A kind of reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc. PUR and other issues, to achieve the effect of good heat resistance, wide application range and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

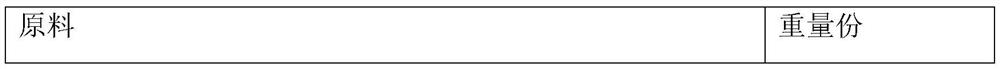

[0040] The reactive polyurethane hot-melt adhesive of the present embodiment, the raw material composition is as follows:

[0041] raw material parts by weight Polypropylene glycol Mn=2000 45 Poly adipate polyester diol Mn=3000 32 Toluene diisocyanate 16 Hydroxy-terminated acrylate-carbonate copolymer resin Mn=2500 5.5 Additives to enhance water resistance 1 1.25 Dibutyltin dilaurate, dibutyltin diacetate (1:2 mixture by weight) 0.25

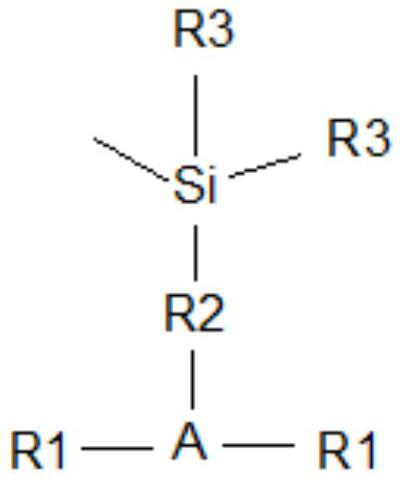

[0042] Among them: the structure of additive 1 for enhancing water resistance is:

[0043]

[0044] The preparation method of the reactive polyurethane hot-melt adhesive of the present embodiment follows the steps:

[0045] Step 1. Put polypropylene glycol, polyadipate polyester diol, and hydroxy-terminated acrylate-carbonate copolymer resin into the reaction kettle according to the metering ratio, heat at 120° C., and vacuum dehydrate for 2 hours under stirring.

[0046] Step 2, drop the te...

Embodiment 2

[0049] The reactive polyurethane hot-melt adhesive of the present embodiment, the raw material composition is as follows:

[0050]

[0051]

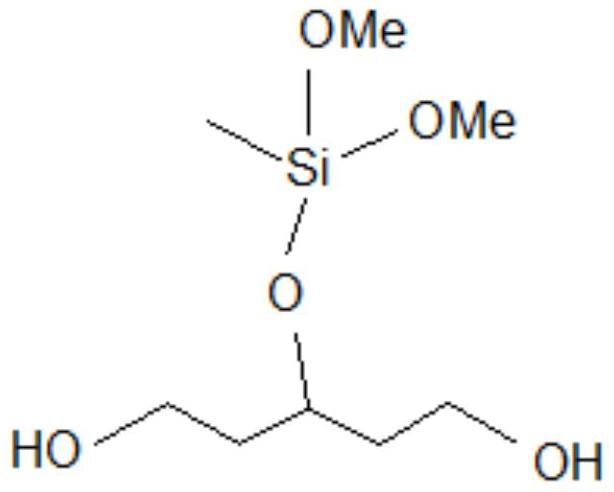

[0052] Among them: the structure of additive 2 for enhancing water resistance is:

[0053]

[0054] The preparation method of this embodiment follows the steps:

[0055] Step 1: Put polypropylene glycol, polyadipate polyester diol, and hydroxyl-terminated acrylate-carbonate copolymer resin into the reaction kettle according to the metering ratio, heat at 140° C., and vacuum dehydrate for 1.5 hours while stirring.

[0056] Step 2, drop the temperature to 100°C and drop in diphenylmethane diisocyanate, 2 The reaction was stirred at 90°C for 1 hour under protection.

[0057] Step 3: Add additive 3 for enhancing water resistance, bismorpholino diethyl ether, vacuumize and stir at 120° C. for 1 hour, and discharge to obtain hot melt adhesive 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com