High-temperature graphene heating plate and preparation method thereof

A technology of high-temperature graphite and heating plate, applied in ohmic resistance heating, heating element materials, ohmic resistance heating parts, etc., can solve the problems of poor heating effect, short life, easy damage, etc., and achieve small electromagnetic radiation and long service life , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

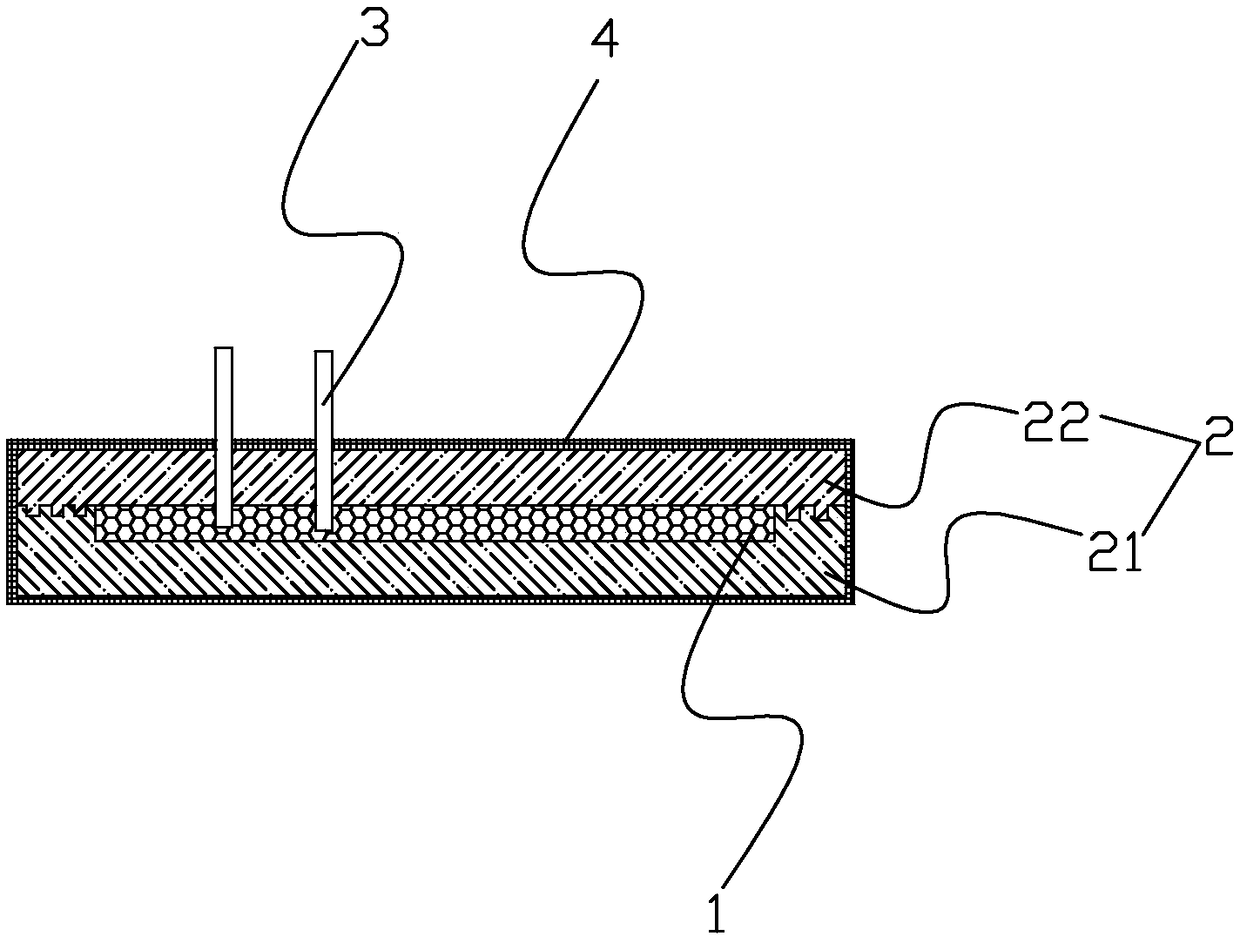

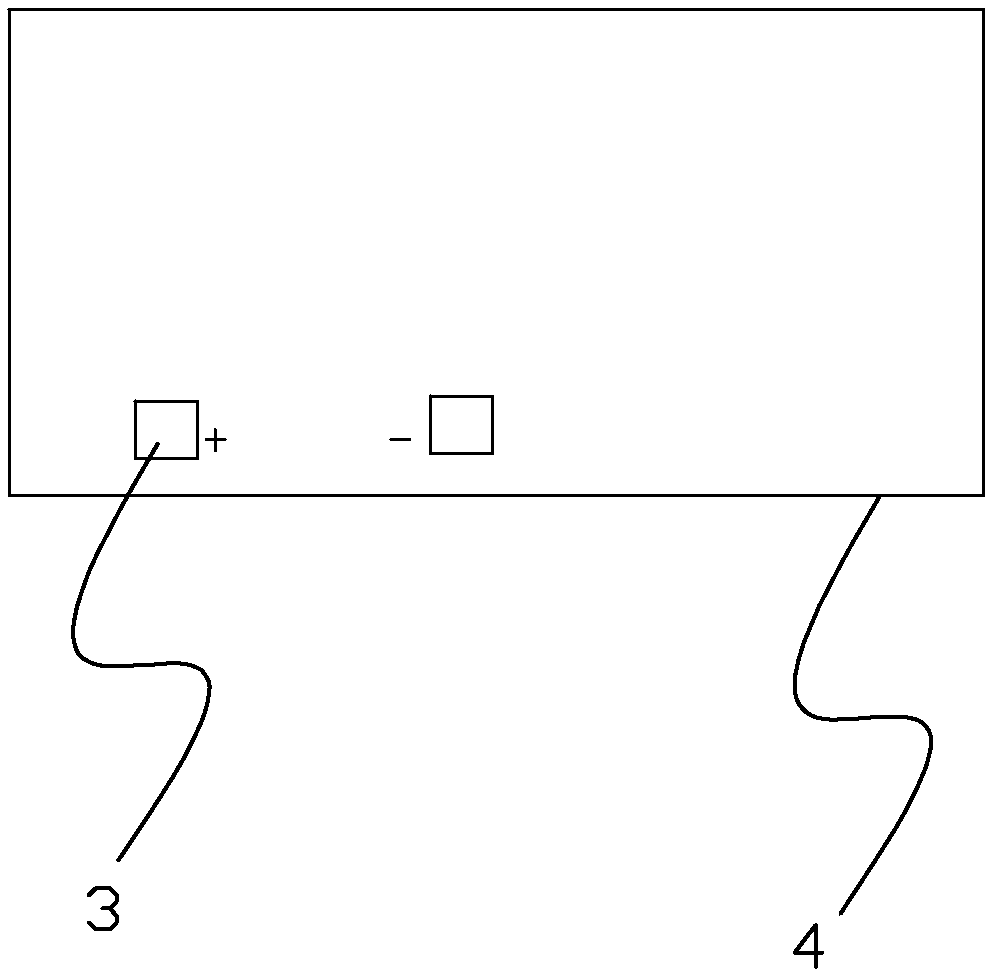

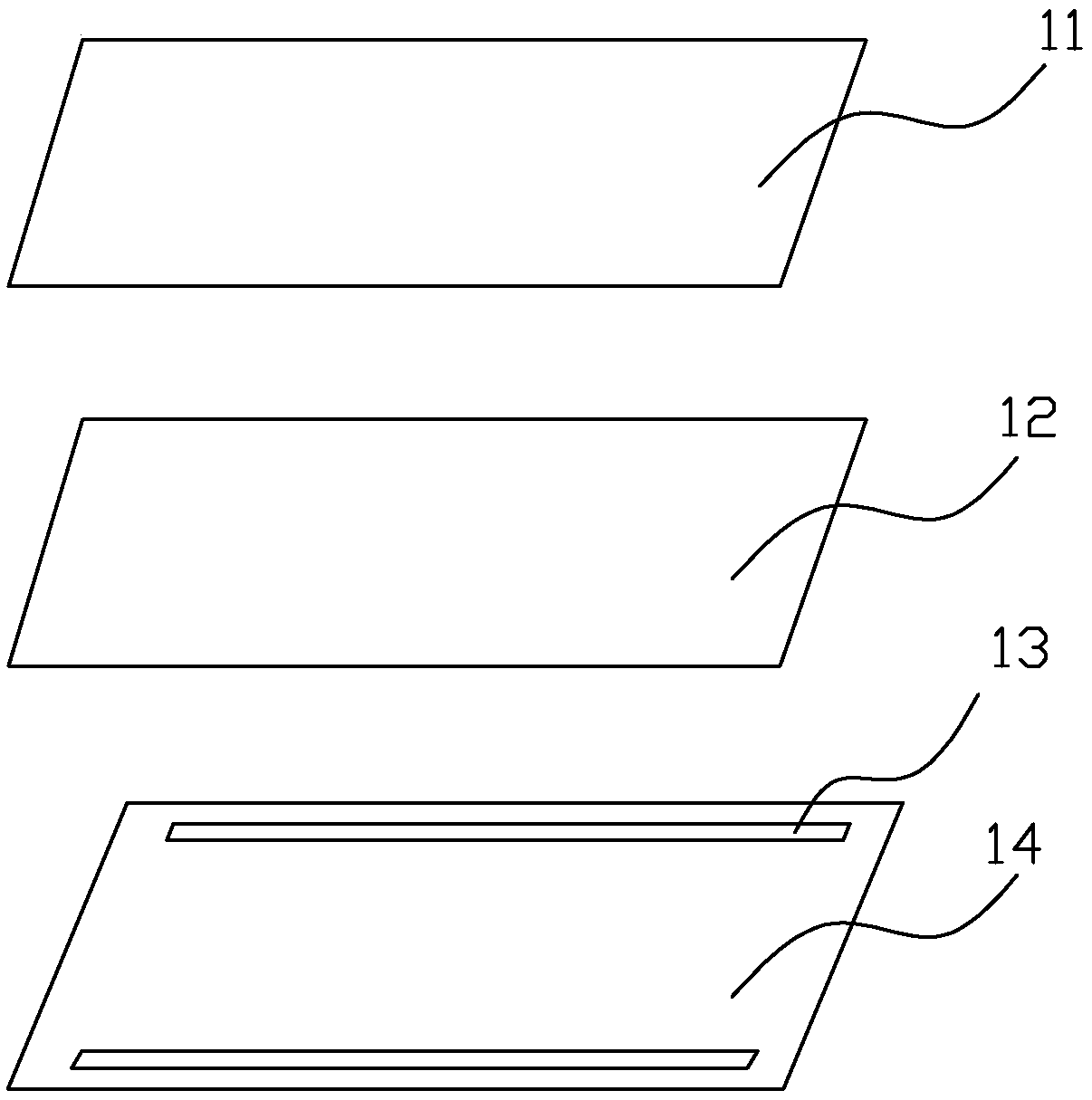

[0029] refer to Figure 1 to Figure 3 , a high-temperature graphene heating plate, comprising a high-temperature graphene heating element 1, a mica insulating plate frame 2, a lead wire 3 and a cover 4, and the mica insulating plate frame 2 is composed of a mica insulating groove 21 and a mica insulating groove arranged on the mica insulating groove The mica insulating cover plate 22 is combined to form an internal cavity; the high-temperature graphene heating element 1 is located in the internal cavity, and the high-temperature graphene heating element is composed of the first protective layer 11, graphite Graphene film layer 12 and the second protective layer 14, the two sides of the second protective layer 14 are provided with metal bus bars 13; one end of the lead 3 is connected to the high-temperature graphene heating element, and the other end passes through the mica insulating frame and The casing is connected to an external power supply; the casing 4 is wrapped around ...

Embodiment 2

[0039] A kind of high-temperature graphene heating plate, its structure is consistent with embodiment one, and the preparation method of described graphene film layer is as follows:

[0040] (1) Weigh 5 parts by weight of graphene, 65 parts by weight of water, and 12 parts by weight of ethylene glycol diacetate, pour them into a high-speed shear after fully mixing and stirring, and shear at a high speed for 1.5h, then add an ultrasonic disperser In, add 2 weight parts of alkylphenol polyoxyethylene ether again, carry out supersonic treatment 5h and obtain graphene dispersion liquid;

[0041] (2) Add 7 parts by weight of rosin resin, 25 parts by weight of silver-plated glass microspheres, and 2 parts by weight of sodium methylene bis-naphthalene sulfonate in the above-mentioned graphene dispersion and stir and mix for 35min to obtain the graphene conductive paste. The graphene conductive paste was sprayed on the substrate, and the substrate was ultrasonically oscillated while s...

Embodiment 3

[0048] A kind of high-temperature graphene heating plate, its structure is consistent with embodiment one, and the preparation method of described graphene film layer is as follows:

[0049] (1) Weigh 5 parts by weight of graphene, 70 parts by weight of water, and 15 parts by weight of ethylene glycol diacetate, pour them into a high-speed shear after fully mixing and stirring, shear at a high speed for 2 hours, and then add them to an ultrasonic disperser , add 3 parts by weight of alkylphenol polyoxyethylene ether, carry out supersonic treatment 6h and obtain graphene dispersion liquid;

[0050] (2) Add 10 parts by weight of rosin resin, 30 parts by weight of silver-plated glass microspheres, and 3 parts by weight of sodium methylene bis-naphthalene sulfonate in the above-mentioned graphene dispersion and stir and mix for 40min to obtain the graphene conductive paste. The graphene conductive paste was sprayed on the substrate, and the substrate was ultrasonically oscillated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com