Two-component formaldehyde-free adhesive composition for artificial board

A technology of aldehyde adhesives and compositions, applied in the direction of adhesive additives, adhesive types, ester copolymer adhesives, etc., can solve mildew, short adhesive pot life, and adhesive degradation failure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples describe the solutions of the present invention in detail, but the protection scope of the present invention is not limited to the examples.

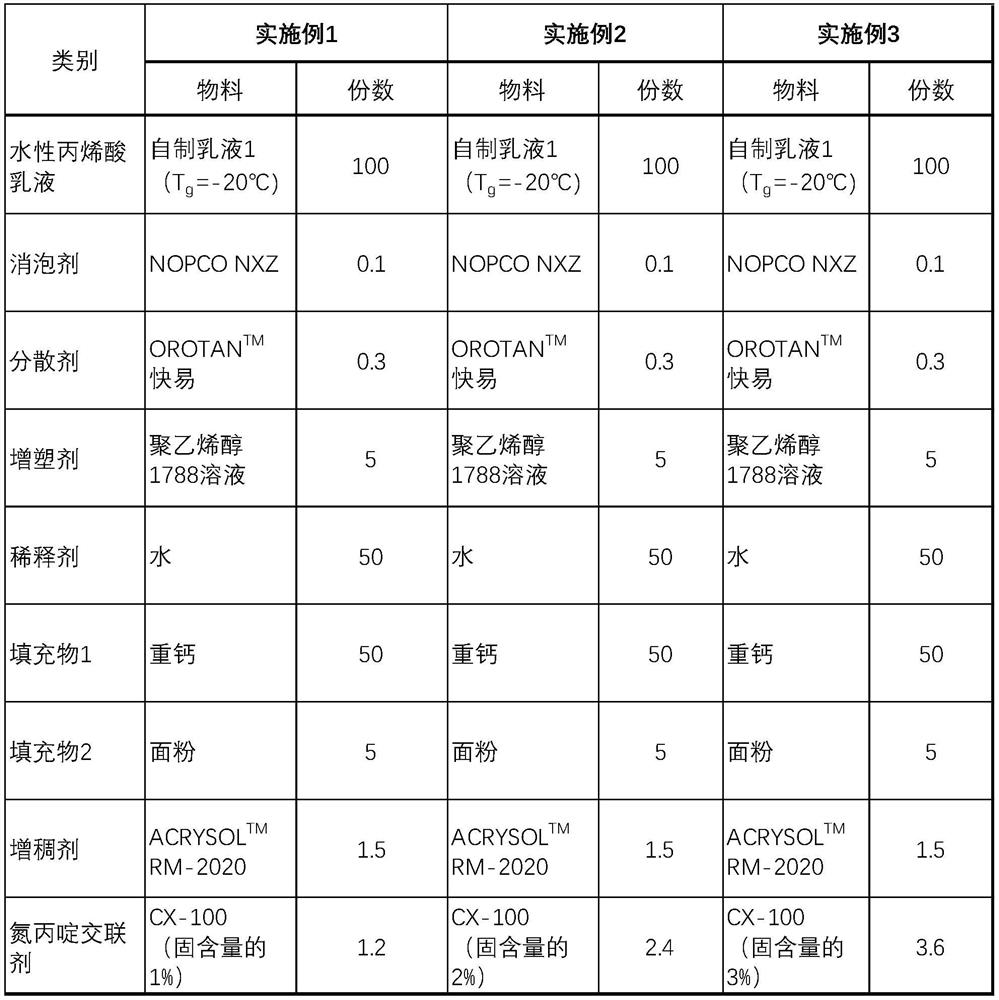

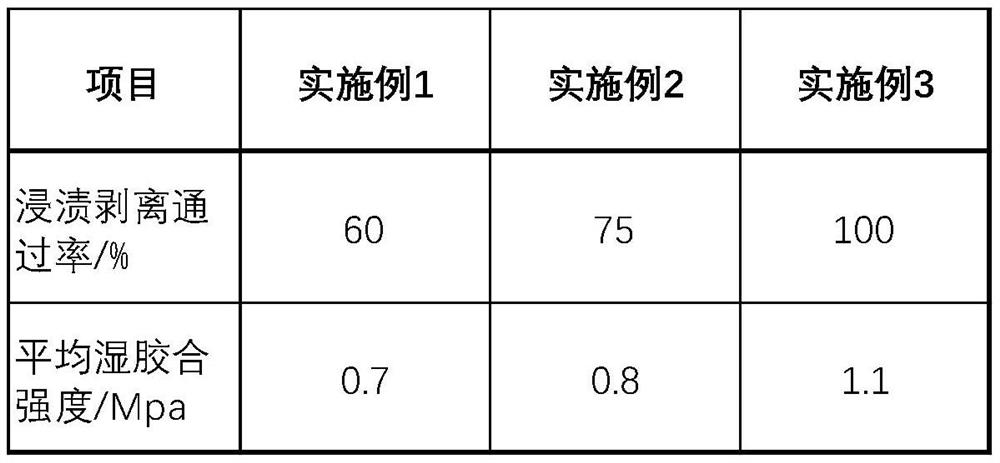

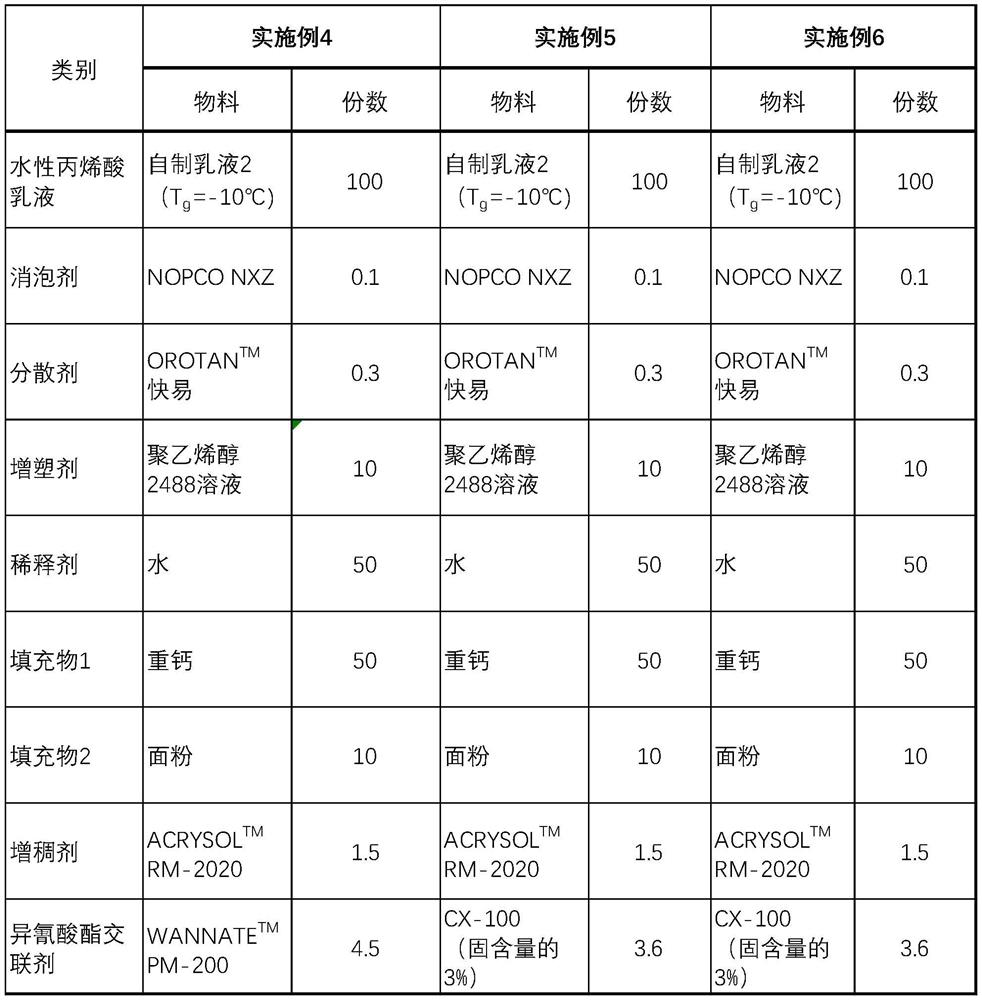

[0026] 1. Example comparison of aziridine crosslinking agents with different additions

[0027] ① Example sample preparation

[0028]

[0029] Explanation: Feed the materials of the examples in the above table sequentially from top to bottom, and use a high-speed dispersing mixer at a speed of 800-1000rpm to feed while stirring. Stir for at least 40 minutes until the viscosity of the adhesive is stable without large particles or agglomerations.

[0030] This method is adopted in the following other embodiments, and will not be repeated in the following.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com