Planing machine

A planer and planing technology, which is applied in the field of woodworking machinery, can solve problems such as low work efficiency, resource waste, and increased manufacturing costs, and achieve the effects of improving automation, avoiding secondary processing, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

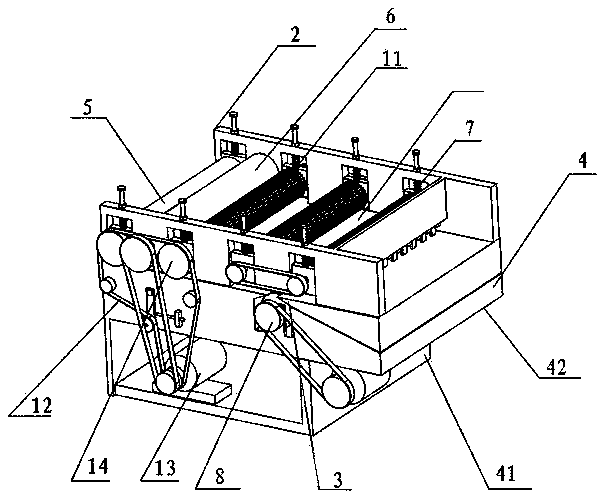

[0030] Such as figure 1 As shown, the present embodiment provides a planer, including a transmission mechanism, a frame 2, a lower planing mechanism 3 and a workbench 4, the frame 2 is arranged on the workbench 4 and props up the transmission mechanism 2, and the transmission mechanism 2 conveys and places For the wood on the workbench 4, the lower planing mechanism 3 cuts the wood delivered by the transmission mechanism 2. The transmission mechanism includes: a transmission roller 11, a transmission chain 12, a transmission motor 13 and a transmission gear 14, and the transmission motor 13 rotates to drive the transmission. Chain 12 and transmission gear 14 finally drive transmission roller 11 to rotate, and the space that timber passes is set between transmission roller 11 and workbench 4, and transmission roller 11 is arranged on the upper end of frame 2, and the quantity of transmission roller 11 is 3, conveys Anti-slip teeth are arranged on the outer surface of the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com