Pressure sensor method and apparatus

A pressure sensor and pressure technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problem of not considering the strong combination of the sensing die and the support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific values and configurations discussed in these non-limiting examples may vary and are cited merely for illustration of at least one embodiment and are not intended to limit the scope of the invention.

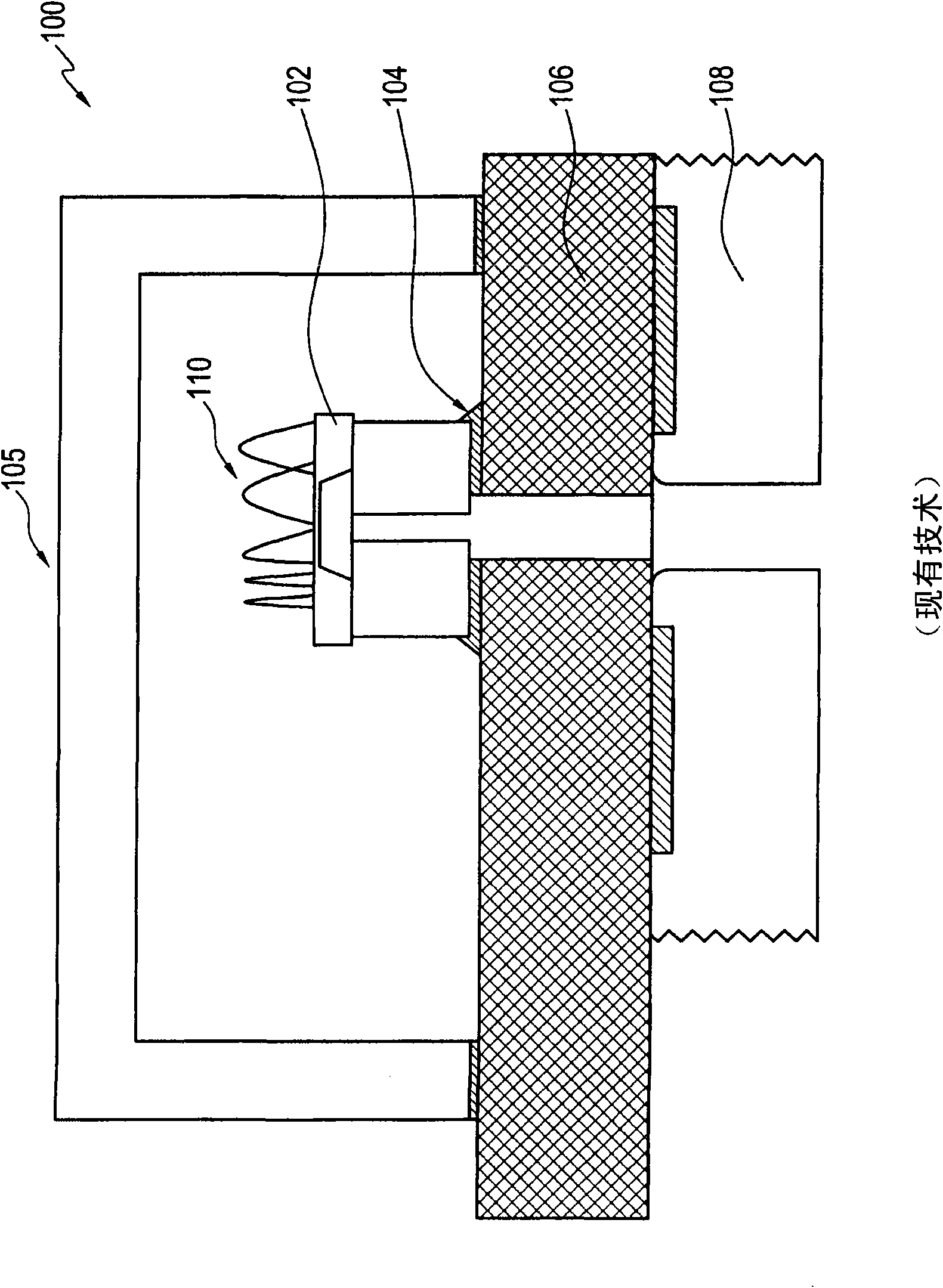

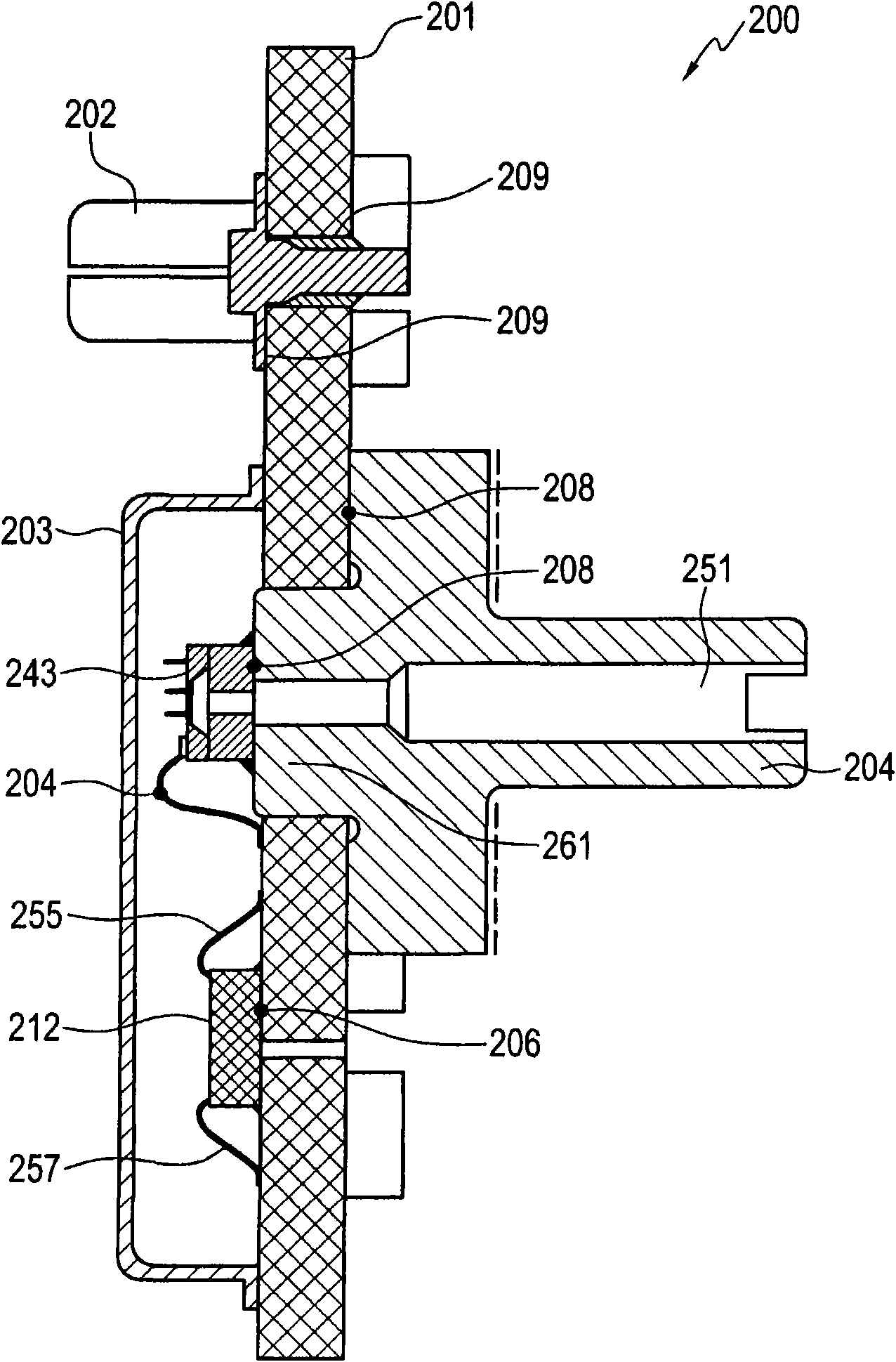

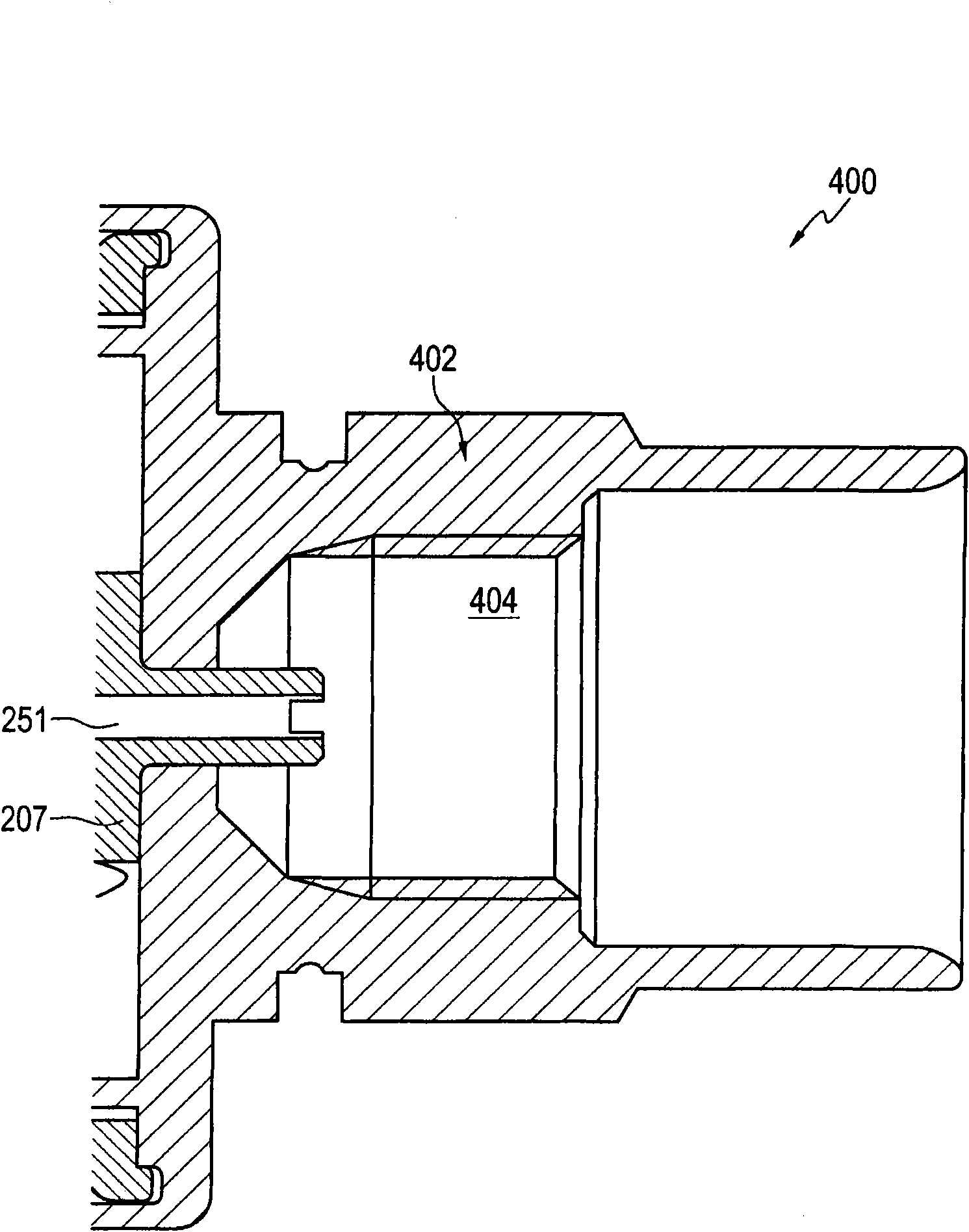

[0024] See the accompanying drawings below, and in particular Figure 5 , which shows a view of the bonding side of a pressure sensor device 500 that can be implemented according to a preferred embodiment. in addition, Figure 6 shows that according to a preferred embodiment Figure 5 A side cross-sectional view of pressure sensor device 500 is shown. noticed in Figure 5 and Figure 6 The same reference numerals are used to denote the same or similar parts or elements. in addition, Figure 5 and Figure 6 Components that are also shown in the prior art views of FIGS. 2-4 are shown. However be aware that: Figure 5 and Figure 6 These components are shown to demonstrate improvements and differences between pressure sensor device 500 and prior art d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com