An improved coke drum bottom de-heading system

A coke and deheading technology, applied in the field of improved coke tank bottom deheading system, can solve problems such as operator's personal danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

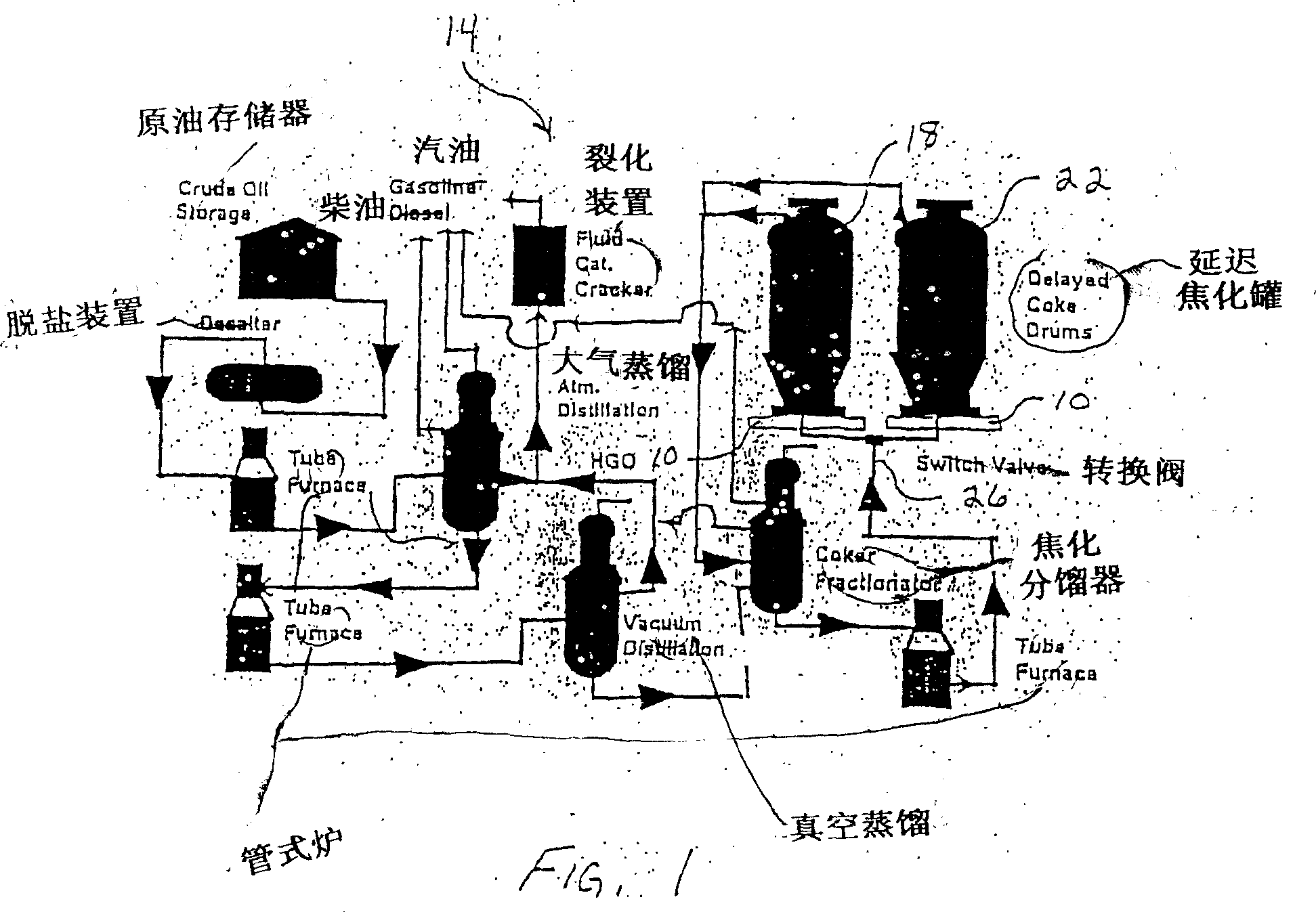

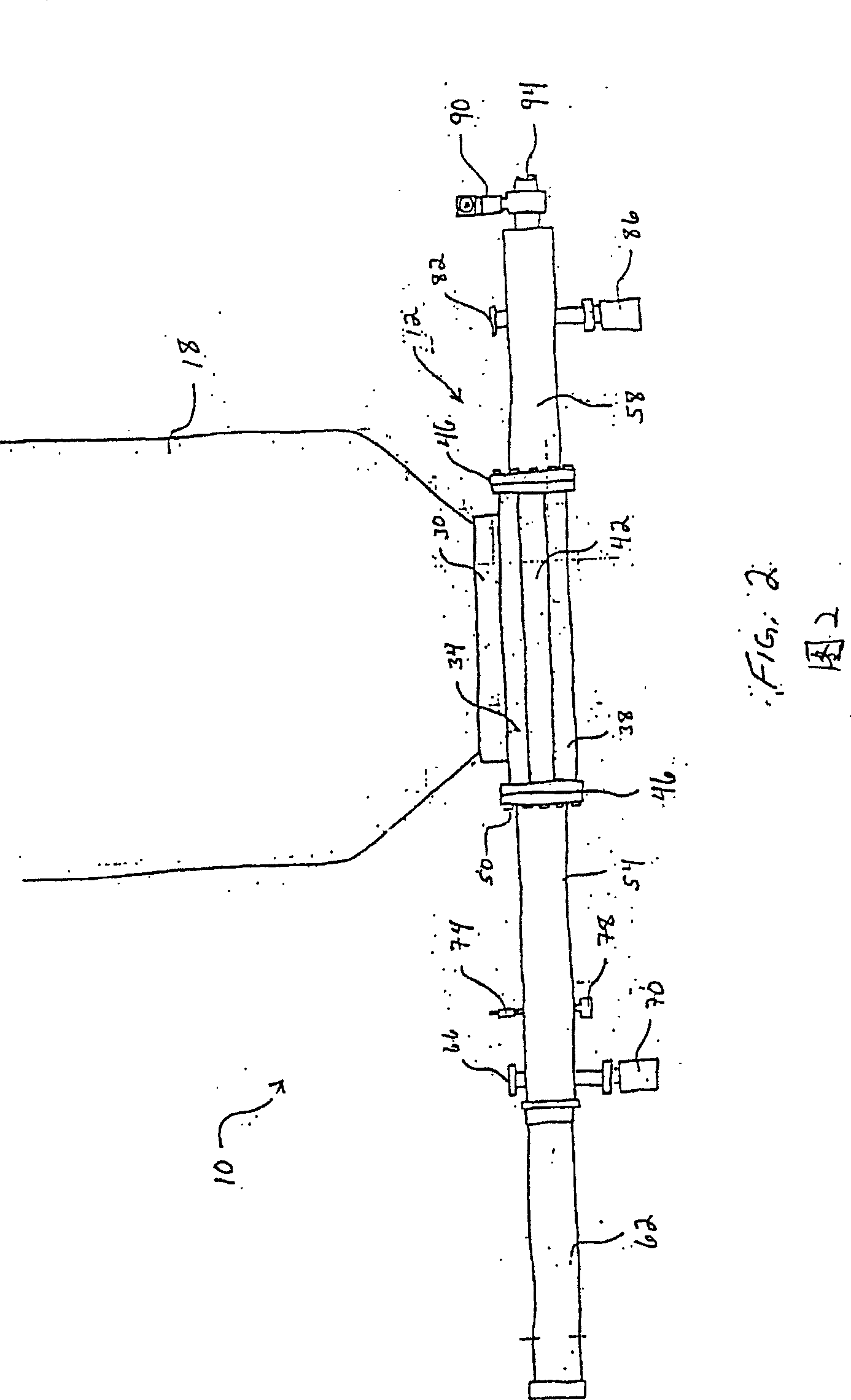

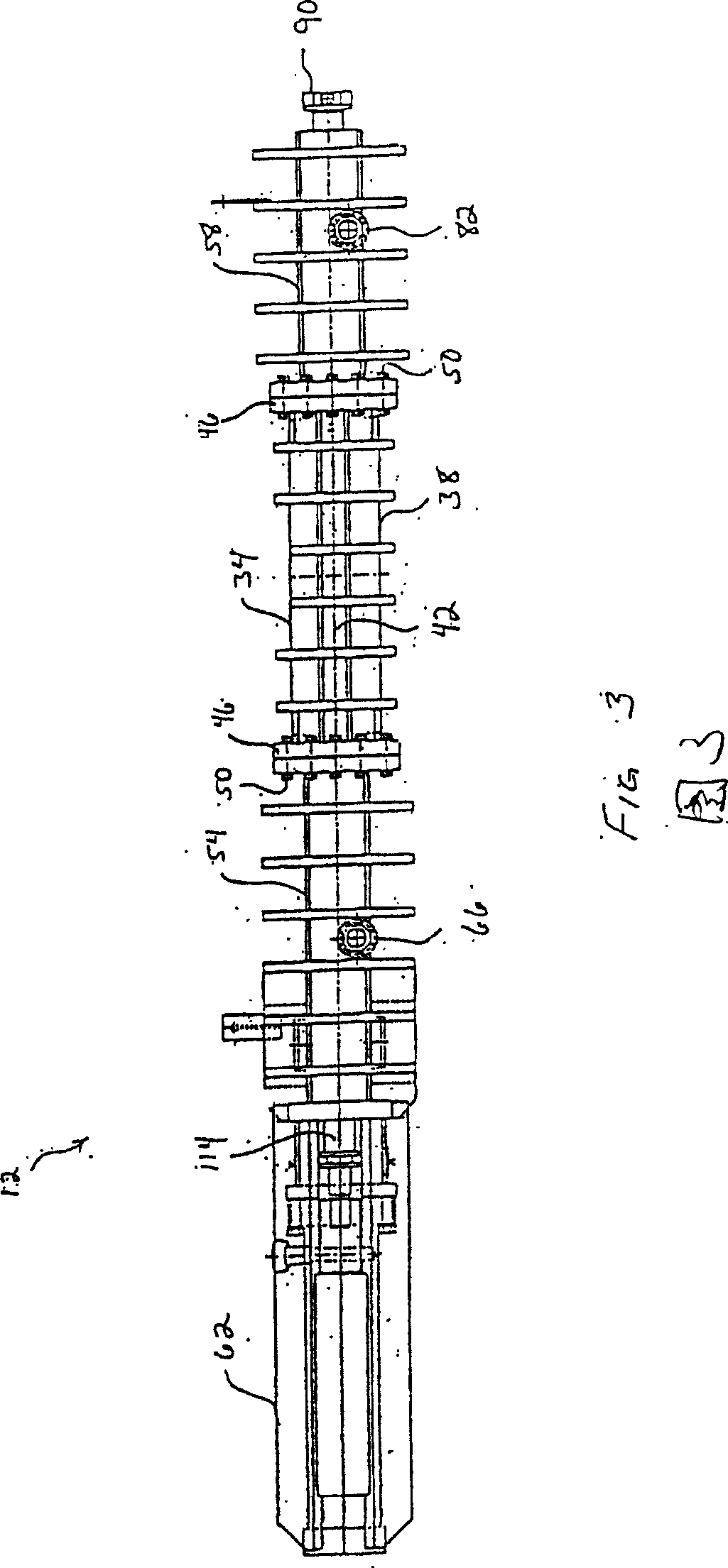

[0046] It will be readily understood that the components of the invention, generally described and illustrated in the drawings, may be arranged and designed in widely varying configurations. Therefore, next more detailed system, device and method of the present invention and from Picture 1-1 The description of the embodiments represented by 1 is not intended to limit the scope of the invention as the claims are, but is merely representative of preferred embodiments of the invention.

[0047] The presently preferred embodiments of the present invention will be best understood by reference to the drawings, wherein like numerals refer to like parts throughout. Although reference is made to the drawings and related descriptions that follow immediately below, it has the first advantage of providing a general background on the coking process, including the de-heading process of the coke drum at the end of the production process.

[0048] General Discussion of Delayed Coking and Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com