Dual-edge dual-way cutting numerical control wood turning tool

A woodworking turning tool and auxiliary cutting edge technology, which is applied in the direction of wood processing equipment, wood drilling tools, wood turning tools, etc., can solve the problems of less research and development of turning tools, high labor intensity, and low product processing efficiency, so as to reduce operation Path length, saving of processing time, effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

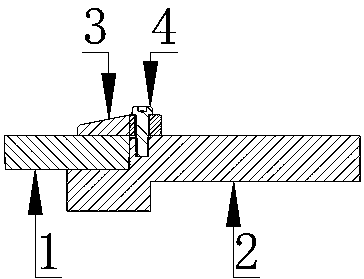

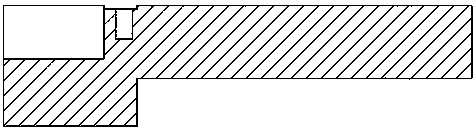

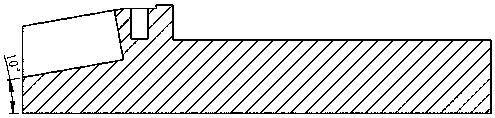

[0024] Double-edged bi-directional cutting CNC woodworking turning tool, in the embodiment figure 1 Fasten the cutter head 1 on the cutter bar 2 with the screw 4 and the pressure plate 3. According to processing needs, the cutter bar 2 can be designed as figure 2 The inclination angle of the middle edge is zero or image 3 The inclination angle of the middle blade is a negative value (-10°) structure.

[0025] Figure 4 It is the front view of the cutter head structure in the embodiment. It can be seen from the figure that the turning cutter head is designed as a positive and negative bidirectional symmetrical cutting edge. There is a gap between the main cutting edge and the auxiliary cutting edge. The V-shaped groove is less than 90°. Ensure that the rake angle is 45° and the secondary cutting edge contacts the processed surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com