Feeding and discharging device for wood lathe

A woodworking lathe and lathe technology, which is applied in the field of wood processing, can solve the problems of work efficiency discount and take up more time, and achieve the effect of improving work efficiency, facilitating clamping and fixing, and saving feeding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

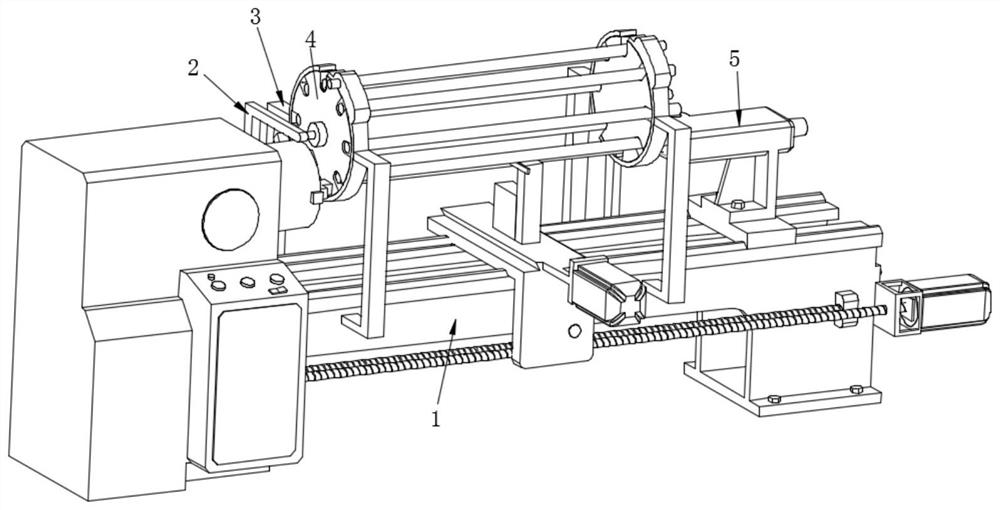

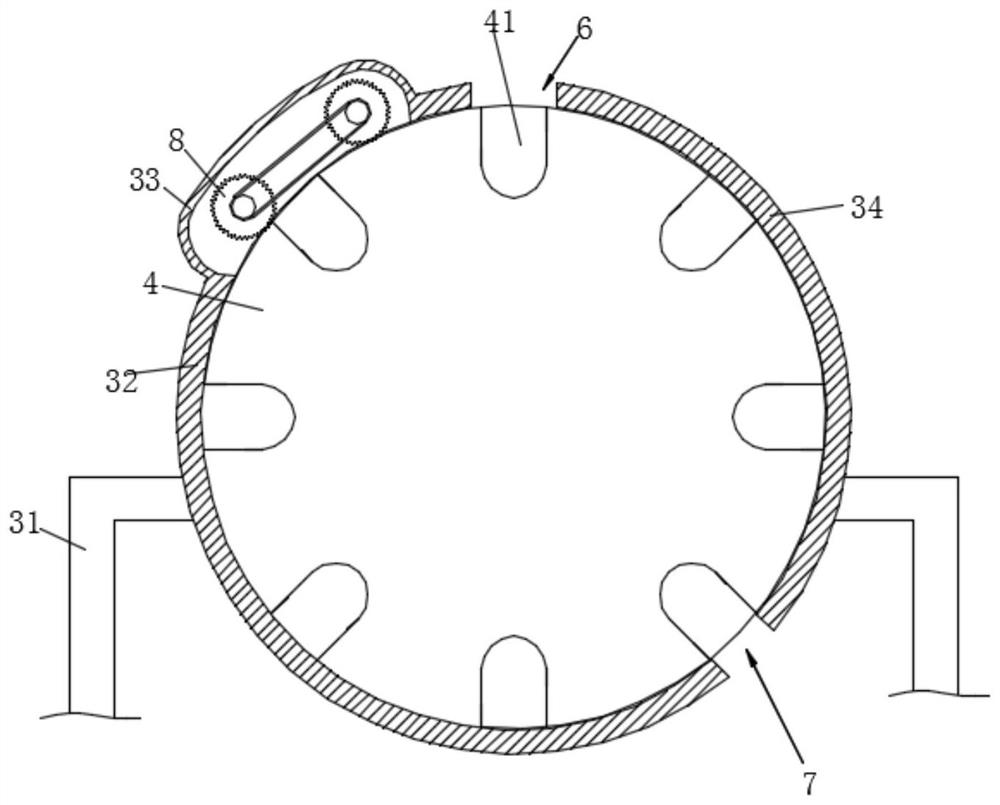

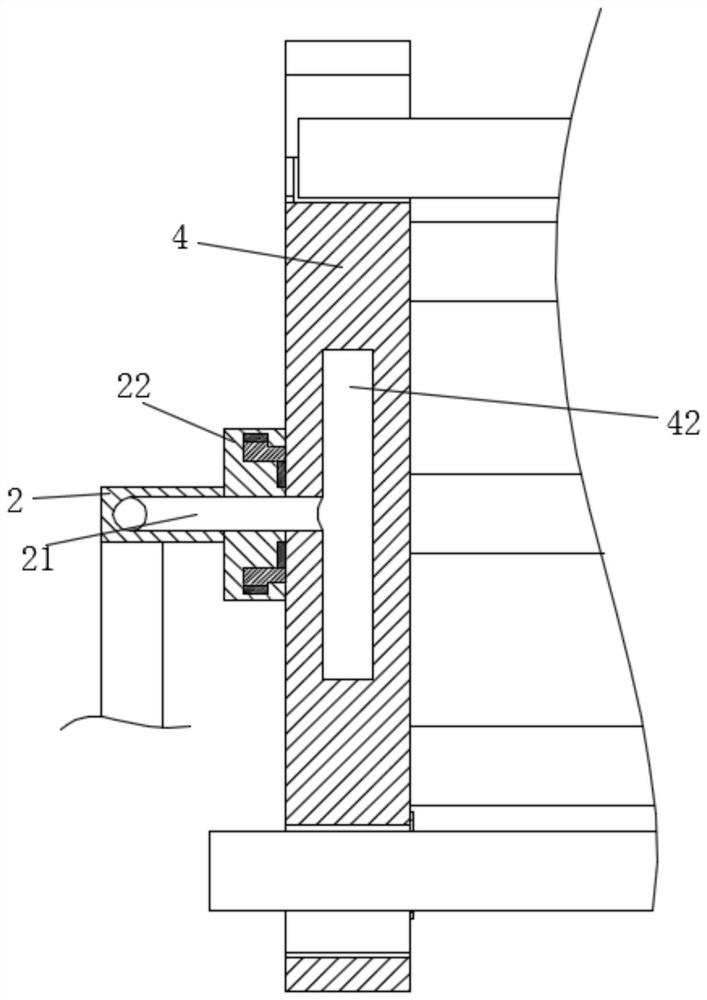

[0024] Such as Figure 1-Figure 2 As shown, in this embodiment, a kind of loading and unloading device for a woodworking lathe is provided, including two rotatable turntables 4 arranged at both ends of the workbench 1, and each of the turntables 4 is correspondingly provided with one for The fixing device 3 supporting the turntable 4, the turntable 4 can rotate inside the corresponding fixing device 3, and the fixing device 3 includes a first ring body 32 and a second ring body 34 whose inner wall is arc-shaped and has equal radii. A ring body 32 and a second ring body 34 are all fixed on the lathe by a bracket 31, the arc centers of the first ring body 32 and the second ring body 34 coincide, and the first ring body 32 and the second ring body 34 There is a gap between them, and the two gaps are the feed port 6 and the discharge port 7 respectively. The first ring body 32 and the second ring body 34 can be regarded as the remaining parts after a ring body is cut. The first ri...

Embodiment 2

[0029] Such as Figure 4-Figure 5 As shown, on the basis of Embodiment 1, an arc-shaped rod 12 is installed on the side wall of the pressure rod 11, the center of the circle of the arc-shaped rod 12 coincides with the rotation axis of the pressure rod 11, and the U-shaped groove 41 The side wall is provided with an arc-shaped groove 44 adapted to the arc-shaped rod 12, and the arc-shaped groove 44 and the arc-shaped rod 12 form an arc-shaped oil cylinder. Sliding inside, multiple arc-shaped grooves 44 corresponding to the same U-shaped groove 41 are connected to a single air pipe 9, a solenoid valve 10 is installed in the middle of the air pipe 9, and the air pipe 9 communicates with the gas injection device through the solenoid valve 10. When the solenoid valve 10 is opened At this time, the gas injection device injects high-pressure gas into the inside of the arc groove 44, and pushes the arc rod 12 to drive the pressure rod 11 to rotate; the inside of the turntable 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com