Comprehensive utilization of phenol-containing wastewater

A technology for phenolic wastewater and wastewater, applied in the field of thermosetting liquid phenolic resin, can solve the problems of wastewater generation, failure to achieve zero discharge of wastewater, and failure to efficiently utilize phenol-containing wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

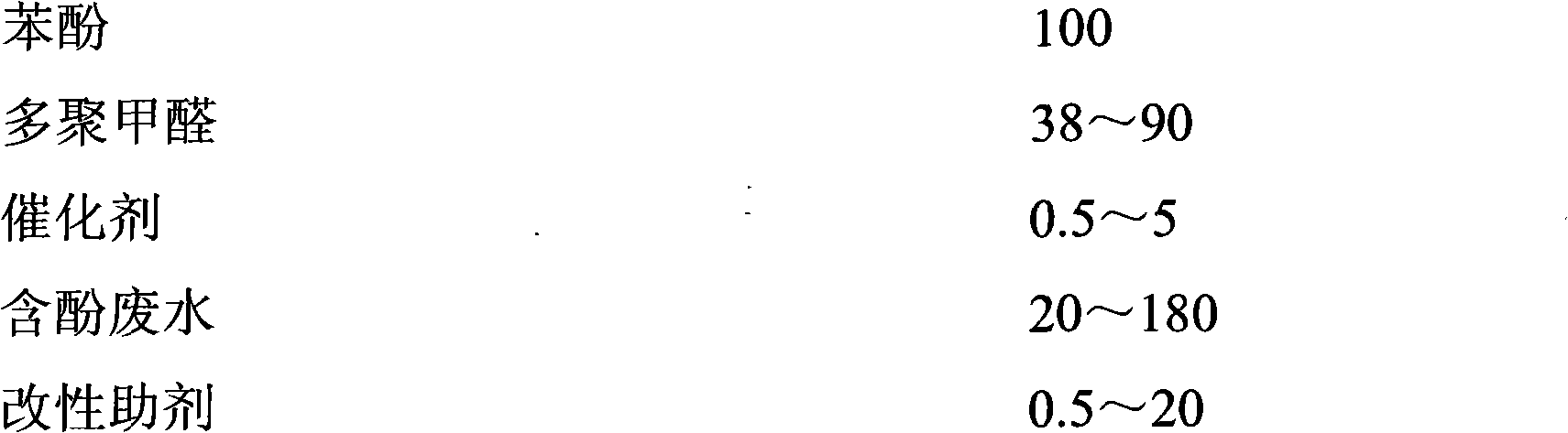

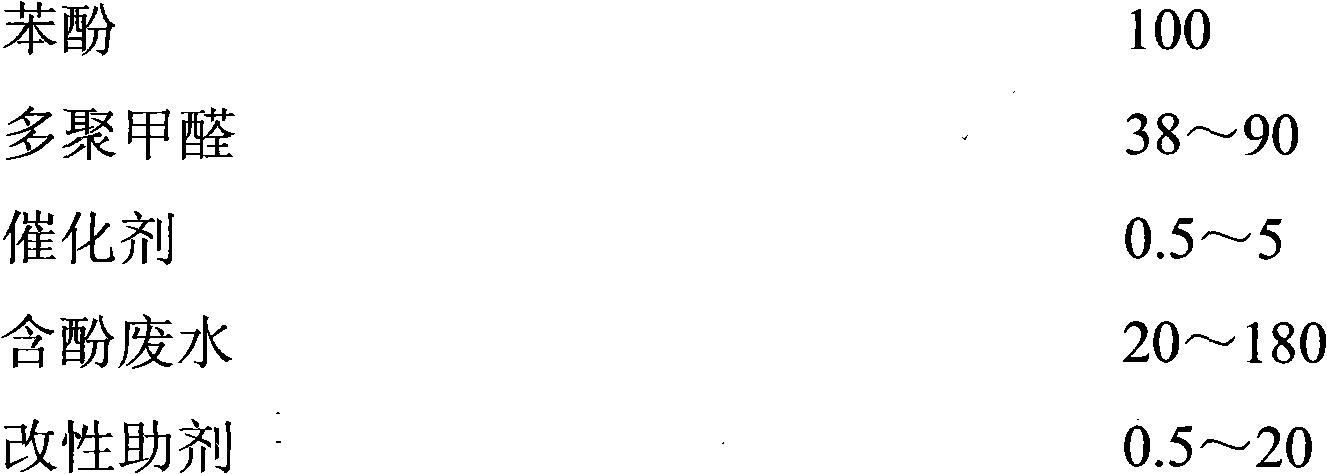

Method used

Image

Examples

Embodiment 1

[0025] Synthetic phenolic rock wool glue

[0026] 1) Add 80g of paraformaldehyde and 160g of phenol-containing wastewater into a four-necked flask equipped with mechanical stirring, a condenser and a thermometer, and cool at a constant temperature of 90°C for 40 minutes;

[0027] 2) Pour out 120g of the upper formaldehyde solution for later use, add 100g of phenol into the four-necked bottle, and heat up to 75°C for 30min;

[0028] 3) Pour 120g of formaldehyde solution into a four-neck bottle, heat up to 90°C for 35 minutes, cool down to 75°C, add 3g of urea, stir for 10 minutes, adjust the pH value to 7-8, cool down to 35°C and discharge .

[0029] The obtained product is a reddish-brown transparent liquid phenolic resin with a viscosity of 15-20mpa.s (25°C), a solid content of 41-45%, free phenol≤7.5%, and free aldehyde<0.5%. It can be used as rock wool glue, Used in the manufacture of rock wool boards.

Embodiment 2

[0031] Synthetic phenolic wood glue

[0032] 1) Add 60g of paraformaldehyde and 100g of phenol-containing wastewater into a four-neck flask equipped with a mechanical stirrer, a condenser and a thermometer, and cool at a constant temperature of 90°C for 40 minutes;

[0033] 2) Pour out 80g of the formaldehyde solution for later use, add 100g of phenol into the four-necked bottle, and heat up to 80°C for 20 minutes;

[0034] 3) Pour 80g of formaldehyde solution into a four-necked bottle, add 4g of sodium hydroxide, and raise the temperature to 92°C for 45 minutes, then cool down to 35°C and discharge.

[0035] The obtained product is a liquid phenolic wood glue with a viscosity of 400-500mpa.s (25°C) and a solid content of 55-60%, which can be applied to glue for wood bonding.

Embodiment 3

[0037] Synthetic expandable phenolic resin

[0038] 1) Add 100g of phenol, 25g of paraformaldehyde, 20g of wastewater containing phenol, and 3g of magnesium oxide into a four-neck flask equipped with mechanical stirring, a condenser and a thermometer, and heat up to 82°C for 40min;

[0039] 2) Add 30g of paraformaldehyde to the four-necked flask, and then slowly raise the temperature to 95°C for 90 minutes;

[0040] 3) After adding 3g of melamine, continue to react for 15 minutes and cool down to 35°C to discharge;

[0041] The obtained product is a reddish-brown liquid phenolic resin with a viscosity of 2000-3000mpa.s (25°C) and a solid content of 78-82%. It can be used to prepare phenolic foam boards and be used as building materials for fire-retardant and heat-retaining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com