A processing method for ultra-long and narrow T-slots

A kind of slot machining and narrowing technology, applied in the field of T-slot through-slot machining, it can solve the problems of tool breakage, unsatisfactory machining method, and T-slot roughing cannot be carried out, achieving stable state, flexible cutting speed, The effect of smooth cutting motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation and processing method of the present invention will be described in further detail below with reference to the accompanying drawings.

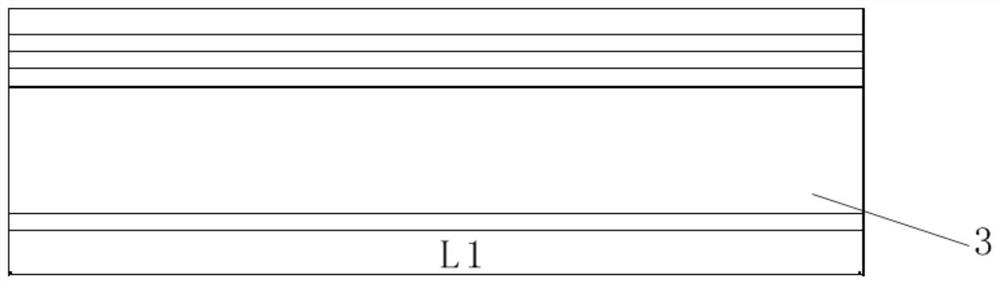

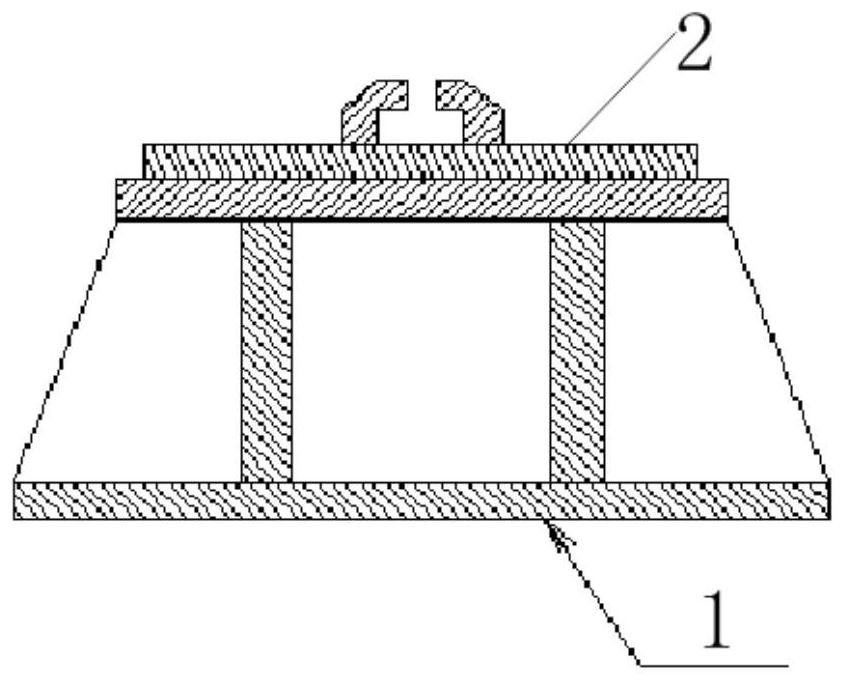

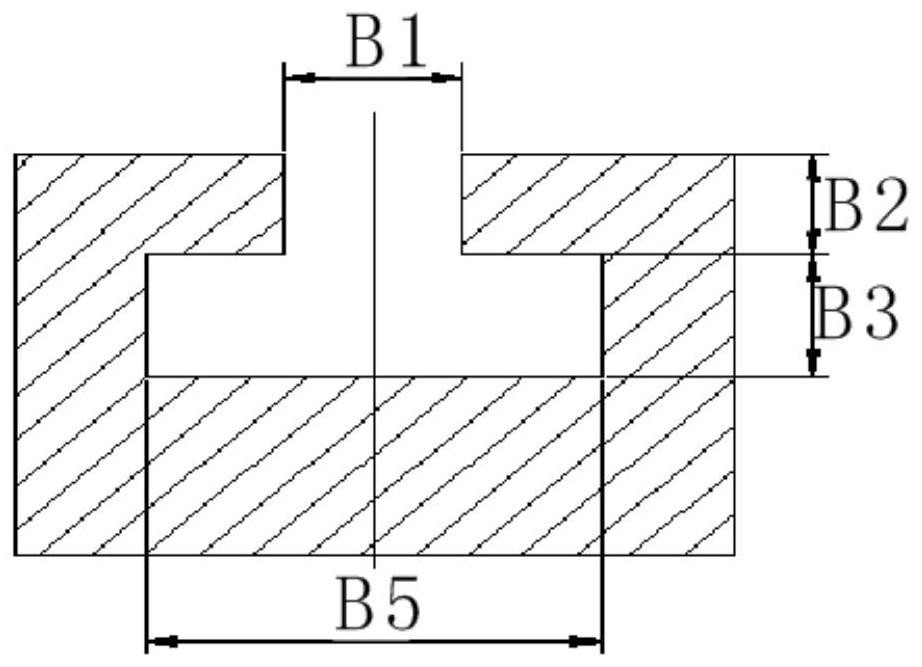

[0037] Analyzing as figure 1 , 2 After the drawing of Part 3 is shown, the workpiece is pre-machined with the machining surface 2 of the straight groove and the bottom surface 1 of the workpiece. The machining method is as follows (such as Figure 4 ).

[0038] 1. The bottom surface 1 of the workpiece becomes the first datum plane after processing. Taking the first datum plane as the bottom surface, place the workpiece on the work table 4. After clamping and aligning, use the rough machining cylindrical alloy end mill 6 to machine the pre-machined straight groove. , to prepare for the cutting position of the planer knife;

[0039]2. Install the planer on the main shaft through the BT40 side-mounted handle 9, and set the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com