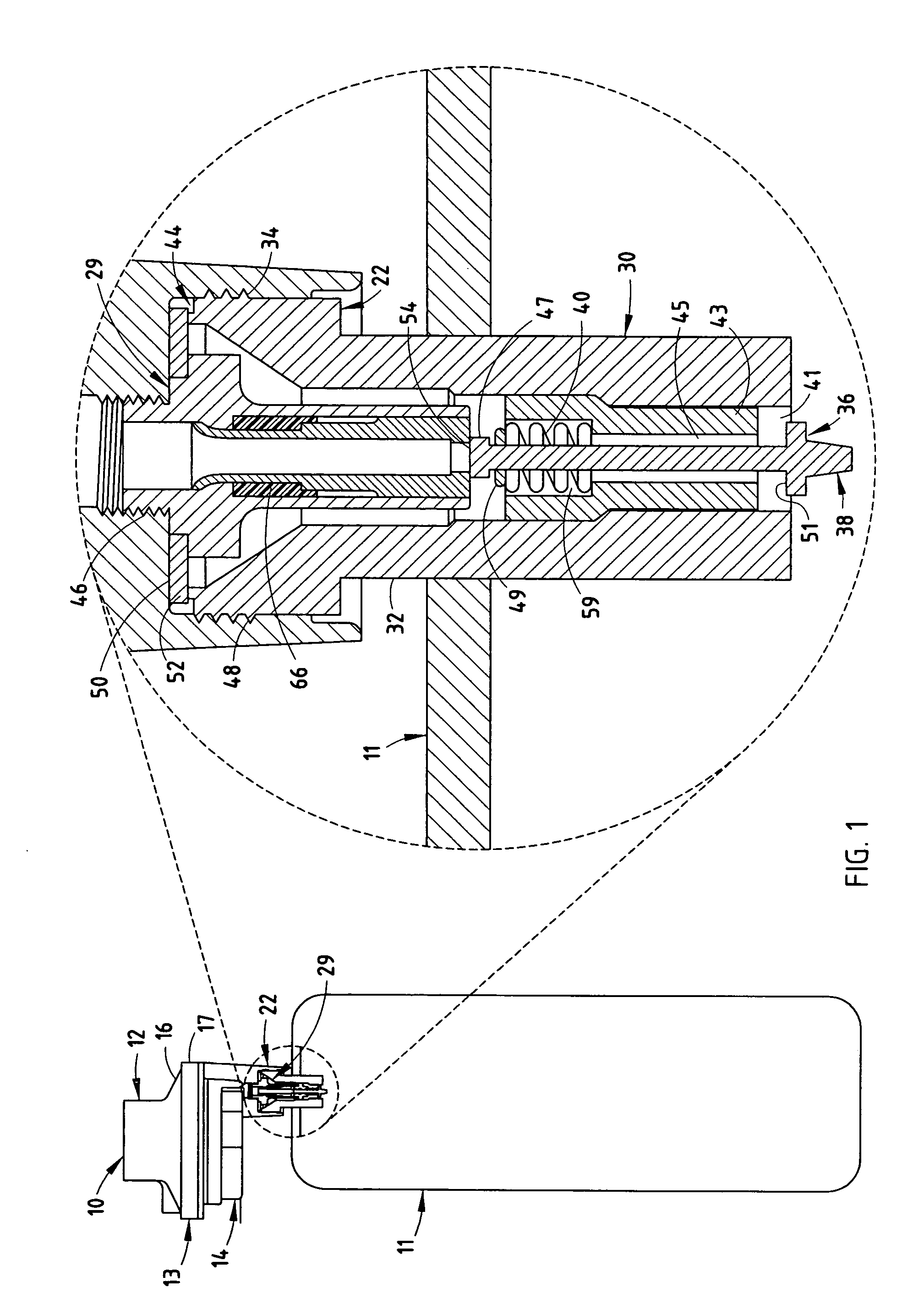

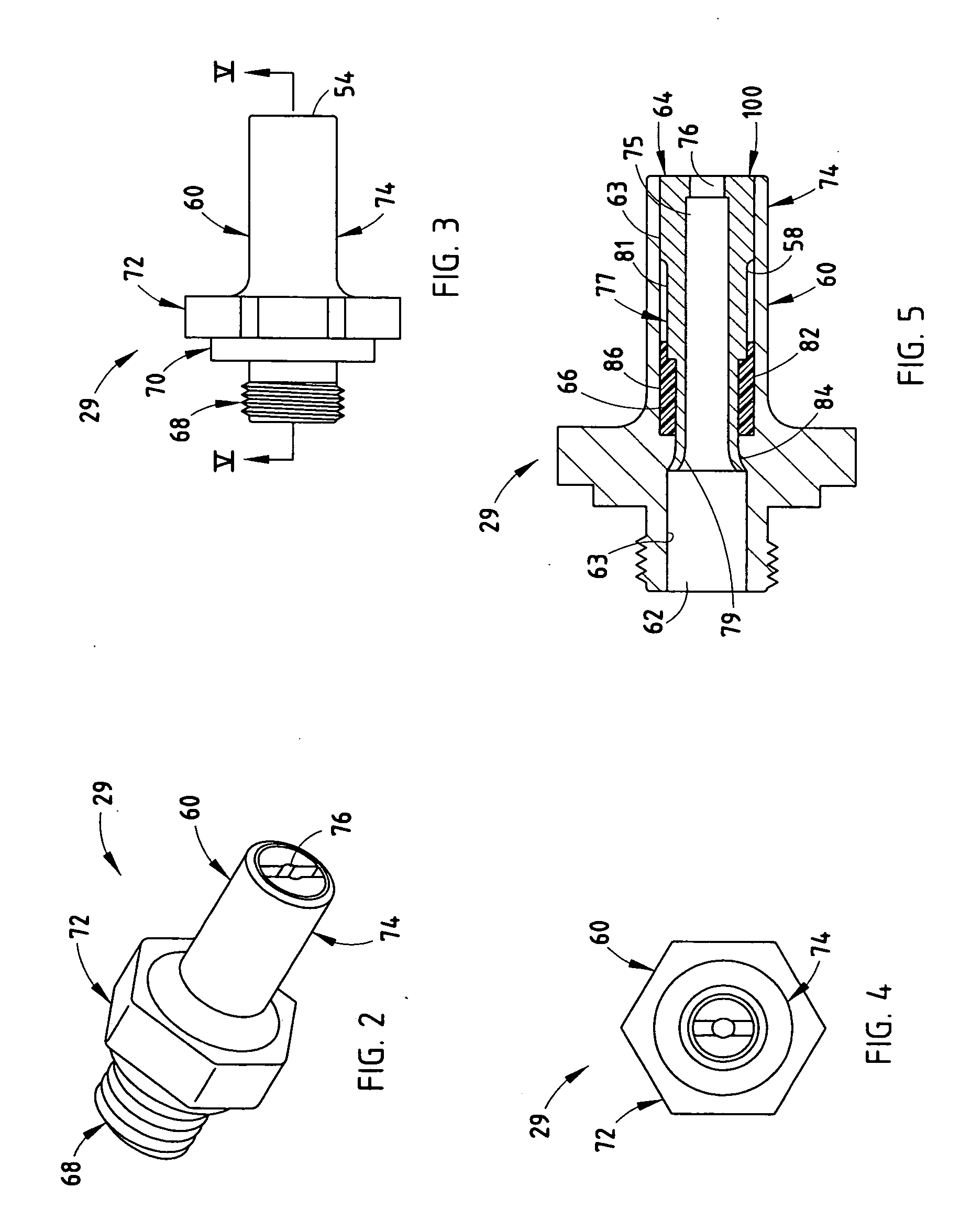

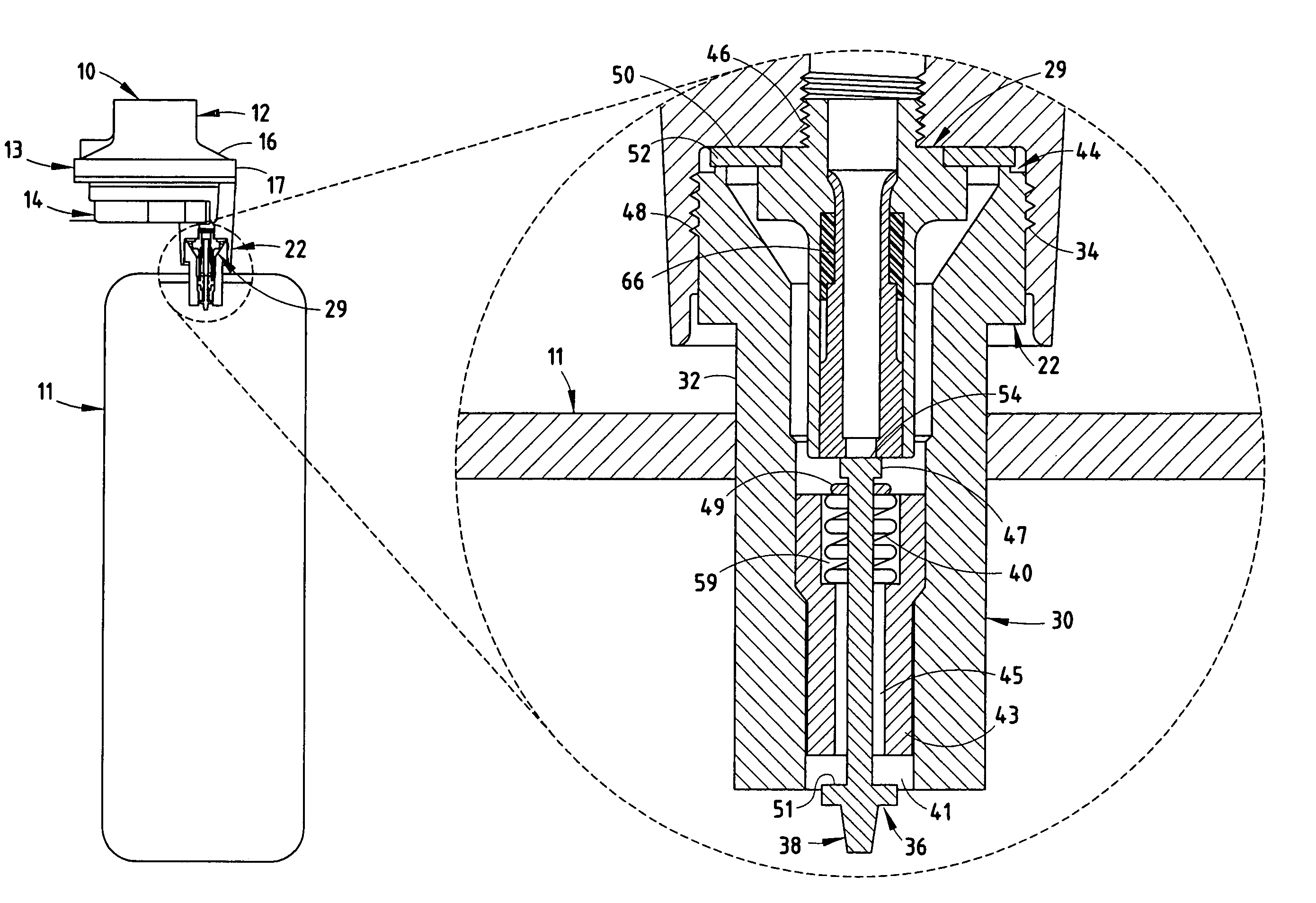

Fire safety device for propane cylinders

InactiveUS20050217725A1Block fluid flowAvoid flowEqualizing valvesSafety valvesGas cylinderFire safety

A fire safety fluid flow device for engagement with a Schrader valve including a sliding valve a housing having a fluid path therethrough and a pressing member. The pressing member presses against the sliding valve of the Schrader valve when engaged therewith to allow fluid flow through the Schrader valve. The pressing member continues to maintain the sliding valve in an open position when the device is below a predetermined temperature and connected to the Schrader valve. The pressing member is configured to no longer press against the sliding valve of the Schrader valve at and above the predetermined temperature to allow the sliding valve of the Schrader valve to thereby stop fluid flow through the Schrader valve.

Owner:LEGGITT S H

Fire safety device for propane cylinders

A fire safety fluid flow device for engagement with a Schrader valve including a sliding valve a housing having a fluid path therethrough and a pressing member. The pressing member presses against the sliding valve of the Schrader valve when engaged therewith to allow fluid flow through the Schrader valve. The pressing member continues to maintain the sliding valve in an open position when the device is below a predetermined temperature and connected to the Schrader valve. The pressing member is configured to no longer press against the sliding valve of the Schrader valve at and above the predetermined temperature to allow the sliding valve of the Schrader valve to thereby stop fluid flow through the Schrader valve.

Owner:LEGGITT S H

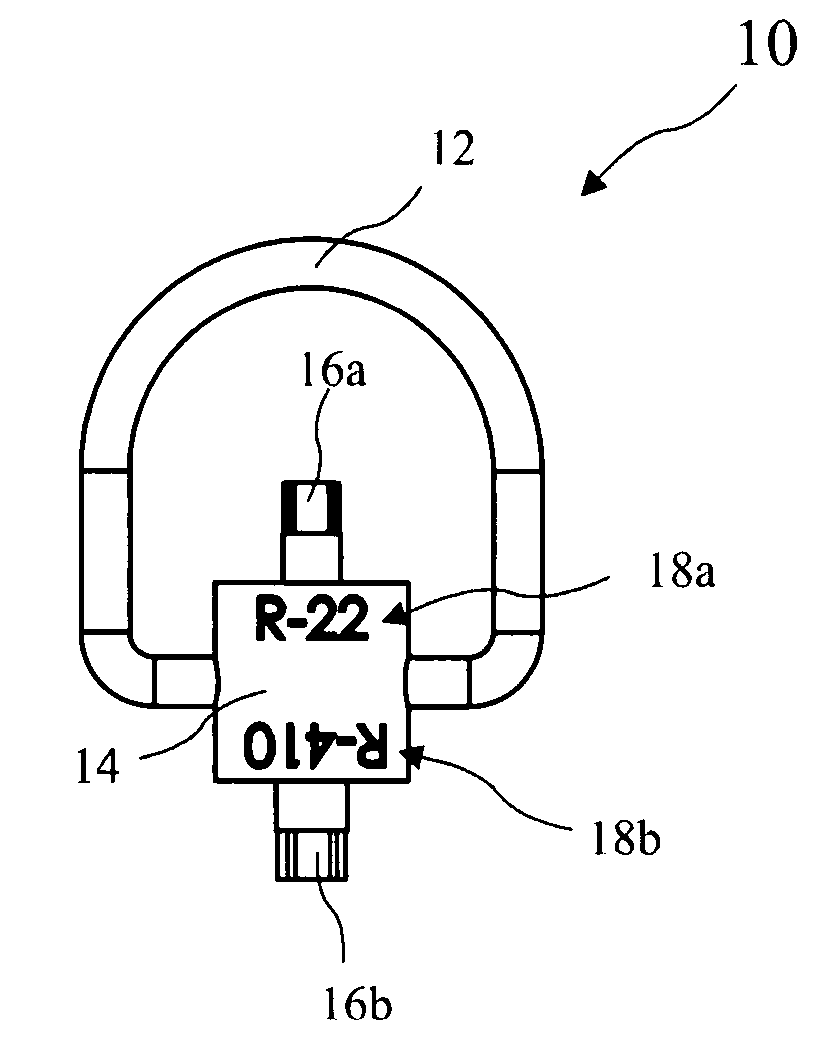

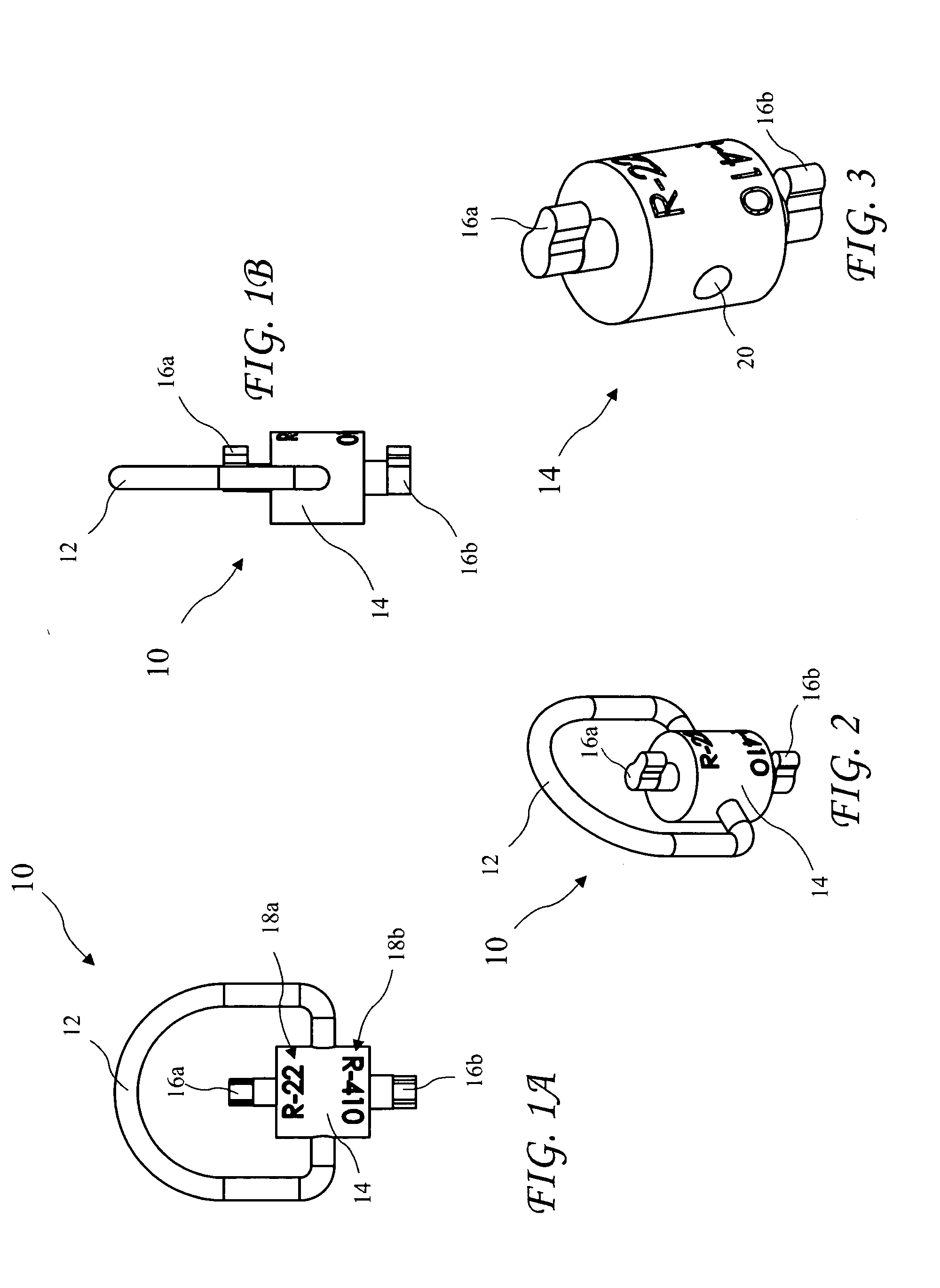

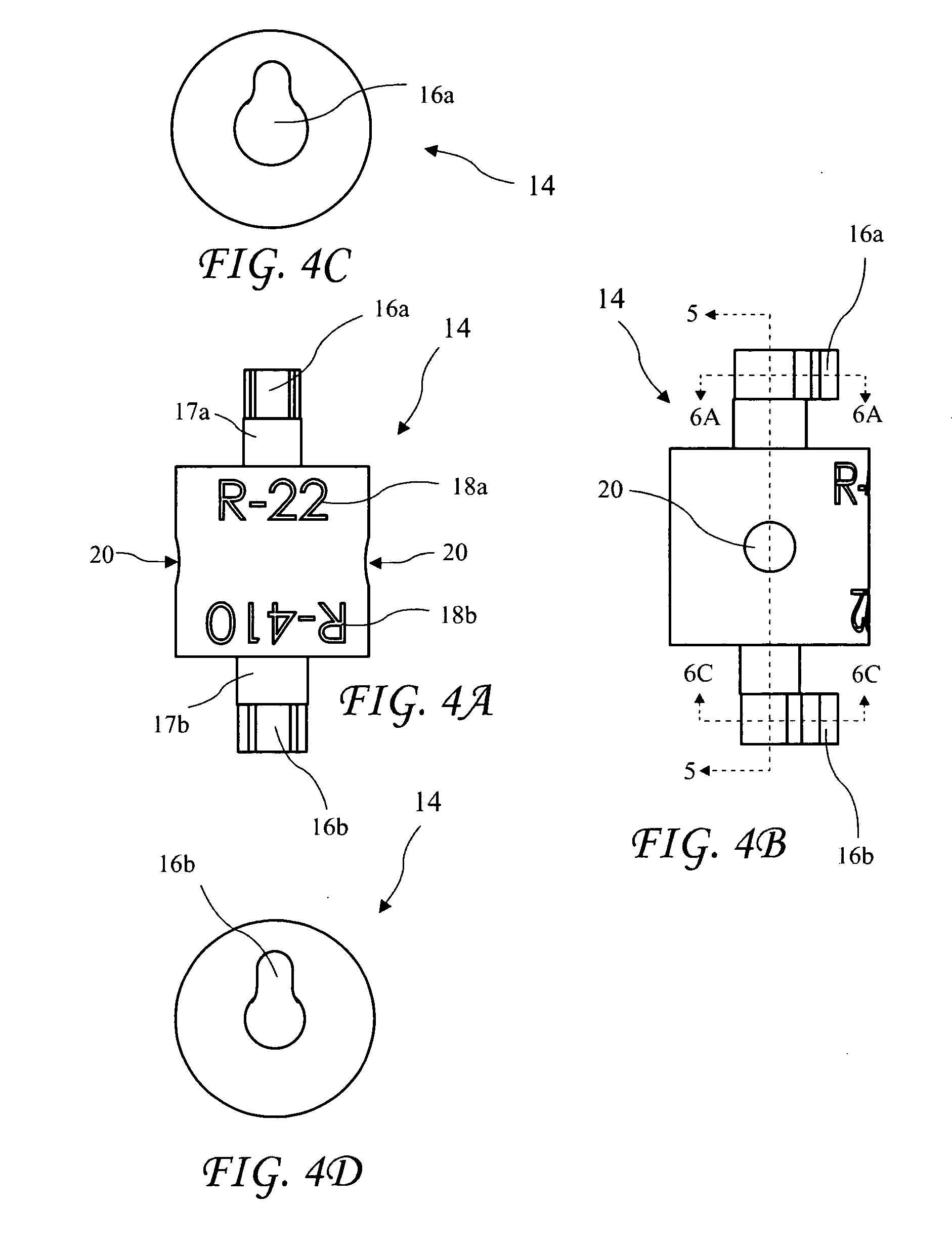

Combination tool

A combination tool includes a compact “D” shaped handle and a rotating drum for tool selection. The straight back segment of the “D” provides an axis for rotation of the drum. The drum includes opposed tool ends, either of which may be rotated into position for use. In a preferred embodiment, the tool ends are keys for releasing a tamper resistant cap over a Schrader valve. Each key is shaped for a cap used with a particular Freon® refrigerant used in an air conditioning unit. The drum includes indicia of which Freon® refrigerant the corresponding key matches.

Owner:BYRNE JOSEPH

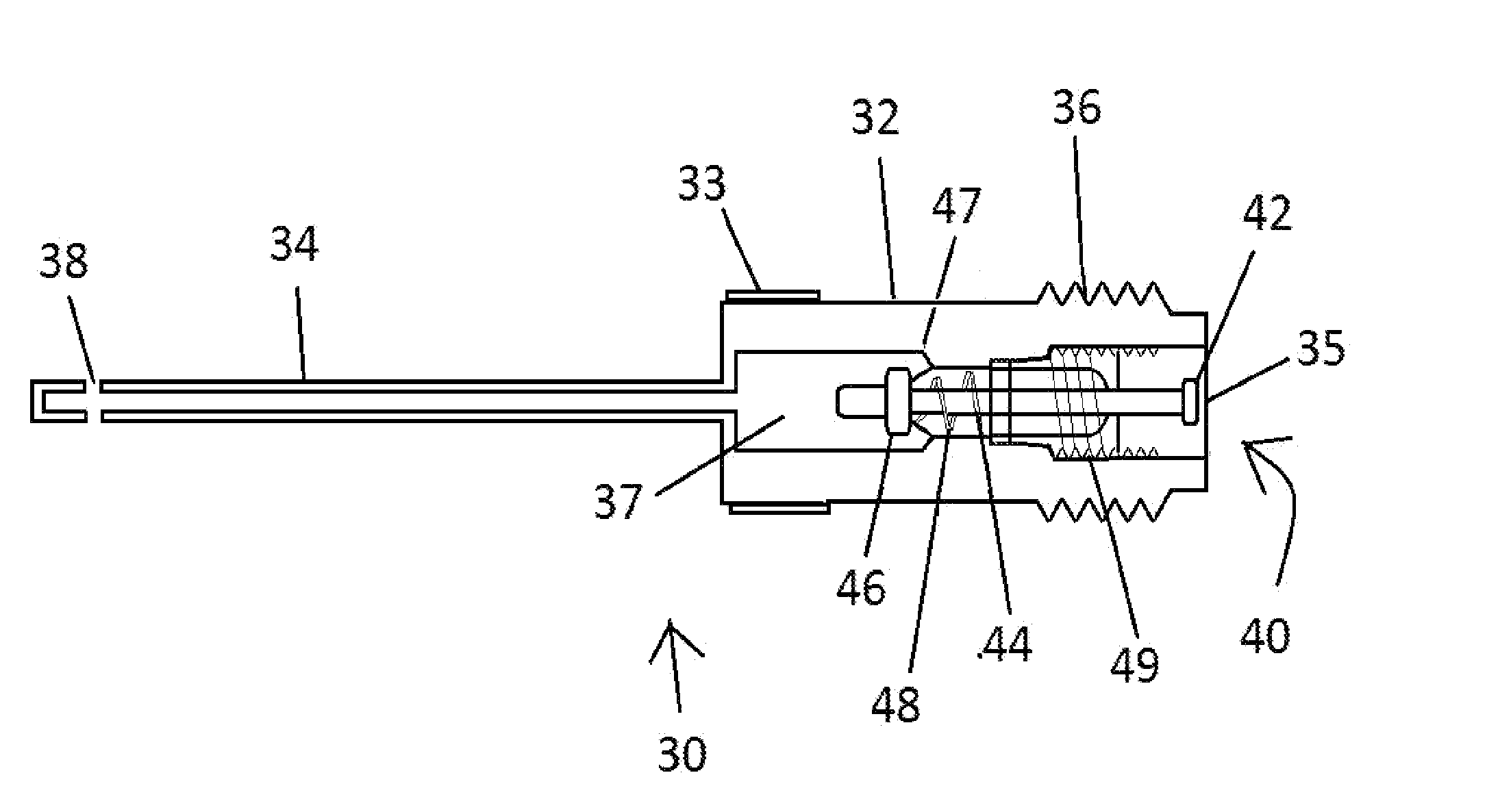

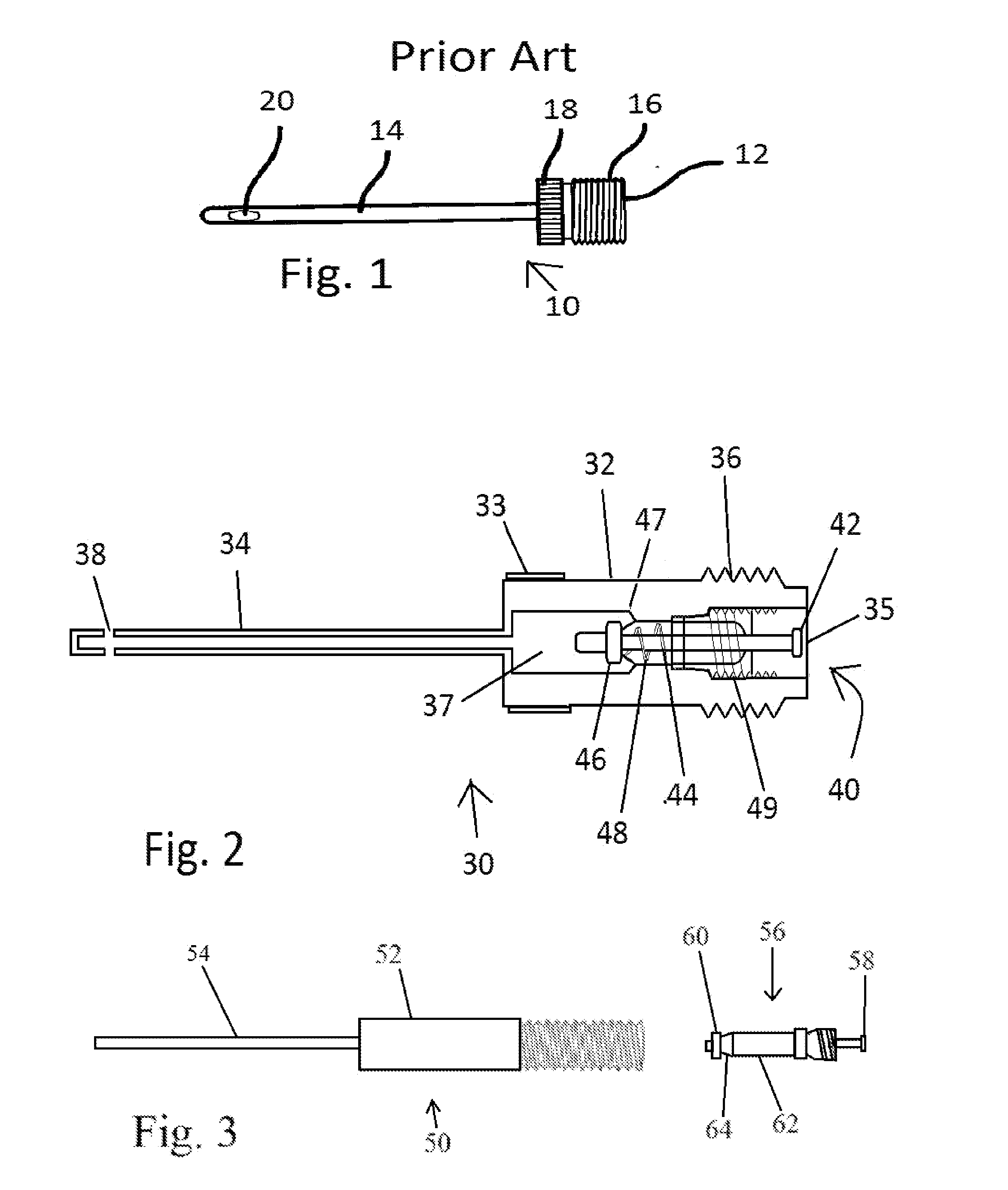

Tire Valve Tool having Air Communication Means

InactiveUS20140014197A1Provide convenienceRemoved and replacedCheck valvesThin material handlingEngineeringCheck valve

A multipurpose tire valve tool is provided for the purposes of maintenance of a Schrader valve and for replacing the tube of a pneumatic tire. The tool comprises a valve core removal key, a valve stem tap arm, a first air inlet end, and a second valve stem attachment end. Through the body of the tool is an air conduit and an internal valve core post for depressing the same. A check valve along the air inlet end allows air to be communicated into the tool, whereby the air flows therethrough and into an attached Schrader valve for filling the tire tube while the tool is thereattached. The tool facilitates removal of the valve core, cleaning of the valve stem threads, and filling the tire or tire tube with air while the tool maintains the position of the valve stem through the rim.

Owner:RENAKER ROBERT +1

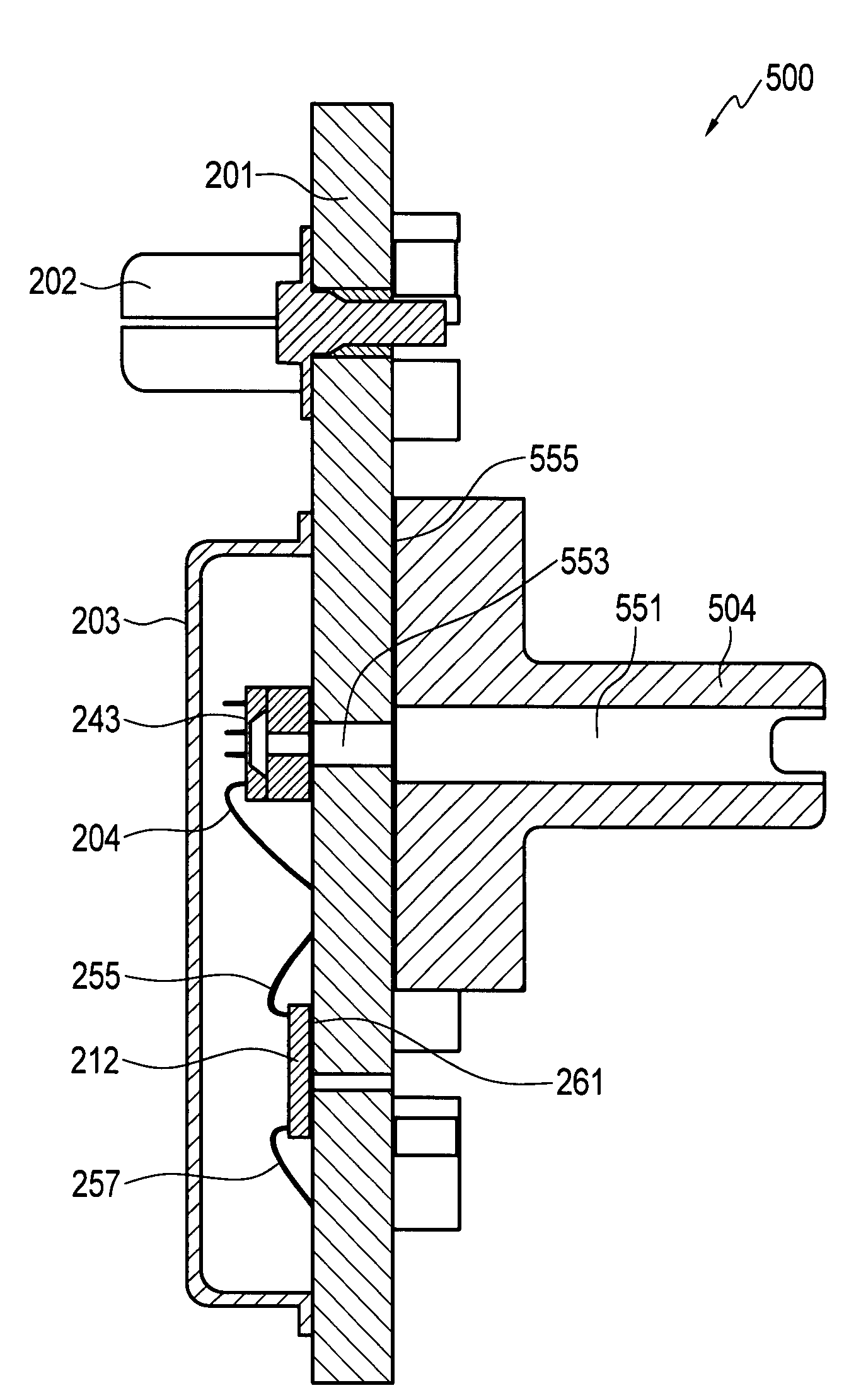

Pressure sensor method and apparatus

InactiveCN101657709AEliminates the need for stickingFluid pressure measurement by electric/magnetic elementsOn boardTransducer

A pressure sensor apparatus and a method of forming the same. A substrate (201 (e.g., Printed circuit board, PCB) can be provided that includes a top side and a bottom side. A pressure transducer (243) can be directly bonded to the top side of the substrate (201), wherein the substrate comprises substrate walls forming a plated through-hole (553) that allows for the passage of a sensed media to contact a back side of the pressure transducer (243). Thereafter, a metal carrier (504) with an integral port (551) is bonded to the bottom side of the substrate (201), thereby forming a chip-on-board pressure sensor (500) in which the need for a plating or coating to allow adhesion between the pressure transducer (243) and the metal carrier (504) is eliminated. The pressure transducer may comprise,for example, silicon or silicon bonded to glass. The metal carrier can be provided with a feature that mates with a valve such as a Schrader valve.

Owner:HONEYWELL INT INC

Inflation apparatus having integral check valve

An inflation device system incorporates and internal valve. The incorporation of an internal valve allows for more precise application and measurement of gas pressure with in an object to which the inflation device is inserted. The valve may be a Schrader valve.

Owner:CONNORS VINCENT

Hose attachment device for clearing drain lines

A hose attachment device for use in combination with a source of pressurized gas or liquid for clearing HVACR drain lines. The device includes a cap having an interior cavity extending from an open bottom end that is sized for engaged receipt of an open-ended drain line extension. One embodiment of the device includes a hose extending through the top of the cap and having a fitting at the proximal end of the hose (extending from the top of the cap) that is sized for attachment to the pressurized source. A valve fitting at the distal end of the hose is sized for engaged receipt of a male valve stem, such as a Schrader valve. Another embodiment of the invention includes a valve fitting extending through top of the cap. A further embodiment of the invention includes an upper component and a lower component forming the cap, wherein the upper component is securable to a nozzle of a garden hose and the bottom component is securable to an open-ended drain line extension.

Owner:RS ACQUISITION SUB LLC

Valve connector

InactiveUS20020046772A1Reduce wearLittle strengthSleeve/socket jointsCheck valvesNormal caseCoupling

By a universal valve connector for inflation valves of vehicle tires (Sclaverand, Dunlop-Woods, or Schrader), whose connector consists of a connector housing (368), which partly is connected to a pressure source, preferably a hand or foot pump, and which partly has a coupling hold (5) with a diameter corresponding to the diameter of the valve, which is to be connected, where the coupling hole is equipped with a securing means for securing on the valve, plus a sealing means against valves of different sizes. This to is achieved by the sealing means (366) being mounted coaxially in the connector housing (368) and being established on at least two parallel, separate levels, having the center line (4) of the connector housing (368), which is coaxial to the center line of the valve, as its normal, where the minor diameters of the sealing means approximately correspond to the major diameter of the current valve dimensions, on which the connector is mounted when used, that the sealing means (366), closest to the opening (8) of the coupling hole (5) in the connector housing (368) has the biggest minor diameter, while the sealing means (366) farthest from the opening (8) of the coupling hole in the connector housing (368) has the smallest minor diameter, and diameters between the extremes are lying corresponding separate distance between these extremes. The valve connector has the possibility of automatically adjust itself to the valve in question and if needed to activate the central core of a Schrader valve. Also, it is possible to use the connector with existing pumps.

Owner:NVB INT AS

Tire valve tool having air communication means

InactiveUS8726476B2Removed and replacedEasy to cleanThin material handlingMetal working apparatusEngineeringCatheter

A multipurpose tire valve tool is provided for the purposes of maintenance of a Schrader valve and for replacing the tube of a pneumatic tire. The tool comprises a valve core removal key, a valve stem tap arm, a first air inlet end, and a second valve stem attachment end. Through the body of the tool is an air conduit and an internal valve core post for depressing the same. A check valve along the air inlet end allows air to be communicated into the tool, whereby the air flows therethrough and into an attached Schrader valve for filling the tire tube while the tool is thereattached. The tool facilitates removal of the valve core, cleaning of the valve stem threads, and filling the tire or tire tube with air while the tool maintains the position of the valve stem through the rim.

Owner:RENAKER ROBERT +1

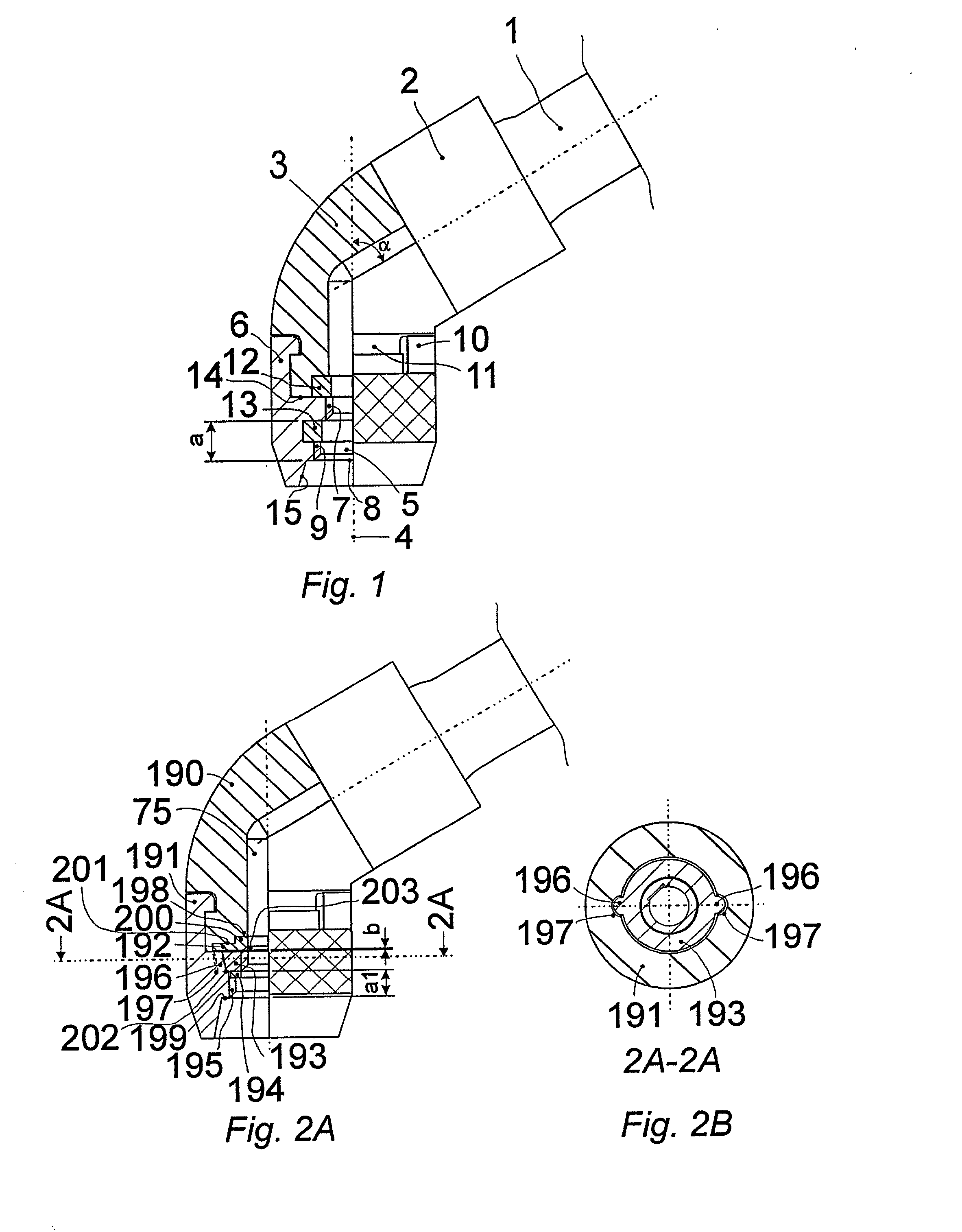

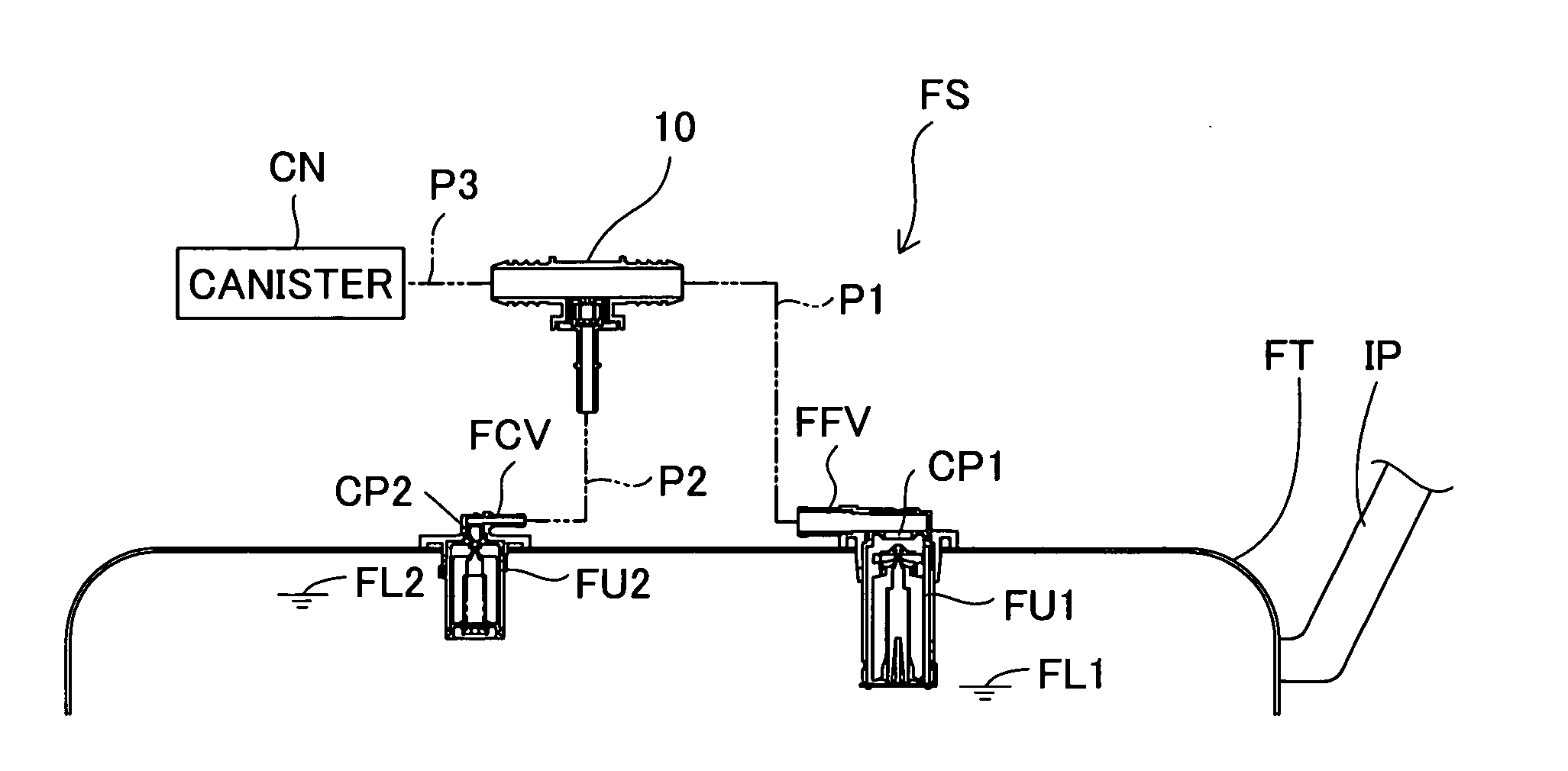

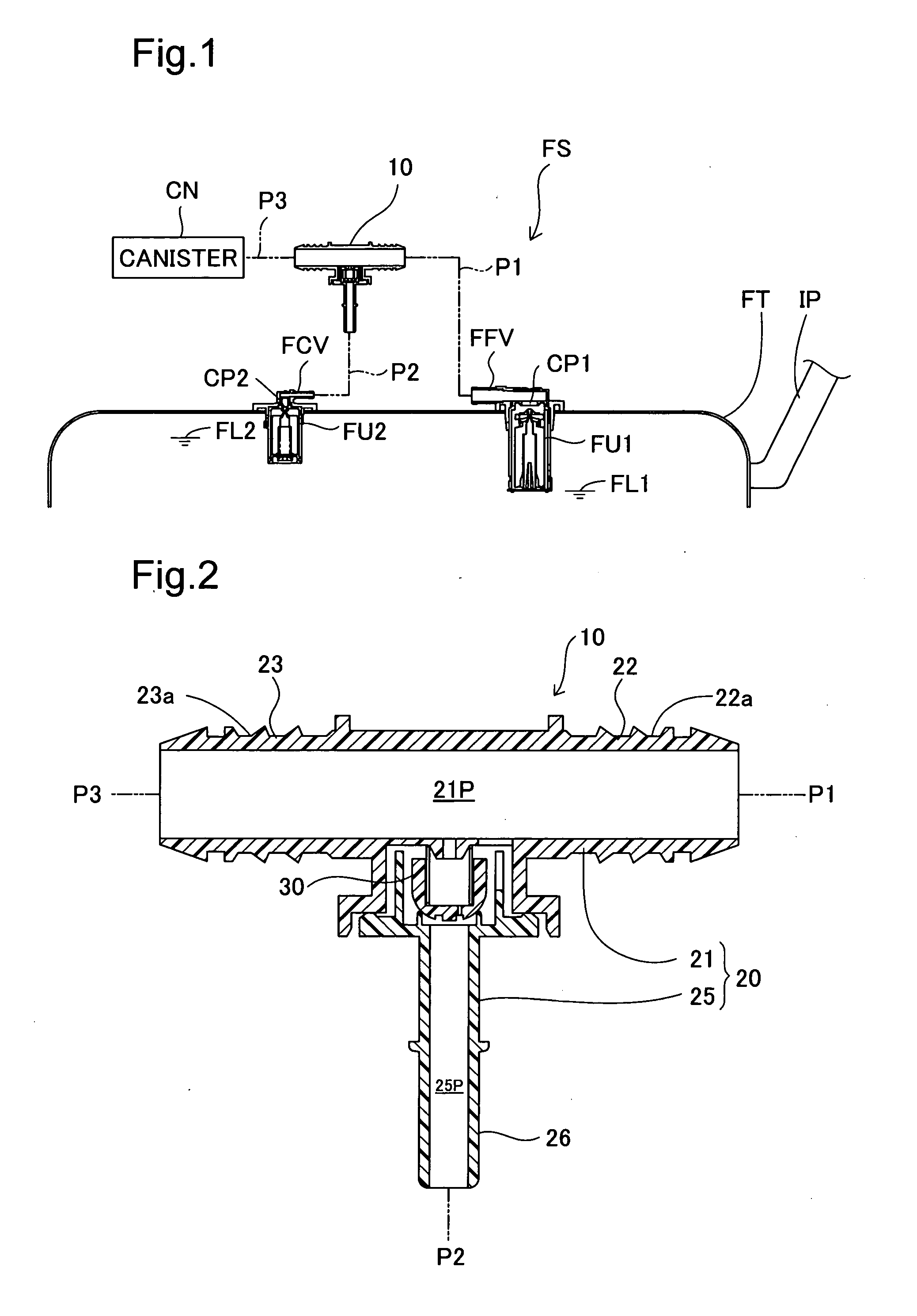

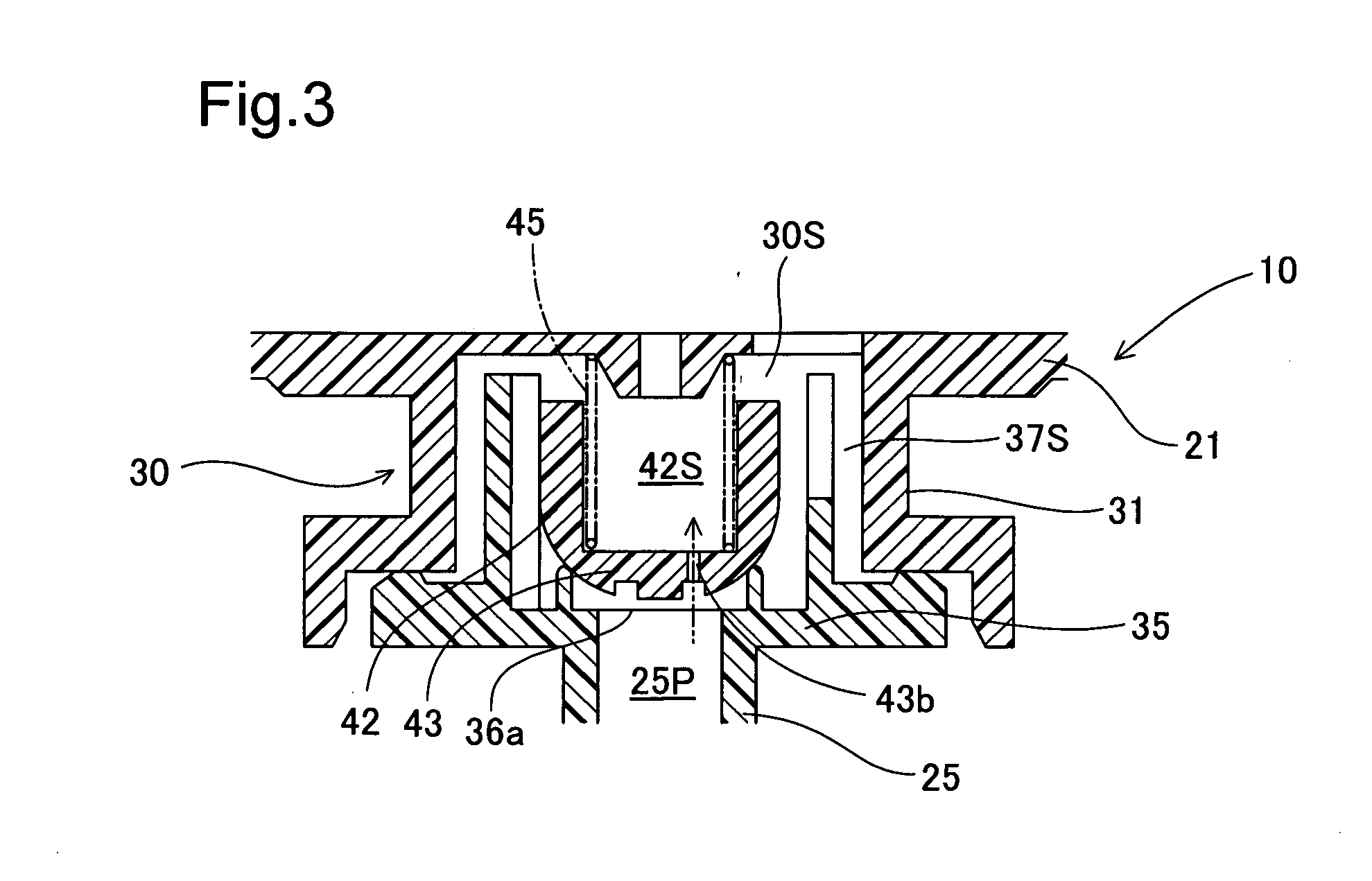

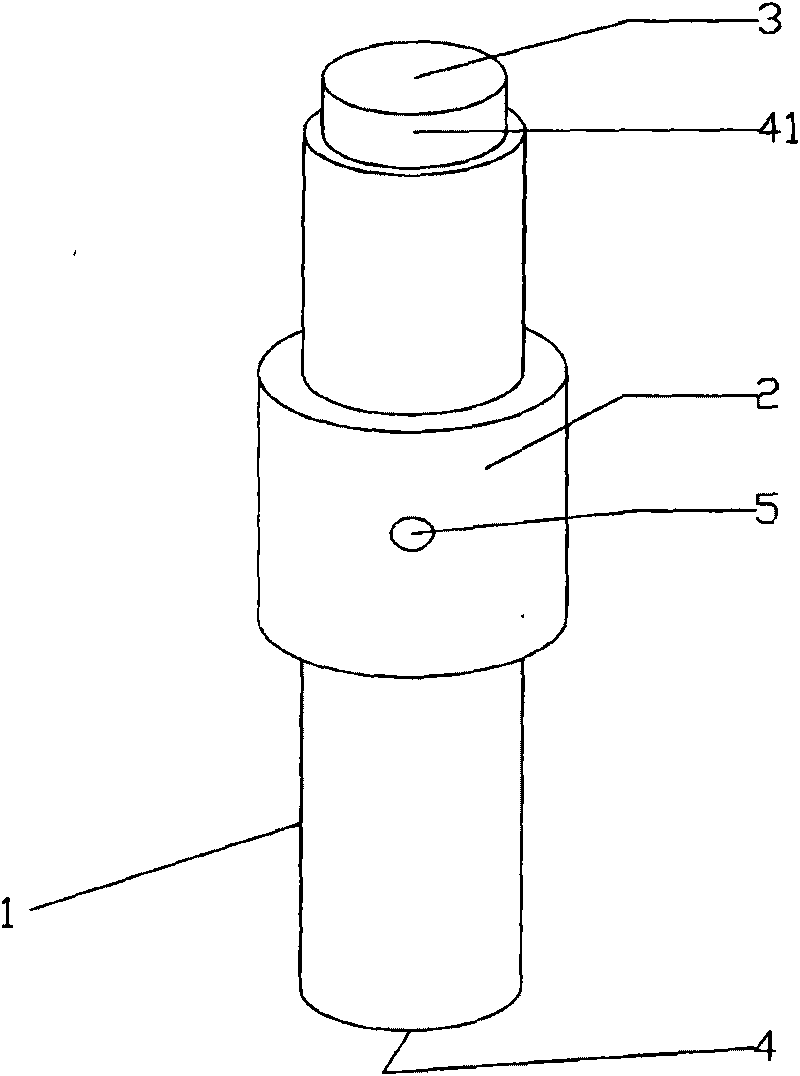

Venting device for fuel tank

ActiveUS20090293849A1Limiting riseWell formedNon-fuel substance addition to fuelMachines/enginesRolloverFuel tank

The fuel tank venting device is furnished with a full fuel control valve and a rollover valve that are installed on a fuel tank, and a fuel tank valve unit having a pressure valve that is situated between a canister and the two valves. The pressure valve is furnished with a casing that has a valve chamber, a valve body housed within the valve chamber, and a spring. The valve body has a disk-shaped valve part and a side wall that projects with tubular contours from the outside perimeter of the valve part, and has a cup shape defining a spring chamber that is bounded by the valve part and the side wall. The valve part is perforated by an orifice of smaller planar dimensions than the valve aperture.

Owner:TOYODA GOSEI CO LTD

Stick for measuring circumferential distance of flange plate

InactiveCN101750000AFlexible and easy to measureAccurate and fast measurementMechanical clearance measurementsButt jointEngineering

The invention provides a stick for measuring the circumferential distance of a flange plate, which comprises a stick body, wherein the two ends of the stick body are respectively provided with measuring scales, the measuring scale valve of one end is larger than that of the other end, and the top of the end with the smaller measuring scale valve is provided with a lug boss. The stick can be suitable for use under various environment conditions such as air medium or underwater, and the like; has simple structure, small volume, convenient carrying, flexible operation, convenience and simpleness; exactly measures the circumferential distance of the flange plate and greatly improves the success rate of the butt joint of the flange plate; and saves time and labor, is safe and reliable, and effectively improves the work efficiency and the accuracy.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Liquid fuel injection

InactiveUS20060144954A1Increase temperatureEliminate needBurnersLiquid fuel feeder/distributionLiquid fuelFuel line

Liquid fuel injectors are provided. The liquid fuel injectors allow the injection of a fine spray of liquid fuel. The liquid fuel injectors utilize a schrader valve movable between an open position and a closed position. When the schrader valve is in the closed position fuel flow is blocked and purge gas is allowed to flow through the fuel injectors. When the schrader valve is in the open position, the flow of purge gas is blocked and fuel is allowed to flow through the fuel injector. In this manner, the fuel injectors provide for an immediate and automatic purge of the fuel lines when the fuel flow is shut off.

Owner:KERR MCGEE CHEM CORP

Weld electrical and gas connector with sealed gas flow

A welding cable connector system having a male connector and a female connector. The male connector includes a first conductive body for conveying welding power. The male connector also includes a first sealed passageway disposed coaxially of the first conductive body for conveying shielding gas, and a first Schrader valve configured to stop flow of shielding gas when the male connector is not engaged. The female connector includes a second conductive body for conveying welding power. The female connector also includes a second sealed passageway disposed coaxially of the conductive body for conveying shielding gas, and a second Schrader valve configured to stop flow of shielding gas when the female connector is not engaged. The male and female connectors are mutually engageable to conduct welding power and shielding gas therethrough. The first and second Schrader valves seal the flow of shielding gas when the connectors are not mutually engaged.

Owner:ILLINOIS TOOL WORKS INC

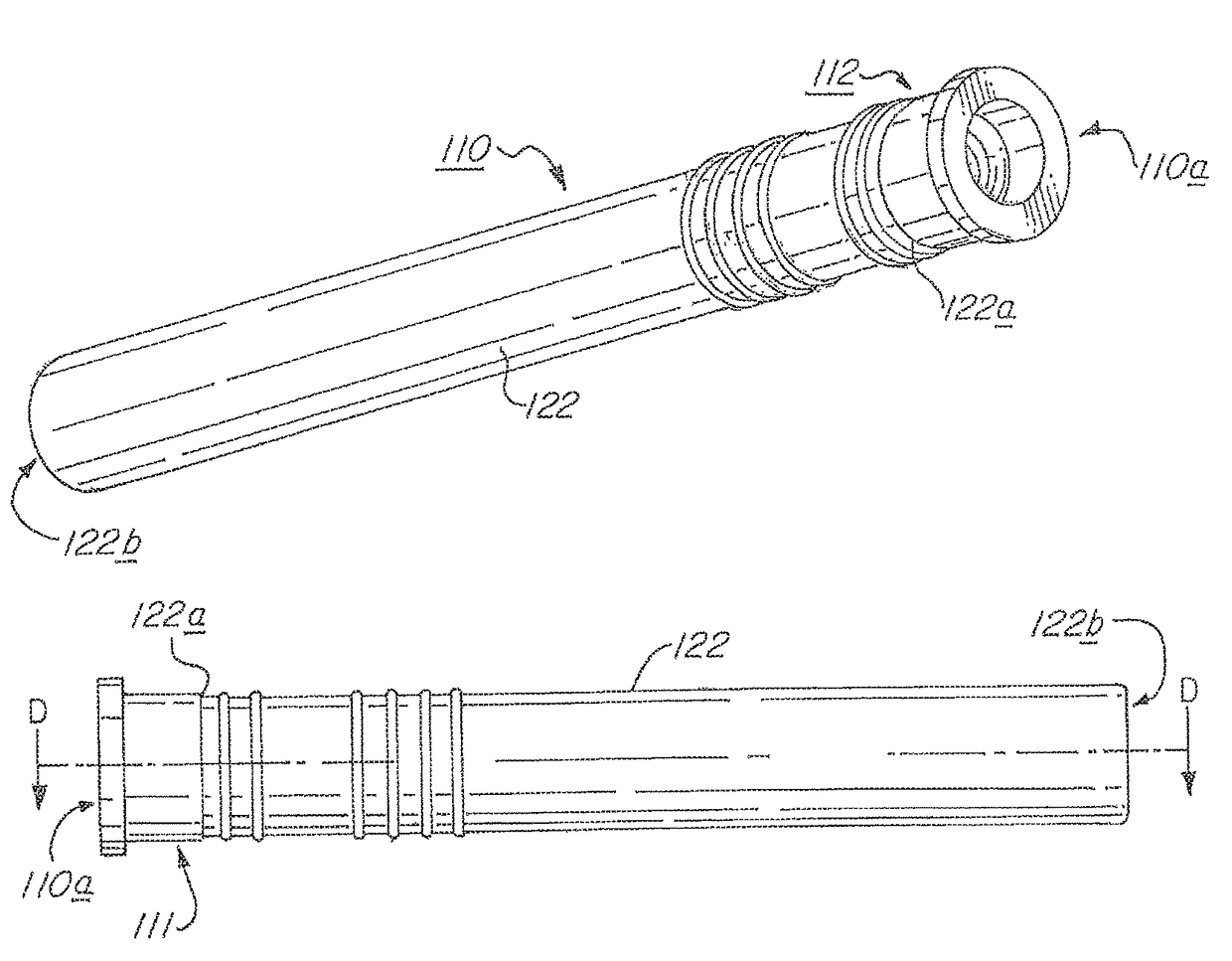

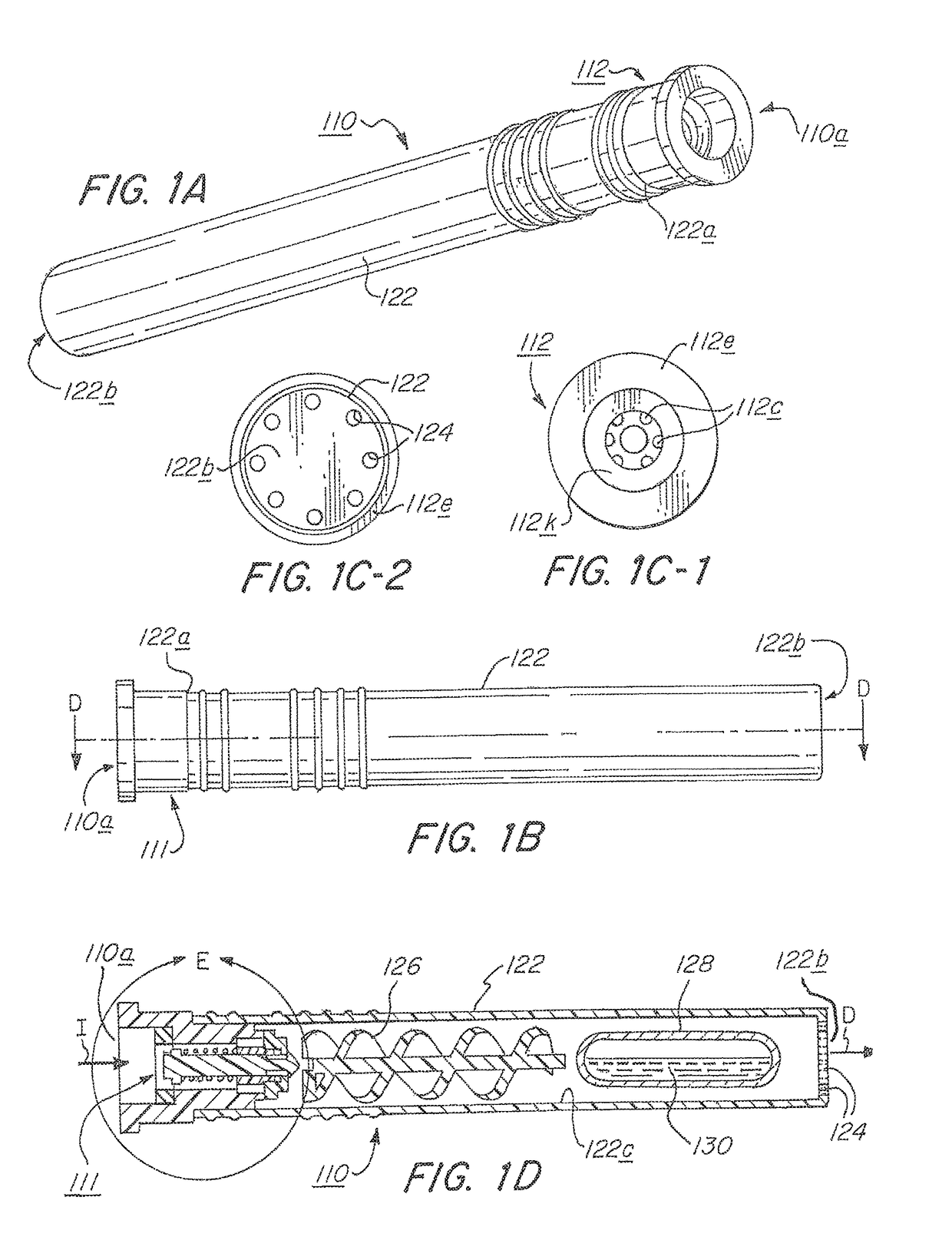

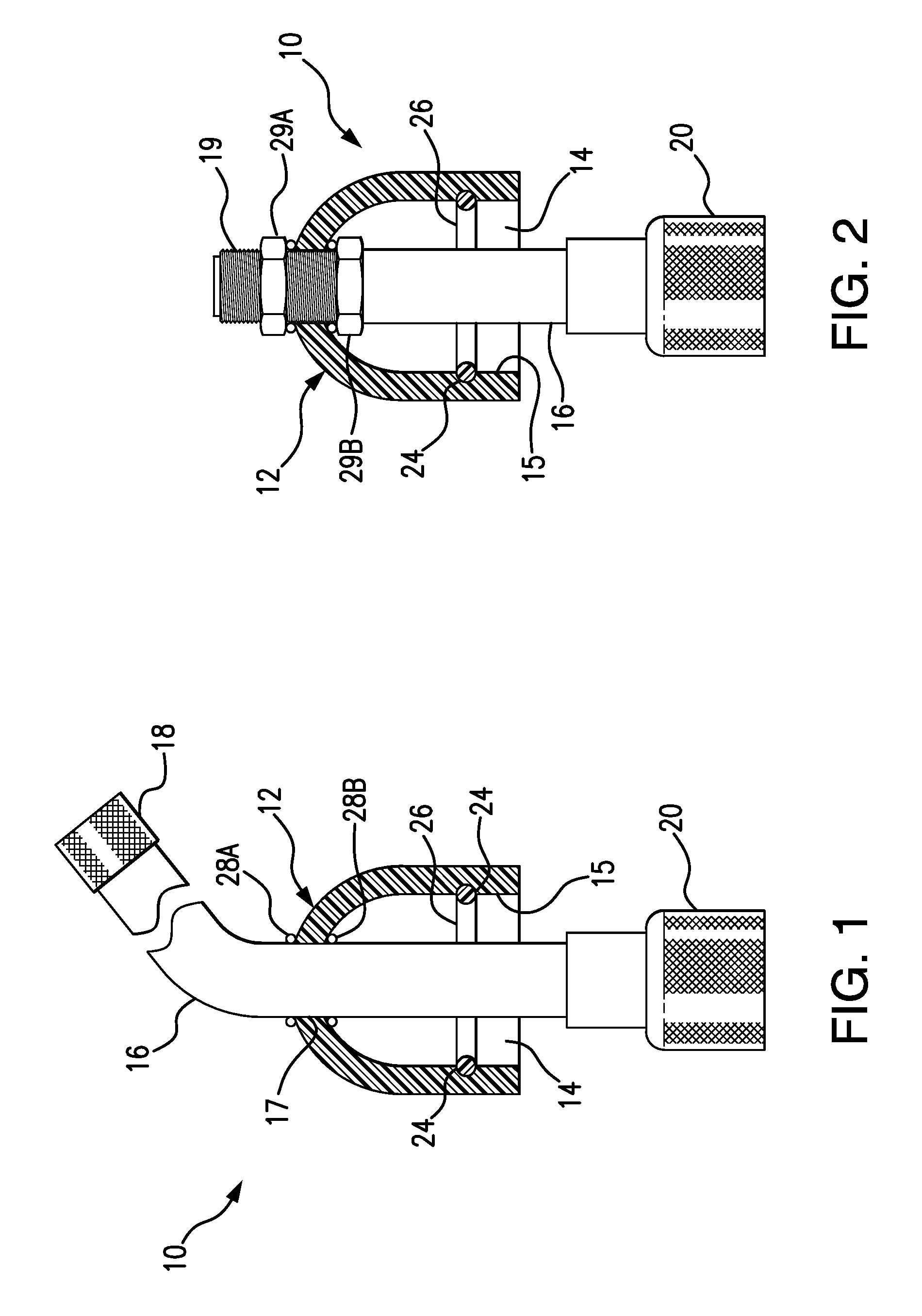

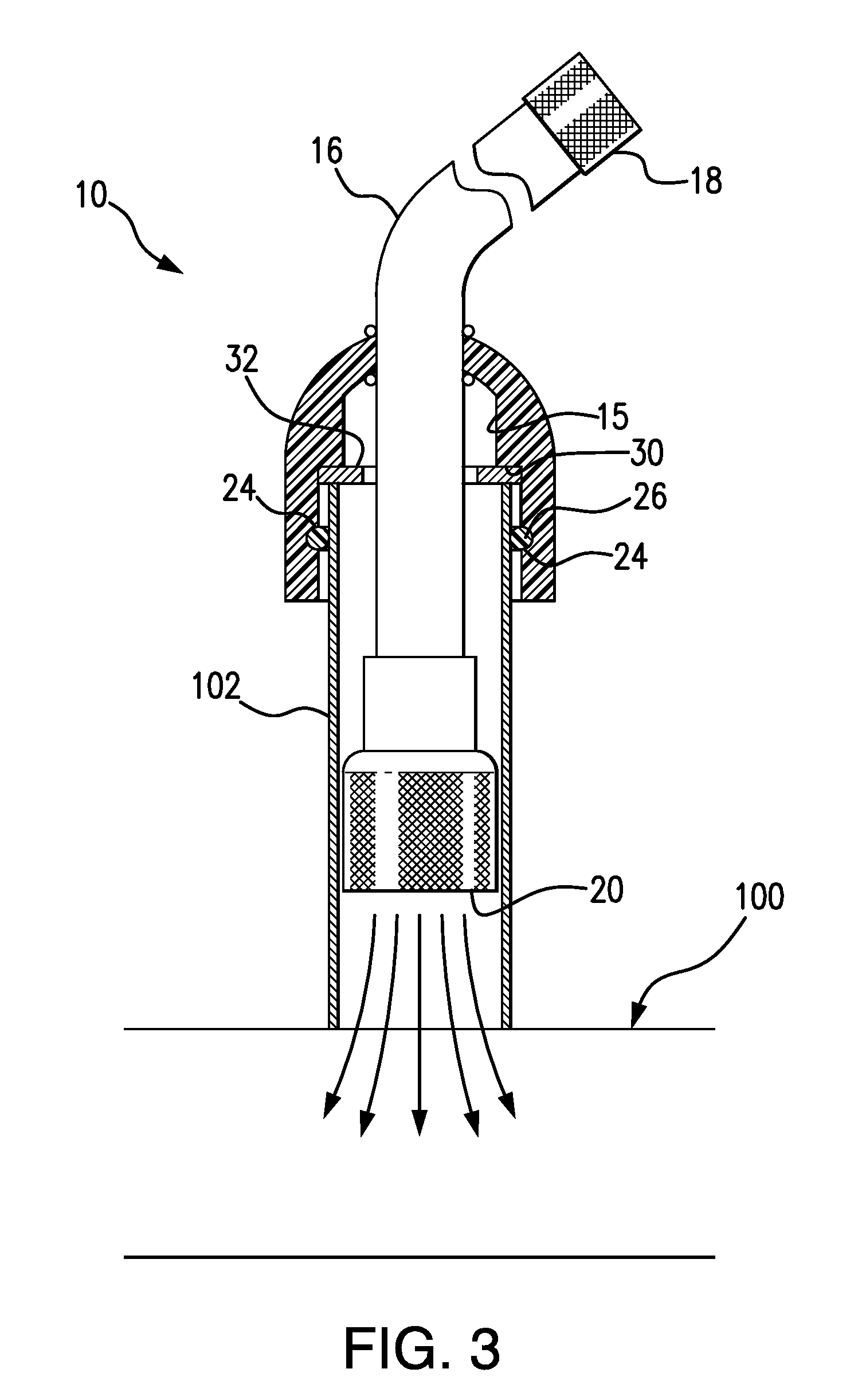

Test kit for detecting acids in refrigerant lubricating oils and method of use

ActiveUS9733229B1Overcome problemsLower levelSamplingMaterial analysis by observing effect on chemical indicatorEngineeringColor changes

A test kit (110) includes an at least partially transparent or translucent tubular collection chamber (122) which has a flow control valve (111) at the inlet end (122a) thereof. Flow control valve (111) has a mouth (112a) that is used to engage a Schrader valve (132) of a HVACR system to flow pressurized refrigerant fluid into the collection chamber (122) via flow control valve (111). The flow of the pressurized refrigerant fluid is throttled by flow control valve (111) to ensure that sufficient lubricating oil is separated from the refrigerant fluid and remains within the collection chamber (122), even as refrigerant is expelled from collection chamber (122) via vent holes (124). A collector (126) serves to accumulate separated lubricating oil. A frangible ampoule (128) which contains a liquid pH indicator (130) is crushed to contact the pH indicator with the separated lubricating oil to test the pH of the oil by color change of the pH indicator.

Owner:ZYNON TECH

Hose attachment device for clearing drain lines

A hose attachment device for use in combination with a source of pressurized gas or liquid for clearing HVACR drain lines. The device includes a cap having an interior cavity extending from an open bottom end that is sized for engaged receipt of an open-ended drain line extension. One embodiment of the device includes a hose extending through the top of the cap and having a fitting at the proximal end of the hose (extending from the top of the cap) that is sized for attachment to the pressurized source. A valve fitting at the distal end of the hose is sized for engaged receipt of a male valve stem, such as a Schrader valve. Another embodiment of the invention includes a valve fitting extending through top of the cap. A further embodiment of the invention includes an upper component and a lower component forming the cap, wherein the upper component is securable to a nozzle of a garden hose and the bottom component is securable to an open-ended drain line extension.

Owner:RS ACQUISITION SUB LLC

Temperature-sensing anti-scald valve

PendingCN110388502APrevent outflowPrevent burn damageOperating means/releasing devices for valvesLift valveEngineeringSchrader valve

The invention discloses a temperature-sensing anti-scald valve. The valve comprises a valve cover, a fluid channel is formed in the valve cover, a fluid inlet and a fluid outlet are formed in the twoends of the fluid channel respectively, a cavity and a channel hole are formed in the fluid channel, a magnetic elastic mechanism is arranged below the cavity, a sealing element sleeves the outer sideof the magnetic elastic mechanism, the sealing element, the cavity and the channel hole form a sealing cavity, and a fluid flows into the channel hole from the fluid inlet, enters the cavity throughthe sealing cavity and finally flows out of the fluid outlet. When the magnetic elastic mechanism is heated, the magnetic elastic mechanism loses magnetism and moves upwards under the action of elasticity to drive the upper surface of the sealing element to be attached to the lower surface of the cavity, and the lower surface of the cavity is sealed to prevent the fluid in the sealing cavity fromflowing out. The magnetic elastic mechanism is used for switch-on and switch-off of the temperature-sensing anti-scald valve, so that the valve is used for limiting flowing of liquid or gas exceedinga specific temperature.

Owner:罗旭

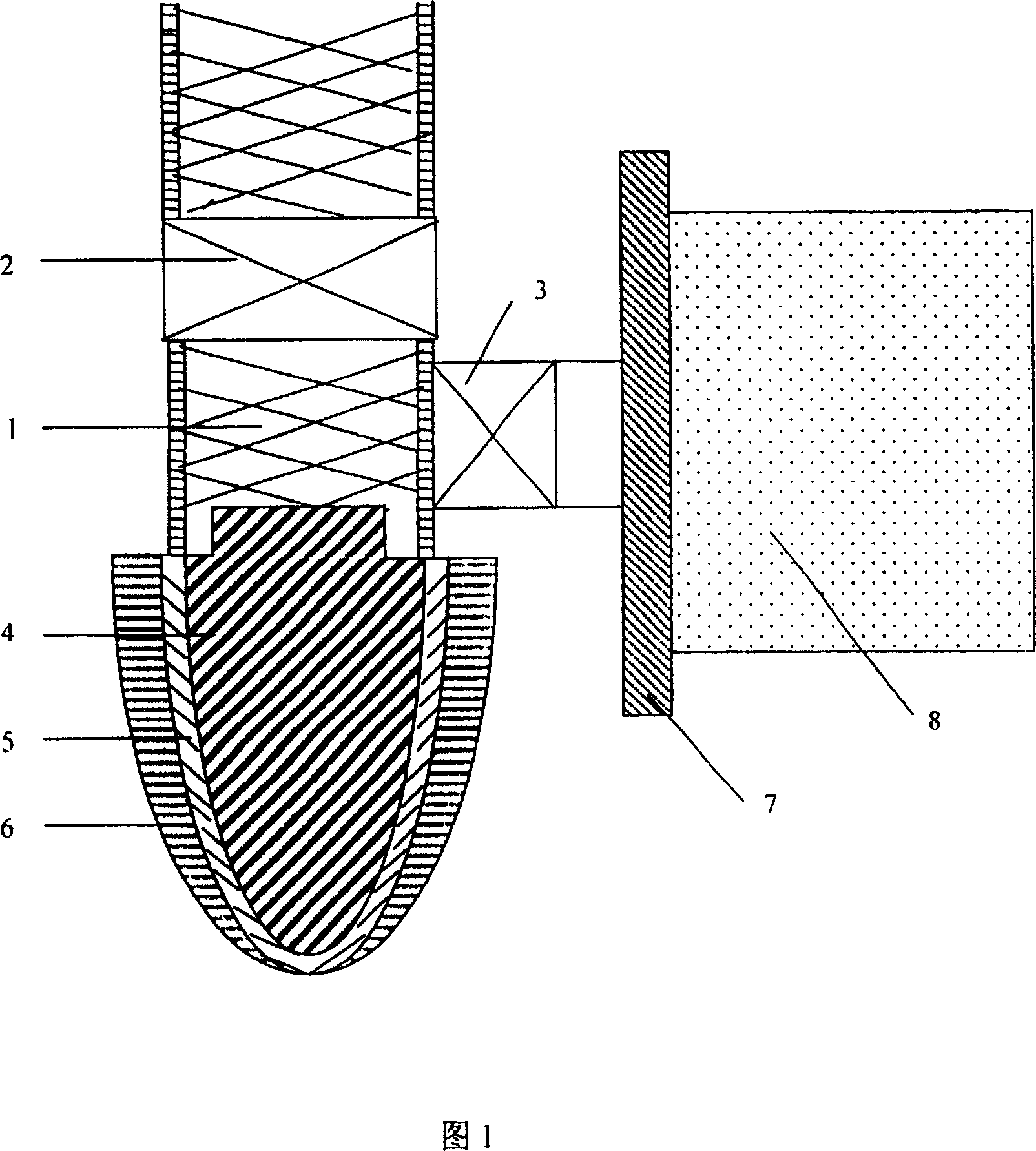

High performance self-adaption gradient water absorber

InactiveCN100352338CImprove water absorptionSmall water absorption resistanceWatering devicesCultivating equipmentsEngineeringSafety valve

A high-performance adaptive gradient water sucker for capillary irrigation system is composed of flexible capillary tube, and its valve, gradient water sucking head connected to anoth end of sade valve, and pressure cleaner. Its advantages are high hydroscopity and long service life.

Owner:SICHUAN SANHE SLOPE TECH CO LTD

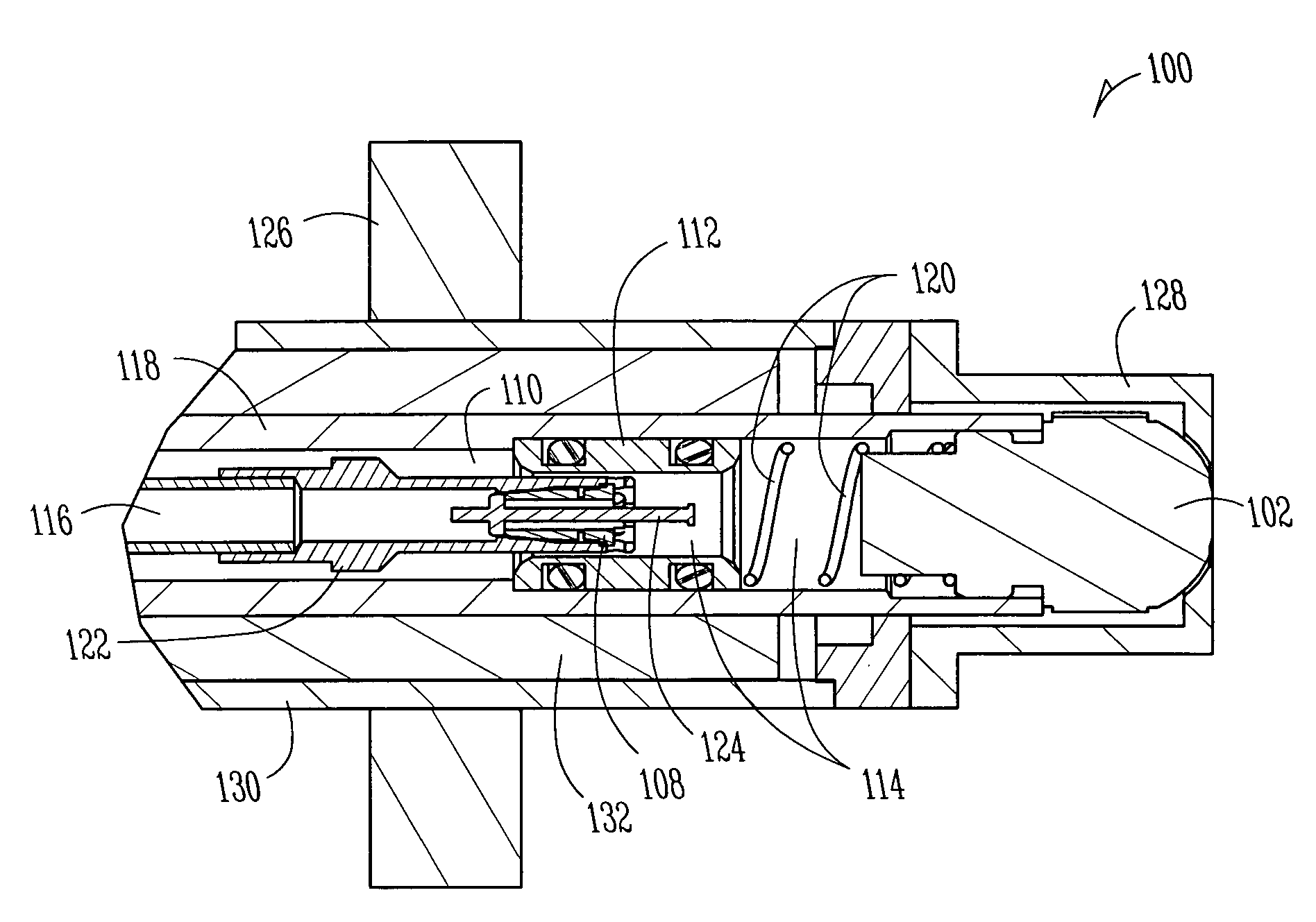

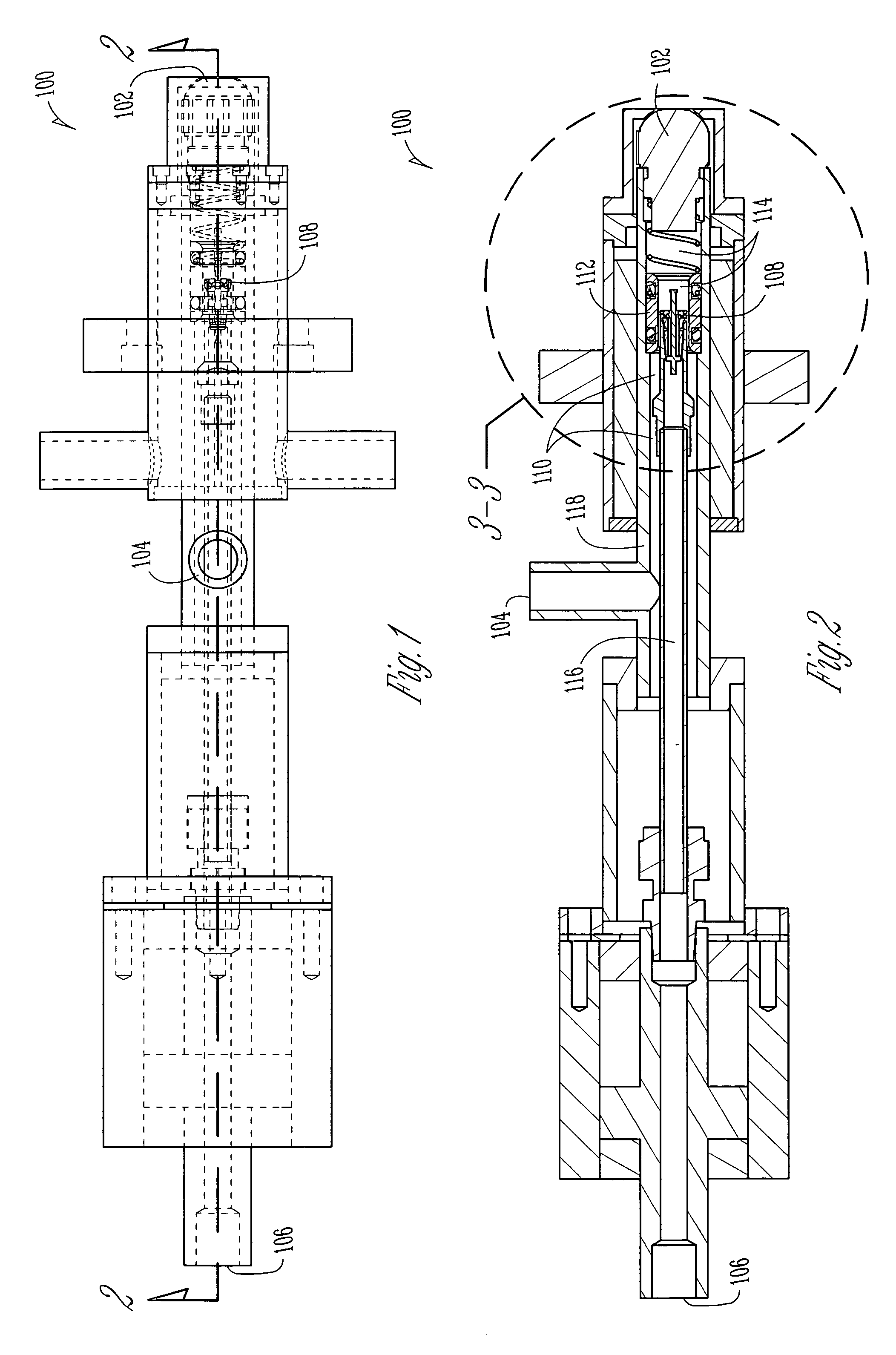

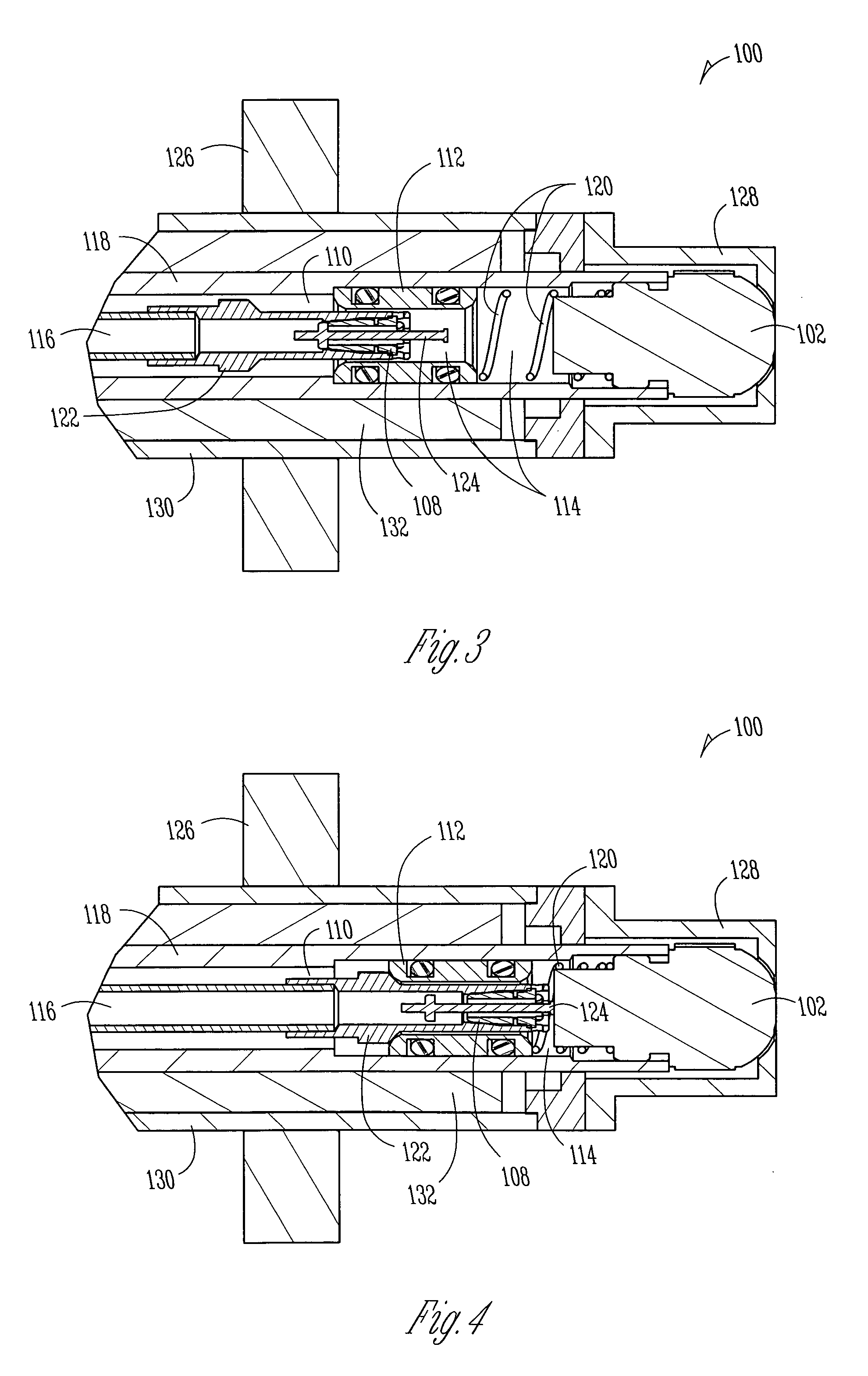

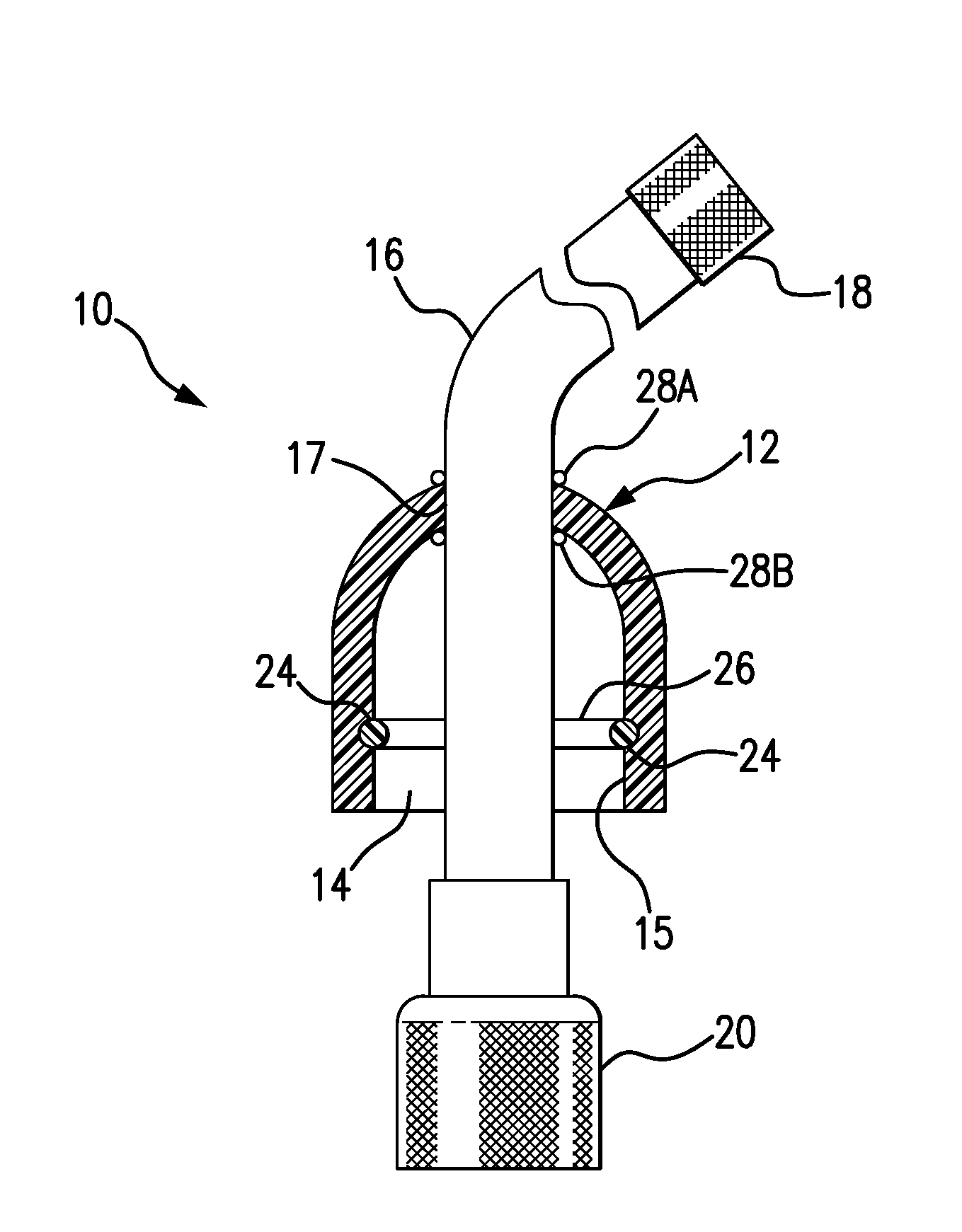

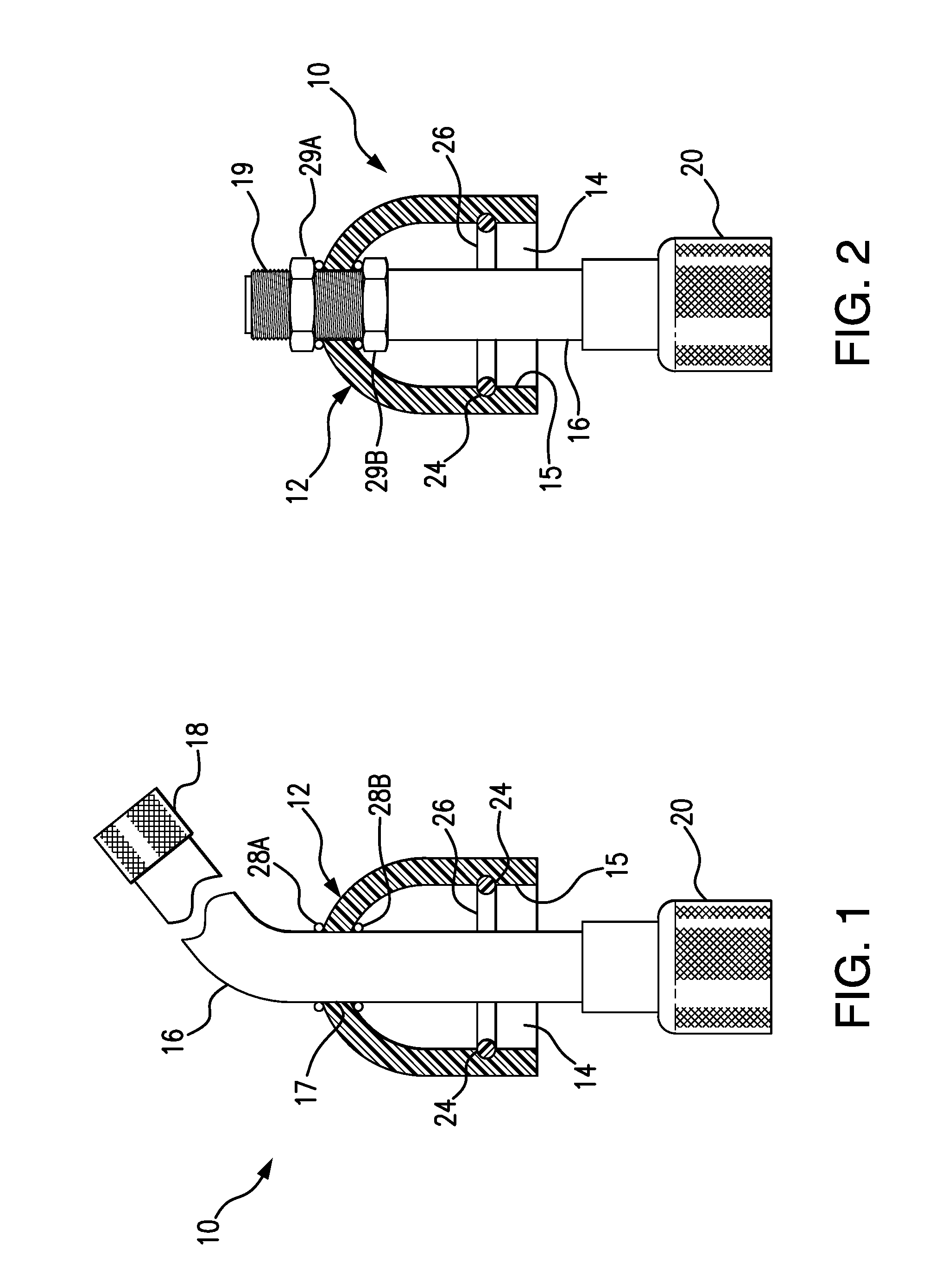

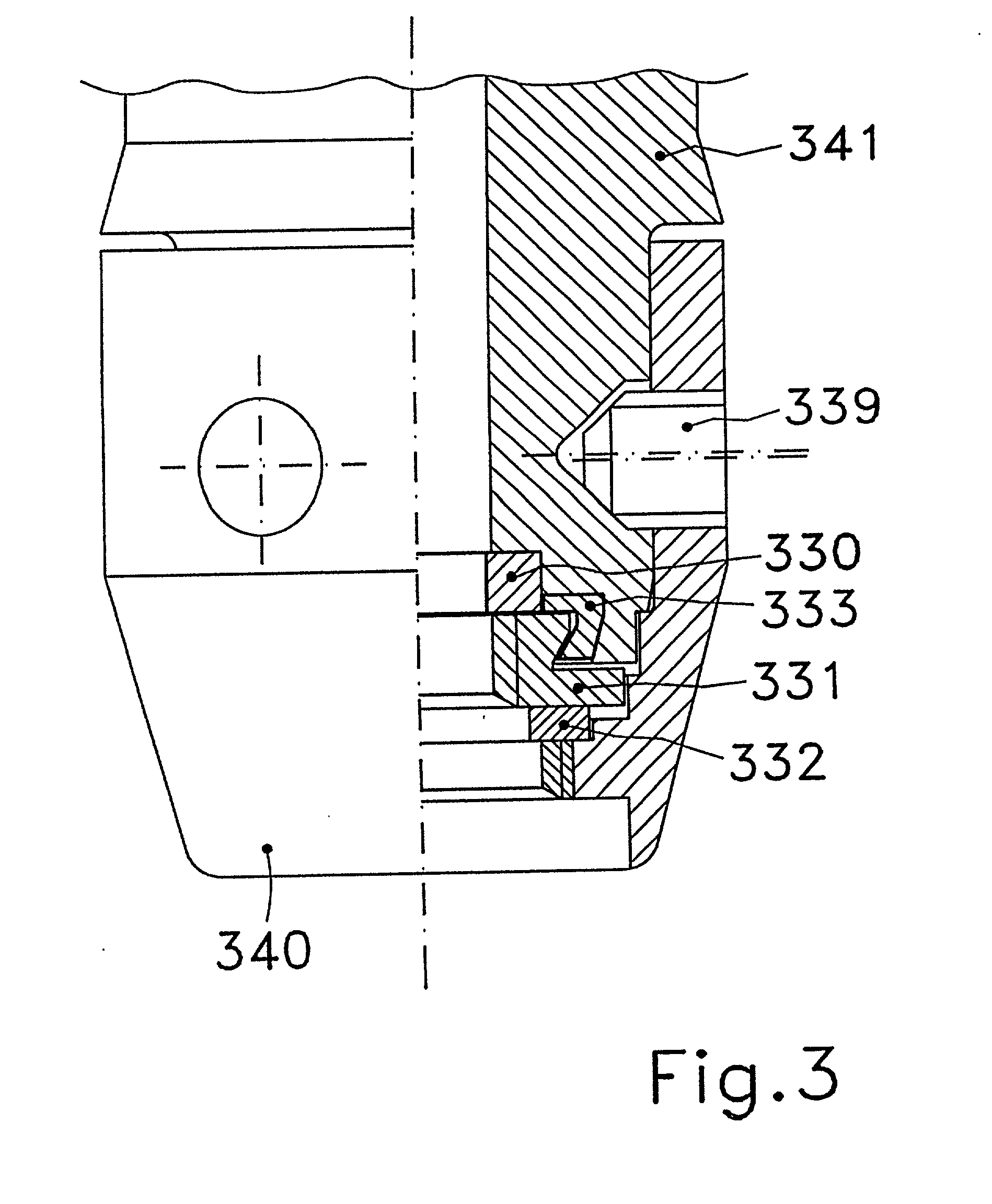

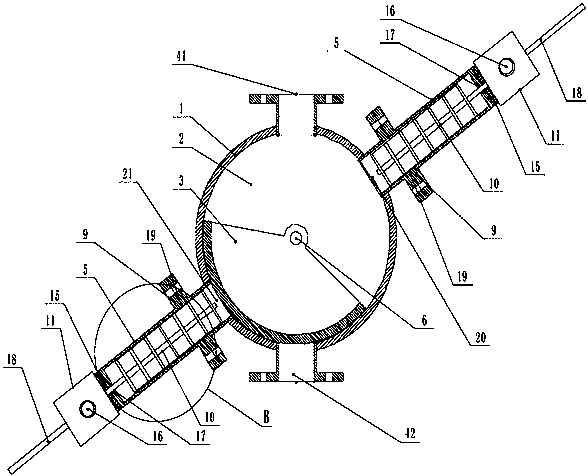

An improved coke drum bottom de-heading system

InactiveCN100465248CEasy to removeSimplify the decoking processSlide valveStationary retortsLinear motionEngineering

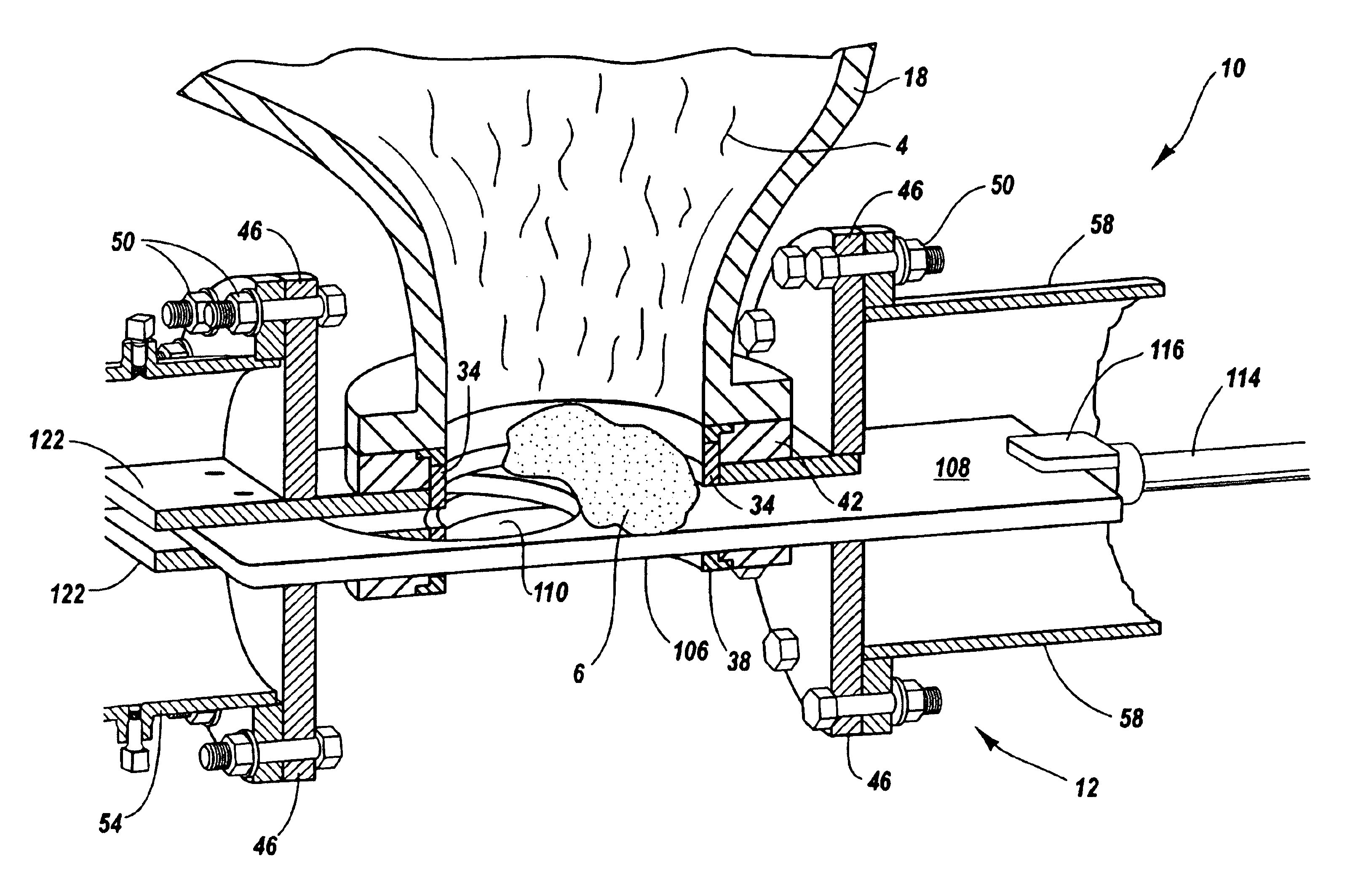

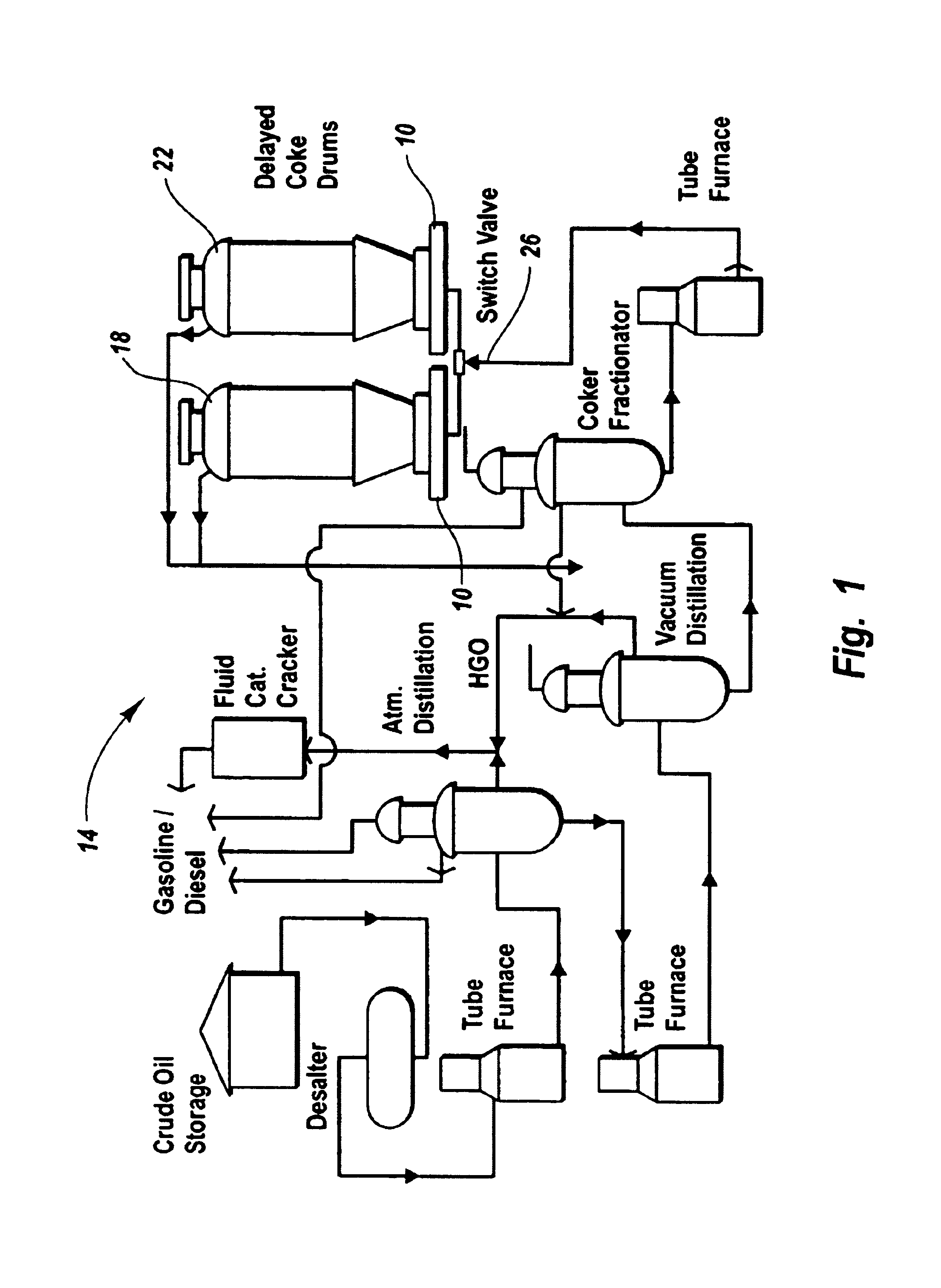

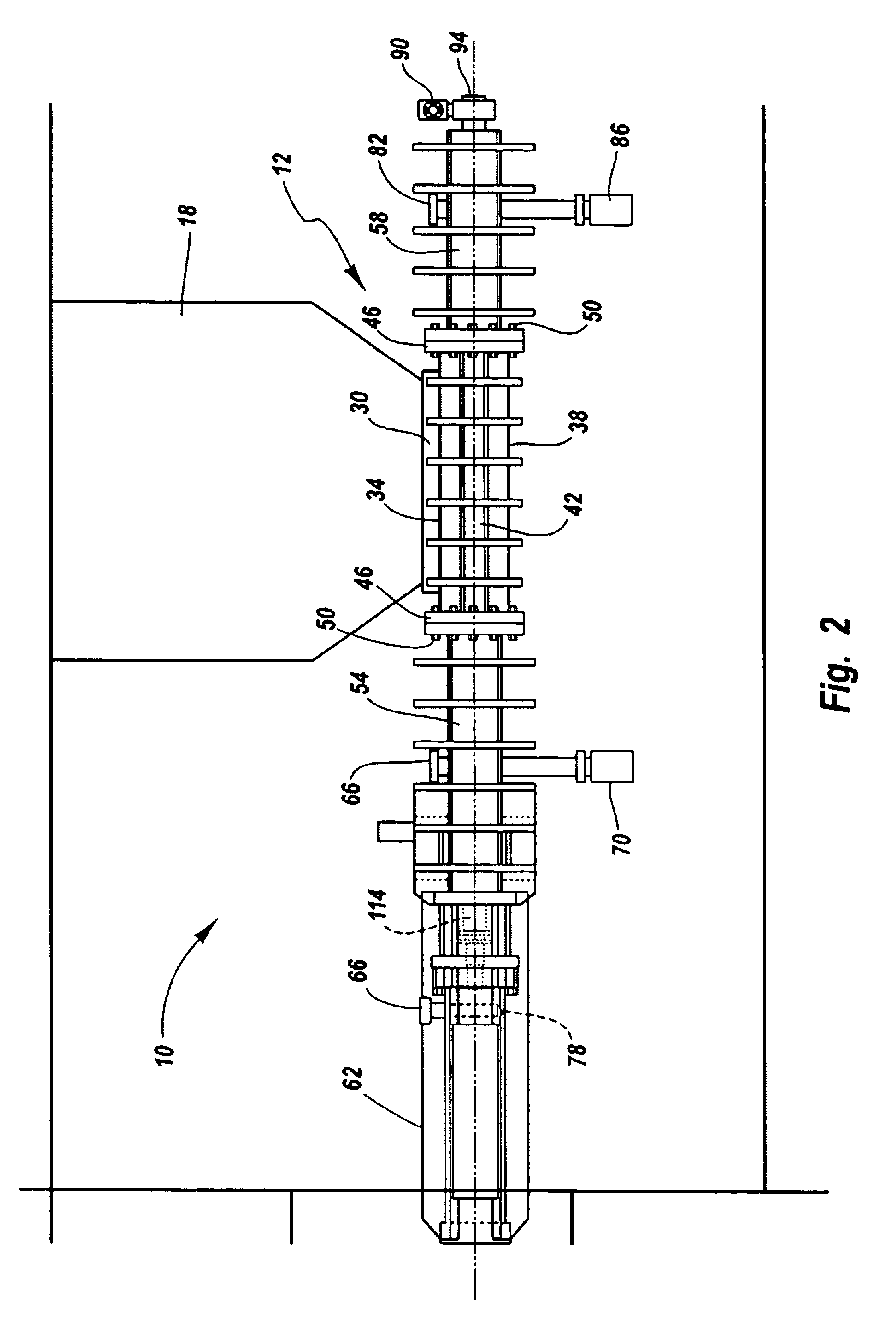

The present invention features a coke drum de-heading system (10) without having to physically remove the head units. This is accomplished using a specially designed dual seated, linear motion goggle blind gate valve, or de-header valve (12), that is removably coupled to and seals against the flanged (42) portion of a coke drum (18) much the same way a conventional head unit would be attached. The de-header valve (12) is equipped with, among other things, a sliding blind (122) that is contained and capable of moving within an upper (34) and a lower (38) seat, wherein one of such seats is a floating dynamic, live loaded seat that is capable of automatic adjustment through one or more loading zones so as to seal the blind (122) between the upper (34) and lower (38) seats. The movement of the sliding blind (122) serves to open and close the de-header valve (12), wherein in a closed position, the de-header valve (12) is prepared to receive the resid byproduct feed from the refinery process used to manufacture coke (4). Once the drum (18) is full, the de-header valve (12) may be actuated (opened), wherein the coke (4) that has accumulated on the blind (106) is sheared by the upper (34) and lower (38) seats, thus de-heading the coke drum (18) and facilitating the removal of coke (4) using methods commonly known in the art.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

Anti-scale valve

InactiveCN109139966ASimple structureSave installation timePlug valvesHollow article cleaningScale unitEngineering

The invention provides an anti-scale valve. The anti-scale valve comprises a valve body, a valve element mounted in a valve cavity of the valve body, and anti-scale units mounted on the valve body. The valve element is connected with a valve shaft at the bottom of the valve body and comprises an arc surface matched with the inner surface of the valve cavity. A valve rod controlling the valve element to rotate is mounted on the valve element. A handle is mounted at the end, stretching out of the valve body, of the valve rod. Each anti-scale unit comprises a first through opening and a second through opening which are formed in the valve body. A sealing shell is mounted on each through opening. Driving units are mounted on the sealing shells. Anti-scale parts are mounted in the sealing shells. The anti-scale units of the anti-scale valve can be replaced at any time, a standby anti-scale unit is always prepared so that a damaged or ineffective anti-scale unit can be replaced at any time,and the damaged or ineffective anti-scale unit can be blocked accurately through the handle without affecting normal operation of equipment no matter whether the valve is opened or closed.

Owner:自贡鑫剑密封科技有限公司

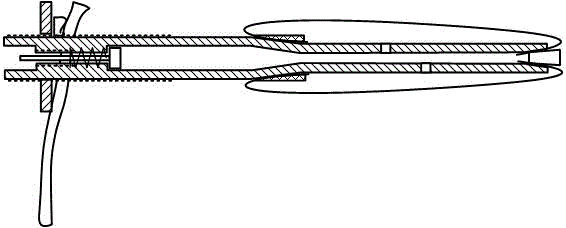

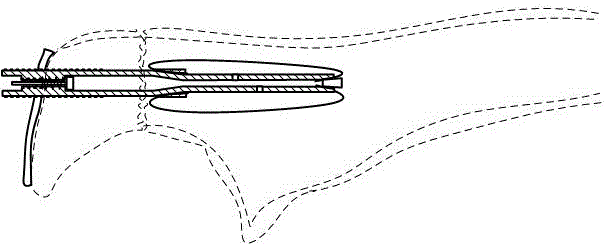

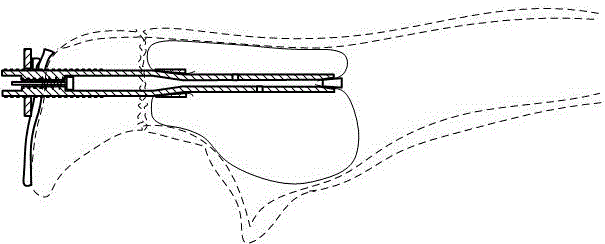

Olecranal fracture fixator

The invention discloses an olecranal fracture fixator. The olecranal fracture fixator comprises an arc-shaped tail end nail plate, an expanding screw, and a screw cap, wherein a through hole allowing the expanding screw to pass through is formed in the tail end nail plate, external threads matched with the screw cap are arranged on the expanding screw, after the screw cap is screwed to the expanding screw, the tail end nail plate tightly pushes against the olecroanon of an applied person, the expanding screw is a hollow pipe and comprises an outer section with large outer diameter and an inner section with small diameter, a conical section is arranged between the outer section and the inner section, an American valve is arranged at the free end of the outer section, a tapered opening is arranged at the free end of the inner section, and at least one air outlet hole is formed in the side wall of the inner section; the olecranal fracture fixator further comprises a section of rubber hose, wherein one end of the rubber hose compresses and hoops the conical section through a sleeve with the inner bore taper being the same as the taper of the conical section, the other overturned end of the rubber hose is stuffed into the tapered opening, and a plunger piston with the taper being the same as that of the tapered opening is adopted for stuffing up. The olecranal fracture fixator realizes fixing through air inflation expansion of the rubber hose, the flexibility of the acting force is adjustable, and the taking out is easy and convenient.

Owner:李志强

Coke drum bottom de-heading system

InactiveUS20050279621A1Efficient and cost-effective and safeSimplified and reliableRetortsSlide valveWindow shutterComputer module

The present invention features a coke drum de-heading system comprising (a) at least one coke drum having an orifice therein; (b) a de-header valve removably coupled to the coke drum designed to de-head the coke drum; and (c) an exchange system, including an upper and lower bonnet and other elements and members adapted to integrate the de-heading system, and particularly the de-header valve, into the manufacturing system. The de-header valve itself comprises (1) a main body having an orifice dimensioned to align with and couple to, in a concentric relationship, the orifice of the coke drum; (2) a live loaded seat assembly coupled to the main body and comprising a dynamic, live loaded seat, a live seat adjustment mechanism coupled to the main body and designed to control and adjust the force and resulting seat load of the dynamic, live loaded seat, and a force transfer module in juxtaposition to the dynamic, live loaded seat for transferring the force from the live loaded seat adjustment mechanism to the dynamic, live loaded seat; (3) a static seat positioned opposite from and counteracting or counterbalancing the dynamic, live loaded seat; and (4) a blind or sliding blind capable moving in a linear, bi-directional manner within the de-header valve and between the dynamic, live loaded seat and the static seat, such that upon actuation of the blind from a closed position to an open position, the coke drum is de-headed.

Owner:DELTAVALVE

Emergency backflow preventing system

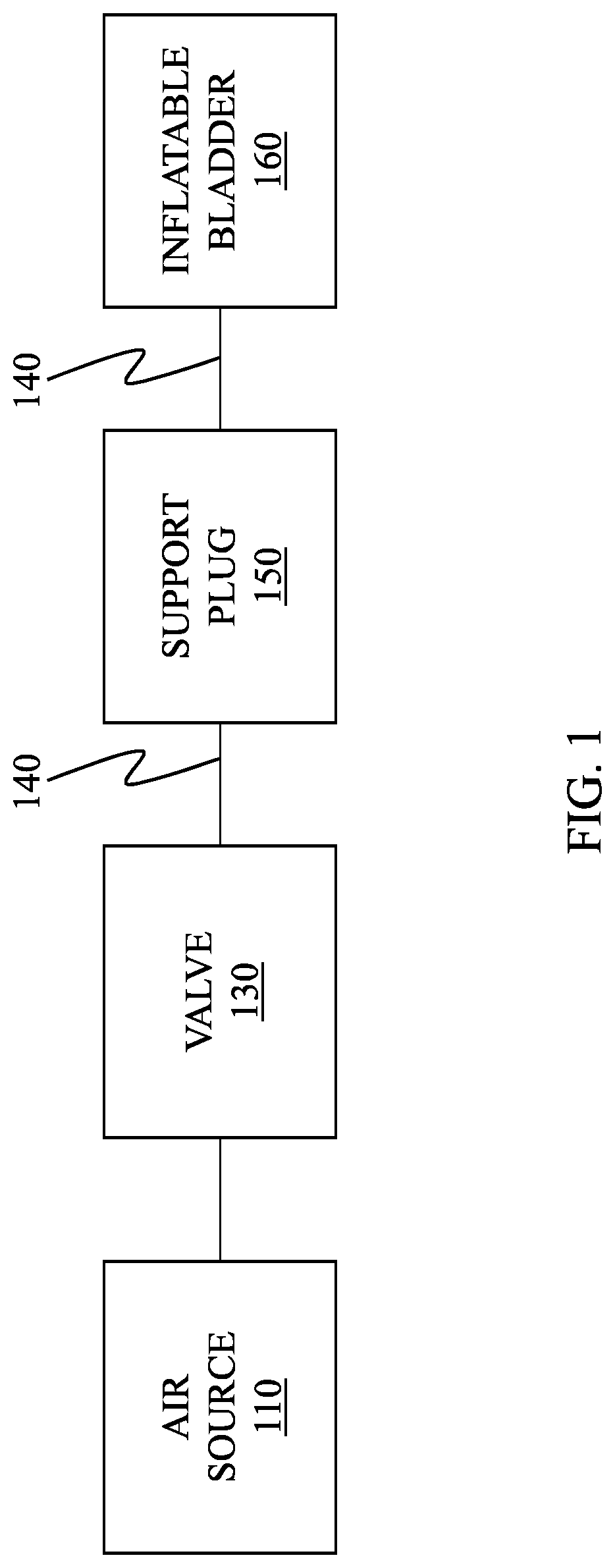

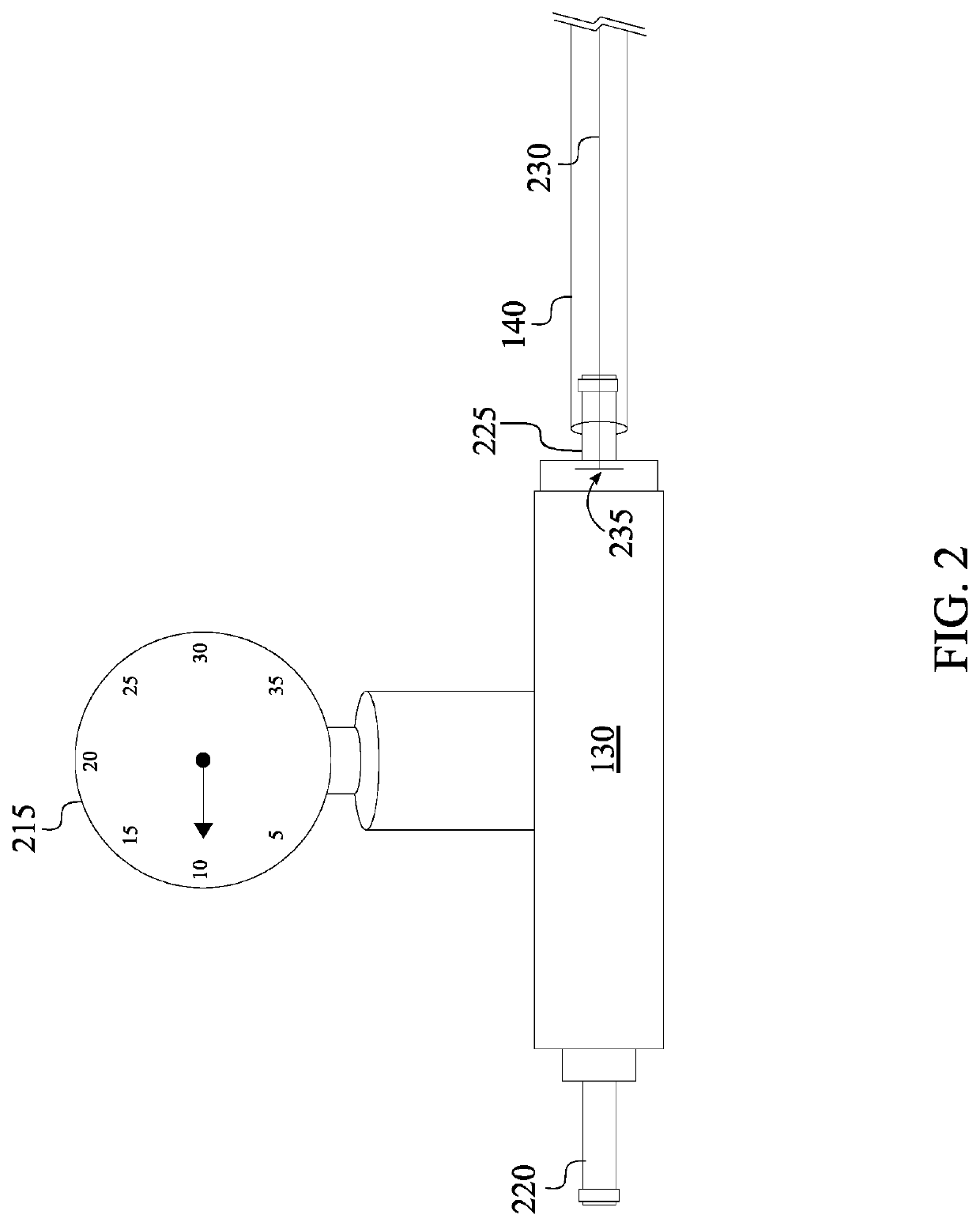

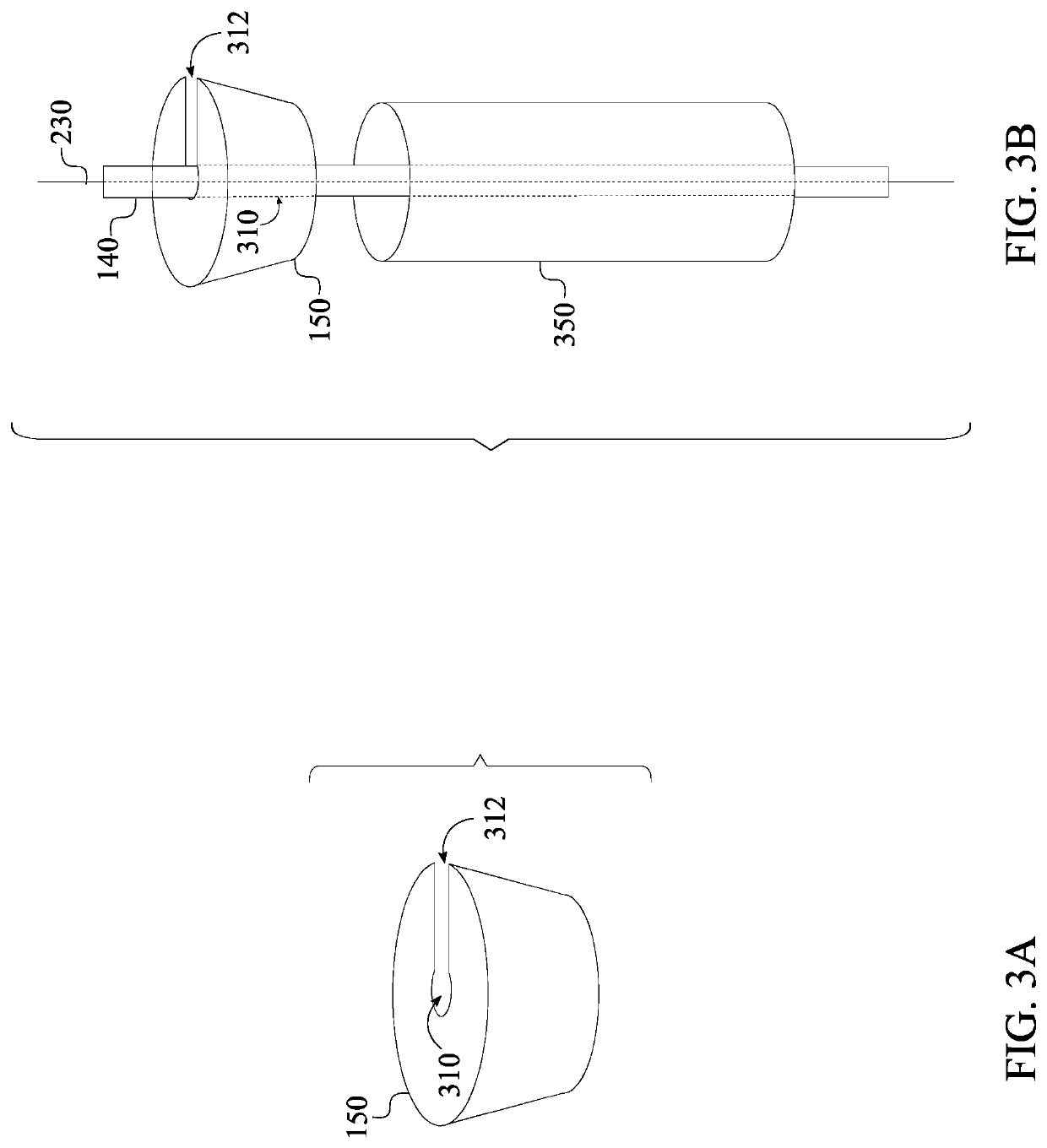

In an exemplary embodiment, an emergency backflow preventing system is disclosed that includes an inflatable bladder, an air supply line demountably coupled to the inflatable bladder, a valve demountably coupled to the air supply line, and an air source functionally coupled to the valve. The inflatable bladder includes a deflated state and an inflated state and is substantially void of air in the deflated state. The inflatable bladder is configured to be inserted within a sewage pipe when in the deflated state. The inflatable bladder is configured to contact a bore of the sewage pipe when in the inflated state and thereby wedge itself within the sewage pipe. The inflatable bladder comprises an elastic polymer. The valve comprises a Schrader valve and an air pressure gauge. A cable is positioned within the air supply line and is anchored within the valve and the inflatable bladder.

Owner:REESE JAMES T +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com