Wood milling machine

A milling machine and woodworking technology, which is applied in the field of woodworking milling machines, can solve problems such as drilling slippage, offsetting the road, and low coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

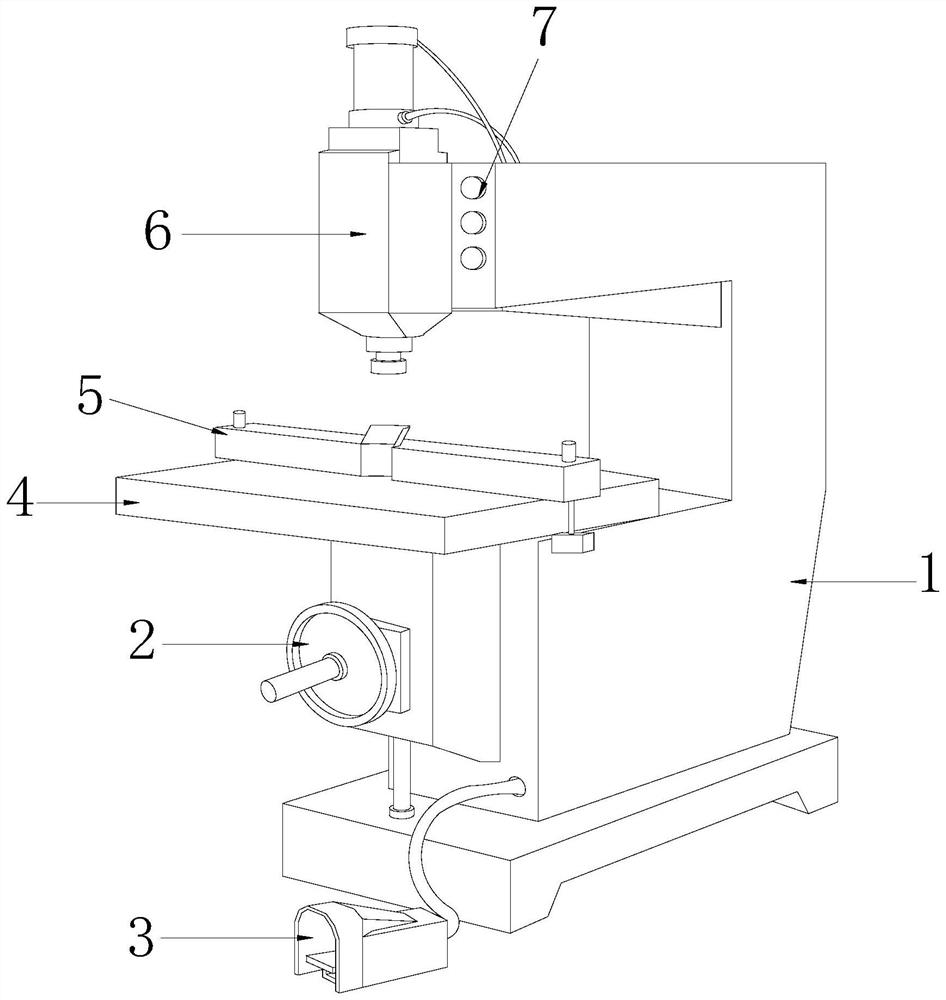

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of technical scheme of woodworking milling machine:

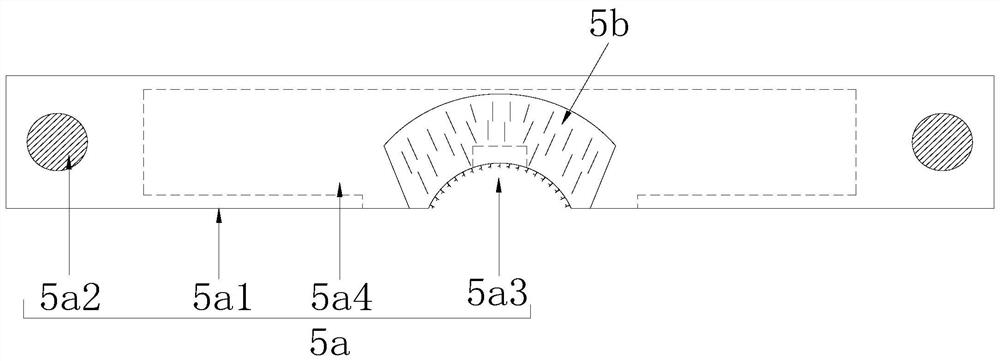

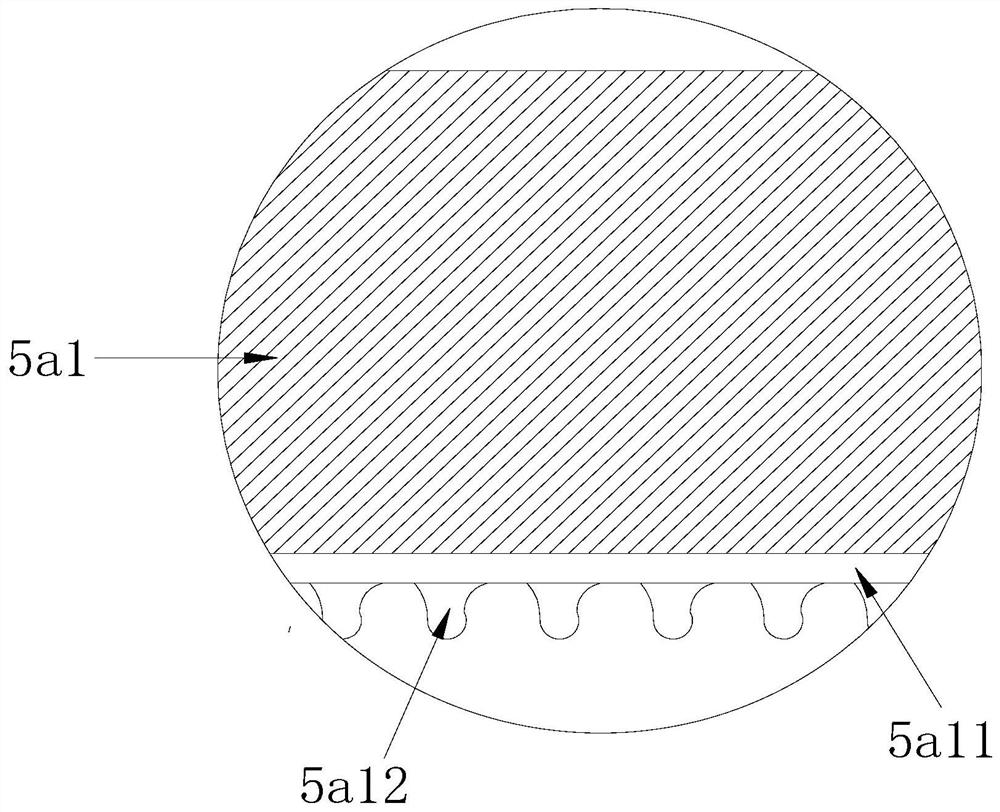

[0028] Such as Figure 1-Figure 2 As shown, a woodworking milling machine, its structure includes a main body 1, an adjusting disc 2, a pedal 3, a workbench 4, a voltage stabilizing device 5, a drilling and milling machine head 6, and a control panel 7, and the adjusting disc 2 is arranged on the main body 1 The lower part of the front surface, the pedal 3 is connected to the main body 1, the workbench 4 is installed in the upper middle part of the main body 1, the voltage stabilizing device 5 is arranged on the upper surface of the workbench 4, the drilling and milling machine The head 6 is arranged on the inner upper part of the main body 1, the control panel 7 is arranged on the upper front surface of the main body 1, the voltage stabilizing device 5 includes a pressing mechanism 5a and a straightening mechanism 5b, and the straightening m...

no. 2 example

[0038] Such as Figure 5 As shown, the present invention provides a kind of technical scheme of woodworking milling machine:

[0039] Such as Figure 5 As shown, a woodworking milling machine, its structure includes the straightening mechanism 5b including a guard plate 5b1, an overflow layer 5b2, a press bar 5b3, and a connecting pipe 5b4, and the guard plate 5b1 is installed on the upper surface of the frame body 5a1, And it is installed corresponding to the positioning arc groove 5a3. The overflow layer 5b2 is arranged on the front surface of the guard plate 5b1 and is an integrated structure. The press bar 5b3 is distributed on the front surface of the guard plate 5b1. On the lower surface of the guard plate 5b1 and extending into the interior of the cavity 5a4, it is beneficial to correct the pressing track of the drilling and milling machine head 6, so as to ensure that the holes drilled on the wood board are regular.

[0040] Such as Figure 5 As shown, the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com