Anti-oxidation coating for working lining of iron ditch and preparation method thereof

An anti-oxidation coating and working lining technology is applied in the field of preparation of blast furnace iron trench protective materials, and can solve the problems affecting the thermal shock resistance stability of iron and iron trench linings, deterioration of structural strength, and shortening of service life of iron trench inner linings, etc. , to achieve the effect of improving service life, good protection and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

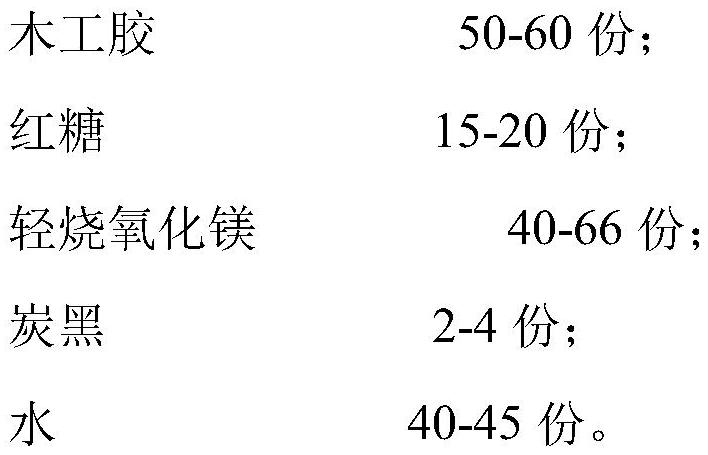

Method used

Image

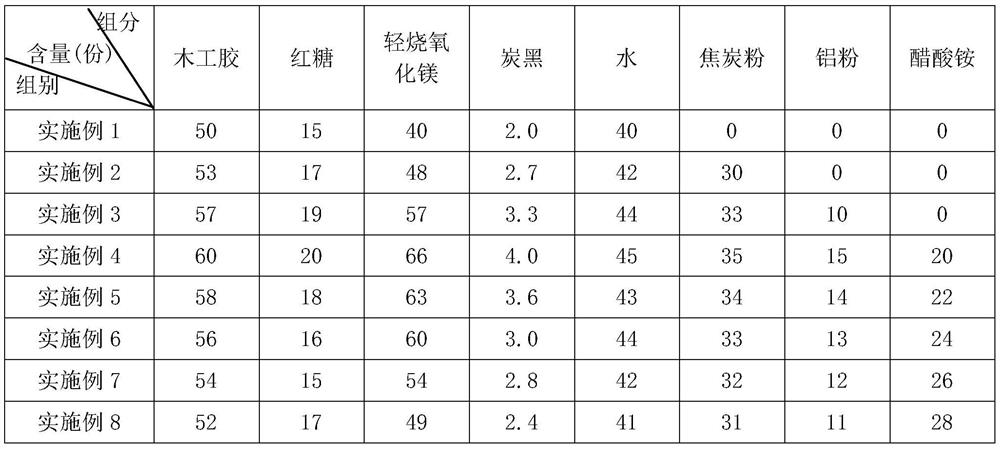

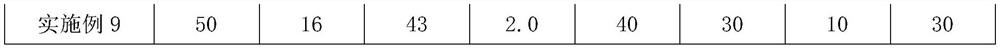

Examples

Embodiment 1

[0034] Example 1: An anti-oxidation coating for iron ditch working lining, the content of the formula components is shown in Table 1. Wherein the carpentry glue adopts polyvinyl acetate adhesive, its viscosity is 500cps, pH value is 4, and solid content is 40%. Among them, the fixed carbon content of carbon black is 99.8%, and the particle size d1 is 250nm; the fixed carbon content of coke powder is 90%, and the particle size d2 satisfies 0<d2≤1nm; the light-burned magnesium oxide is in powder form and the particle size d3 is 180 mesh. The preparation method of the anti-oxidation coating for the working lining of the iron ditch comprises the following steps:

[0035] S1. Ammonium acetate is dissolved in water to form an aqueous solution of ammonium acetate;

[0036] S2. Stir the wood glue at a speed of rotating speed v=120r / min, add brown sugar, light-burned magnesia, aluminum powder, coke powder and carbon black while stirring in order to form an initial mixture;

[0037] S3....

Embodiment 2

[0038] Example 2: An anti-oxidation coating for the working lining of iron trenches. The difference between this example and Example 1 lies in that the content of the formula components in this example is shown in Table 1. Wherein the carpentry glue adopts polyvinyl acetate adhesive, its viscosity is 600cps, pH value is 5, and solid content is 45%.

Embodiment 3

[0039] Example 3: An anti-oxidation coating for working lining of iron trenches. The difference between this example and Example 1 is that the content of the formula components in this example is shown in Table 1. Wherein the carpentry glue adopts polyvinyl acetate adhesive, its viscosity is 700cps, pH value is 6, and solid content is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com