Double-side planer for machining bamboo flattened plate

A double-sided planer and flat plate technology, which is applied to wood processing equipment, processing machines for manufacturing flat surfaces, planers, etc., can solve problems such as unsmooth feeding, inconsistent cutting amount, and indiscriminate roughing and finishing. Achieve smooth feeding, improve surface quality, and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

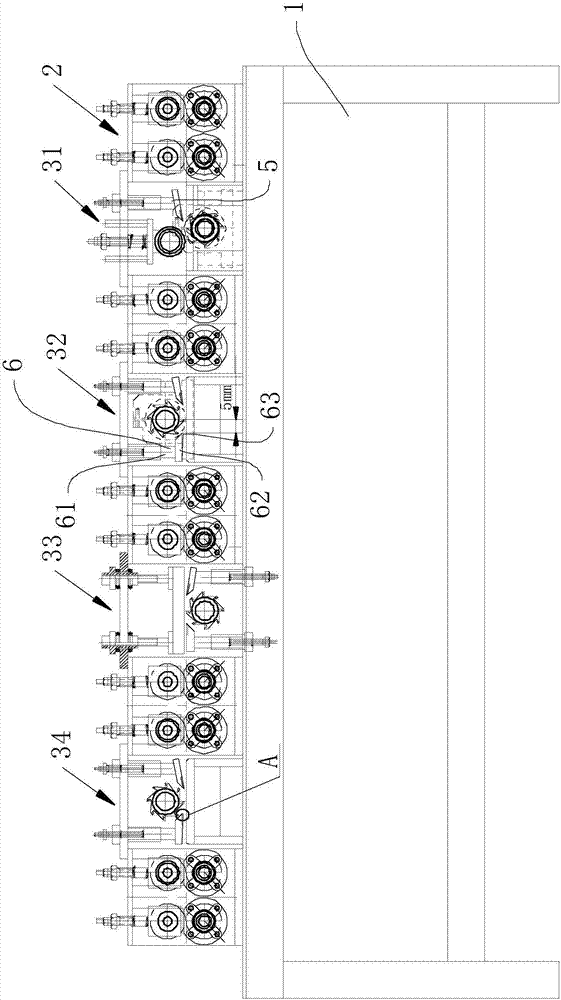

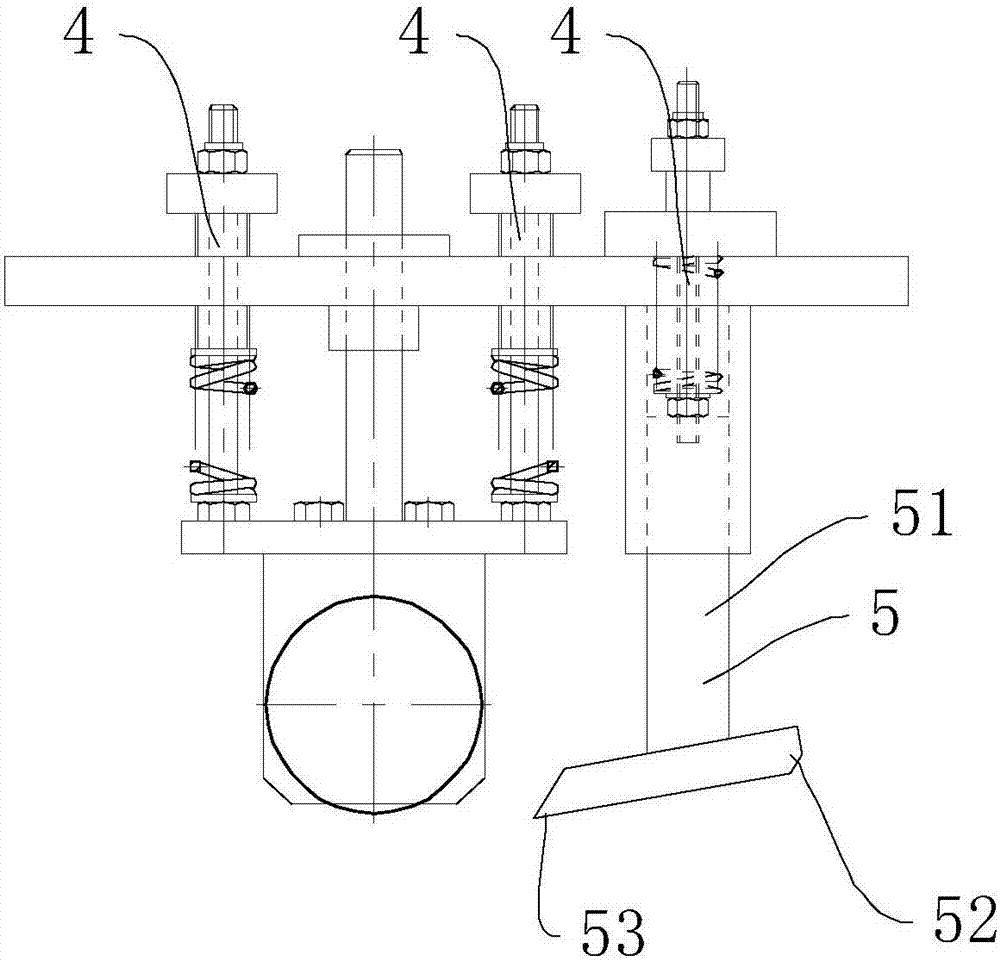

[0026] Such as figure 1 Shown is a double-sided planer for processing bamboo flat panels, including a frame 1, a transmission mechanism 2 fixed on the frame for transmitting bamboo flat panels, and a planing mechanism fixed on the frame.

[0027] There are four planing mechanisms, including the first planing mechanism 31, the second planing mechanism 32, the third planing mechanism 33, and the fourth planing mechanism 34 arranged in sequence along the bamboo display plate conveying direction. The feed end and the discharge end of the first planing mechanism 31, the second planing mechanism 32, the third planing mechanism 33, and the fourth planing mechanism 34 are all connected to the transmission mechanism 2; the first planing mechanism 31, the second The planing mechanism 32, the third planing mechanism 33, and the fourth planing mechanism 34 plan the lower surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com