Heavy-cut double-faced woodworking thickness planer and processing method thereof

A double-sided, woodworking technology, used in wood processing appliances, processing machines for manufacturing flat surfaces, planers, etc., can solve the problems of restricting development and growth, low efficiency, poor processing accuracy, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

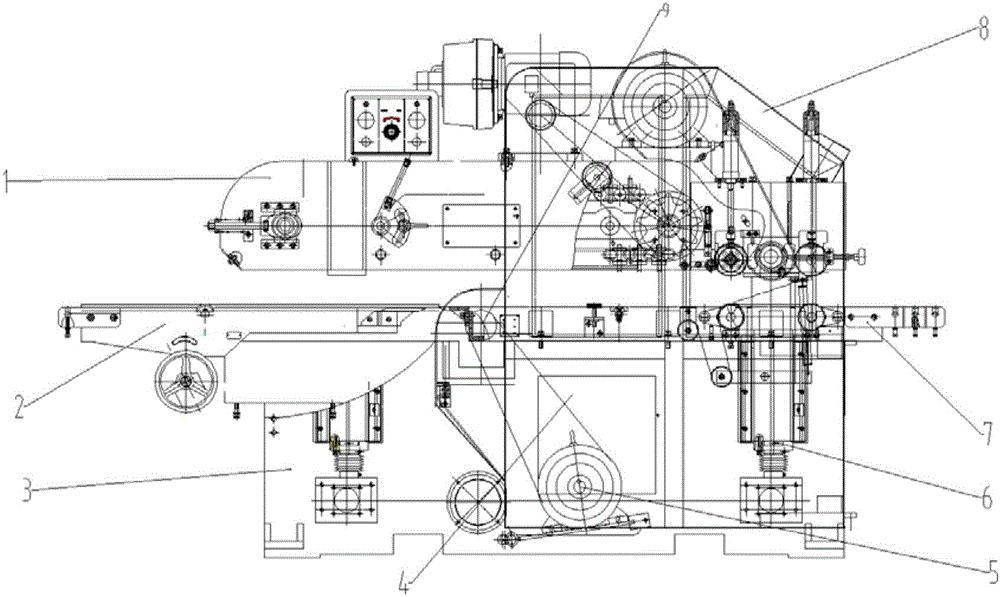

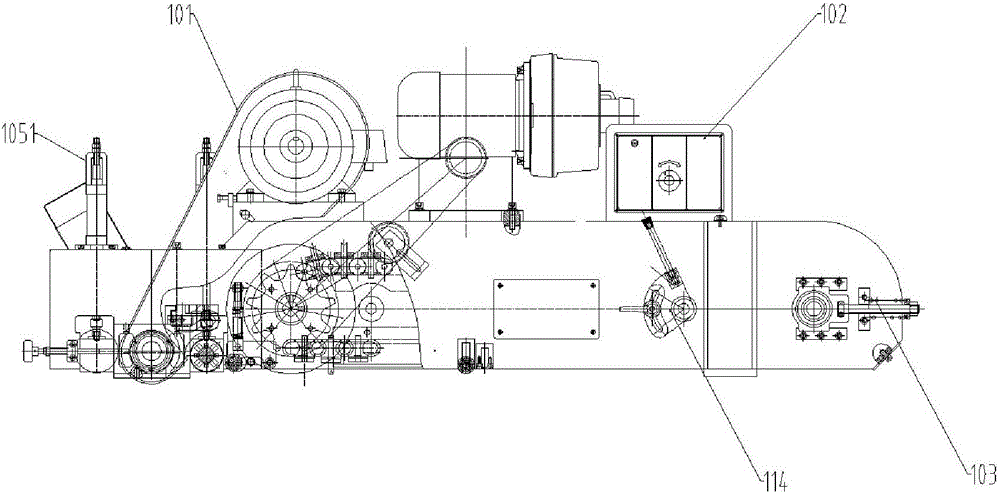

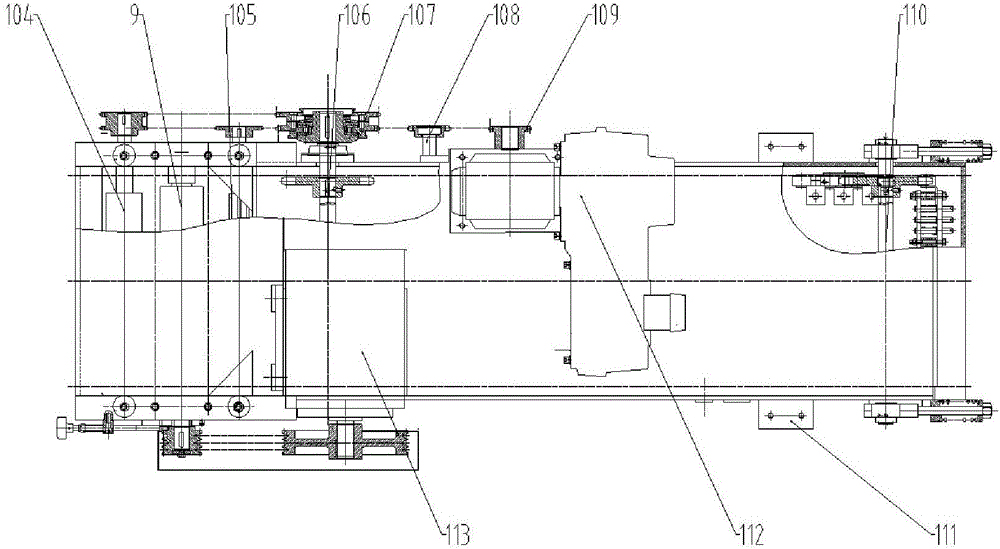

[0036] like figure 1 , 2 , 3 and 4, a heavy-cut double-sided woodworking planer, including bed assembly 1, front table assembly 2, bed foot 3, control box 4, motor belt tensioning assembly 5, lifting transmission Assembly 6, rear table assembly 7, rear cover 8, planer assembly 9, bed assembly 1 includes pulley device 101, air pressure control box 102, spring pressing device 103, pressure roller 104, feed roller Assembly 105, bed driving shaft 106, clutch parts 107, bed tensioning wheel 108, reducer sprocket 109, driven shaft 110, lifting block connecting groove 111, worm gear reducer and belt continuously variable transmission device 112, upper planer Motor 113, feeding height fine-tuning device 114, feeding roller assembly 105 includes cylinder 1051, cylinder seat 1052, floating joint 1053, feeding roller axle seat 1054, feeding roller 1055;

[0037] The front workbench assembly 2 and the rear workbench assembly 7 are respectively fixed above the bed foot 3, the planer assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com